Nylon BCF (bulked continuous filament) superfine fiber and preparation method thereof

A superfine fiber and nylon technology, applied in the field of spinning, can solve the problems of uneven cooling of superfine fibers, easy occurrence of filaments, broken ends, affecting product quality, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

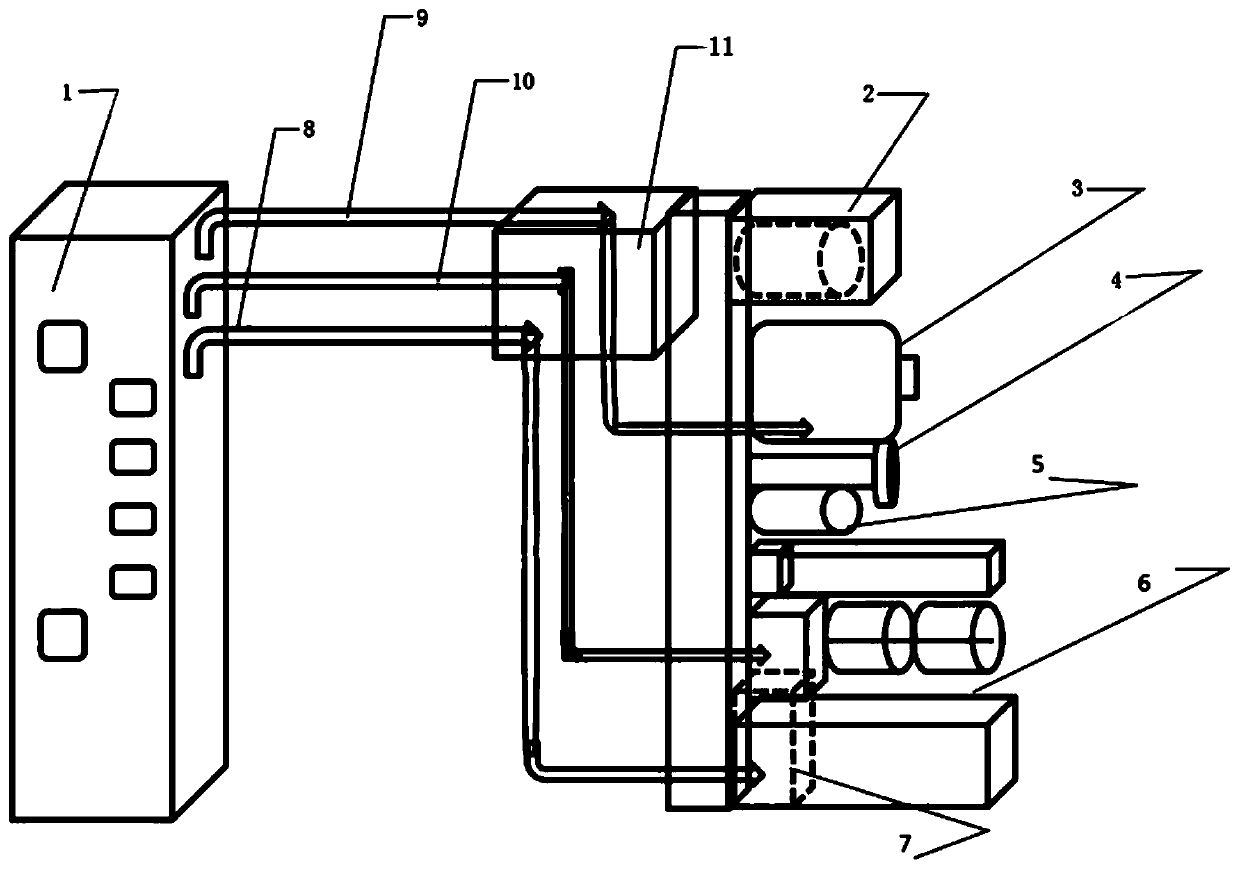

[0030] The invention provides a kind of preparation method of nylon BCF superfine fiber, and this method comprises the following steps:

[0031] (1) slices are melted and extruded by a screw machine;

[0032] (2) Spinning:

