Large-height-width-ratio microstructure transfer printing method

A high-aspect-ratio micro-, micro-nano structure technology is applied in the field of high-aspect-ratio microstructure transfer, which can solve the problem of difficult and high-aspect-ratio microstructure effective transfer, low success rate of ink transfer, and difficulty in realizing large height and width. Compared with the transfer of microstructures, it achieves the effect of low equipment environment requirements, wide range and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

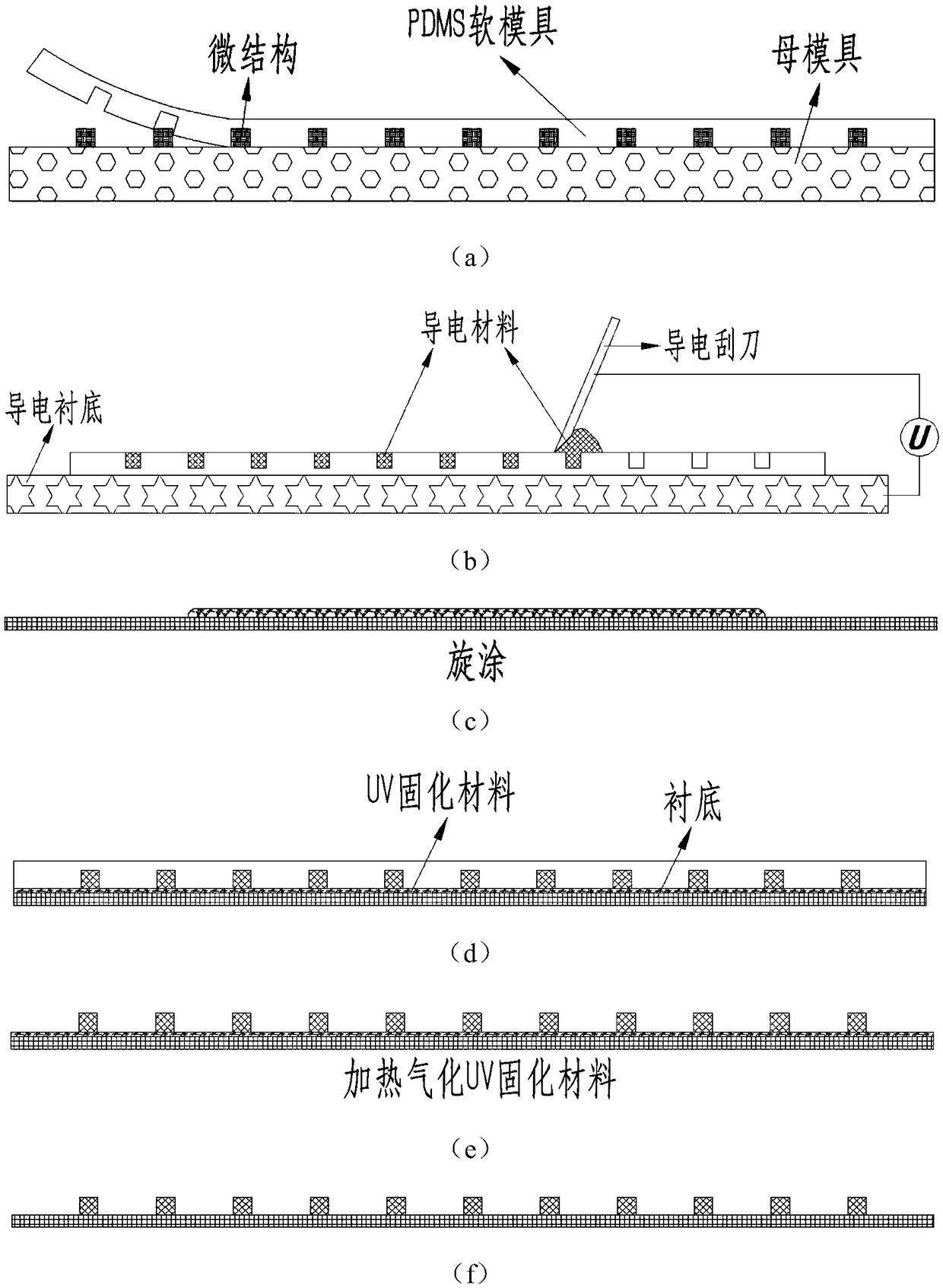

[0057] In this embodiment, the electric field-driven fused jet deposition 3D printing technology is used to manufacture the master mold required for micro-transfer printing. First, the microstructure in the master mold is transferred to the PDMS soft mold, wherein the microstructure is a PMMA wire grid structure; Fill the groove of the mold with conductive silver paste (containing glass powder) and pre-cure it; then select a common glass substrate and use UV-assisted transfer technology to transfer the conductive structure to the common glass substrate; finally sinter the conductive structure post-processing.

[0058] The specific process flow is: PDMS soft mold manufacturing, scrape coating of conductive materials, coating of UV curing materials, UV assisted transfer, and post-processing. Such as figure 1 (a) ~ (e) shown.

[0059] Specific steps are as follows:

[0060] Step 1: PDMS soft mold fabrication.

[0061] Step 1-1: Take the 3D printing master mold with a size of ...

