Patents

Literature

44results about How to "Adjust the mixing ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

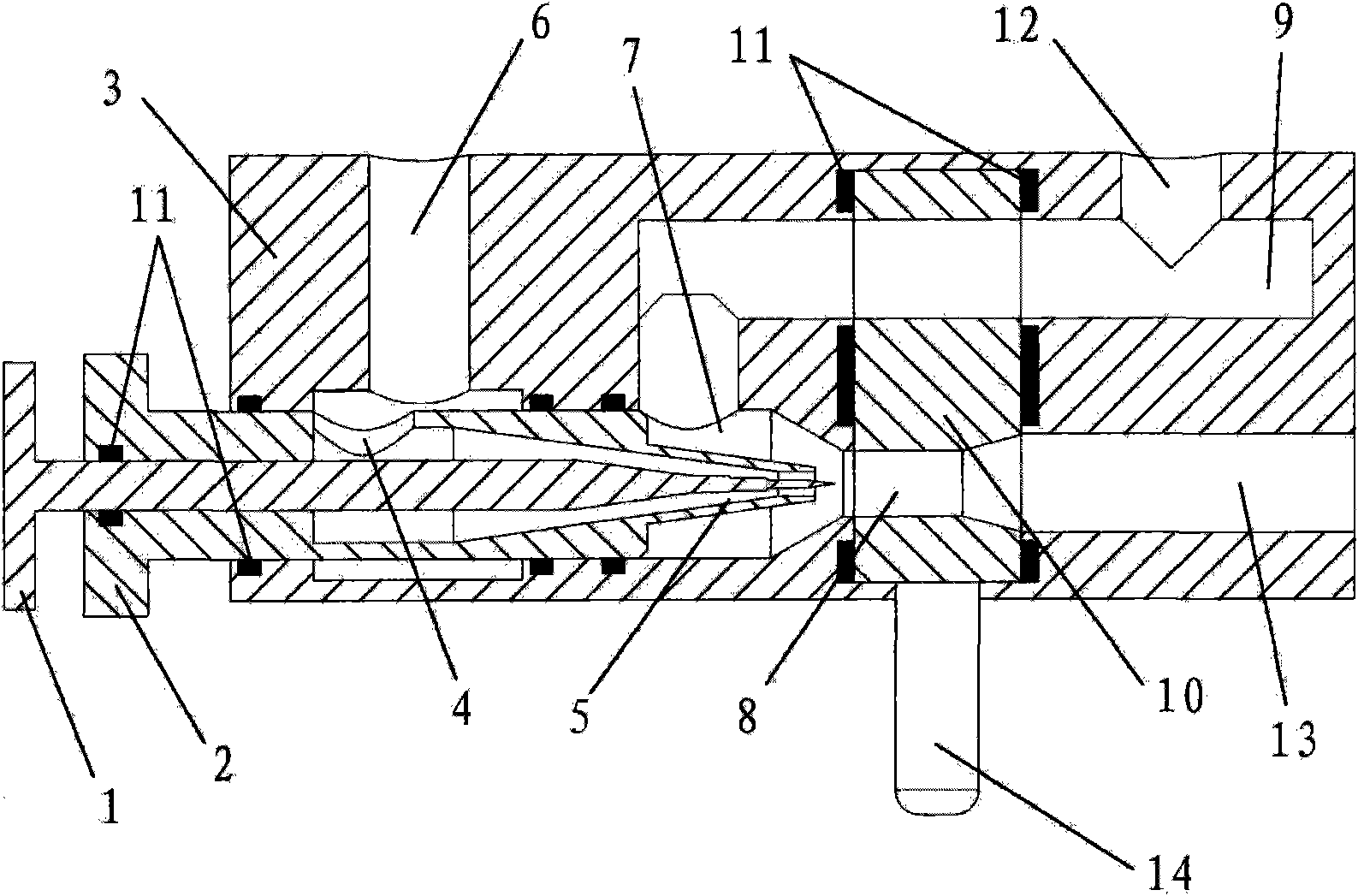

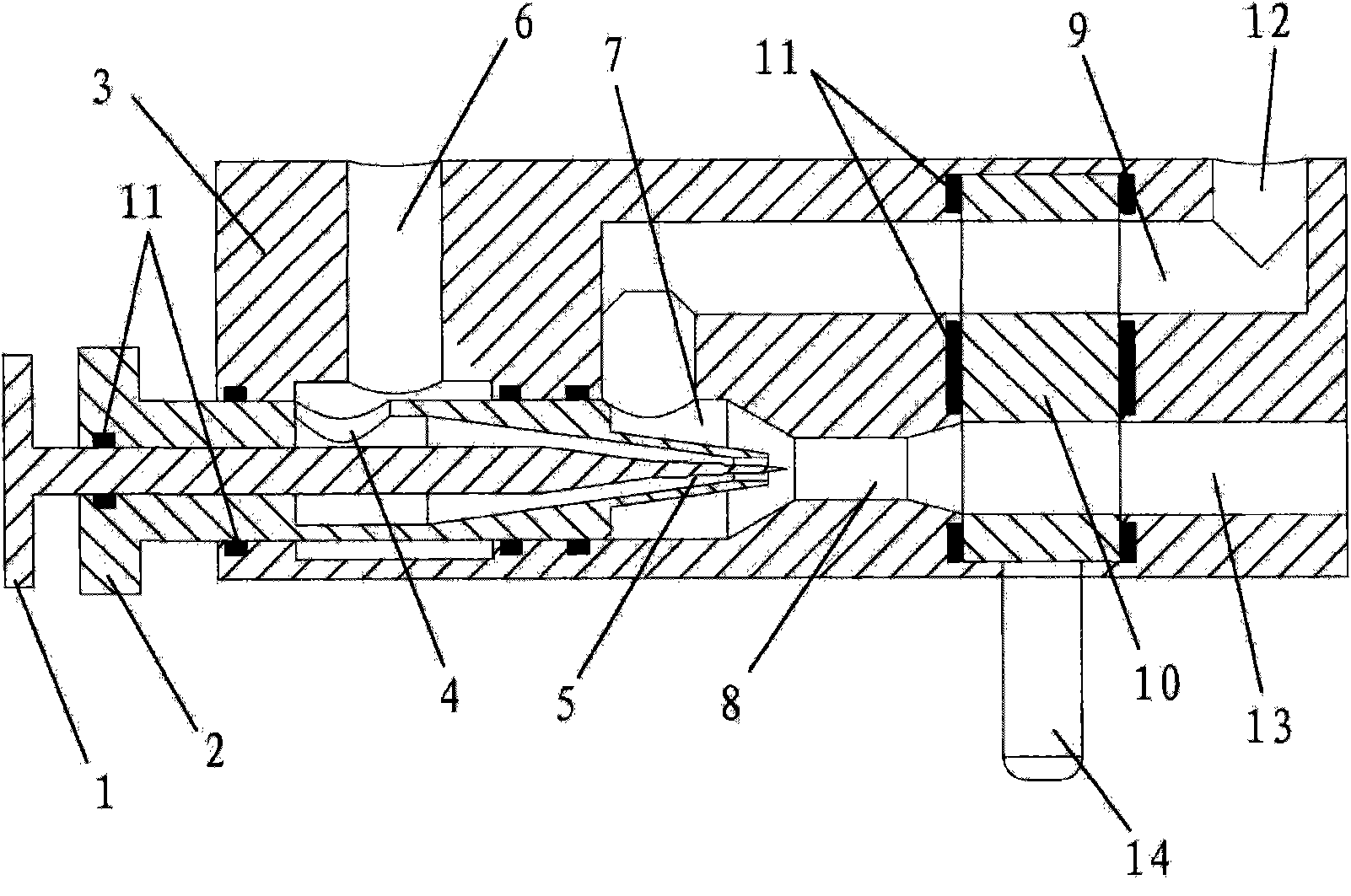

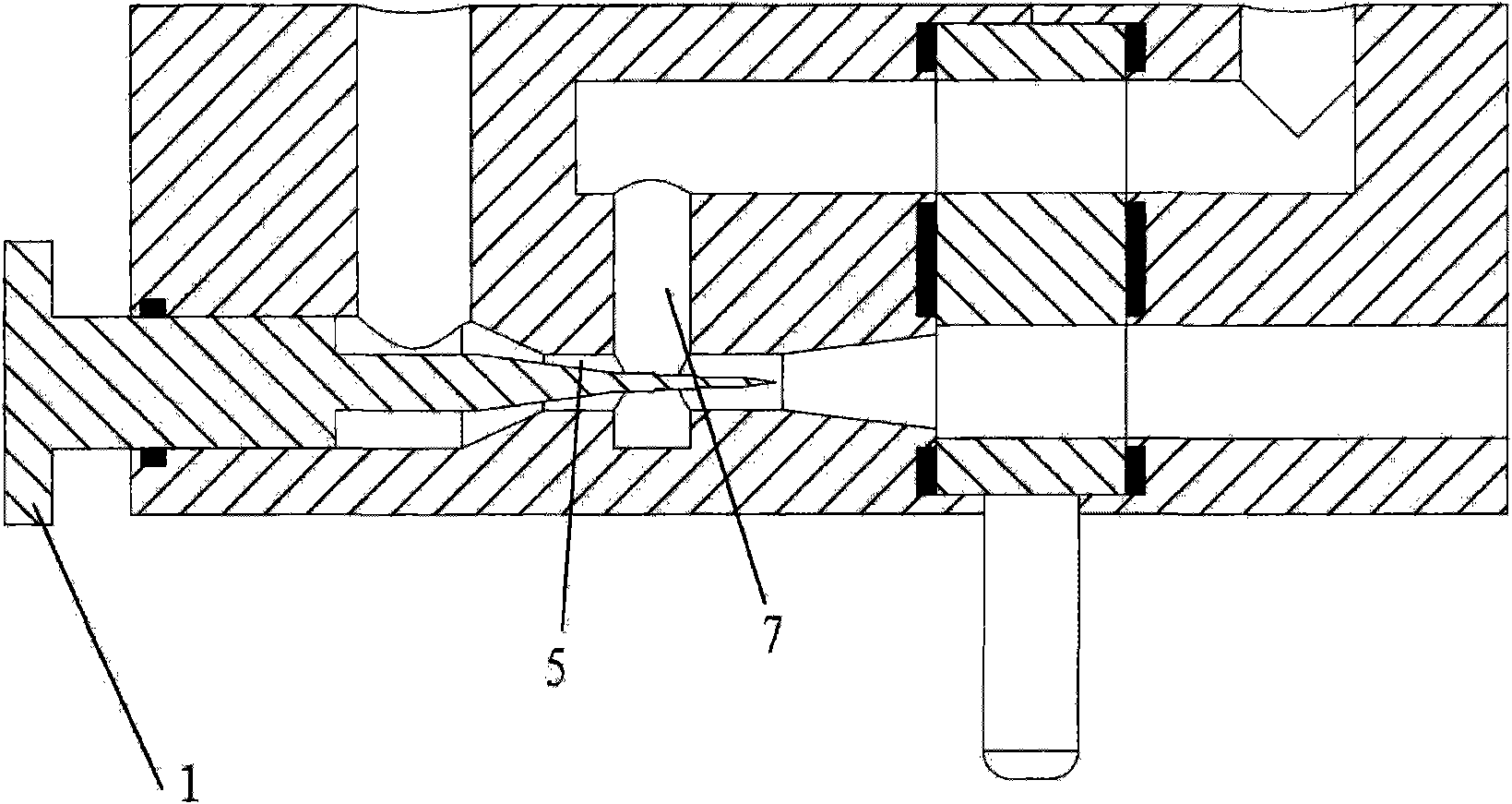

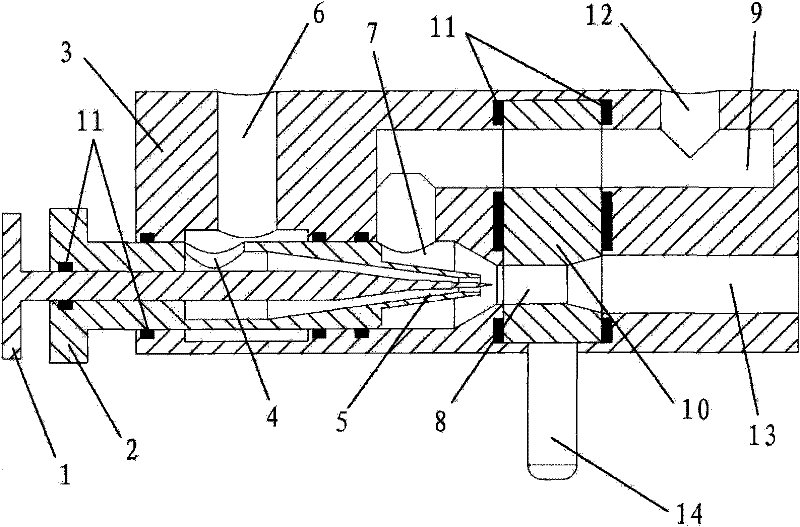

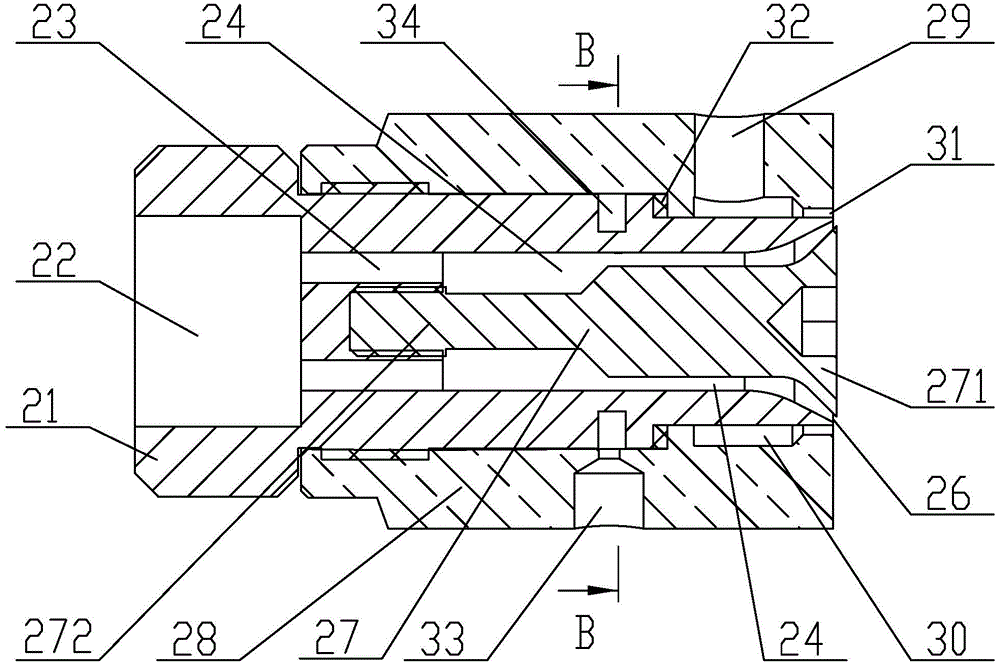

