A process for preparing aluminum oxide dispersion strengthened copper with high strength and high conductivity

A dispersion-strengthened copper and high-conductivity technology is applied in the field of preparation of high-strength and high-conductivity alumina dispersion-strengthened copper, which can solve the problems of product structure, poor performance, complicated procedures, and increased cost, and achieve excellent high-temperature softening resistance. Performance, product quality stability, the effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

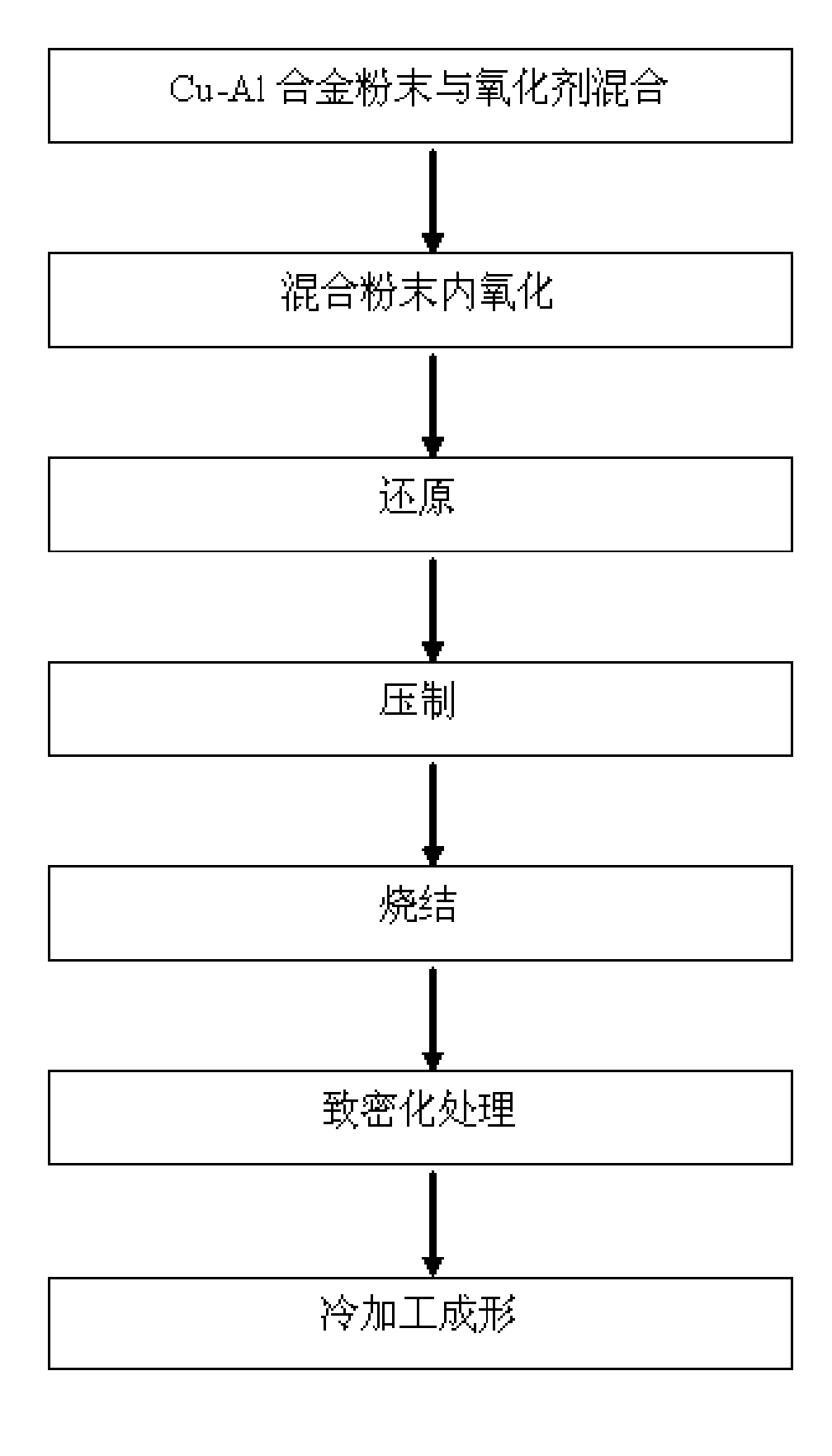

[0025] see figure 2 , the aluminum content is 0.1wt%, the rest is copper as the matrix material, and the copper-aluminum alloy powder with the impurity content less than 0.5wt% is used as the raw material.

[0026] (1) Mixing of Cu-Al alloy powder and oxidant: Mix the mixed powder of Cu-Al alloy powder and oxidant in a planetary ball mill at 200 rpm for 0.5 hour, the oxygen content in the oxidant is in atomic ratio to the aluminum content in the alloy powder is 3:2;

[0027] (2) Internal oxidation: heat the mixed powder to 800°C, and internally oxidize for 3 hours under a nitrogen atmosphere;

[0028] (3) Reduction: Reduction in a hydrogen atmosphere at 750°C for 1 hour;

[0029] (4), pressing: the powder at 600N / mm 2 Molded under pressure;

[0030] (5), sintering: sintering in a hydrogen atmosphere at 1050°C for 1 hour;

[0031] (6) Densification treatment: directly deform the sintered body by 40% under high pressure on the hydraulic press to make the relative density r...

Embodiment 2

[0035] see figure 2 , using copper-aluminum alloy powder with an aluminum content of 0.6wt%, the rest being copper as a base material, and an impurity content of less than 0.5wt% as a raw material;

[0036] (1), Cu-Al alloy powder is mixed with oxidizing agent: the mixed powder of Cu-Al alloy powder and oxidizing agent is mixed in drum mixer for 3 hours, and the atomic ratio of oxygen content in oxidizing agent and aluminum content in alloy powder is 4: 2;

[0037] (2) Internal oxidation: heat the mixed powder to 1000°C, and perform internal oxidation under nitrogen atmosphere for 1 hour;

[0038] (3) Reduction: Reduction in a hydrogen atmosphere at 1000°C for 1 hour;

[0039] (4), pressing: the powder at 600N / mm 2 Molded under pressure;

[0040] (5), sintering: sintering in a hydrogen atmosphere at 850°C for 4 hours;

[0041] (6) Densification treatment: the sintered body is pressed and deformed again in a mold to make its relative density reach 98%, and then annealed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com