Embodiment 2

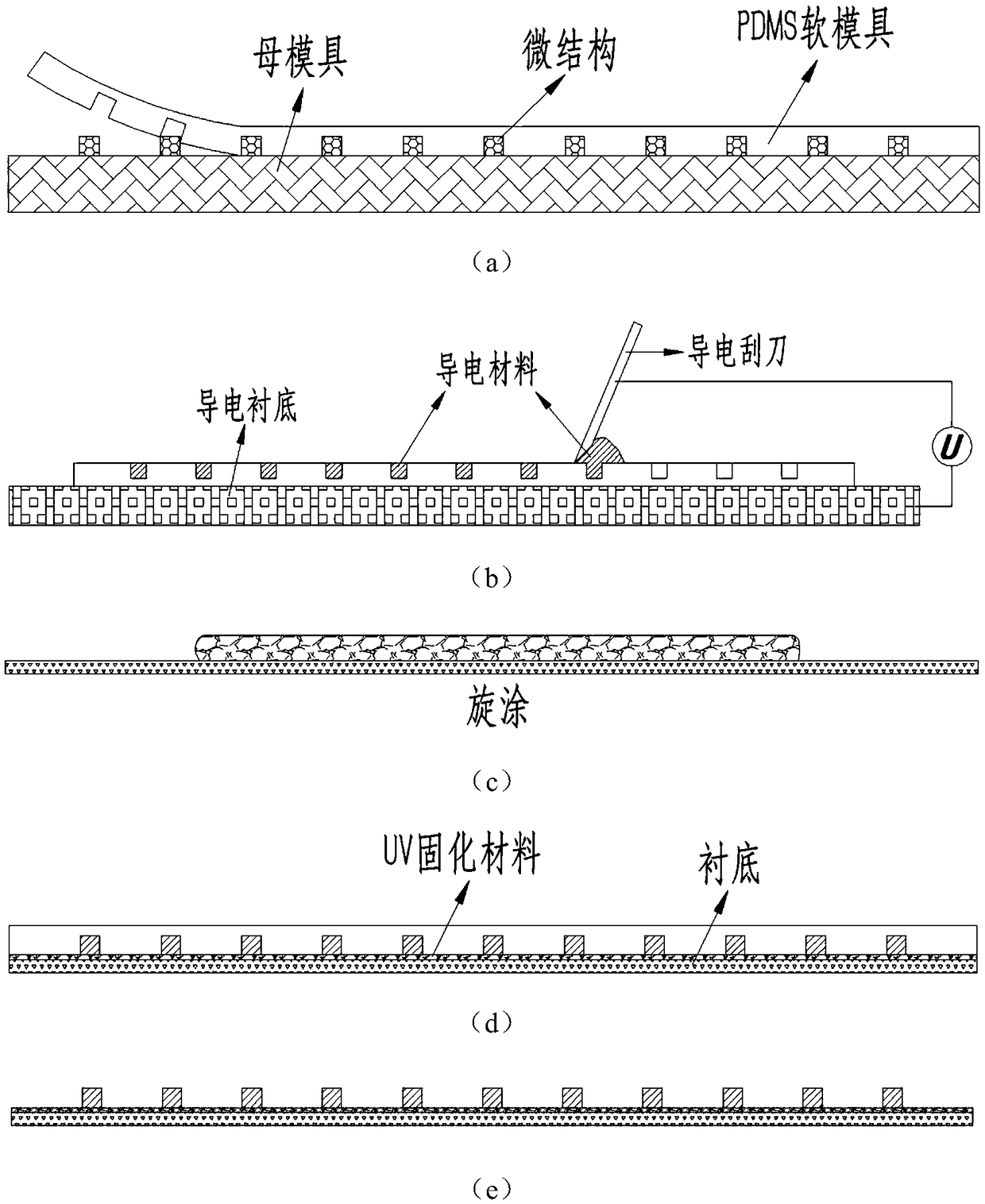

[0076] In this embodiment, the silicon mold manufactured by electron beam lithography is used as the master mold for micro-transfer printing. First, the microstructure on the silicon mold is transferred to the PDMS soft mold, wherein the microstructure is a grid structure; then, the microstructure on the PDMS soft mold The groove is filled with nano-silver conductive ink and pre-cured; after that, the PET film is selected as the target substrate, and the conductive structure is transferred to the PET film by UV-assisted transfer technology; finally, the conductive structure is post-processed.

[0077] The specific process flow is: PDMS soft mold manufacturing, scrape coating of conductive materials, coating of UV curing materials, UV assisted transfer, and post-processing. Such as figure 2 (a) ~ (e) shown.

[0078] Specific steps are as follows:

[0079] Step 1: PDMS soft mold fabrication.

[0080] Step 1-1: Take a 4-inch wafer silicon mold with a grid structure on it. The...

Embodiment 3

[0095] In this embodiment, the electric field-driven fused jet deposition 3D printing technology is used to manufacture the master mold required for micro-transfer printing. First, the microstructure is transferred to the PDMS soft mold, wherein the microstructure is a PCL grid structure; then, the groove of the PDMS soft mold The silver nanowire liquid is filled and pre-cured; after that, the PET film is selected as the substrate, and the conductive structure is transferred to the PET film by UV-assisted transfer technology; finally, the conductive structure is further post-processed.

[0096] The specific process flow is: PDMS soft mold manufacturing, scrape coating of conductive materials, coating of UV curing materials, UV assisted transfer, and post-processing. Such as figure 2 (a) ~ (e) shown.

[0097] Specific steps are as follows:

[0098] Step 1: PDMS soft mold fabrication.

[0099]Step 1-1: Take the 3D printing master mold with a size of 200mm×200mm, on which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com