Preparation method of pure spun blended yarn of horn gourd fiber

A pure spinning technology of horn melon fiber, which is applied in yarn, textiles and papermaking, etc., can solve the problems that the horn melon fiber cannot be smoothly formed into slivers, and the horn melon fiber is greatly damaged, so as to achieve less short fiber content of the horn melon fiber, Reduced broken ends and high quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation method of pure spun blended yarn of horn melon fiber, the steps are as follows:

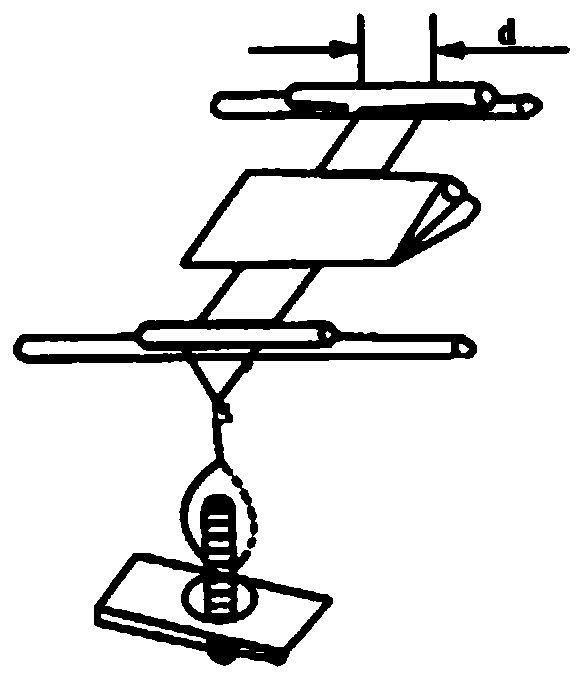

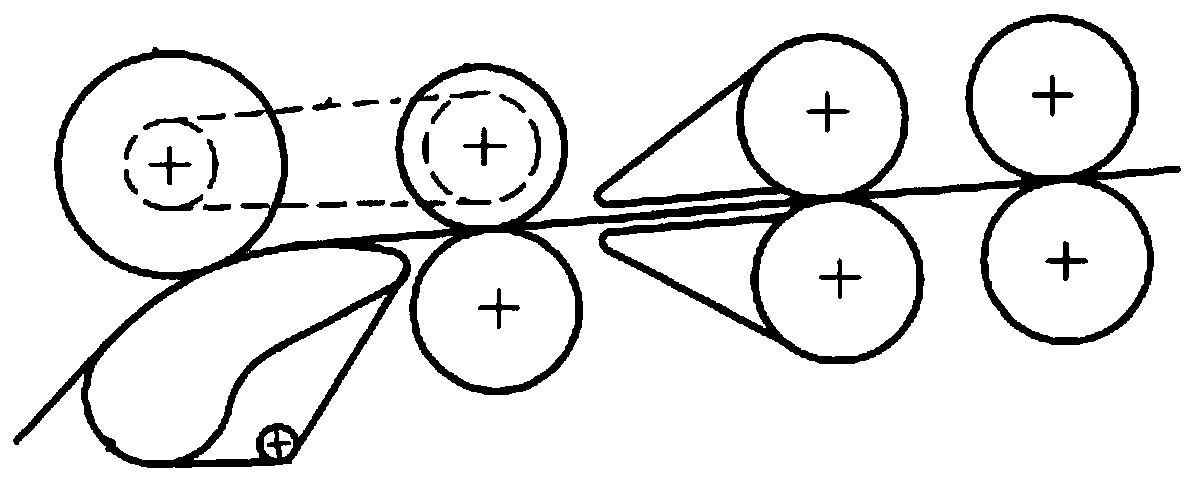

[0061] (1) Slivering: the gourd fiber is separated into single fiber state by feeding the licker-in roller and carding the metal card clothing on the surface of the opening roller, and is transported into the rotating sliver drum under the negative pressure airflow generated by the exhaust fan And arrange in parallel along the inner side of the cylinder wall of the sliver tube, under the action of centrifugal force, slide into the sliver groove and fold into ring-shaped whiskers. The process parameters of the sliver are as follows:

[0062]

[0063]

[0064] (2) Drawing: A total of two mergings are carried out, and parallel drafting is adopted. The two mergings are the first drawing and the second drawing respectively. The process parameters of the drawing are as follows:

[0065]

[0066] (3) Roving: The process parameters are as follows:

[0067]

[0068] (4)...

Embodiment 2

[0072] The preparation method of pure spun blended yarn of horn melon fiber, the steps are as follows:

[0073] (1) Slivering: the gourd fiber is separated into single fiber state by feeding the licker-in roller and carding the metal card clothing on the surface of the opening roller, and is transported into the rotating sliver drum under the negative pressure airflow generated by the exhaust fan And arrange in parallel along the inner side of the cylinder wall of the sliver tube, under the action of centrifugal force, slide into the sliver groove and fold into ring-shaped whiskers. The process parameters of the sliver are as follows:

[0074]

[0075] (2) Drawing: A total of two mergings are carried out, and parallel drafting is adopted. The two mergings are the first drawing and the second drawing respectively. The process parameters of the drawing are as follows:

[0076]

[0077] (3) Roving: The process parameters are as follows:

[0078]

[0079] (4) Spun yarn: ...

Embodiment 3

[0084] The preparation method of pure spun blended yarn of horn melon fiber, the steps are as follows:

[0085] (1) Slivering: the gourd fiber is separated into single fiber state by feeding the licker-in roller and carding the metal card clothing on the surface of the opening roller, and is transported into the rotating sliver drum under the negative pressure airflow generated by the exhaust fan And arrange in parallel along the inner side of the cylinder wall of the sliver tube, under the action of centrifugal force, slide into the sliver groove and fold into ring-shaped whiskers. The process parameters of the sliver are as follows:

[0086]

[0087] (2) Drawing: A total of two mergings are carried out, and parallel drafting is adopted. The two mergings are the first drawing and the second drawing respectively. The process parameters of the drawing are as follows:

[0088]

[0089] (3) Roving: The process parameters are as follows:

[0090]

[0091] (4) Spun yarn: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com