Application of a Catalyst in Alkaline Fuel Cell

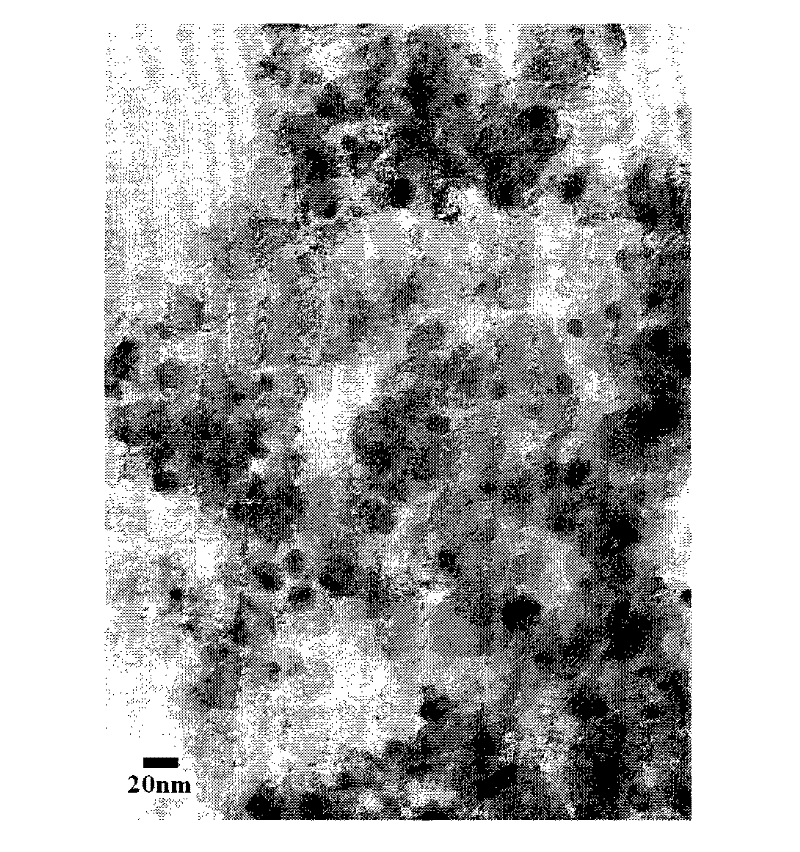

A technology of fuel cells and catalysts, applied in physical/chemical process catalysts, battery electrodes, circuits, etc., to achieve good application effects, small particles, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

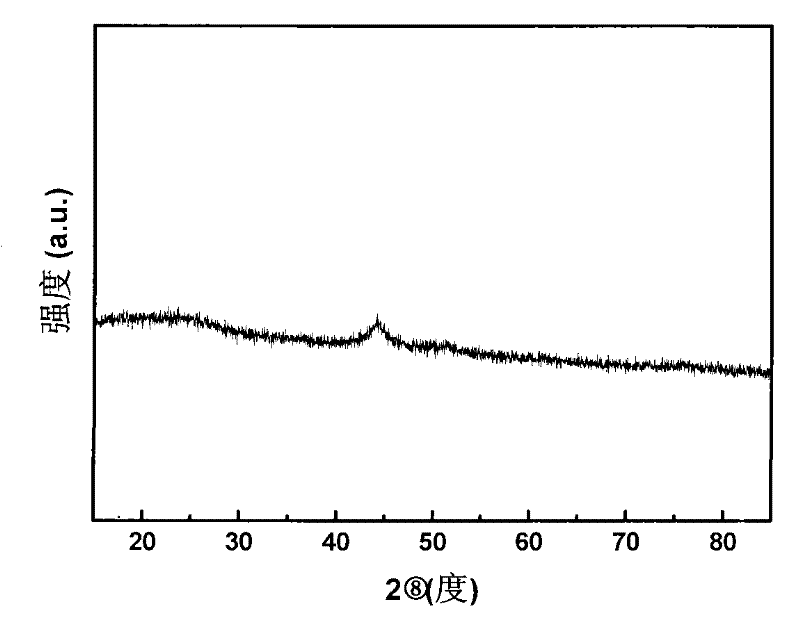

[0029] Preparation and activity test of 29% Co-N / C catalyst:

[0030] Add 2.0mL of cobalt nitrate hexahydrate ethanol solution with a concentration of 10mgCo / mL and 80mg of imidazole into 50mL of ethanol, ultrasonically stir until uniform, and obtain mixed solution A; add 0.1g of XC-72 carbon powder into 50mL of ethanol, ultrasonically Mix evenly to obtain slurry B; mix the above slurry A with solution B, evaporate ethanol to dryness under stirring condition at 60°C, after drying, pass through N 2 , heat-treated at 600° C. for 2 hours, and cooled to room temperature to obtain a Co-N / C catalyst with an active component content of 29% and a N:Co molar ratio of 4.4:1.

