Debris flow wing drainage guide groove structure

A drainage channel and debris flow technology, used in waterway systems, sewer systems, water supply devices, etc., can solve problems such as shortening the service life of drainage channel structures, road blockage, and debris fluid backfilling and burial, eliminating accumulation and siltation. problems, reduce abrasion, and increase the effect of debris flow throwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

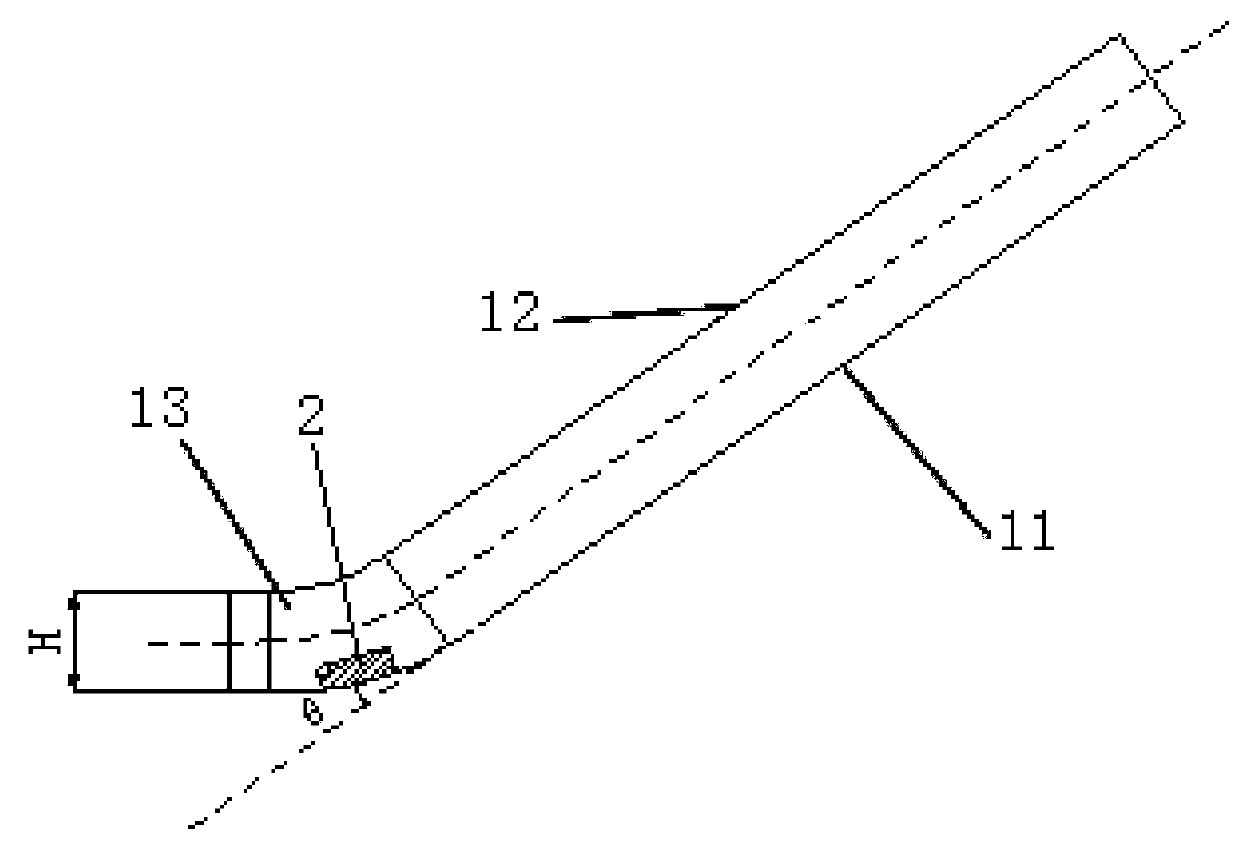

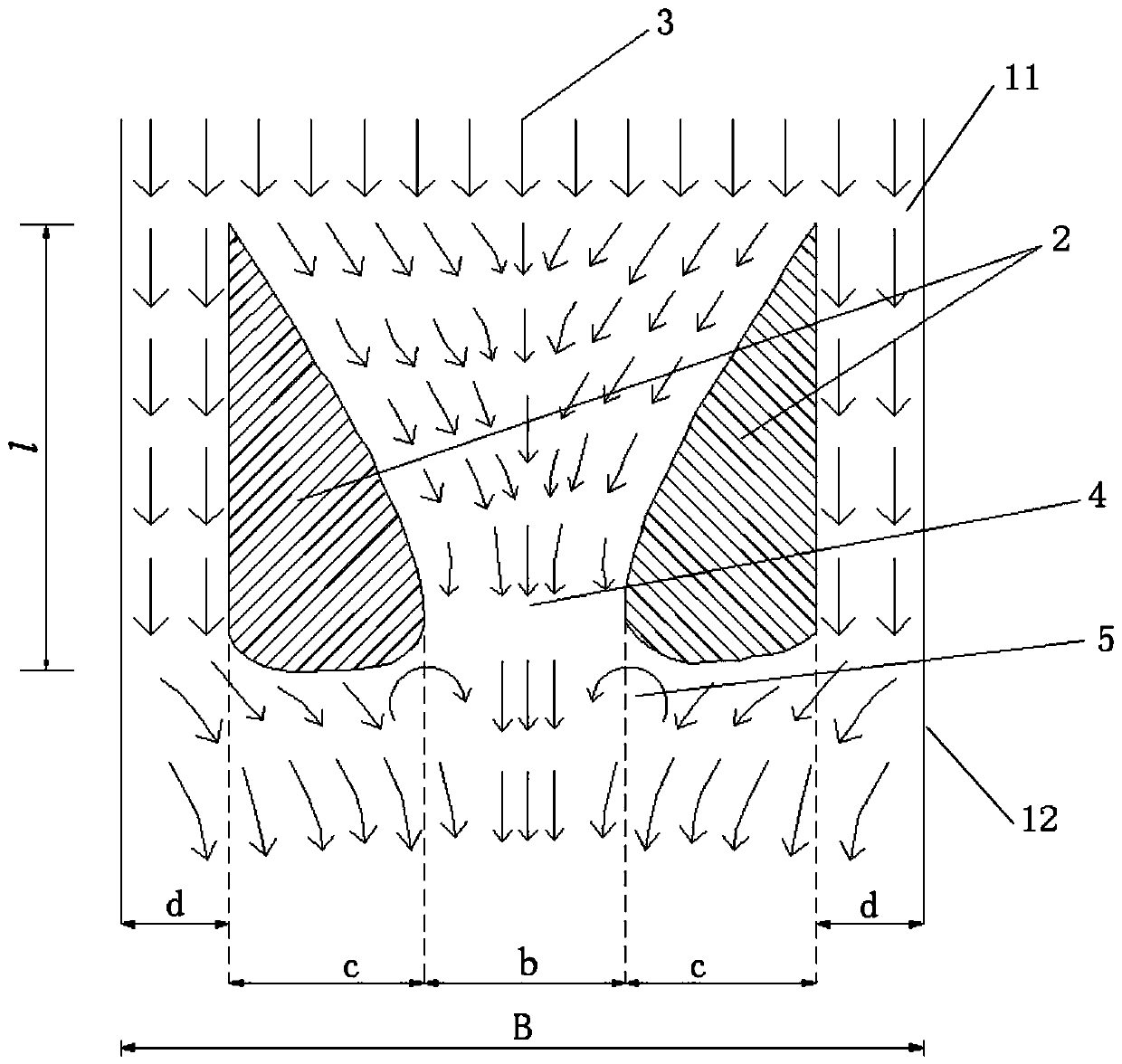

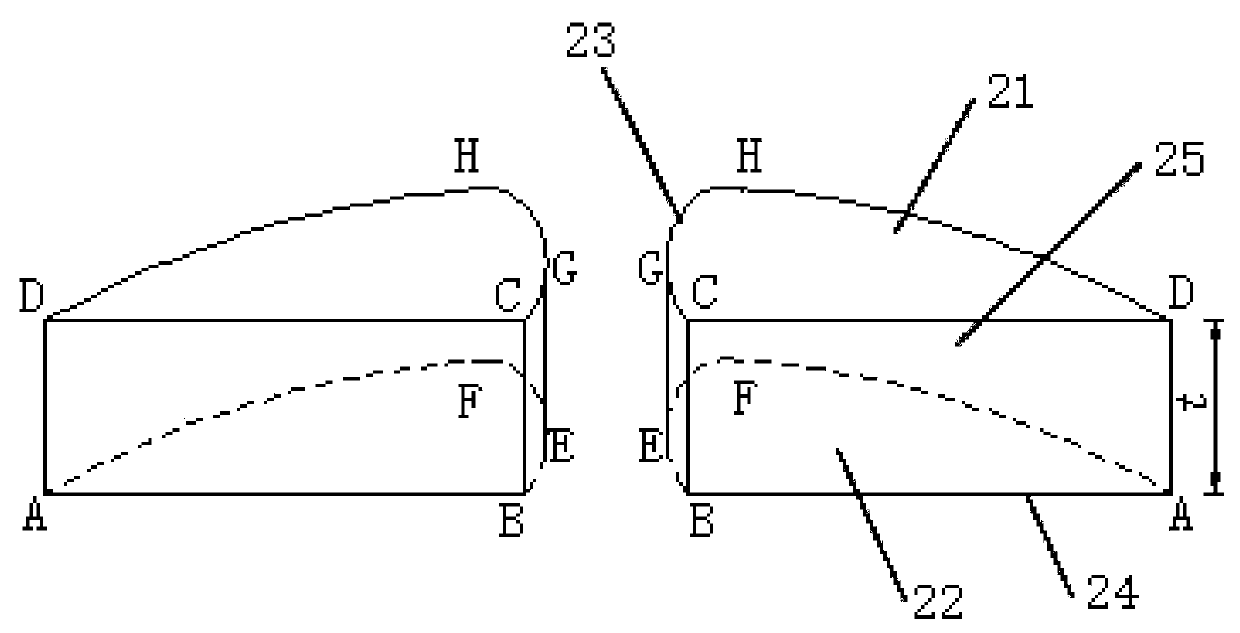

[0028] see Figure 1-Figure 3 , a debris flow airfoil guide channel structure, including the guide channel bottom surface 11 and the guide channel side walls 12 arranged on both sides of the guide channel bottom surface, the outlet section 13 of the guide channel adopts an arc-shaped structure and is reversed. The inclination angle θ is an acute angle, which is the angle between the tangent of the anti-warping point of the outlet section of the drainage channel and the straight line of the bottom surface of the inlet section of the drainage channel, so that the debris fluid is thrown horizontally or obliquely upward at the outlet section; The throwing distance solves the problem that the mud-rock fluid in the traditional linear row channel is buried at the outlet and causes the mud-rock fluid to block the river. In this embodiment, the anti-war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com