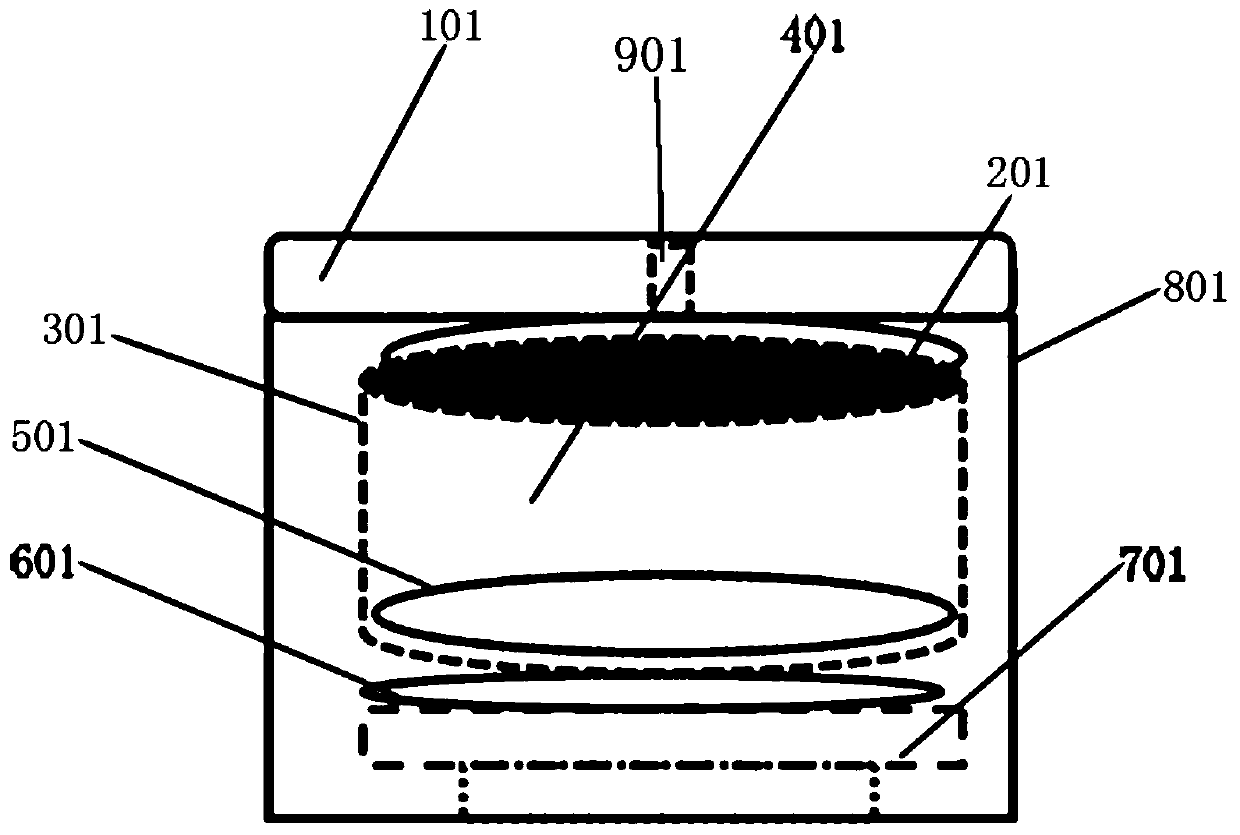

[0033] The molten liquid after melt extrusion enters the spinning assembly through the inlet of the spinning assembly cover, such as figure 2 , image 3 As shown, it enters the component through the entrance of the component cover, passes through the first filter screen, the sea sand in the sand box, the second filter screen, and the third filter screen in sequence, and then sprays out through the spinneret with special-shaped holes.

