High-strength and high-conductivity carbon nano tube strengthening copper-based composite material and preparing method thereof

A copper-based composite material and carbon nanotube technology are applied in the field of single-walled carbon nanotube-reinforced copper-based composite materials and their preparation, which can solve the problems of macroscopic comprehensive performance, mechanical properties, unsatisfactory thermal conductivity and electrical conductivity, etc. To the mechanical properties and electrical properties, the preparation process is simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

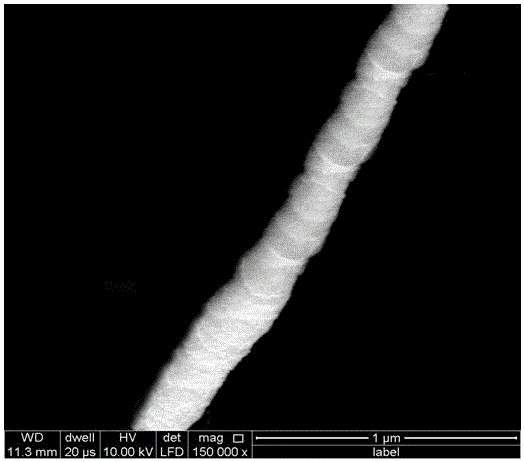

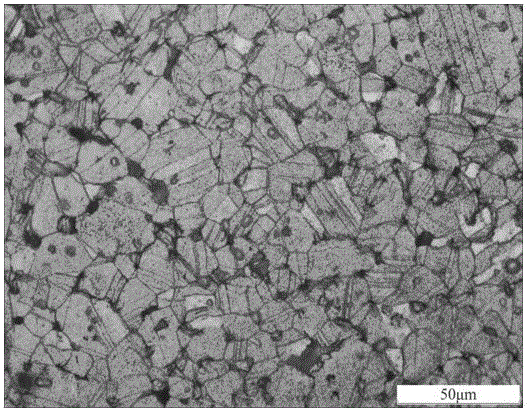

[0053] 2.5 mL of nickel / copper-coated single-walled carbon nanotubes (such as figure 1 as shown, figure 1 It is a scanning electron microscope photo of nickel / copper-plated single-walled carbon nanotubes. It can be seen that the bimetallic coating on the surface of carbon nanotubes is relatively uniform and continuous, and the coated carbon nanotubes used have a large aspect ratio. ) was dissolved in 60mL of absolute ethanol, the average diameter of single-walled carbon nanotubes was 2-6nm, and the average length was 5-30um, and then 47.5mL of 200-mesh pure copper powder was added to the resulting solution, at a frequency of 59Hz and a power of 60W, Under the condition that the temperature of the water bath is 40°C, the water bath is ultrasonically combined with mechanical stirring until all the anhydrous ethanol is volatilized, and the evenly mixed powder is placed in a vacuum drying oven. ﹣2 Dry at MPa for 36 hours. Put the dried powder into a powder metallurgy mold, and u...

Embodiment 2

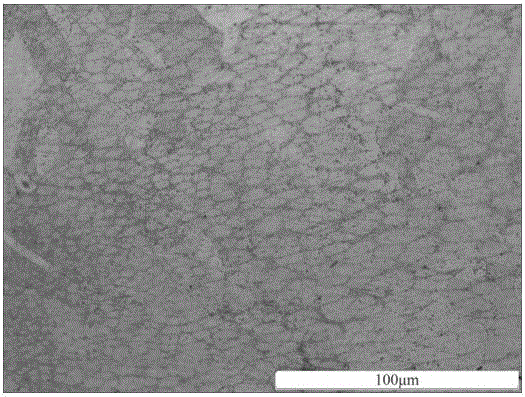

[0055] Dissolve 5mL of nickel-plated / copper single-walled carbon nanotubes in 60mL of absolute ethanol, the average diameter of single-walled carbon nanotubes is 2-6nm, and the average length is 5-30um, and then add 45mL of 200-mesh pure copper powder into the resulting solution In the process, under the conditions of frequency 59Hz, power 60W, and water bath temperature of 50°C, the water bath is ultrasonically combined with mechanical stirring until the absolute ethanol is completely volatilized, and the evenly mixed powder is placed in a vacuum drying oven. 1.5×10 ﹣2 Dry at MPa for 24 hours. Put the dried powder into a powder metallurgy mold, and unidirectionally press it into a cylindrical billet with a diameter of 40 mm and a height of 12 mm under a pressure of 100 MPa. The density reaches 67.4% after holding the pressure for 5 minutes. Put the compact into an argon-protected sintering furnace, heat up to 350°C at a rate of 15°C / min, keep it warm for 15 minutes, continue...

Embodiment 3

[0057] Dissolve 2.5mL of nickel-plated / copper single-walled carbon nanotubes in 60mL of absolute ethanol, the average diameter of single-walled carbon nanotubes is 2-6nm, and the average length is 5-30um, and then add 47.5mL of 200-mesh pure copper powder In the obtained solution, under the conditions of frequency 59Hz, power 100W, and water bath temperature of 60°C, the water bath is ultrasonically combined with mechanical stirring until the absolute ethanol is completely volatilized, and the evenly mixed powder is placed in a vacuum drying oven. The degree is 1.5×10 ﹣2 Dry at MPa for 24 hours. Put the dried powder into a powder metallurgy mold, cold isostatically press it into a cylindrical billet with a diameter of 40 mm and a height of 12 mm under a pressure of 200 MPa, hold the pressure for 15 minutes, and the density reaches 65.4%. Put the compact into an argon-protected sintering furnace, heat up to 350°C at a rate of 15°C / min, keep it for 15 minutes, continue heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com