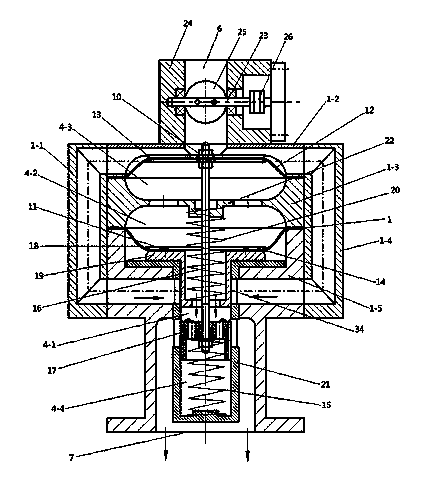

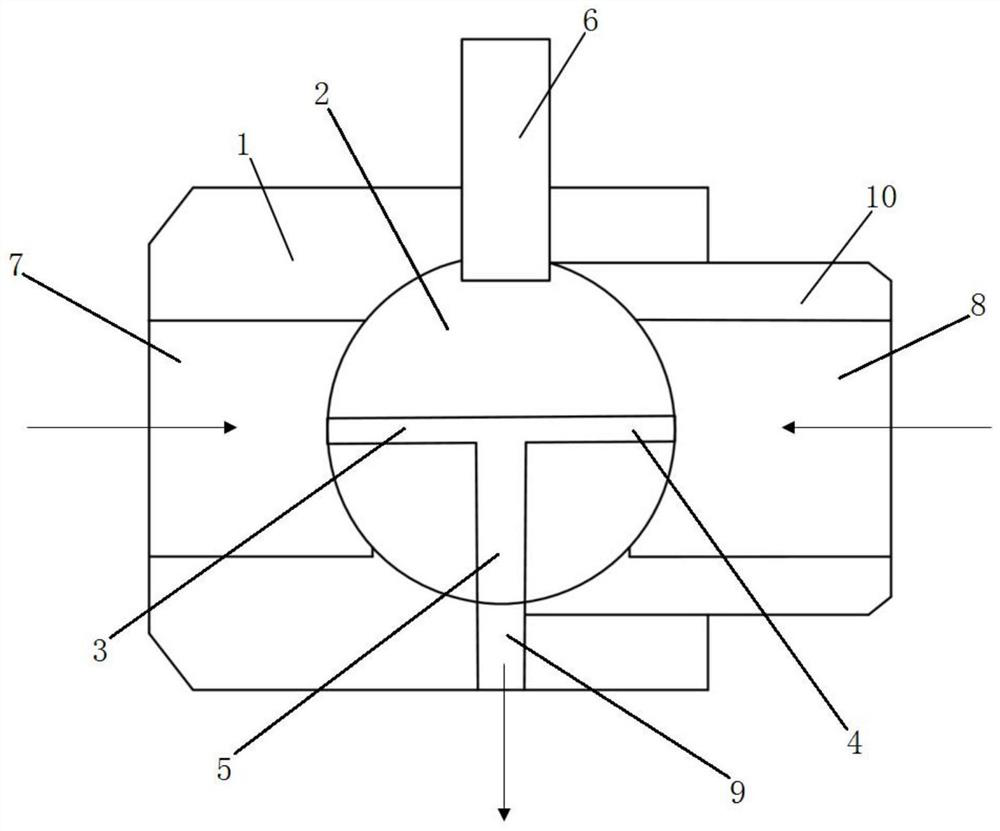

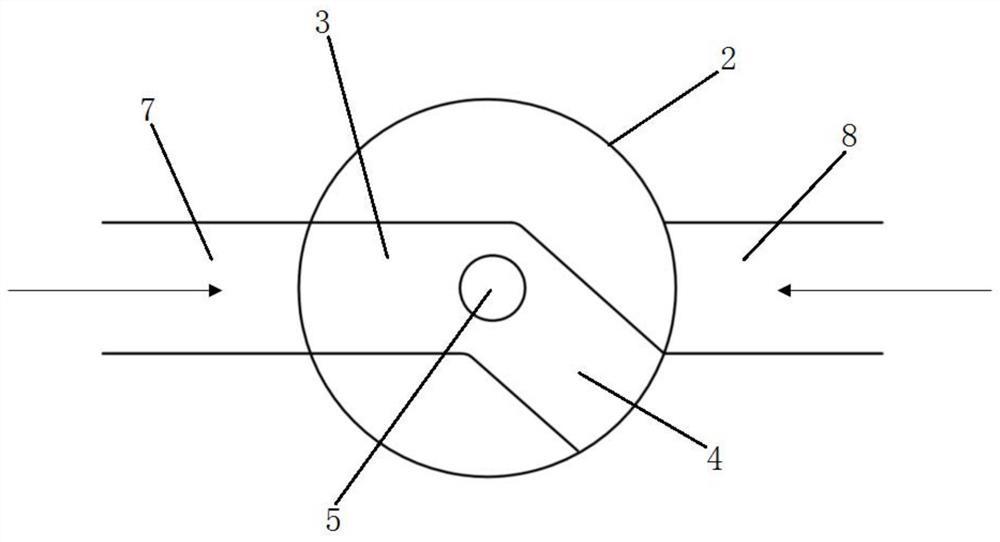

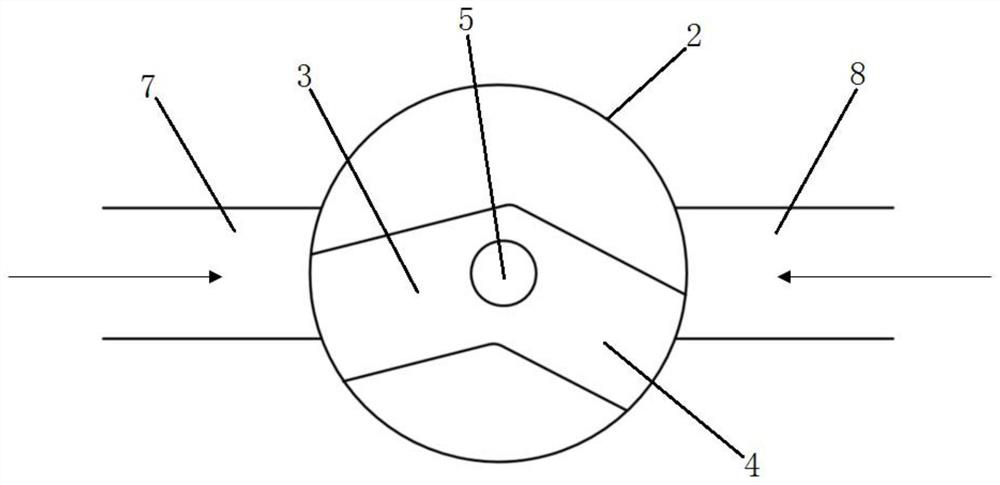

Water mixing valve

ActiveCN102086941AImprove the water effectMixed water comfortOperating means/releasing devices for valvesMultiple way valvesWater dischargeThermal water

