High-performance metal-matrix composite preparation method

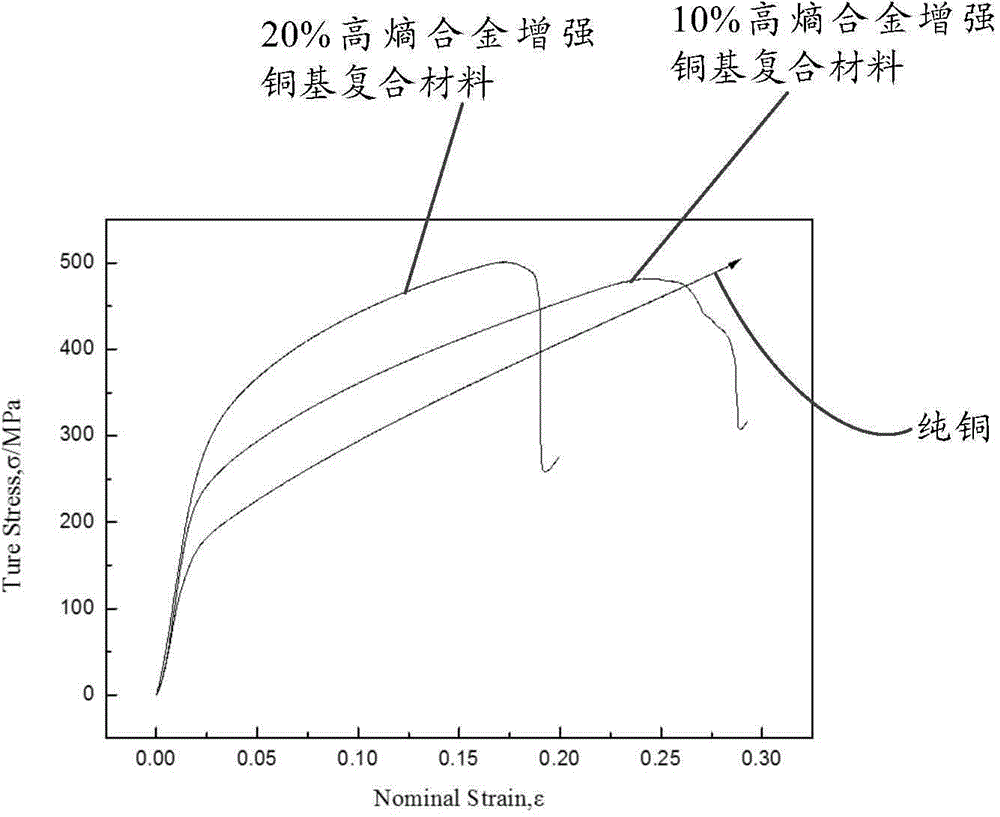

A copper-based composite material and technology of composite materials, applied in the field of powder metallurgy, can solve the problems of destroying the interface stability of composite materials, complex preparation process of composite materials, low interface wettability, etc., achieving high density, wide application range, good interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take granular raw materials Al, Fe, Cr, Co and Ni metal powder, the weight ratio is: Al is 4.809g, Fe is 9.955g, Cr is 9.269g, Co is 10.500g, and Ni is 10.460g. For example, the above raw materials Al, Fe, Cr, Co and Ni are metal powders with a purity of 99.5% and a particle size of 200 mesh respectively;

