A method for spinning combed noil by rotor spinning

A rotor and cotton yarn technology, applied in the field of spinning, can solve the problems of undiscovered records of pure cotton combed noil yarns, low yarn strength, and high end breakage rate, so as to reduce end breakage, enhance twisting efficiency, The effect of enhancing strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for spinning combed noil by rotor spinning. The combed noil is spun through a spinning process, and the spinning process includes the following steps: raw material selection process, cotton opening and cleaning process, carding process, drawing frame process and rotor spinning process;

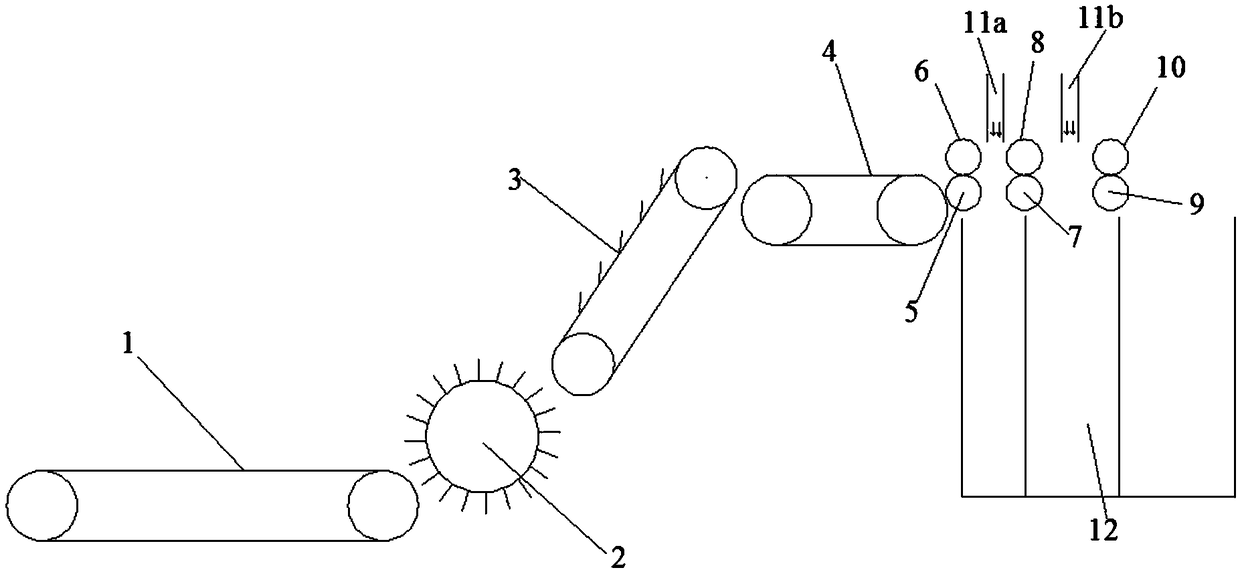

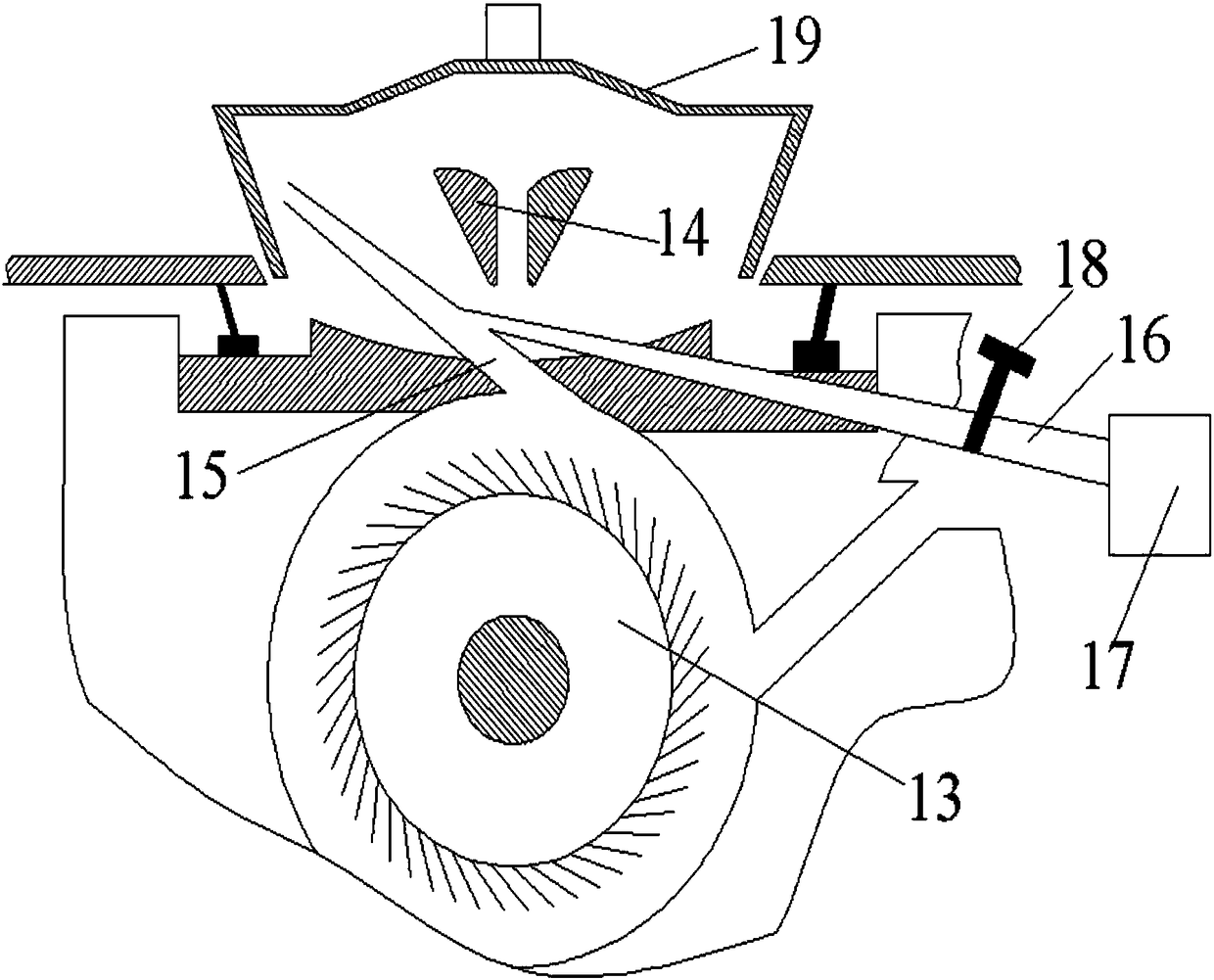

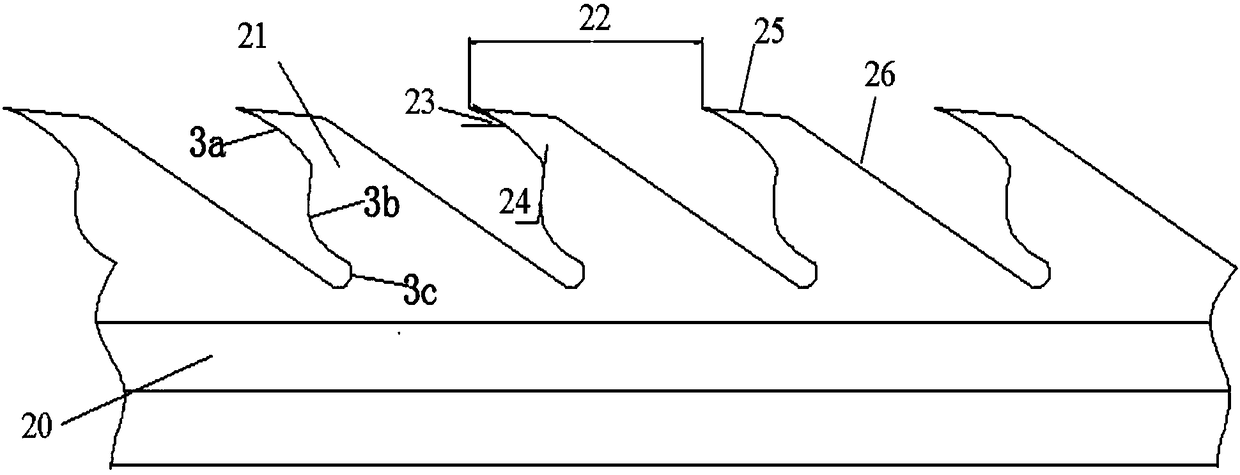

[0040] The raw material selection device used in the raw material matching process is as follows: figure 1 As shown, the raw material selection device is mainly composed of cotton feeding curtain 1, beater 2, horn nail curtain 3, cotton equalizing curtain 4, rear roller 5, middle roller 7, front roller 9 and collecting device 12 arranged in sequence along the raw material conveying direction The top of the back roller 5, the middle roller 7 and the front roller 9 are closely attached to the rear top roller 6, the middle top roller 8 and the front top roller 10 respectively, and a blowing pipe Ⅰ11a is installed between the rear top roller 6 and the middle top roller 8 , between...

Embodiment 2

[0051] A method for spinning combed noil by rotor spinning. The combed noil is spun through a spinning process, and the spinning process includes the following steps: raw material selection process, cotton opening and cleaning process, carding process, drawing frame process and rotor spinning process;

