Transition metal phosphide/porous carbon anode composite material for sodium-ion battery and preparation method thereof

A technology of sodium ion batteries and porous carbon materials, which is applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of reducing the cycle stability of electrode materials, reducing the rate performance of electrode materials, and volume changes, etc. Prospects for industrial application, improved cycle stability, rate performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] First weigh 1.71g of copper chloride dihydrate to fully dissolve it in 200mL of dimethylformamide solution, then weigh 12.6g of 1,3,5-trimellitic acid and slowly add it to the above solution under magnetic stirring , after stirring evenly, transfer the obtained mixed solution to a stainless steel hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C. After reacting for 16 hours, the resulting precipitate is repeatedly washed with methanol and dimethylformamide, and dried to obtain copper Precursors of metal-organic framework materials.

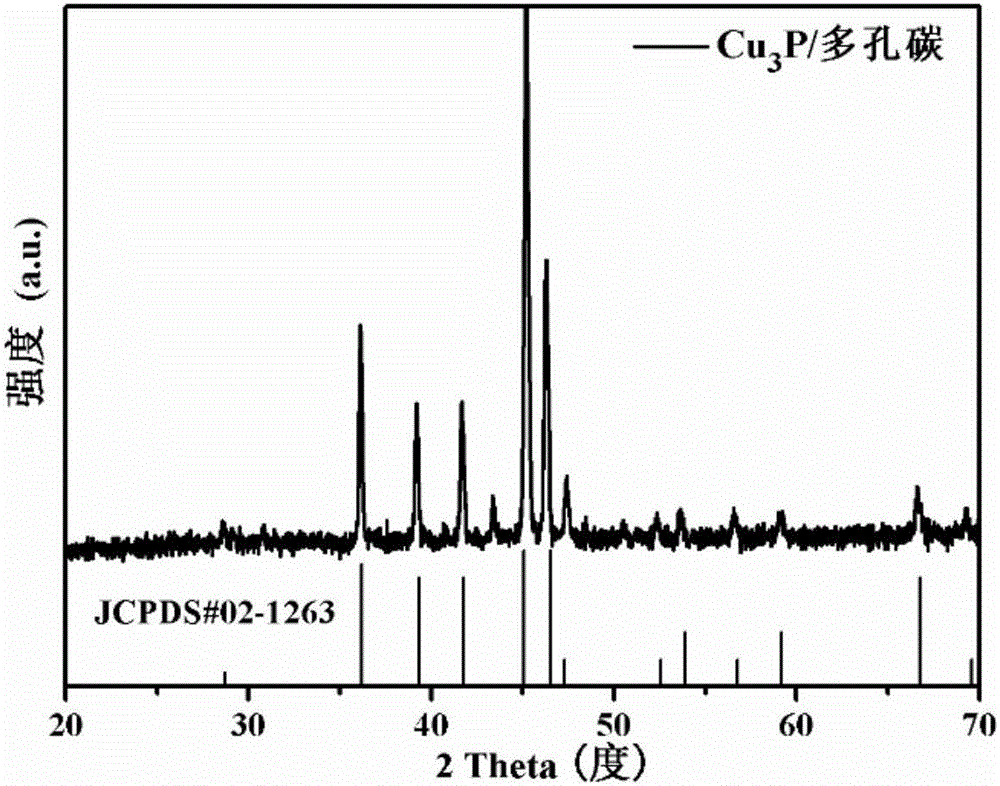

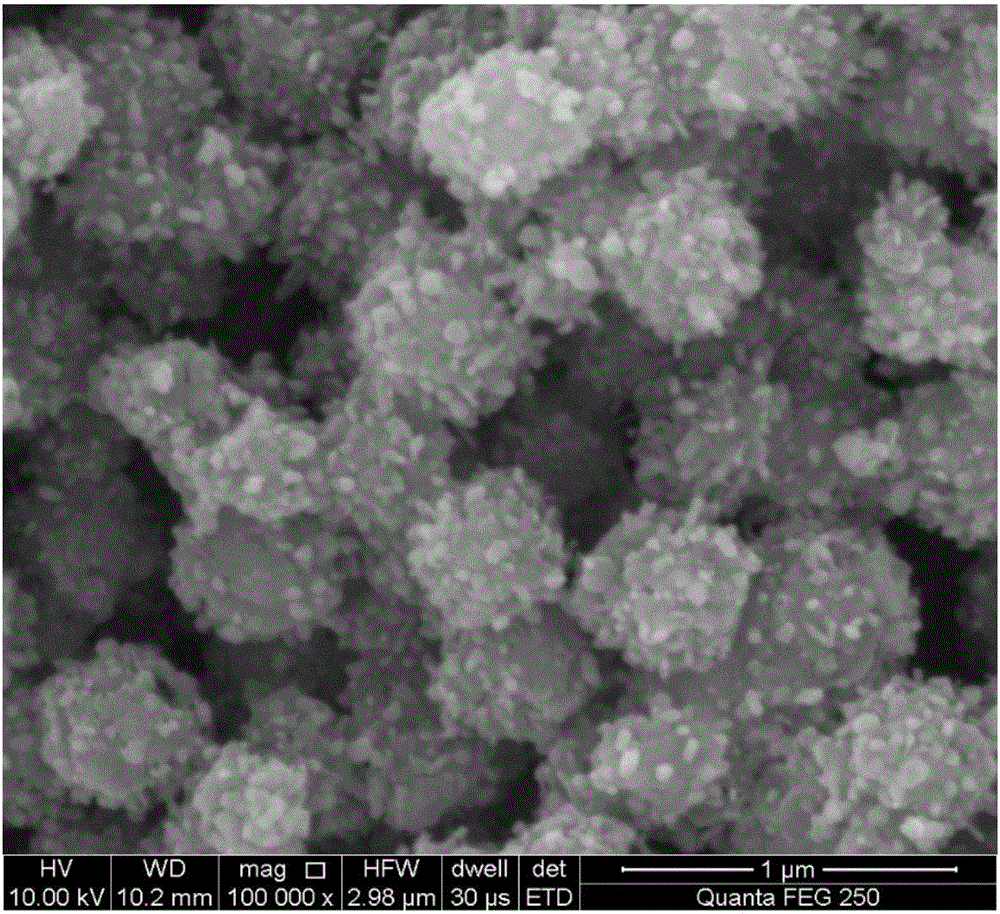

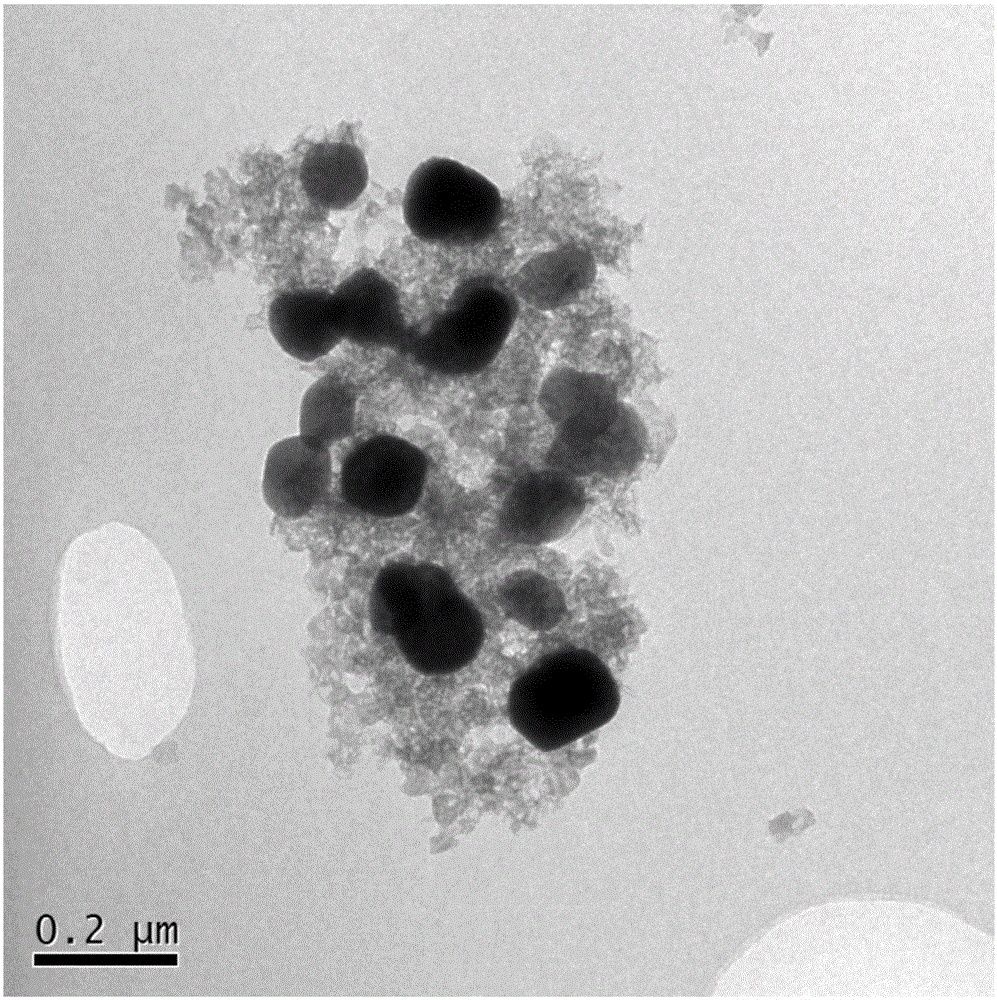

