Pearlescent pigments with large aspect ratio and a method of their preparation

A pearlescent pigment and metal technology, applied in the wet preparation of dyed pigments, chemical instruments and methods, fibrous fillers, etc., can solve the problems of small and large aspect ratio, difficult to display satisfactory gloss, large aspect ratio and small etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

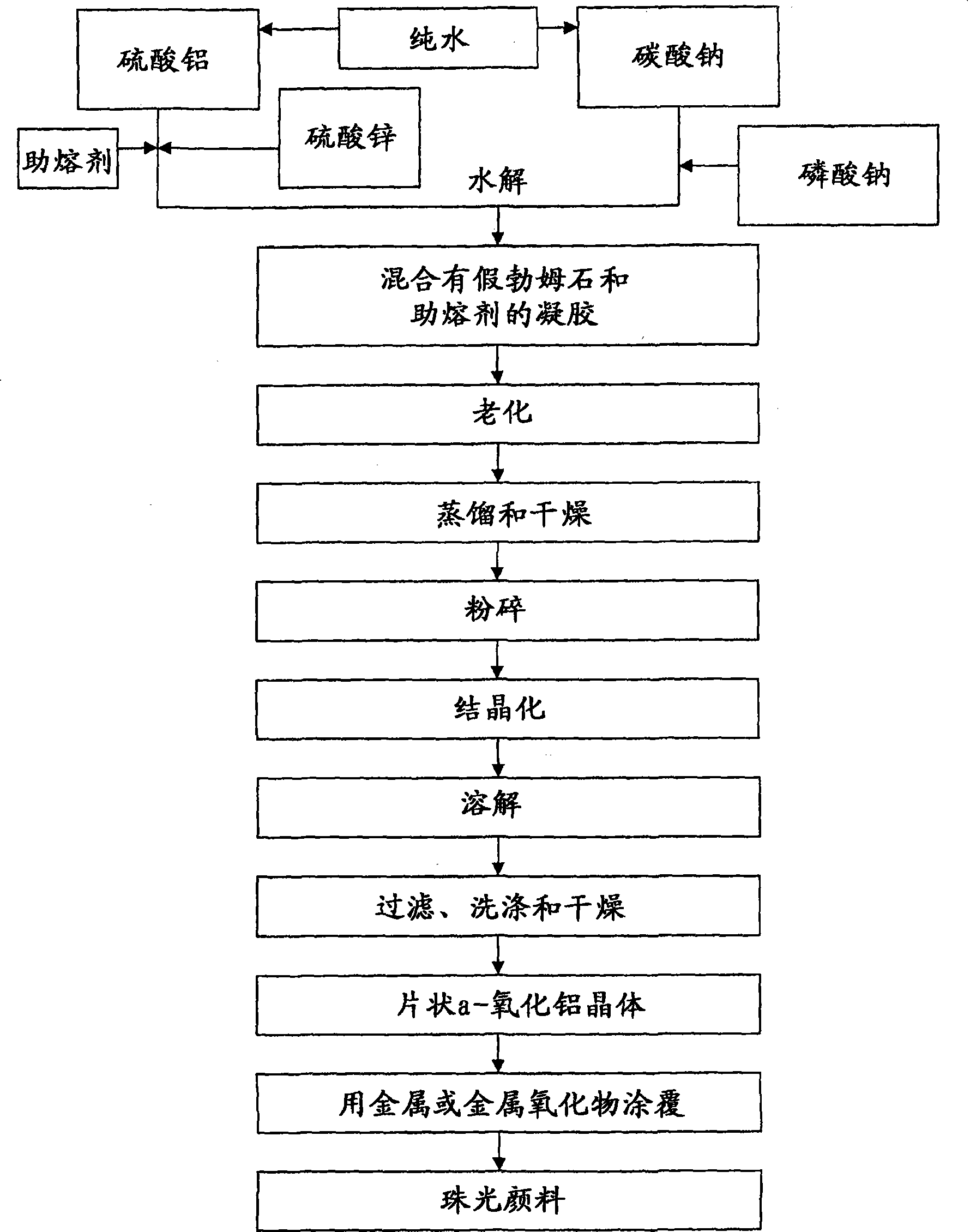

Method used

Image

Examples

Embodiment 1

[0062] By mixing 670 g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O), 345g of sodium sulfate (Na 2 SO 4 ), 280g of potassium sulfate (K 2 SO 4 ), and 1.5g34% zinc sulfate (ZnSO 4 ·7H 2 O) aqueous solution to prepare a homogeneous mixture solution. By dissolving 324g of sodium carbonate (Na 2 CO 3 ) and 2.7g of sodium phosphate ((NaPO 3 ) 6 ) to prepare an alkaline solution. While stirring, the aluminum sulfate mixed solution (65° C.) was titrated with an alkali solution at a rate of 25 ml / min to adjust the pH to 6.8 to prepare a gel mixed with pseudoboehmite and a flux. Then, the hybrid gel was aged at 90°C for 20 hours, vacuum distilled at 60°C, and dried at 110°C for 20 hours. Flaky α-alumina crystals were prepared by pulverizing the dried mixed gel to a size of about less than 5 mm, and performing crystallization in an alumina crucible (2 L) at 1200° C. for 7 hours. The flux was separated from the flaky α-alumina crystals by cooling the crucible to room temper...

Embodiment 2

[0065] Transparent flaky α-alumina crystals were prepared in the same manner as in Preliminary Example 1 except that 3 g of 34% zinc sulfate was used.