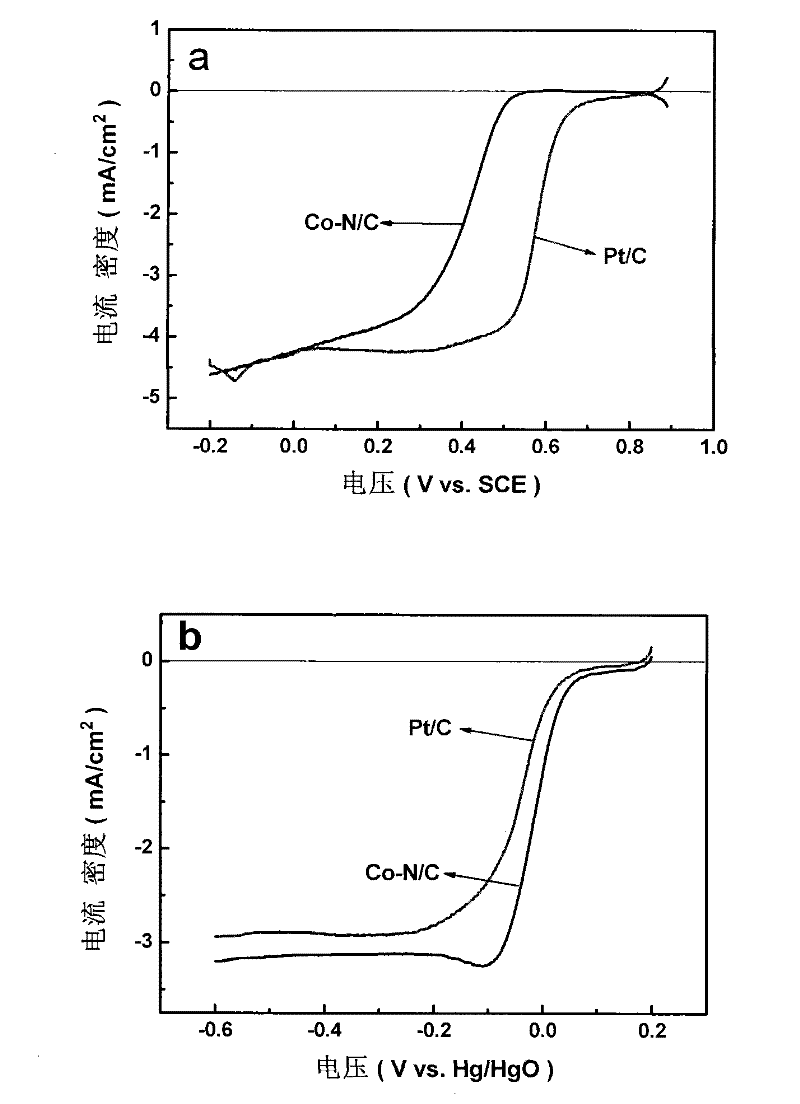

[0031] Electrochemical oxygen reduction (ORR) polarization curve tests were carried out on the catalyst prepared above and the commercial Pt / C comparison catalyst respectively, and the test conditions were as follows:

[0032] Cyclic voltammetry (CV) tests were performed on a CHI 600 electrochemical tester and a ...

Embodiment 2

[0038] Preparation and activity test of 10% Fe-N / C catalyst:

[0039] Add 1.33mL of ferrous chloride dihydrate isopropanol solution with a concentration of 5mgFe / mL and 55.2mg of hexamethylenediamine into 40mL of isopropanol, ultrasonically stir until uniform to obtain mixed solution A; mix 0.18g XC- Add 72 carbon powder into 60mL isopropanol, and mix evenly by ultrasonic to obtain slurry B; mix the above slurry A with solution B, and evaporate the isopropanol to dryness under stirring at 75°C. After drying, pass in NH 3 , heat-treated at 300°C for 1 hour, and cooled to room temperature to obtain an Fe-N / C catalyst with an active component content of 10% and a N:Fe molar ratio of 8:1.

[0040] Electrochemical oxygen reduction (ORR) polarization curve tests were carried out on the catalyst prepared above and the commercial Pt / C comparison catalyst respectively, and the test conditions were as follows:

[0041] Cyclic voltammetry (CV) tests were performed on a CHI 600 electroch...

Embodiment 3

[0047] Preparation and activity test of 80% Ni-N / C catalyst:

[0048] Add 5.93mL of ethanol solution of nickel oxalate dihydrate with a concentration of 8mgNi / mL and 747.7mg of aniline into 80mL of ethanol, ultrasonically stir until uniform, and obtain mixed solution A; add 0.04g of BP2000 carbon powder into 20mL of ethanol, and ultrasonically mix uniform to obtain slurry B; mix the above slurry A with solution B, evaporate ethanol to dryness at 60°C under stirring condition, after drying, pass through N 2 , heat-treated at 750°C for 2.5 hours, and cooled to room temperature to obtain a Ni-N / C catalyst with an active component content of 80% and a N:Ni molar ratio of 10:1.

[0049] Electrochemical oxygen reduction (ORR) polarization curve tests were carried out on the catalyst prepared above and the commercial Pt / C comparison catalyst respectively, and the test conditions were as follows:

[0050] Cyclic voltammetry (CV) tests were performed on a CHI 600 electrochemical teste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com