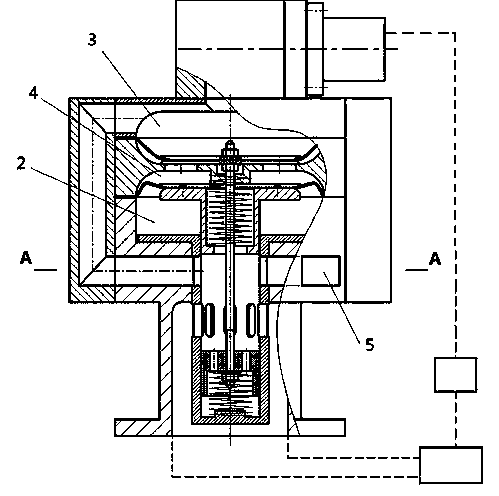

The invention relates to a water mixing valve comprising a valve body, a nozzle, a hot water regulating cavity, a water mixing cavity and a double-linkage valve, wherein the valve body is provided with a valve body cooling water inlet, a valve body hot water inlet and a valve body water outlet; the nozzle is communicated with the valve body cooling water inlet and provided with a nozzle cooling water inlet and a nozzle cooling water outlet; the valve body is internally provided with the hot water regulating cavity connected with the valve body hot water inlet and the water mixing cavity connected with the valve body water outlet; the water mixing cavity is connected with the hot water regulating cavity through a valve body hot water outlet positioned on one end of the hot water regulating cavity and is also connected with the nozzle through the nozzle cooling water outlet; and the double-linkage valve is arranged above the hot water regulating cavity and the water mixing cavity and used for controlling the water discharge of the hot water regulating cavity and the water mixing cavity. The water mixing valve can be used for more flexibly regulating the water mixing proportion of cold and hot water so as to ensure that the water mixing and discharging effects of the valve is better.

Owner:BEIJING TUS CLEAN ENERGY TECH CO LTD +1

Water mixing valve

ActiveCN102086941BImprove the water effectMixed water comfortOperating means/releasing devices for valvesMultiple way valvesWater dischargeEngineering

The invention relates to a water mixing valve comprising a valve body, a nozzle, a hot water regulating cavity, a water mixing cavity and a double-linkage valve, wherein the valve body is provided with a valve body cooling water inlet, a valve body hot water inlet and a valve body water outlet; the nozzle is communicated with the valve body cooling water inlet and provided with a nozzle cooling water inlet and a nozzle cooling water outlet; the valve body is internally provided with the hot water regulating cavity connected with the valve body hot water inlet and the water mixing cavity connected with the valve body water outlet; the water mixing cavity is connected with the hot water regulating cavity through a valve body hot water outlet positioned on one end of the hot water regulatingcavity and is also connected with the nozzle through the nozzle cooling water outlet; and the double-linkage valve is arranged above the hot water regulating cavity and the water mixing cavity and used for controlling the water discharge of the hot water regulating cavity and the water mixing cavity. The water mixing valve can be used for more flexibly regulating the water mixing proportion of cold and hot water so as to ensure that the water mixing and discharging effects of the valve is better.

