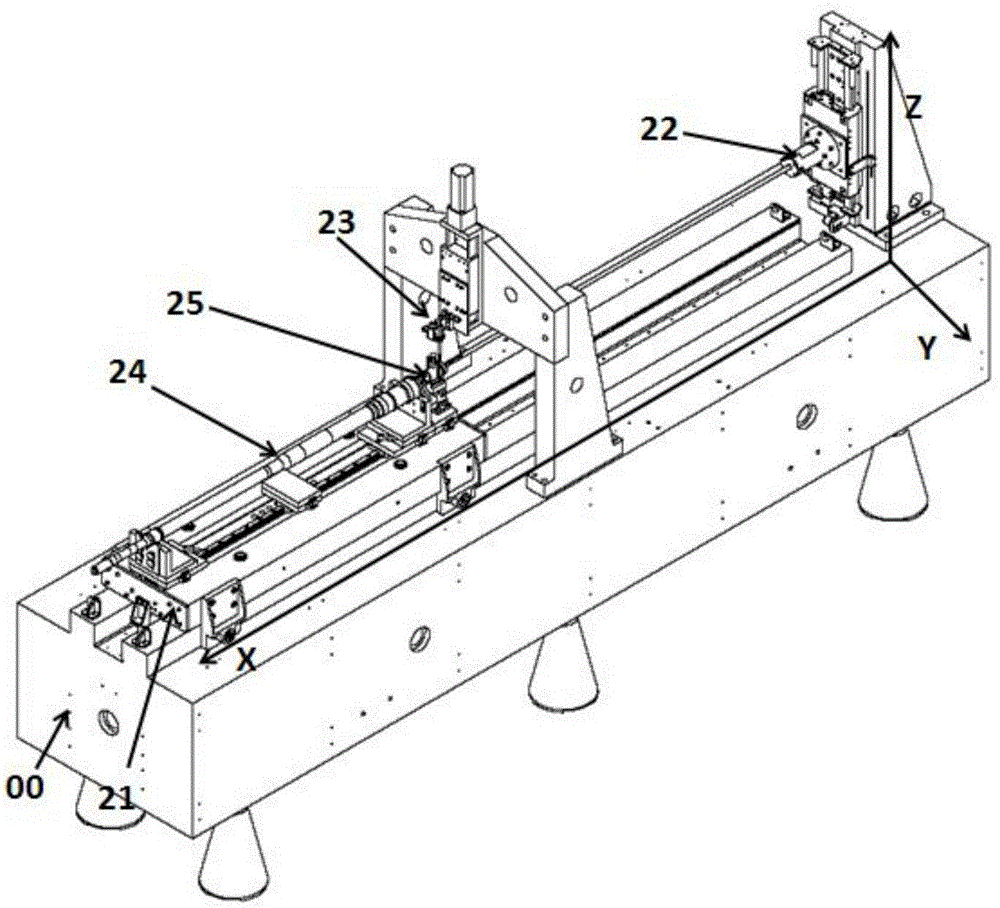

Large-aspect-ratio hollow-thin-wall thin and long shaft precision detection equipment and detection method thereof

A hollow thin-walled, detection equipment technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of decreased measurement accuracy and repeatability, unable to detect the inner cavity, affecting measurement efficiency, etc., to improve measurement accuracy and Measurement efficiency, shortened stabilization time, reasonable effect of measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