[0046] Weigh 0.5g copper-based metal organic framework material and 1g sodium dihydrogen hypophosphite, pour the two into the corundum porcelain boat, and place the two porcelain boats in the downwind direction and upwind direction of the vacuum tube furnace respectively, and then , the temperature of the tube furnace was raised to 500°C by introducing argon gas, and after fully reacting for 6 hours, the resulting r...

Embodiment 2

[0053] First weigh 1.71g of copper chloride dihydrate to fully dissolve it in 200mL of dimethylformamide solution, then weigh 12.6g of 1,3,5-trimellitic acid and slowly add it to the above solution under magnetic stirring , after stirring evenly, transfer the obtained mixed solution to a stainless steel hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C. After reacting for 16 hours, the resulting precipitate is repeatedly washed with methanol and dimethylformamide, and dried to obtain copper Precursors of metal-organic framework materials.

[0054] Weigh 0.5g copper-based metal organic framework material and 0.25g sodium dihydrogen hypophosphite, pour the two into the corundum porcelain boat, and place the two porcelain boats in the downwind direction and upwind direction of the vacuum tube furnace respectively, Subsequently, the temperature of the tube furnace was raised to 500°C by introducing argon gas, and after fully reacting for 6 hours, the resul...

Embodiment 3

[0058] First weigh 1.71g of copper chloride dihydrate to fully dissolve it in 200mL of dimethylformamide solution, then weigh 12.6g of 1,3,5-trimellitic acid and slowly add it to the above solution under magnetic stirring , after stirring evenly, transfer the obtained mixed solution to a stainless steel hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C. After reacting for 16 hours, the resulting precipitate is repeatedly washed with methanol and dimethylformamide, and dried to obtain copper Precursors of metal-organic framework materials.

[0059] Weigh 0.5g copper-based metal organic framework material and 2g sodium dihydrogen hypophosphite, pour the two into the corundum porcelain boat, and place the two porcelain boats in the downwind direction and upwind direction of the vacuum tube furnace respectively, and then , the temperature of the tube furnace was raised to 500°C by introducing argon gas, and after fully reacting for 6 hours, the resulting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com