Owner:BEIJING TUS CLEAN ENERGY TECH CO LTD +1

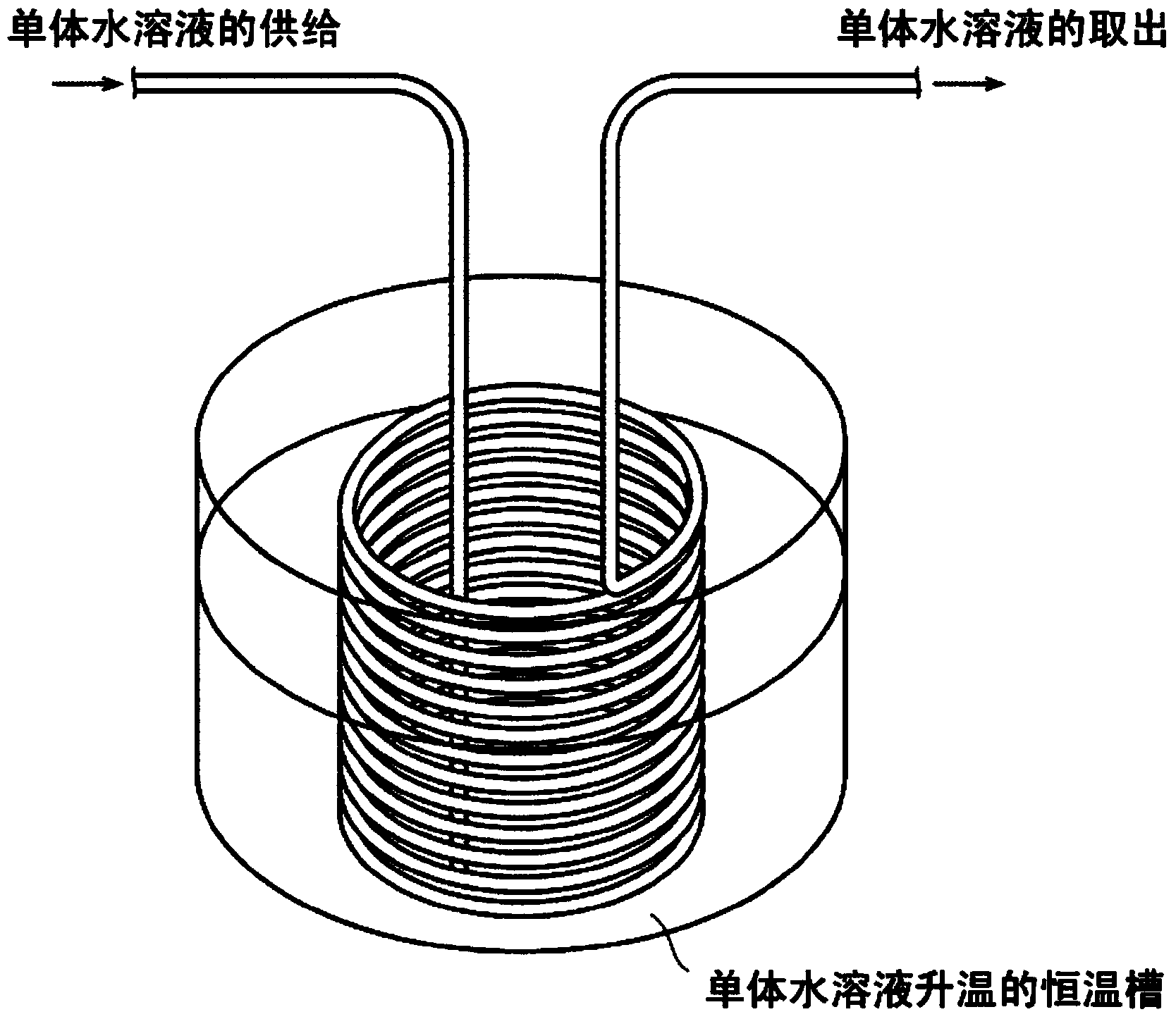

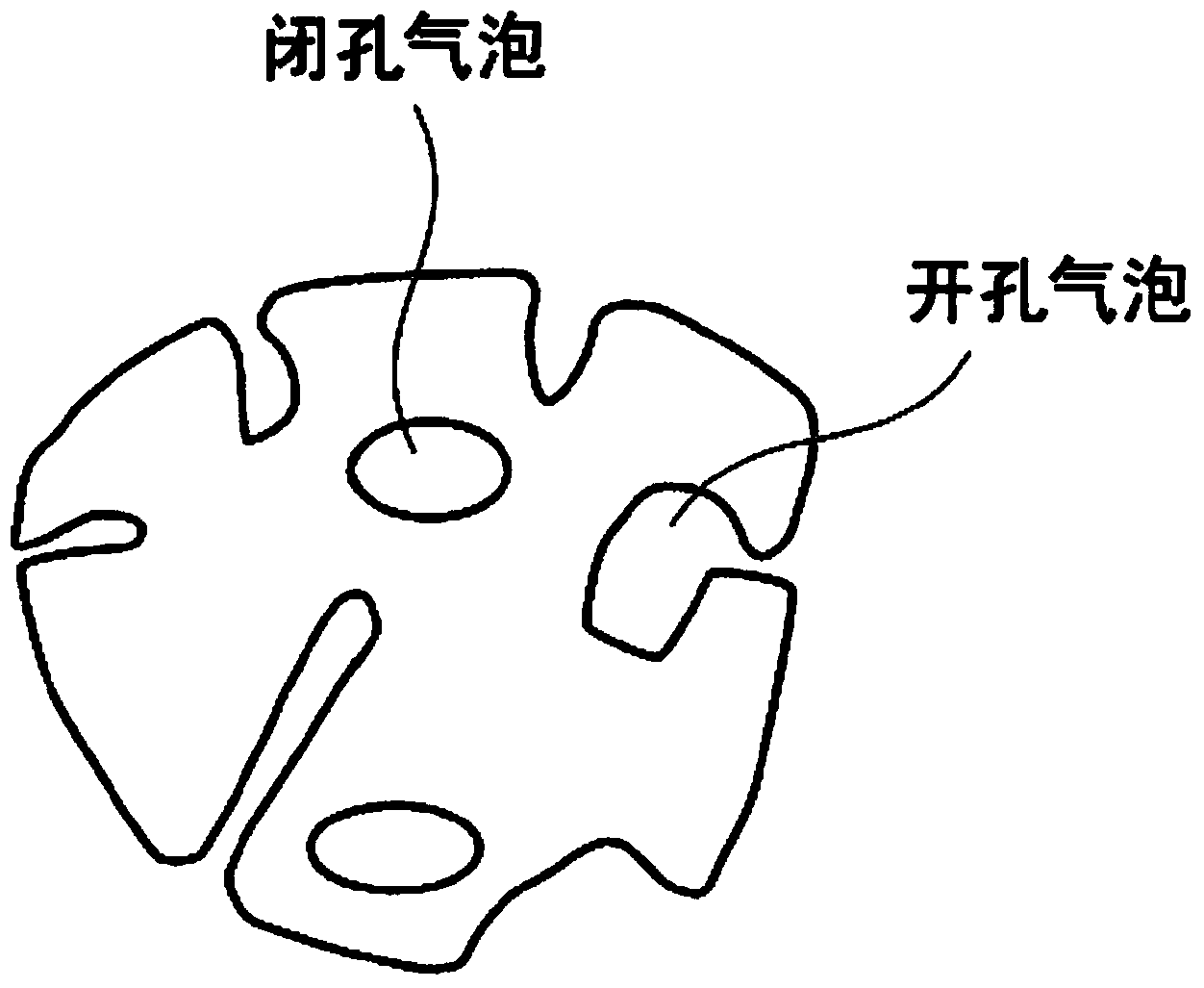

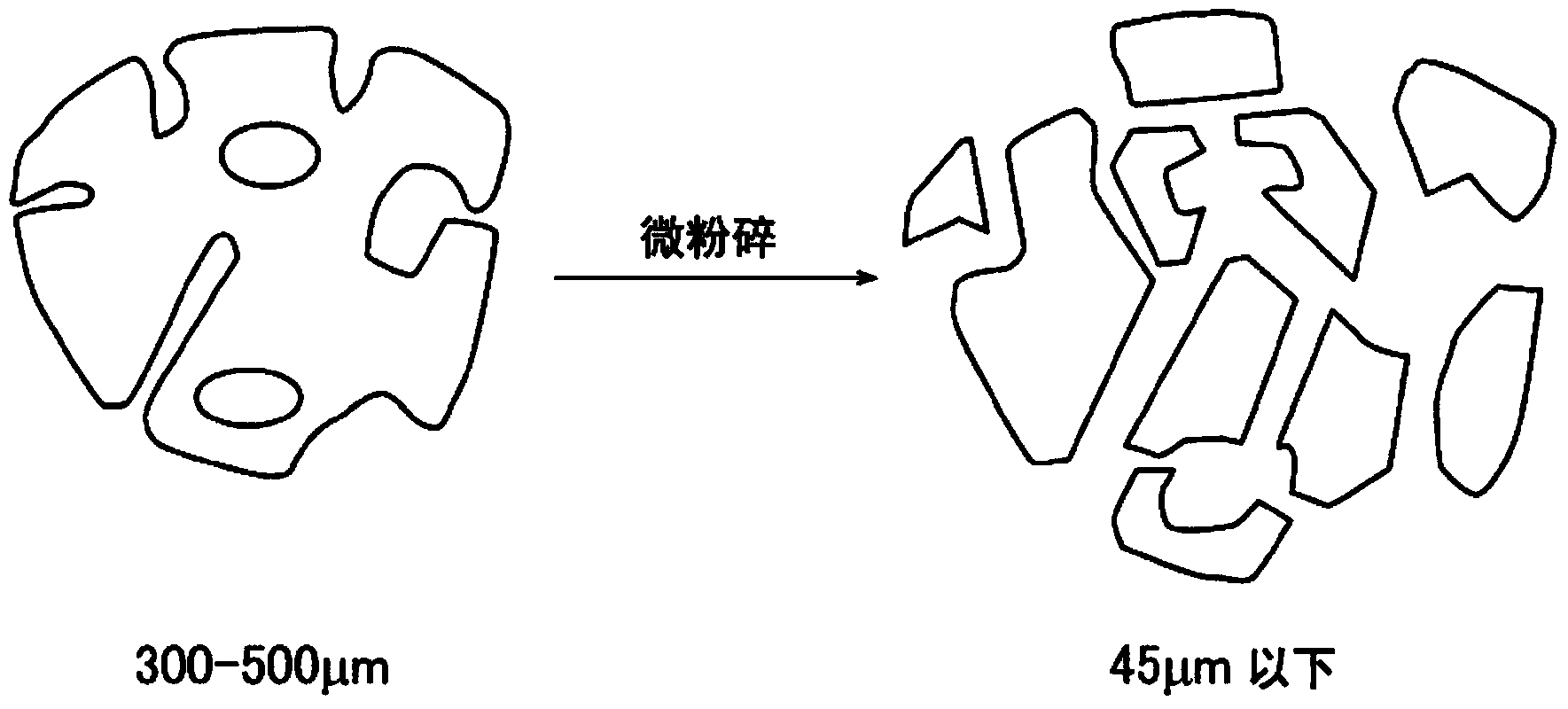

Manufacturing method for polyacrylic acid (salt) -based water-absorbent resin powder

