Filling device for wine production

A filling equipment and filling box technology, applied in packaging, bottling machines, bottle filling, etc., can solve problems such as inconvenient filling, wine pollution, and failure to prevent bottle bursting, so as to avoid filling in place and avoid Accidents and the effect of reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

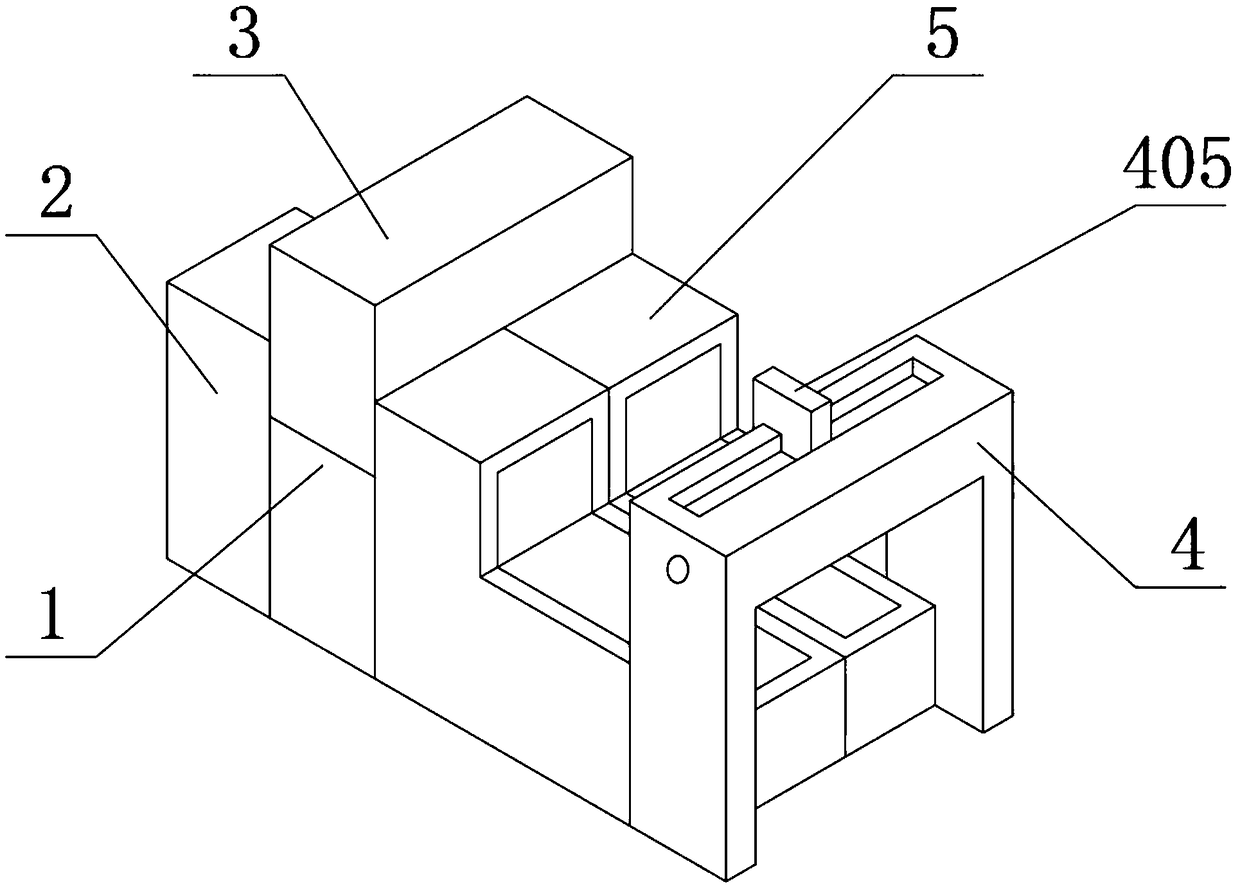

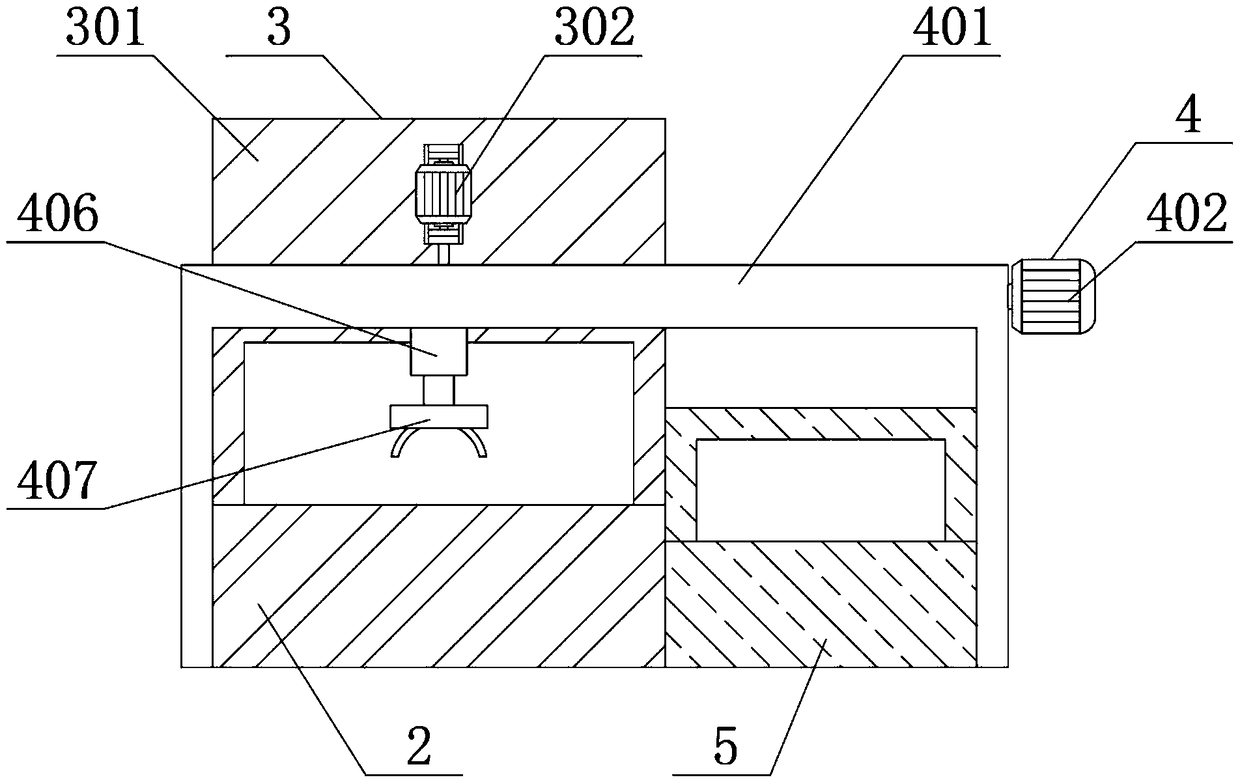

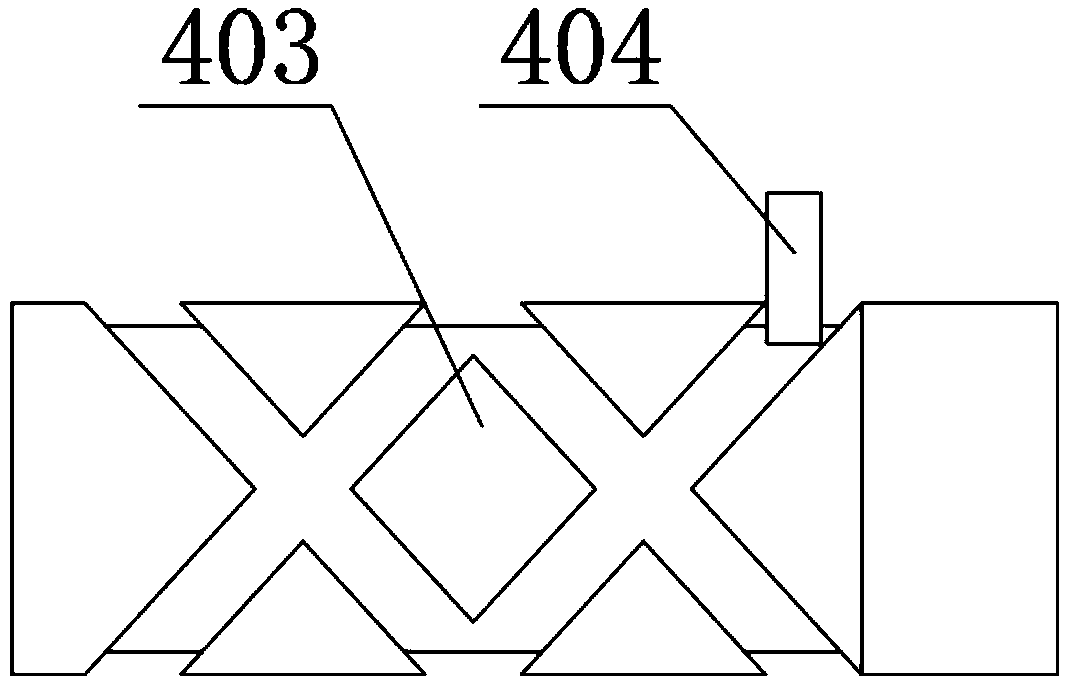

[0032] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , The present invention provides a technical solution:

[0033] A filling equipment for wine production, comprising a box body 1 and a conveying device 2. The left and right ends of the box body 1 are fixedly connected with a conveying device 2. The conveying device 2 includes a conveying box 201, and the left and right ends of the box body 1 are fixed The conveying box 201 is connected, and the inner side of the front end of the left conveying box 201 is fixedly connected with a first motor 202. Conveying roller 203. A first conveyor belt 204 is provided on the outside of the first conveyor roller 203, which facilitates the conveying of wine bottles and facilitates the subsequent filling work. The inner side of the top surface of the conveying box 201 is fixedly connected with a first electric telescopic rod 205. The bottom end of the first electric telescopic rod 205 is fixedly connected with a sto...

Embodiment 2

[0037] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , The present invention provides a technical solution:

[0038] A filling equipment for wine production, comprising a box body 1 and a conveying device 2. The left and right ends of the box body 1 are fixedly connected with a conveying device 2. The conveying device 2 includes a conveying box 201, and the left and right ends of the box body 1 are fixed The conveying box 201 is connected, and the inner side of the front end of the left conveying box 201 is fixedly connected with a first motor 202. Conveying roller 203. A first conveyor belt 204 is provided on the outside of the first conveyor roller 203, which facilitates the conveying of wine bottles and facilitates the subsequent filling work. The inner side of the top surface of the conveying box 201 is fixedly connected with a first electric telescopic rod 205. The bottom end of the first electric telescopic rod 205 is fixedly connected with a sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com