[0066] The obtained flaky α-alumina crystals were confirmed to have an average particle thickness of 0.22 μm and an average particle size of 18.3 μm. Atomic analysis revealed the presence of 0.2 parts by weight of zinc oxide.

[0067] Embodiment: prepare pearlescent pigment

[0068] Example 1:

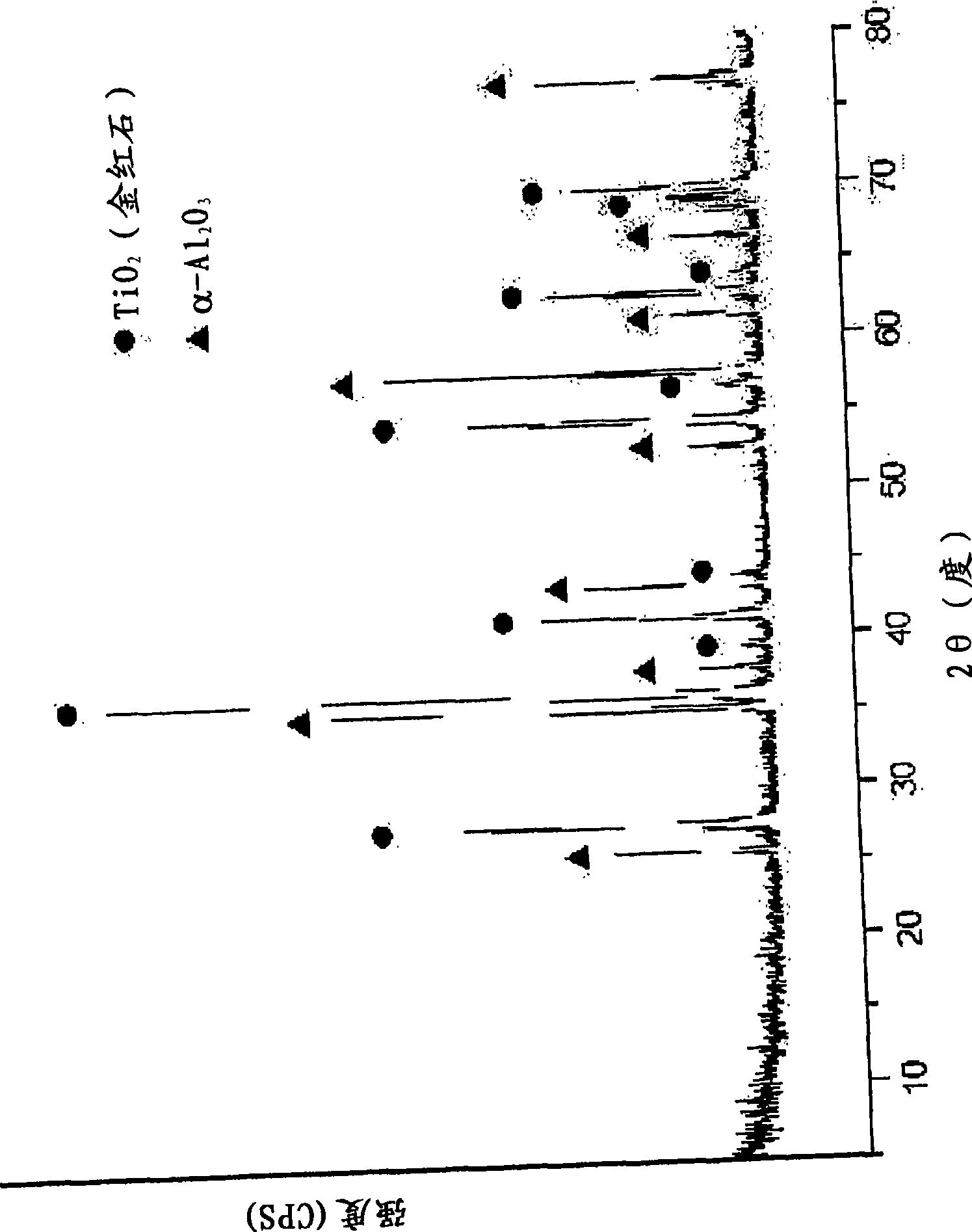

[0069] The flaky α-alumina particles (100 g) prepared in Preliminary Example 1 were suspended in deionized water (2 L), and the temperature was raised to 70°C. Chloric acid (5%) was added to adjust the pH to 2 and stirred for 30 minutes. By adding 40% TiOCl 2 and sodium hydroxide solution to form TiO(OH) on the surface of α-alumina particles 2 coating. With TiOCl 2 And the addition amount of sodium hydroxide solution increases, and the color changes to the interference color of silver (75nm), gold (110nm), red (130nm), purple (1...

Embodiment 3

[0073] The flaky α-alumina particles (100 g) prepared in Preliminary Example 1 were suspended in deionized water (2 L), and the temperature was raised to 70°C. Chloric acid (5%) was added to adjust the pH to 2 and stirred for 30 minutes. By adding 60ml of 5% SnCl 4 ·5H 2 O solution and sodium hydroxide solution to form TiO(OH) on the surface of α-alumina particles 2 coating. Add TiOCl 2 and sodium hydroxide solution until a golden color is obtained, followed by stirring for more than 30 minutes. Aqueous sodium hydroxide solution was added to adjust the pH to 3. Ferric chloride solution was added until the desired color (pearl gray) was obtained, followed by filtration, washing and drying. Calcination was carried out at 900° C. to provide a coating of titanium dioxide and iron oxide (125 nm) on the surface of the flaky α-alumina particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com