Owner:NIPPON SHOKUBAI CO LTD

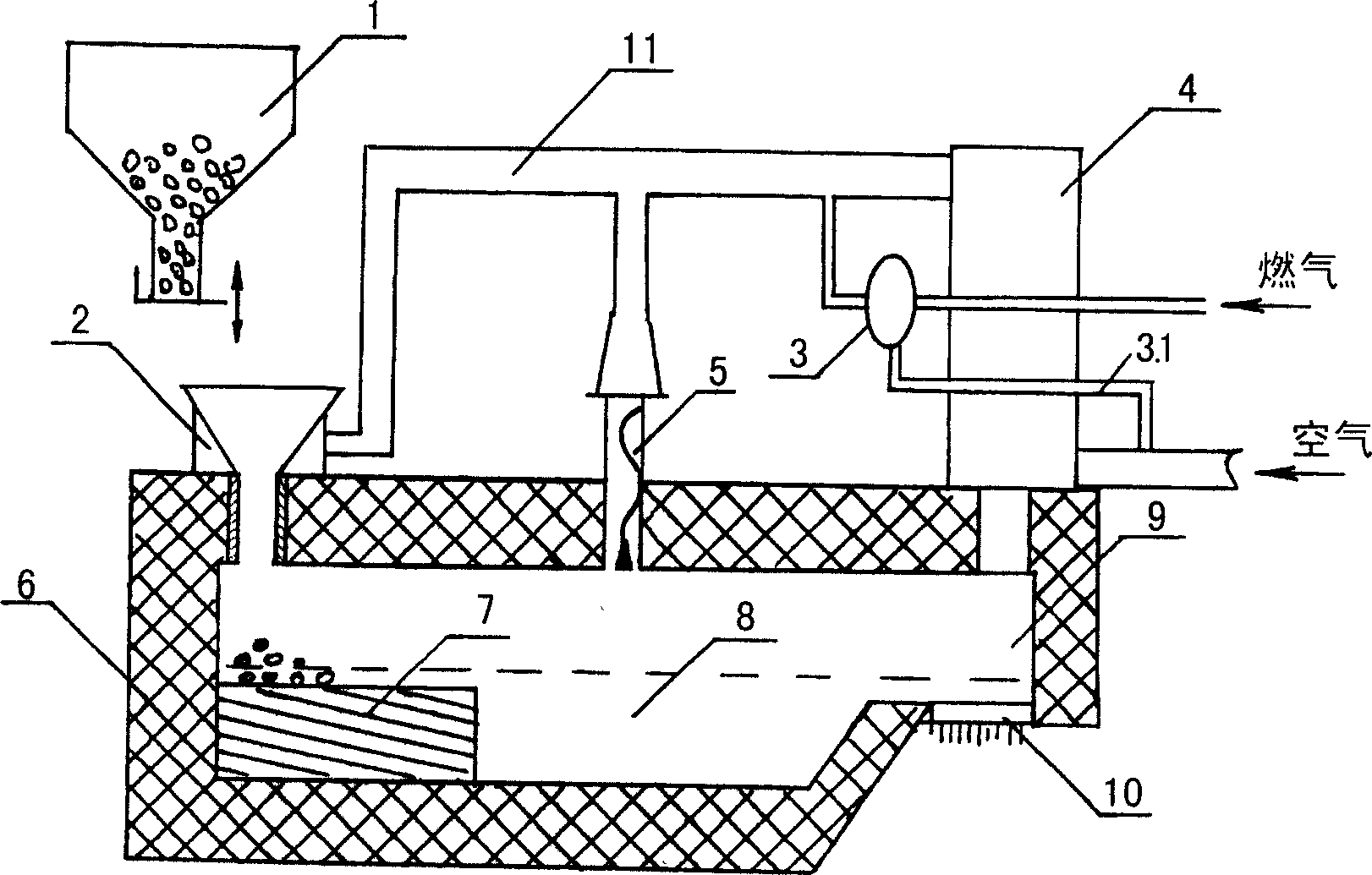

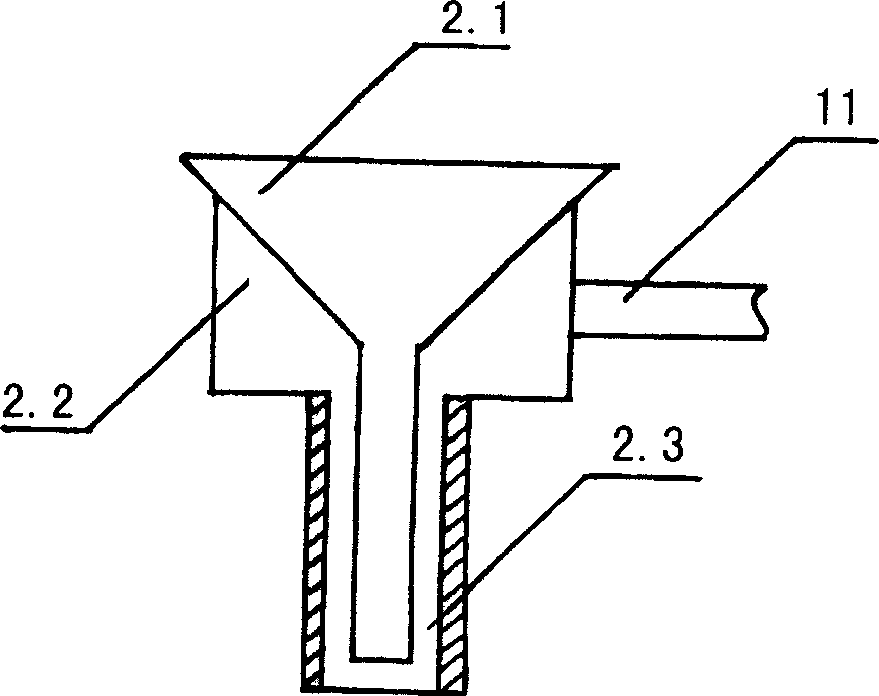

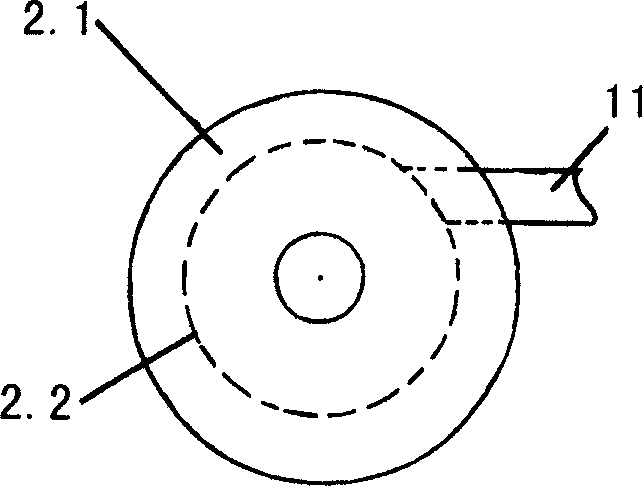

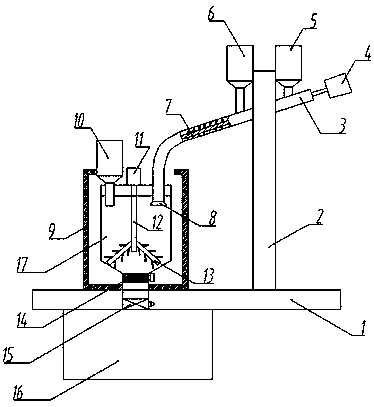

Ore melting and moltenmass modulating method and equipment for continuous basalt fiber production

InactiveCN1814561ALower levelImprove burner structureGlass making apparatusBasalt fiberMelt temperature

The invention relates to ore melting and molten mass adjusting method in continuously basalt fiber producing process. It completes the milting process under the condition of low molten mass level height in melting technology process of localized heating in melting furnace. The invention could effectively melt ore, equalize the mass, and remove air bubble. And it increases the melt temperature of ore to achieve the effect of increasing kinds of fiber and improving quality.

