A double twister yarn guide device

A technology of yarn guiding device and two-for-one twisting machine, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of affecting the quality of work, the tension cannot be adjusted, and the textile effect is poor, so as to achieve the effect of simple and convenient adjustment, reduce tension fluctuation, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

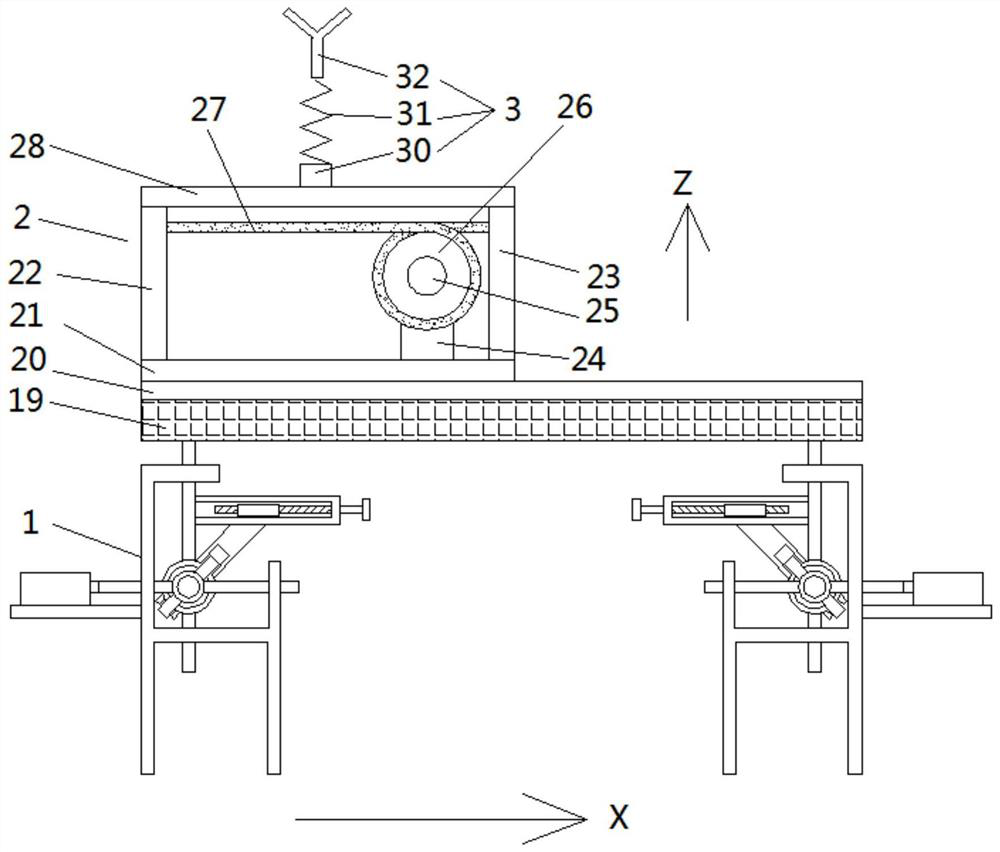

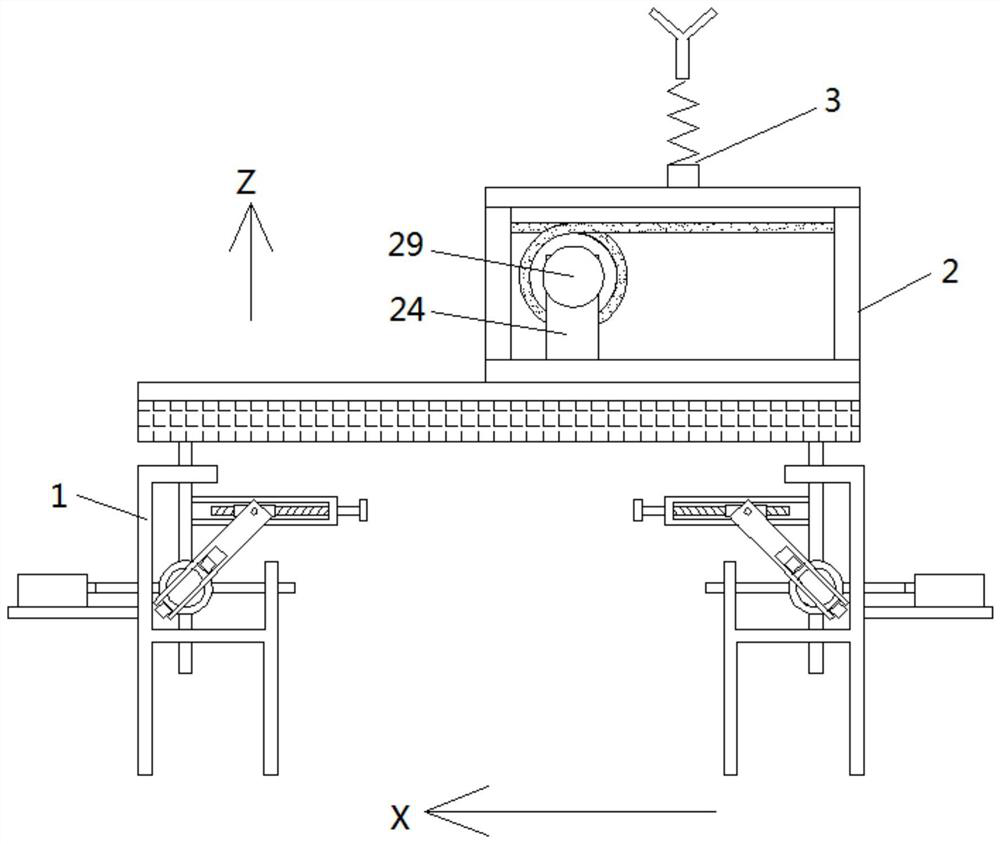

[0028] A yarn guiding device for a two-for-one twister, comprising a pair of vertical adjustment assemblies 1 for adjusting the Z-axis position and distributed along the X-axis direction, and a horizontal adjustment assembly installed