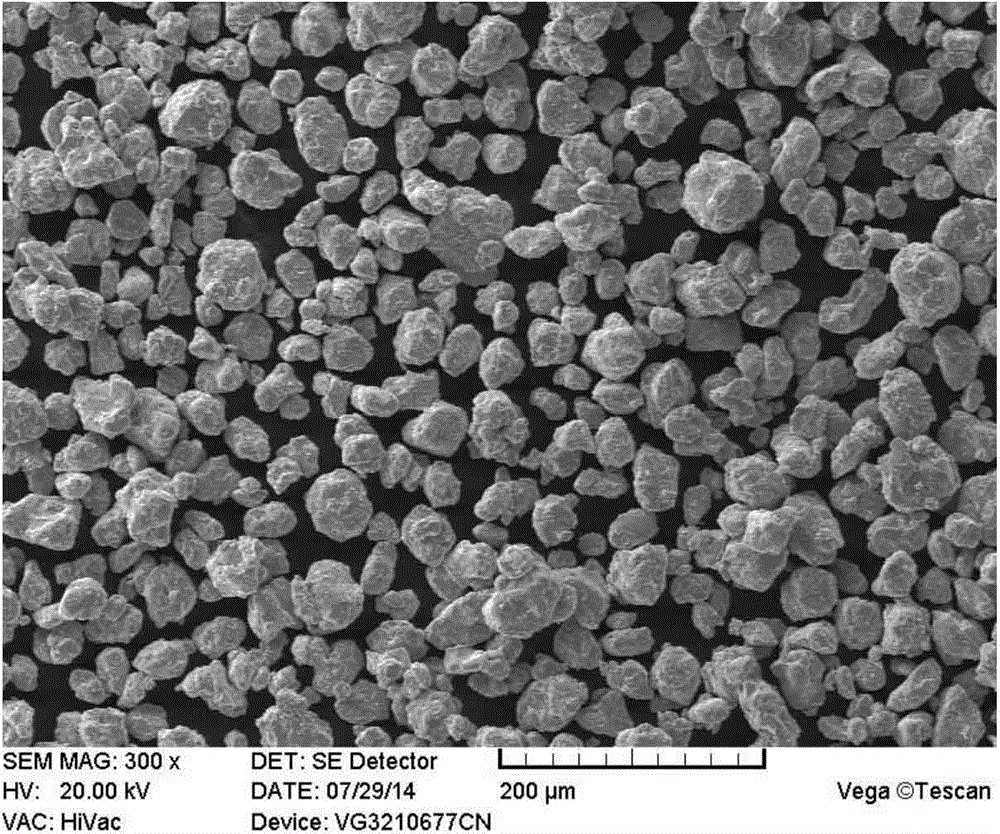

[0044] The AlFeCrCoNi high-entropy alloy powder is prepared by a ball mill under the protection of an argon atmosphere with a rotation speed of 300 rpm, a ball-to-material ratio of 15:1 or 10:1, and ball milling for 60 hours. In addition, n-heptane process control agent can be added to prevent particle agglomeration caused by cold welding;

[0045]Weighing the pure copper powder with a weight of 32g and a particle size of 200 mesh, and the high-entropy alloy powder with a weight of 8g;

[0046] The high-entropy alloy powder and the pure copper powder were ball milled for 4 hours under the protection of an argon atmosphere at a speed of 250 rpm to obtain a composite ...

Embodiment 2

[0051] Take block-shaped raw materials Al, Fe, Cr, Co and Ni, and the weight ratio is: 3.206g for Al, 6.636g for Fe, 6.180g for Cr, 7.000g for Co, and 6.970g for Ni. For example, the above-mentioned raw materials Al, Fe, Cr, Co and Ni have a purity of 99.9% respectively;

[0052] Put the above-mentioned raw materials Al, Fe, Cr, Co and Ni into the copper mold crucible of the electric arc melting furnace, and evacuate to 510 -3 MPa, filled with argon to -0.05MPa;

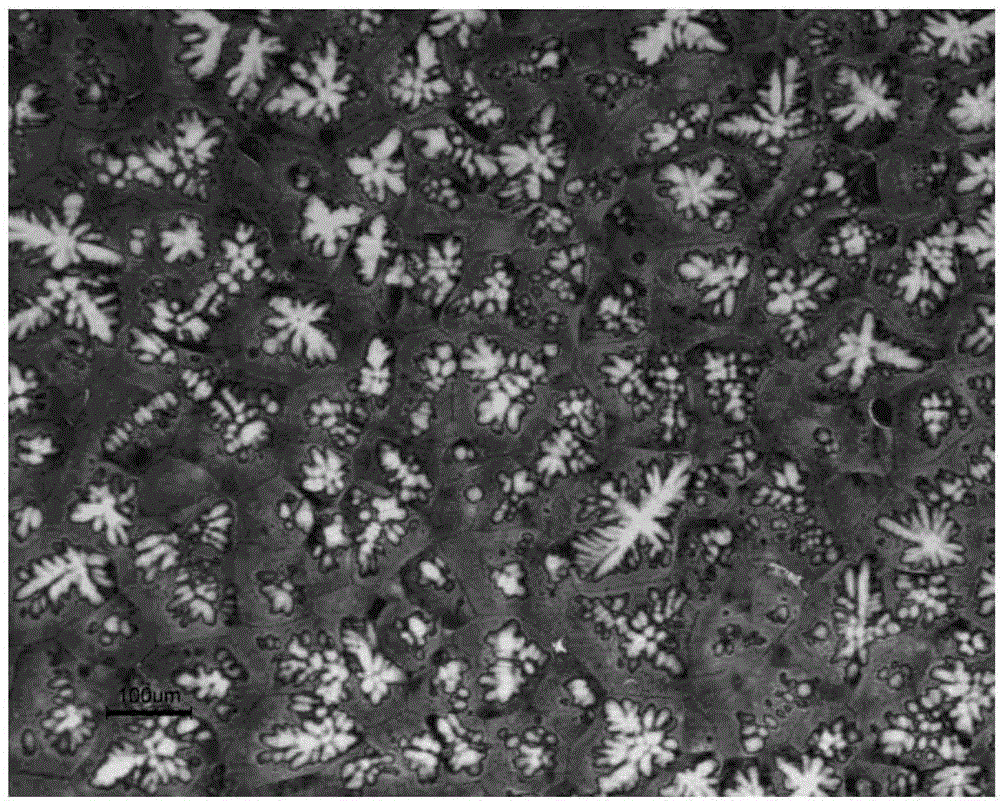

[0053] Carry out vacuum melting, the melting current is 250A, the electromagnetic stirring current is 10A, the melting time is 1 minute, after repeated flipping and melting for 6 times, cool to room temperature, and take out the AlFeCrCoNi high-entropy alloy;

[0054] Cutting the AlFeCrCoNi high-entropy alloy wire into 1 mm thick flakes, and after ultrasonic cleaning with acetone, crushing the flakes into granules;

[0055] The AlFeCrCoNi high-entropy alloy particles were further pulverized by ball milling with bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com