Owner:玄武岩纤维复合材料科技发展有限公司

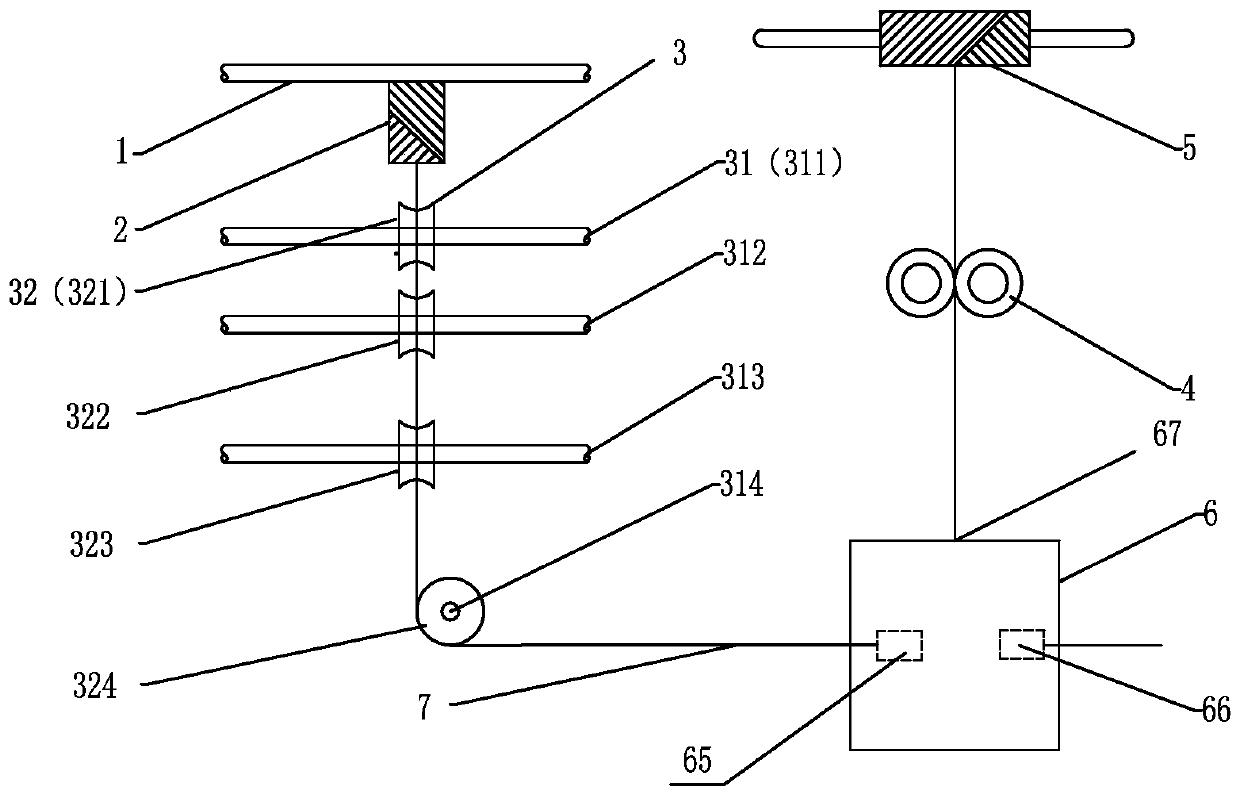

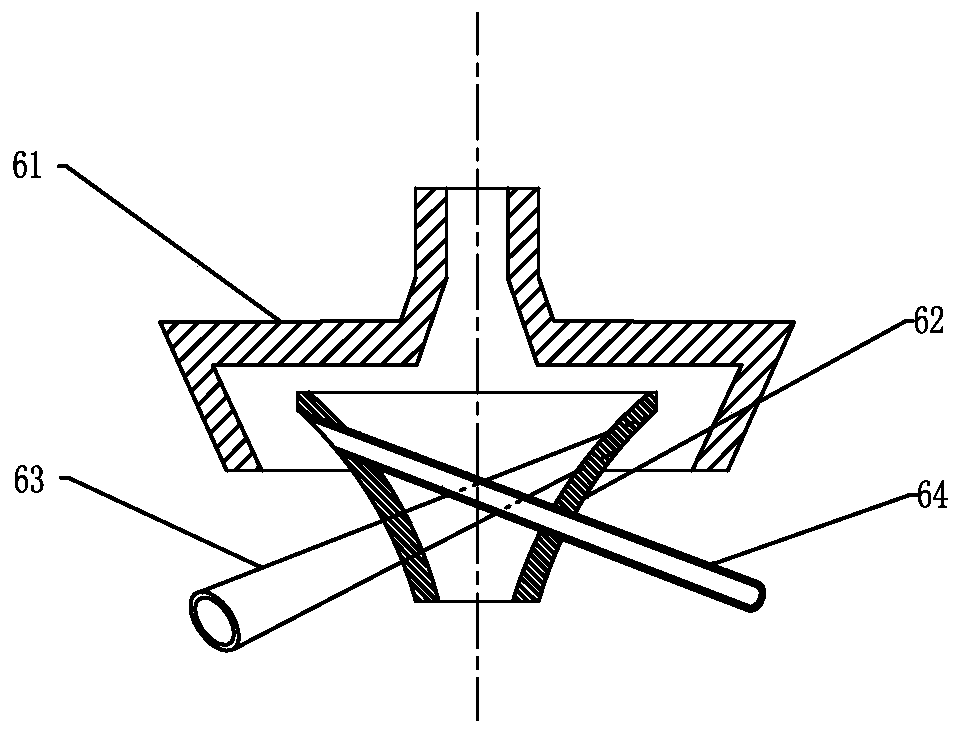

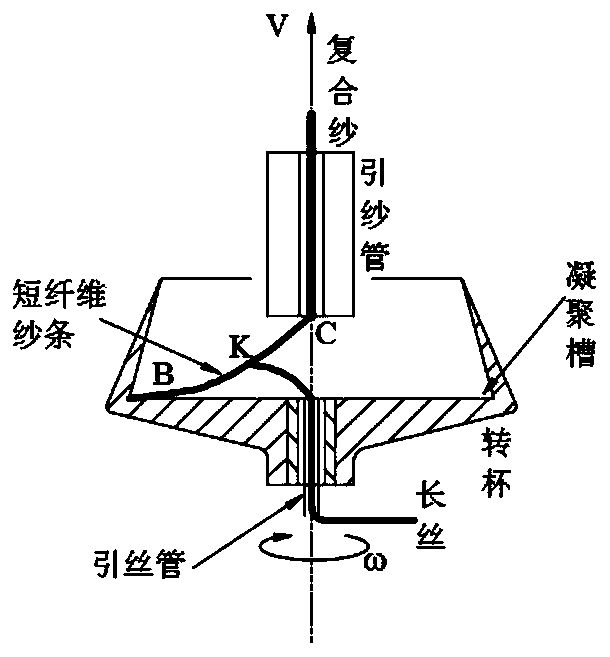

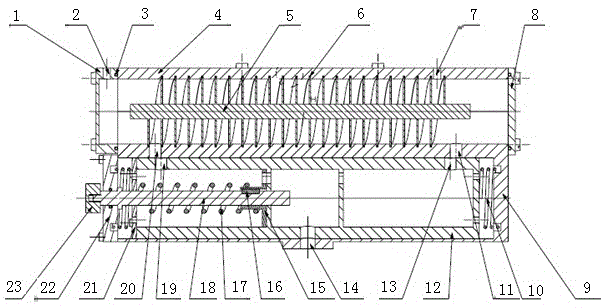

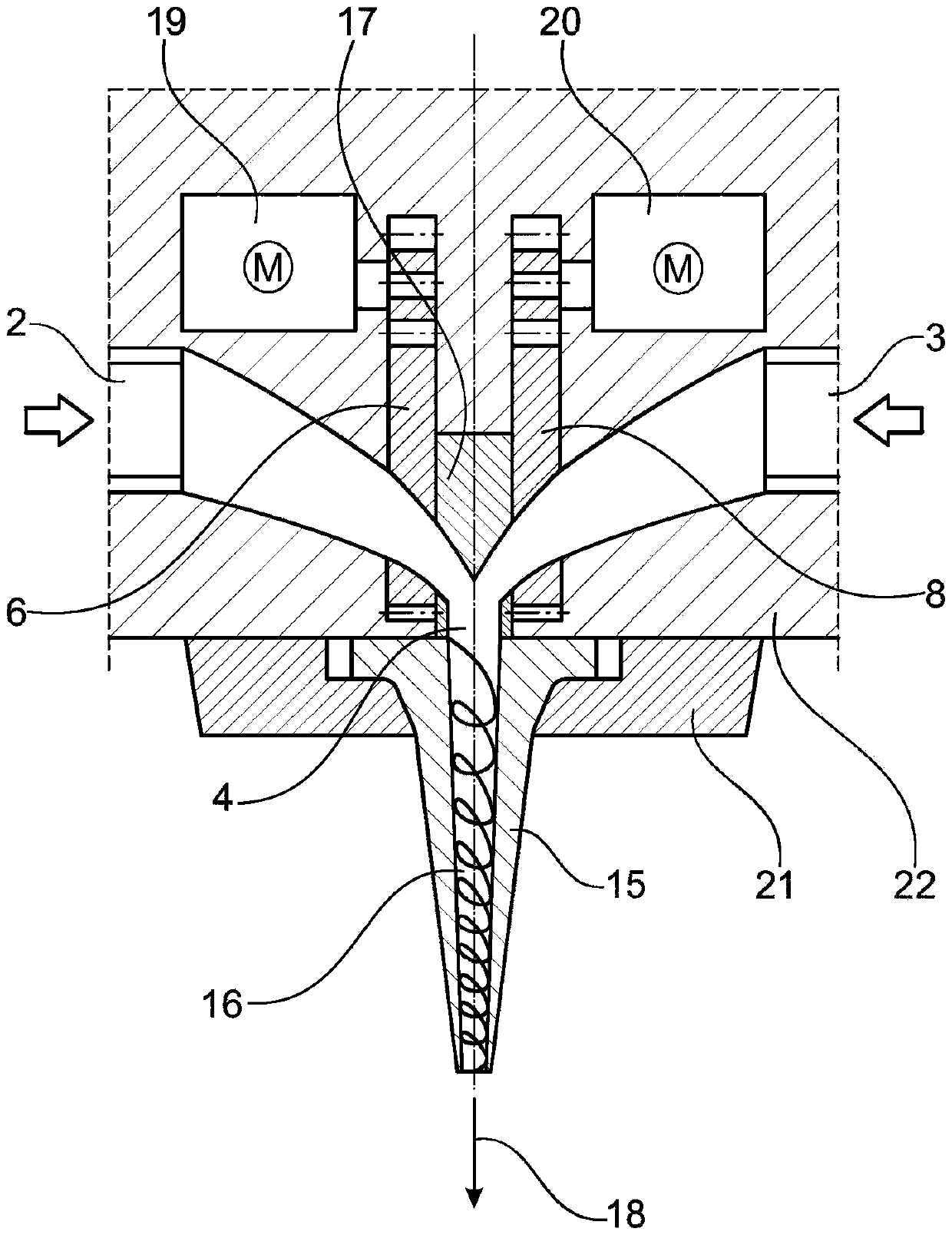

Production device and process of rotor-spun filament as well as short-fiber core-spun yarn and covered yarn

PendingCN110144660AReduce broken endsImprove efficiencyContinuous wound-up machinesOpen-end spinning machinesEngineeringFilament yarn

The invention relates to a production device and process of a rotor-spun filament as well as a short-fiber core-spun yarn and a covered yarn, and belongs to the technical field of spinning. The production device comprises a filament frame, a filament drum, yarn guide rods, yarn guides, filament guides, a yarn forming device, yarn introducing rollers and a spindle, wherein the filament drum is arranged on the filament frame; a plurality of yarn guide rods are arranged below the filament frame; the yarn guides are arranged on the yarn guide rods; the filament frame and the yarn guide rods are fixed above a vehicle body; the filament guides are arranged below the yarn guides; the filament guides are connected with the yarn forming device; the yarn introducing rollers and the spindle are arranged in turn above the yarn forming device. The production device has the advantages of high composite yarn forming efficiency, adjustable tension over a relatively wide range and the like, can producethe core-spun yarn with relatively large tension and the covered yarn with relatively small tension, and can produce the covered yarns with different filament coating effects by controlling the tension of the filaments.

Owner:JIANGNAN UNIV

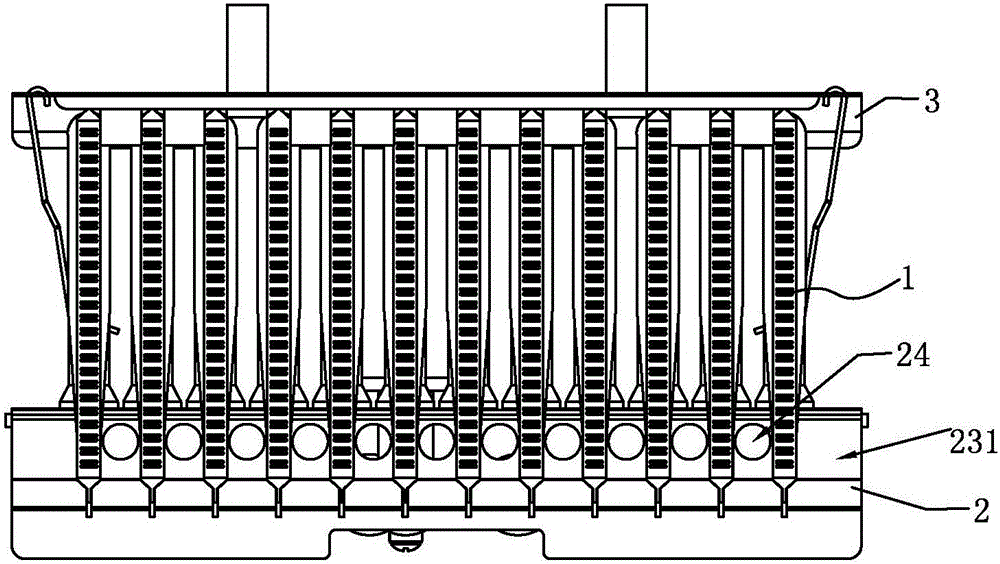

Combustion assembly of gas water heater

InactiveCN105716080ABurn fullyAdjust the mixing ratioFluid heatersGaseous fuel burnerBusiness efficiencyCombustor

The invention discloses a combustion assembly of a gas water heater. The combustion assembly comprises fire gates, a front fire gate bracket, a rear fire gate bracket, spray nozzles and a gas distributing rod, and further comprises two brackets, wherein the plurality of fire gates are arranged by spacing apart a certain distance to form a combustor; gas ports are formed in the front fire gate bracket; the front end of the combustor is arranged on the front fire gate bracket, and the rear end of the combustor is arranged on the rear fire gate bracket; gas inlet ends of ejecting tubes of the fire gates are in butt joint with the gas ports; the front fire gate bracket comprises a perpendicular bracket plate and a horizontal bracket plate; the gas ports are formed in the perpendicular bracket plate; air holes are formed in the horizontal bracket plate; the air holes are spaced with the gas ports; the brackets are arranged at the two ends of the perpendicular bracket plate, and are detachably connected; and the two ends of the gas distributing rod are fixedly connected to the brackets. By adopting the structure, the air holes are formed in the horizontal bracket plate, so that primary air amount and secondary air mount can be guaranteed, and therefore, the gas is combusted sufficiently, and the energy efficiency ratio is increased; besides, the distances between the spray nozzles and the ejecting tubes of the fire gates can be regulated, so that the mixing ratio of the gas and air is regulated, and therefore, the combustion assembly is convenient to use, and is suitable for different specifications.