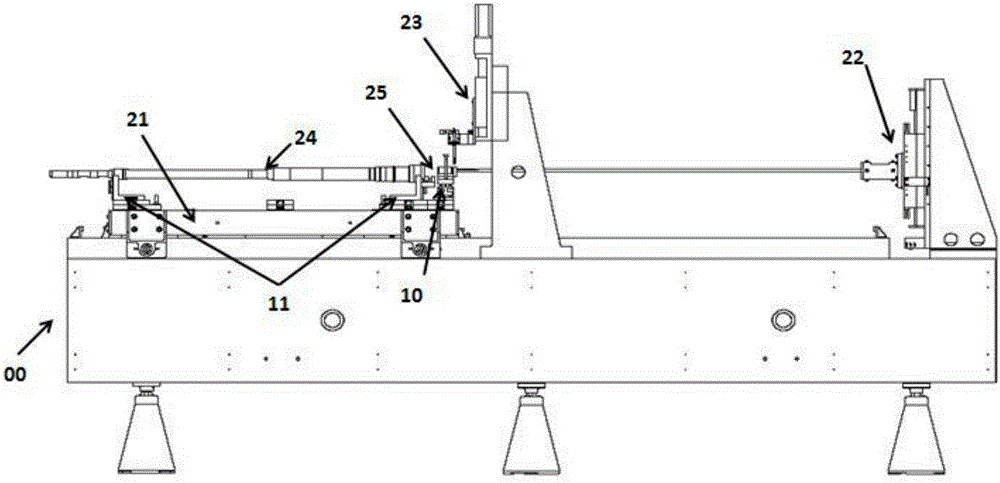

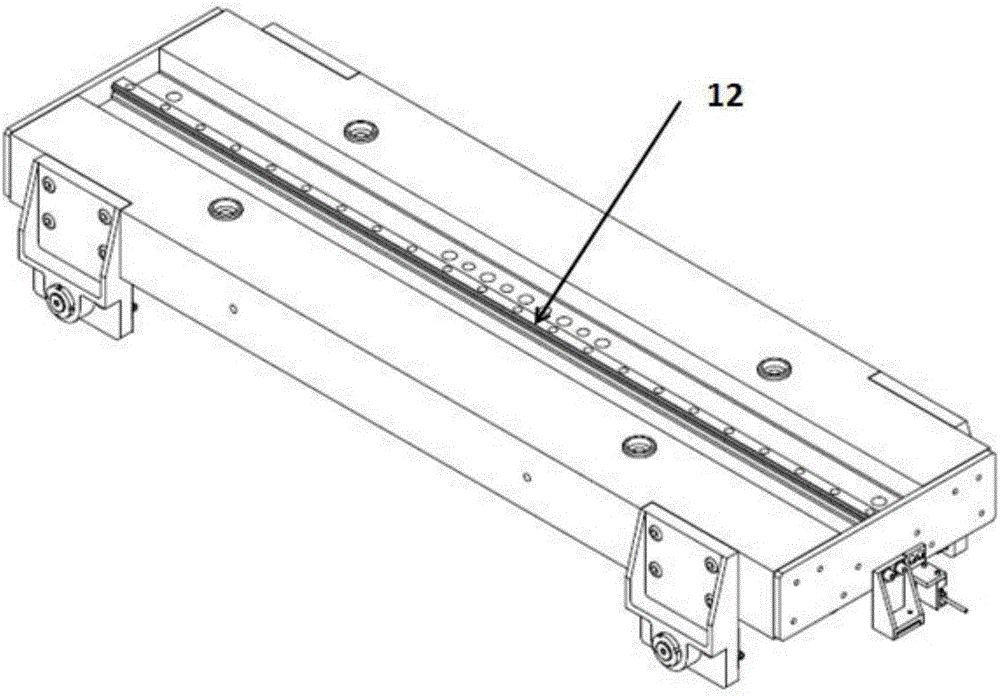

Embodiment

[0070] For the workpiece to be tested, see the attached Figure 8 , 41 shown in the figure is the first measurement section, 42 is the second measurement section, it is required to measure the wall thickness difference on the two sections, and according to the wall thickness difference data of the two sections, the outer circle and For the coaxiality of the inner wall, measure 4 measuring points at 90° equal divisions on each section.

[0071] First, place the two ends of the workpiece 24 under test on the two V-block support mechanisms 30 of the workpiece adjustment unit 11 and position them axially with ball bearings 32 to complete the support of the workpiece 24 under test;

[0072] Further, adjust the calibration ring adjustment unit 10 to make the axis of the calibration ring 25 parallel to the X axis, adjust the measuring rod adjustment unit 15 so that the axis of the measuring rod 14 is parallel to the axis of the calibration ring 25, and adjust the measured workpiece a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com