Production device and process of rotor-spun filament as well as short-fiber core-spun yarn and covered yarn

A production device and staple fiber technology, which is applied in the field of spinning, can solve the problems of yarn breakage, end breakage, and the small adjustable range of filament tension, and achieve the effects of high efficiency, reduced end breakage, and strong three-dimensional effect of yarn color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

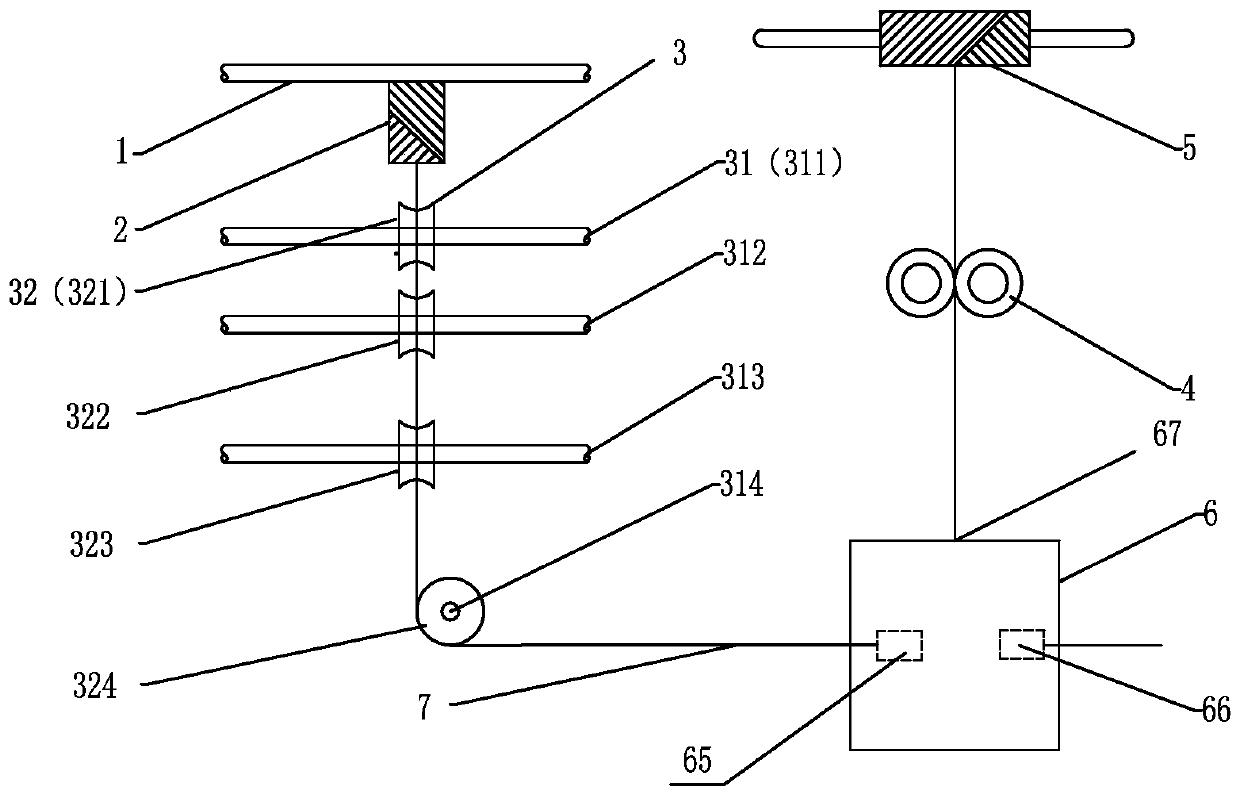

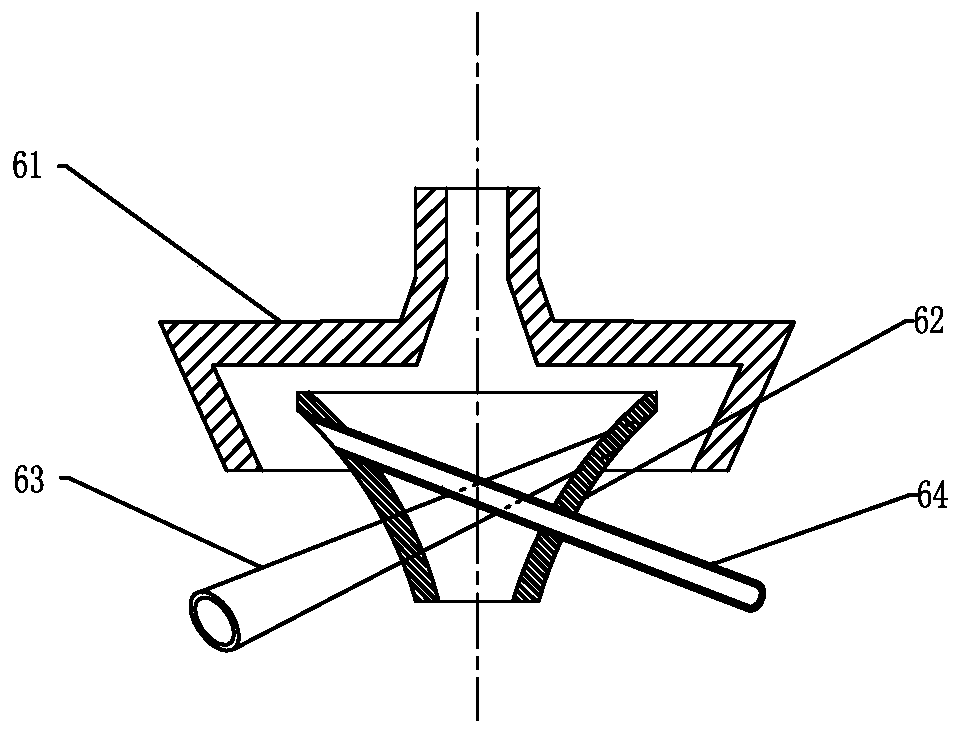

[0029] Such as Figure 1-2 As shown, the rotor spinning filament and short fiber core-spun yarn and covered yarn production device includes a filament frame 1, a filament tube 2, a yarn guide device 3, a yarn drawing roller 4, a yarn tube 5 and a yarn forming device 6 ; The filament frame 1 is provided with a filament tube 2, a filament guide device 3 below the filament frame 1, and the guide device 3 is connected with the yarn forming device 6, and the yarn forming device 6 top is successively provided with a yarn guiding roller 4 and a yarn tube 5. Both the filament frame 1 and the guide wire device 3 are fixedly connected to the vehicle body through a bracket, and the yarn forming device 6 is located on the vehicle body;

[0030] The wire guide device 3 includes several groups of wire guide rods 31 and wire guides 32; the wire guide 32 is arranged on the wire guide rods 31; the long filament 7 on the filament tube 2 enters into a yarn through the wire guide 32 device 6.

...

Embodiment 2

[0041] The production process of rotor spinning filament and short fiber core-spun yarn and covered yarn includes the following steps:

[0042] (1) The uncolored cotton fiber sliver enters the carding roller through the cotton feeding roller; the carded fiber sliver enters the rotor 61 through the fiber conveying channel, and is combined and condensed into a fiber strand, and the weight of the fiber strand is 18g / 10m;

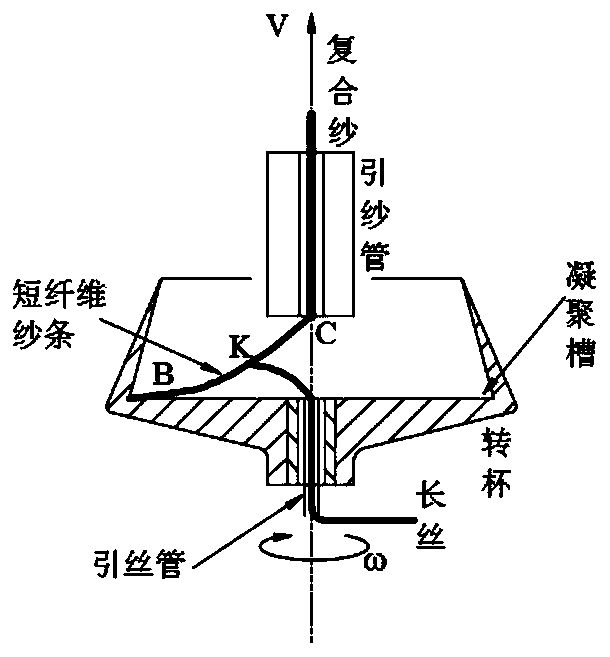

[0043] (2) The red 70D polyester filament is introduced into the rotor 61 by the yarn guide 32, and the feeding speed of the filament 7 is 85.7m / min;

[0044] (3) Natural-colored cotton fiber and red 70D polyester filament are synthesized and compounded into yarn, which is drawn out by yarn-drawing roller 4 through false twister and yarn-drawing tube to obtain 21S+70D red and white pink covered yarn, and the yarn-drawing speed is 85.7 m / min.

Embodiment 3

[0046] The production process of rotor spinning filament and short fiber core-spun yarn and covered yarn includes the following steps:

[0047] (1) The red cotton fiber sliver enters the carding roller through the cotton feeding roller; the carded fiber sliver enters the rotor cup through the fiber conveying channel, and is condensed into fiber strands, and the weight of the fiber sliver is 21g / 10m;

[0048] (2) The black 70D polyester filament is introduced into the rotor 61 by the yarn guide 32, and the feeding speed of the filament 7 is 53.9m / min;

[0049] (3) Red cotton fiber and black 70D polyester filament are synthesized and compounded into yarn, which is drawn out by yarn delivery roller 4 through false twister and yarn delivery tube to obtain 13S+70D red and black covered yarn, and the yarn delivery speed is 47m / min. Because the feeding speed of the black filament is greater than the yarn drawing speed, the black filament is tightly wrapped on the outside of the red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com