Owner:GUANGDONG XIANGJI ELECTRICAL APPLIANCE

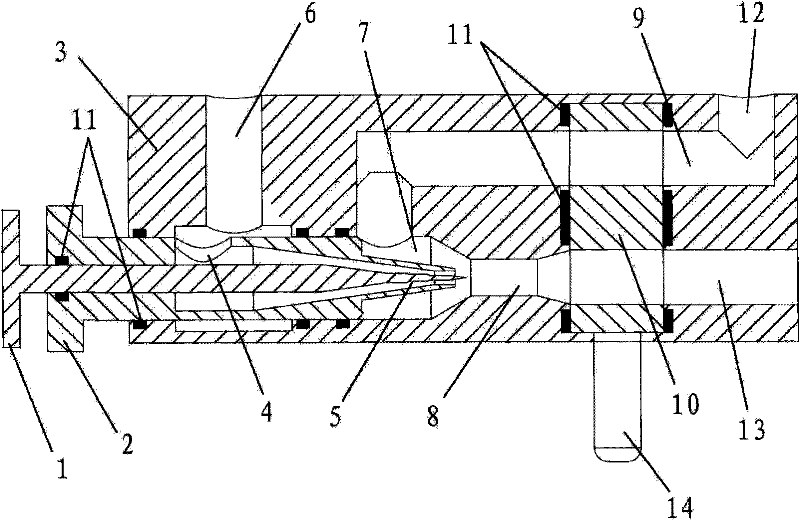

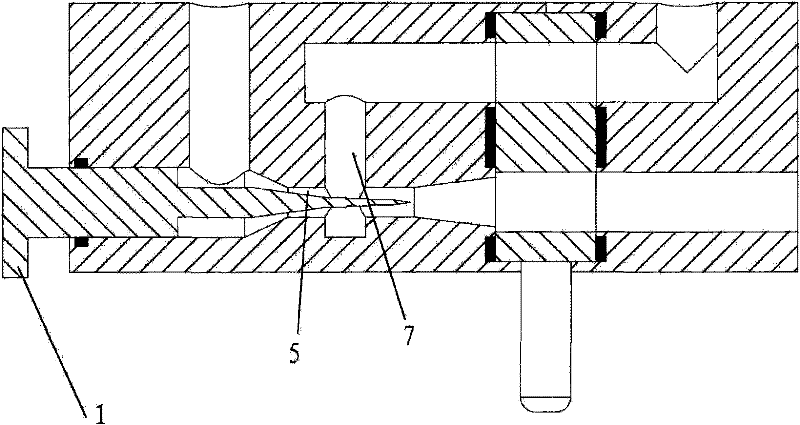

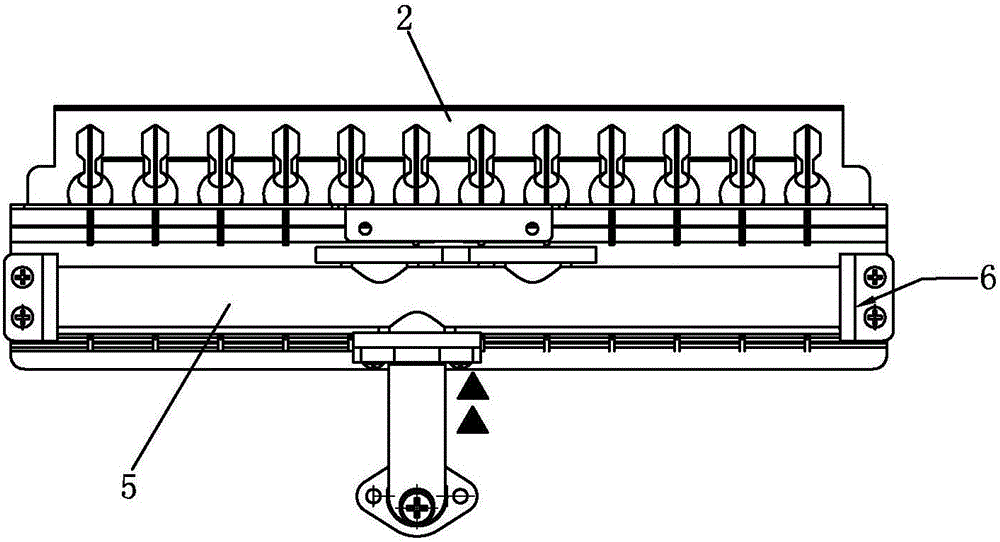

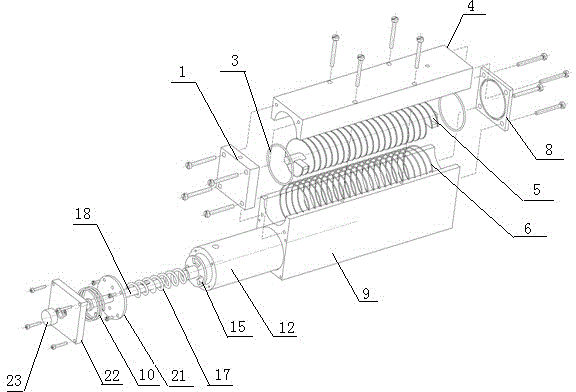

High-speed fuel oil atomizing spray nozzle for thermally spraying fuel gas

ActiveCN104674156AImprove uniformityCompact structureMolten spray coatingLiquid spraying apparatusSpray nozzleFuel oil

The invention discloses a high-speed fuel oil atomizing spray nozzle for a thermally spraying fuel gas. The high-speed fuel oil atomizing spray nozzle comprises a primary cavity, wherein a secondary cavity is assembled on the outer wall of the primary cavity; a gas inlet is formed in the inlet end of the primary cavity, an inner cavity is formed in the outlet end of the primary cavity, a similar cone is mounted in the inner cavity, a ring-shaped primary chamber which is gradually expanded towards the peripheral side in the shape of horn from the inside to the outside is formed between the outer wall of the similar cone and the inner wall of the inner cavity, a ring-shaped primary spray nozzle is formed in an opening in the outlet end of the primary cavity, a gas inlet is communicated with the end part, which is arranged on the inner part of the primary cavity, of the primary cavity through a gas conveying channel, an oil injection hole is formed in the secondary cavity, the oil injection hole is communicated with the middle part of the primary chamber through an oil conveying channel, a ring-shaped secondary chamber for conveying secondary gas flow is formed in the secondary cavity, the secondary chamber is communicated with the outer part through a ring-shaped secondary spray nozzle, the secondary spray nozzle is positioned at the peripheral side of the primary spray nozzle, so that secondary gas flow sprayed out by the secondary spray nozzle and mixed gas flow sprayed out by the primary spray nozzle are crossed at a set included angle and collide. The high-speed fuel oil atomizing spray nozzle is used for atomizing the fuel oil through gas power, so that the gas and the fuel oil are uniformly mixed and atomized, and stably combusted.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