on the two vertical adjustment assemblies 1 for adjusting the X-axis position 2. The yarn guide assembly 3 installed on the horizontal adjustment assembly 2 and used for yarn guide.

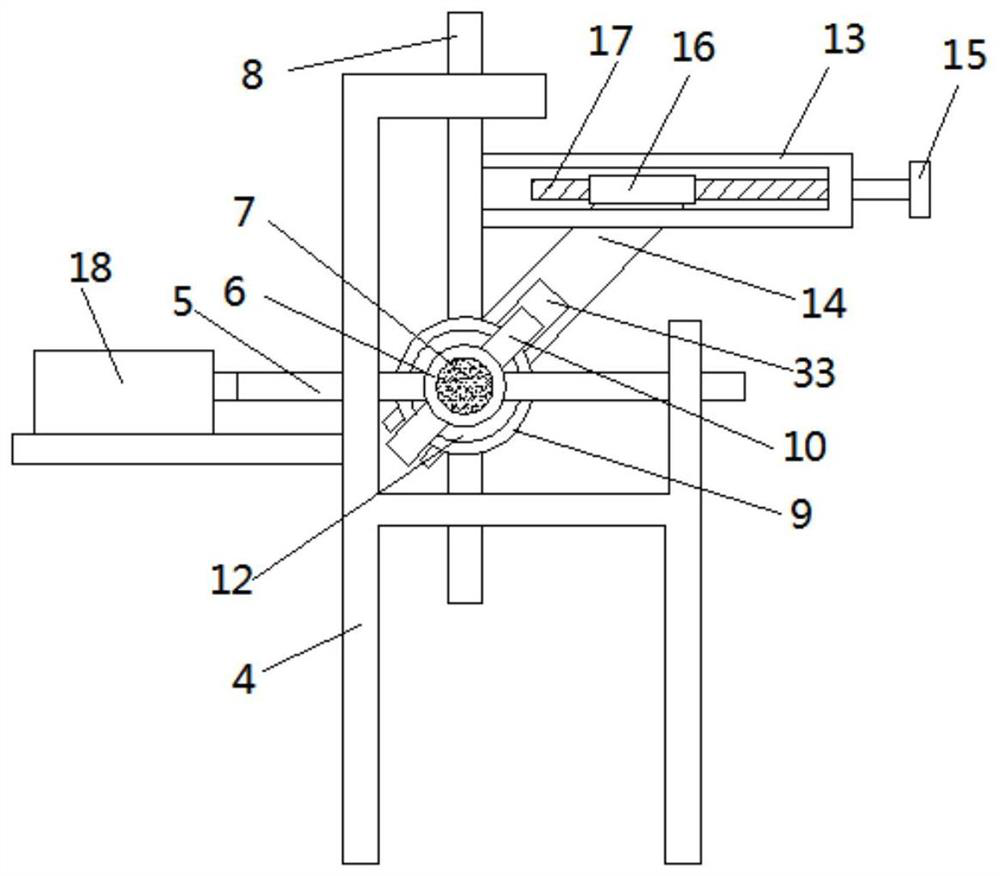

[0029] The vertical adjustment assembly 1 includes an underframe 4, a driving rod 5 installed on the underframe 4 through a sliding bearing and parallel to the X-axis, a first fixed plate 6 installed on the driving rod 5, and rotatably installed on the first fixed plate through a rolling bearing. On the disk 6, the driving disk 7 with the driving groove 34 on the surface is installed on the bottom frame 4 and the transmission rod 8 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com