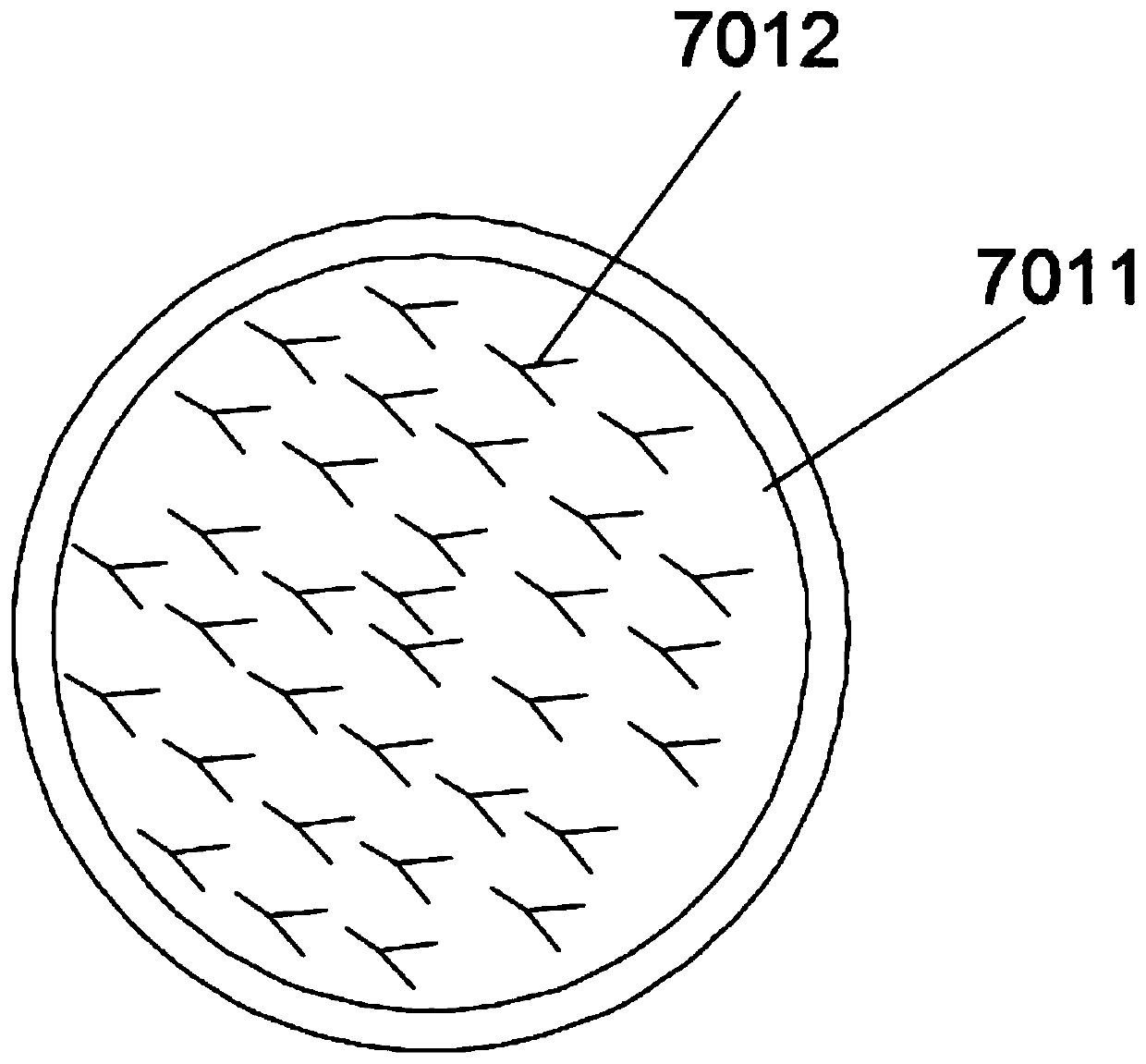

[0034] Wherein, the special-shaped hole spinneret is a spinnerette with 105 holes of special-shaped trilobal holes (there are 105 trilobal micropores on the spinneret), and the aspect ratio of the trilobal holes on the spinneret is 3.8. Among them, the filter sea sand mesh of the component is 25 mesh.

[0035] The comp...

Embodiment 1

[0057] A preparation method of nylon BCF superfine fiber, the method may further comprise the steps:

[0058] (1) slices are melted and extruded by a screw machine;

[0059] (2) Spinning:

[0060] The molten liquid after melt extrusion enters the spinning assembly through the inlet of the spinning assembly cover, such as figure 2 , image 3 As shown, it enters the component through the entrance of the component cover, passes through the first filter screen, the sea sand in the sand box, the second filter screen, and the third filter screen in sequence, and then sprays out through the spinneret with special-shaped holes.

[0061] Wherein, the special-shaped hole spinneret is a special-shaped 105-hole spinneret (the special-shaped hole is a trilobal hole), and the aspect ratio of the trilobal hole on the spinneret is 3.8. Among them, the filter sea sand mesh of the component is 25 mesh.

[0062] The component firstly filters the molten liquid through sea sand, which can fil...

Embodiment 2

[0081] A preparation method of nylon BCF superfine fiber, the method may further comprise the steps:

[0082] (1) slices are melted and extruded by a screw machine;

[0083] (2) Spinning:

[0084] The molten liquid after melt extrusion enters the spinning assembly through the inlet of the spinning assembly cover, such as figure 2 , image 3 As shown, it enters the component through the entrance of the component cover, passes through the first filter screen, the sea sand in the sand box, the second filter screen, and the third filter screen in sequence, and then sprays out through the spinneret with special-shaped holes.

[0085] Wherein, the special-shaped hole spinneret is a special-shaped 105-hole spinneret (the special-shaped hole is a trilobal hole), and the aspect ratio of the trilobal hole on the spinneret is 3.8. Among them, the filter sea sand mesh of the component is 25 mesh.

[0086] The component firstly filters the molten liquid through sea sand, which can fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curvature | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com