[0052] The raw material selection device used in the raw material matching process, the raw material selection device is mainly composed of cotton feeding curtain 1, beater 2, horn nail curtain 3, cotton uniform curtain 4, rear roller 5, middle roller 7, The front roller 9 and the collection device 12 are composed; the rear roller 5, the middle roller 7 and the top of the front roller 9 are respectively tightly attached to the rear top roller 6, the middle top roller 8 and the front top roller 10, and the rear top roller 6 and the middle top roller Blow pipe Ⅰ11a is installed between 8, blow pipe Ⅱ11b is installed between middle top roller 8 and front top roller 10, the center ...

Embodiment 3

[0063] A method for spinning combed noil by rotor spinning. The combed noil is spun through a spinning process, and the spinning process includes the following steps: raw material selection process, cotton opening and cleaning process, carding process, drawing frame process and rotor spinning process;

[0064] The raw material selection device used in the raw material matching process, the raw material selection device is mainly composed of cotton feeding curtain 1, beater 2, horn nail curtain 3, cotton uniform curtain 4, rear roller 5, middle roller 7, The front roller 9 and the collection device 12 are composed; the rear roller 5, the middle roller 7 and the top of the front roller 9 are respectively tightly attached to the rear top roller 6, the middle top roller 8 and the front top roller 10, and the rear top roller 6 and the middle top roller Blow pipe Ⅰ11a is installed between 8, blow pipe Ⅱ11b is installed between middle top roller 8 and front top roller 10, the center ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com