Full automatic electroplating production line

An electroplating production line, fully automatic technology, applied to circuits, electrolytic processes, electrolytic components, etc., can solve the problems of manual loading and unloading, inconsistent electroplating quality, and inability to achieve electroplating effects, etc., to achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

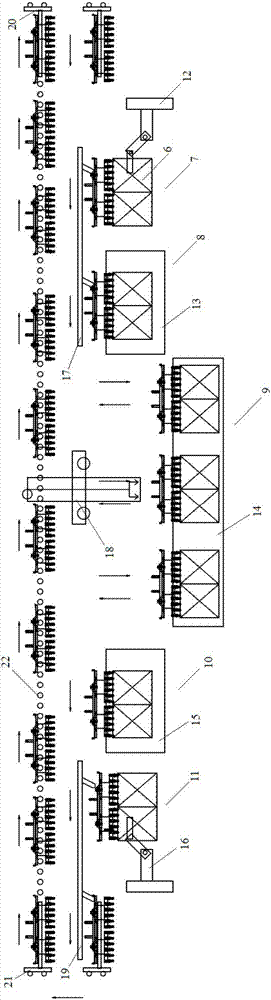

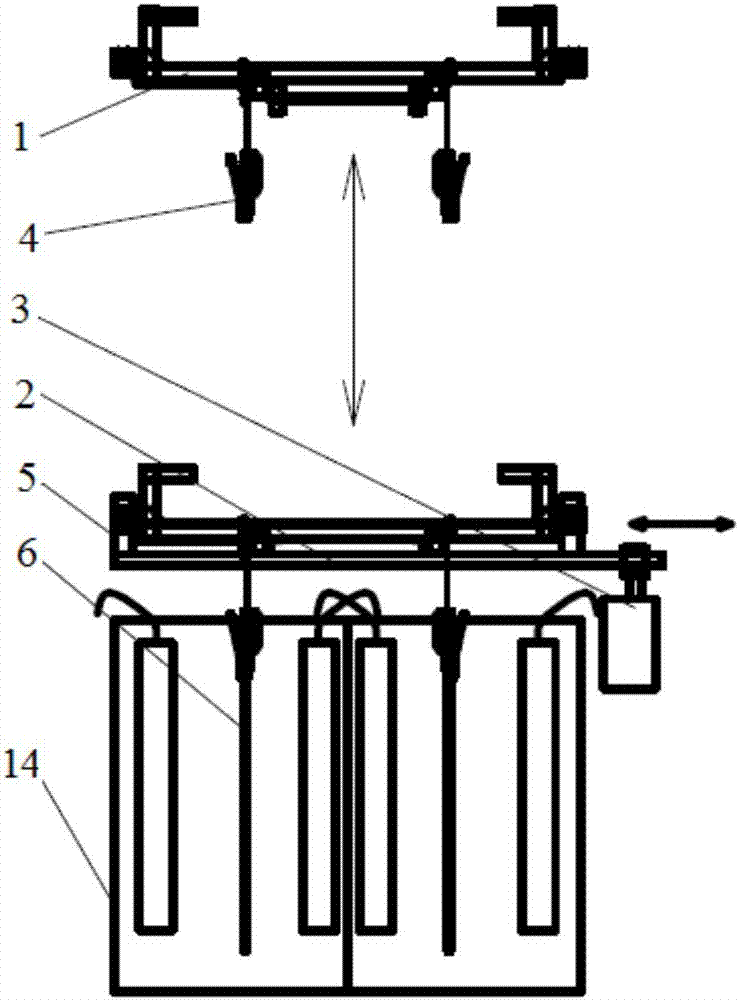

[0032] This embodiment provides a fully automatic electroplating production line, which can not only realize automatic loading and unloading, but also ensure that the electroplating quality of all workpieces is uniform, and can also achieve good electroplating effects for workpieces with high aspect ratios.

[0033] see figure 1 , The automatic electroplating production line of this embodiment includes: several movable plating parts loading mechanisms, return mechanisms and electroplating devices.

[0034] The plated piece loading mechanism is used to load the plated pieces 6 to be electroplated and arranged in sequence for use;

[0035] The electroplating device is used to perform loading, electroplating pre-treatment, electroplating, electroplating post-treatment, and blanking operations on the plated piece 6 in sequence, so as to complete the entire electroplating process for the plated piece 6;

[0036] The return mechanism is used to automatically return the loading mech...

Embodiment 2

[0056] In Embodiment 1, there is only one row of electroplating devices in the entire automatic electroplating production line, and only one row of electroplating tanks 14 with relatively large capacity is provided on the electroplating station 9 of the electroplating device, which can accommodate several plating pieces 6 . And in the second embodiment, in order to improve work efficiency to the greatest extent, N rows of parallel electroplating devices can be set to work at the same time in the electroplating production line, and M rows of electroplating tanks 14 can be set in each row of electroplating devices, N≥1, M≥1 . . At this time, the working principle is completely the same as that in the first embodiment, and will not be repeated here.

Embodiment 3

[0058] In the first embodiment, the return mechanism and the electroplating device are arranged up and down. However, in the third embodiment, it is preferable that the return mechanism and the electroplating device are arranged horizontally. In the up-and-down arrangement / horizontal arrangement, the return mechanism is kept parallel to the electroplating device.

[0059] When adopting the horizontal setting method, the first lift car 20 / second lift car 21 reciprocates on the horizontal track between the loading station 7 / unloading station 11 and the roller conveying line 22, so as to load the idle plating parts The mechanism is delivered to the loading station 7 by the roller conveyor line 22 / delivered to the roller input line by the blanking station 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com