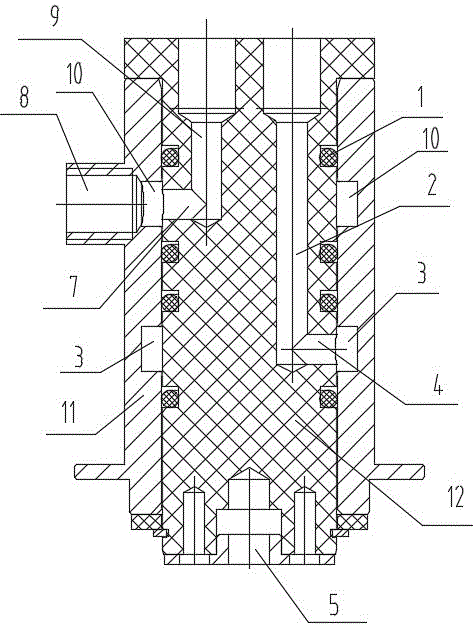

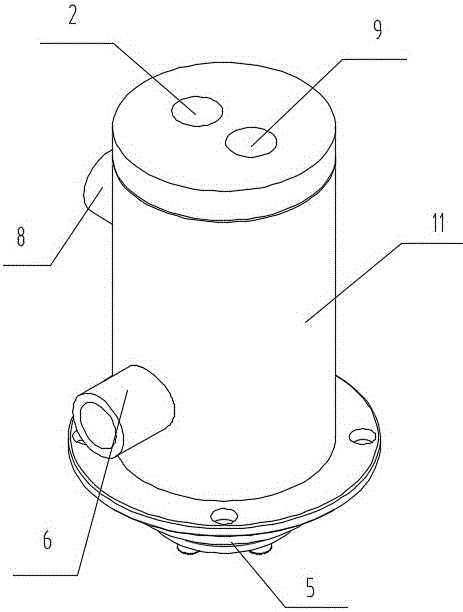

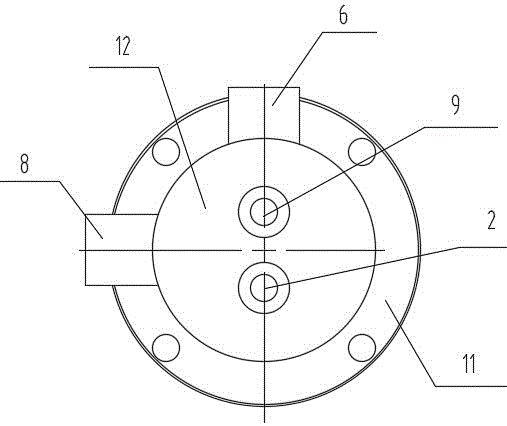

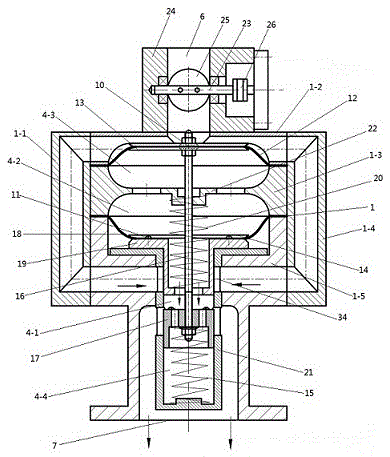

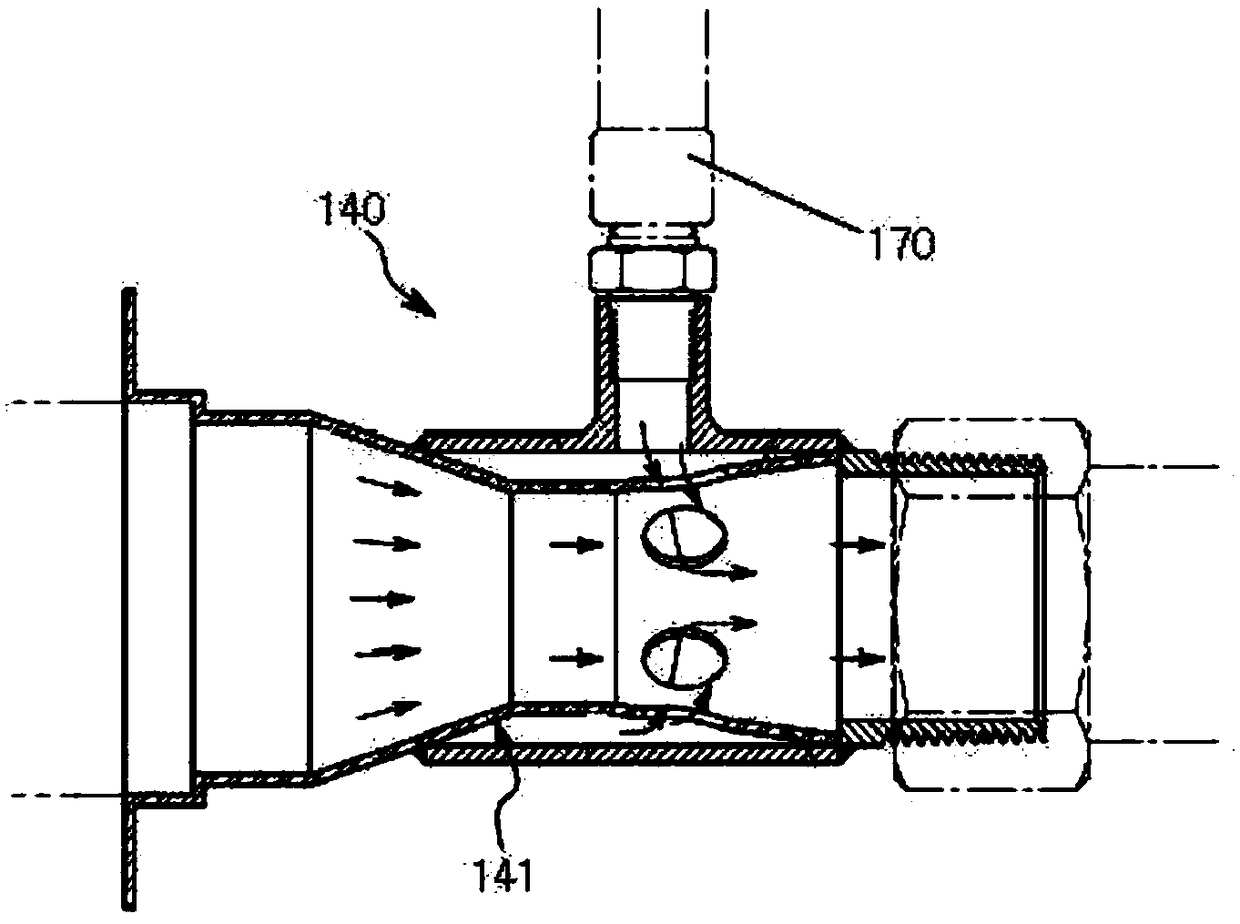

Binary fluid matching and mixing device

ActiveCN103816823AAchieve hybridTo achieve temperature compensationFlow mixersMixer accessoriesBinary fluidDistribution system

The invention provides a binary fluid matching and mixing device. The binary fluid matching and mixing device comprises a valve body, a temperature adjusting device, a mixing device, a pressure adjusting device and a flow adjusting device, wherein the valve body comprises an upper cavity and a lower cavity; the temperature adjusting device is mounted in the upper cavity; the mixing device is positioned inside the lower cavity of the valve body; the pressure adjusting device is mounted between two ends of the mixing device and the lower cavity; the flow adjusting device is used for controlling the gas flow on one side, so as to control the volume ratio of binary gas. The binary fluid matching and mixing device can realize temperature compensation and mixing of fluid, and the ratio and flow are continuously adjusted. The structure is compact, a plurality of flow meters and proportional valves or flow controllers are canceled, the quantity of components is reduced, the structure of a fluid air distribution system is simplified, and the cost is reduced.

Owner:JIANGSU UNIV

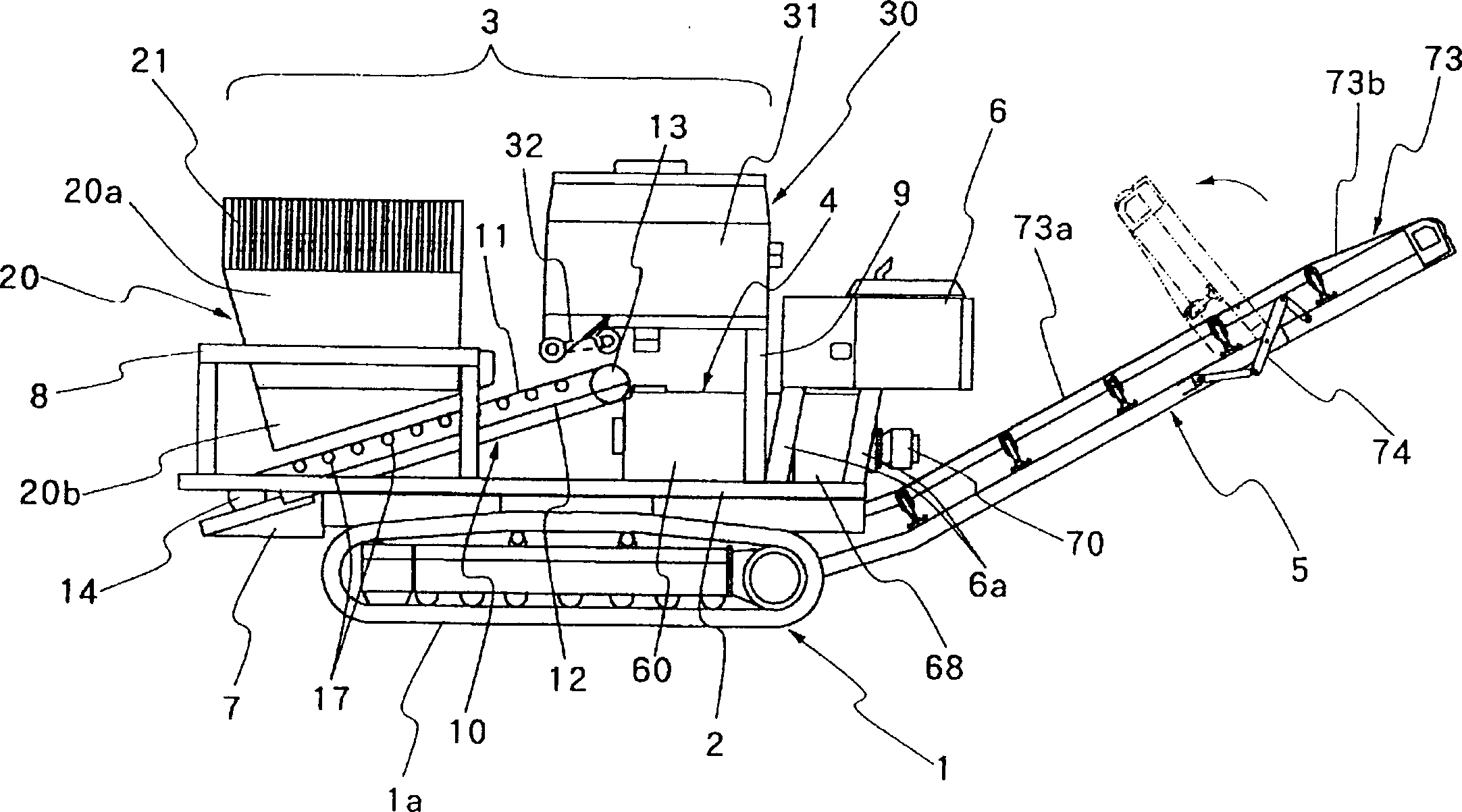

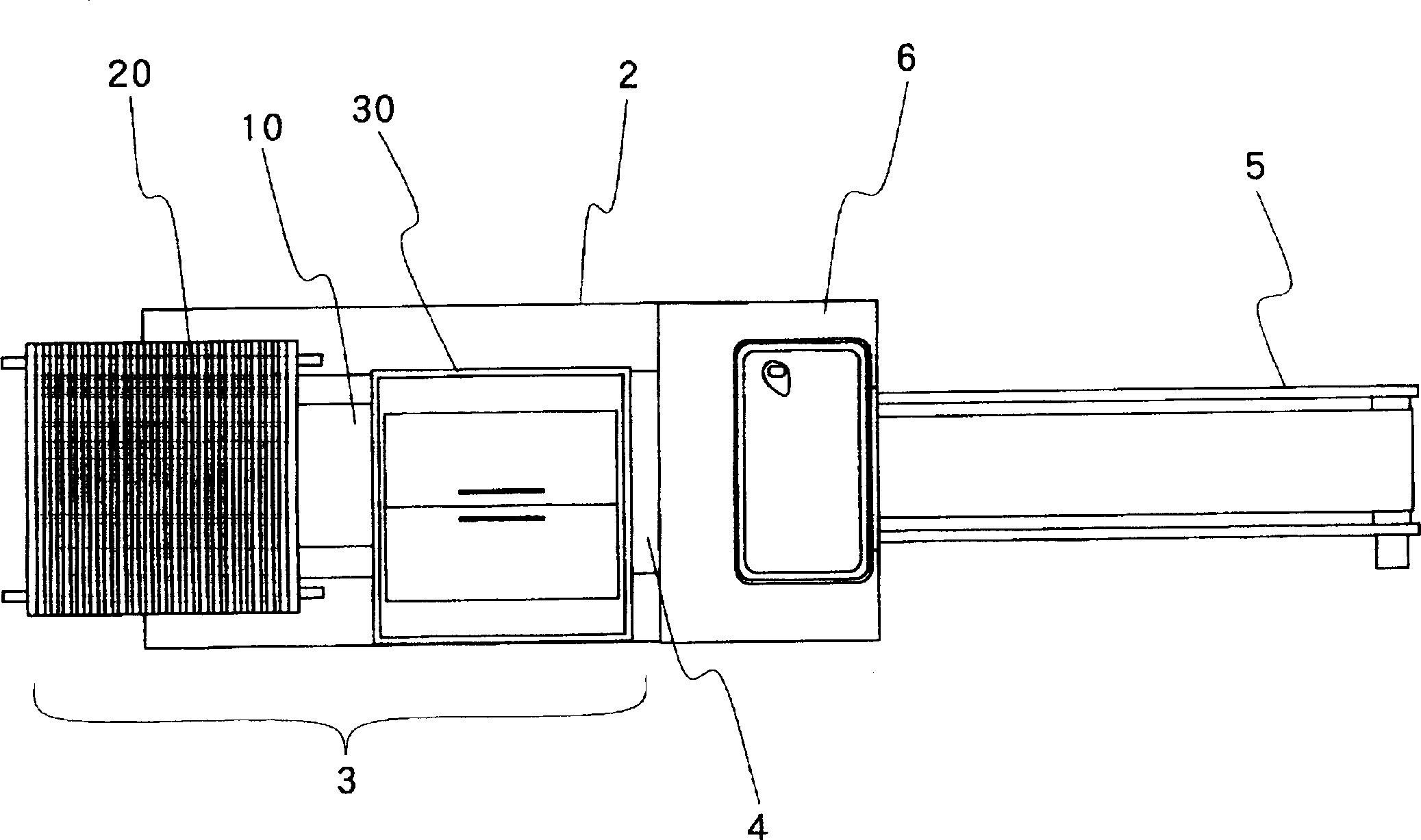

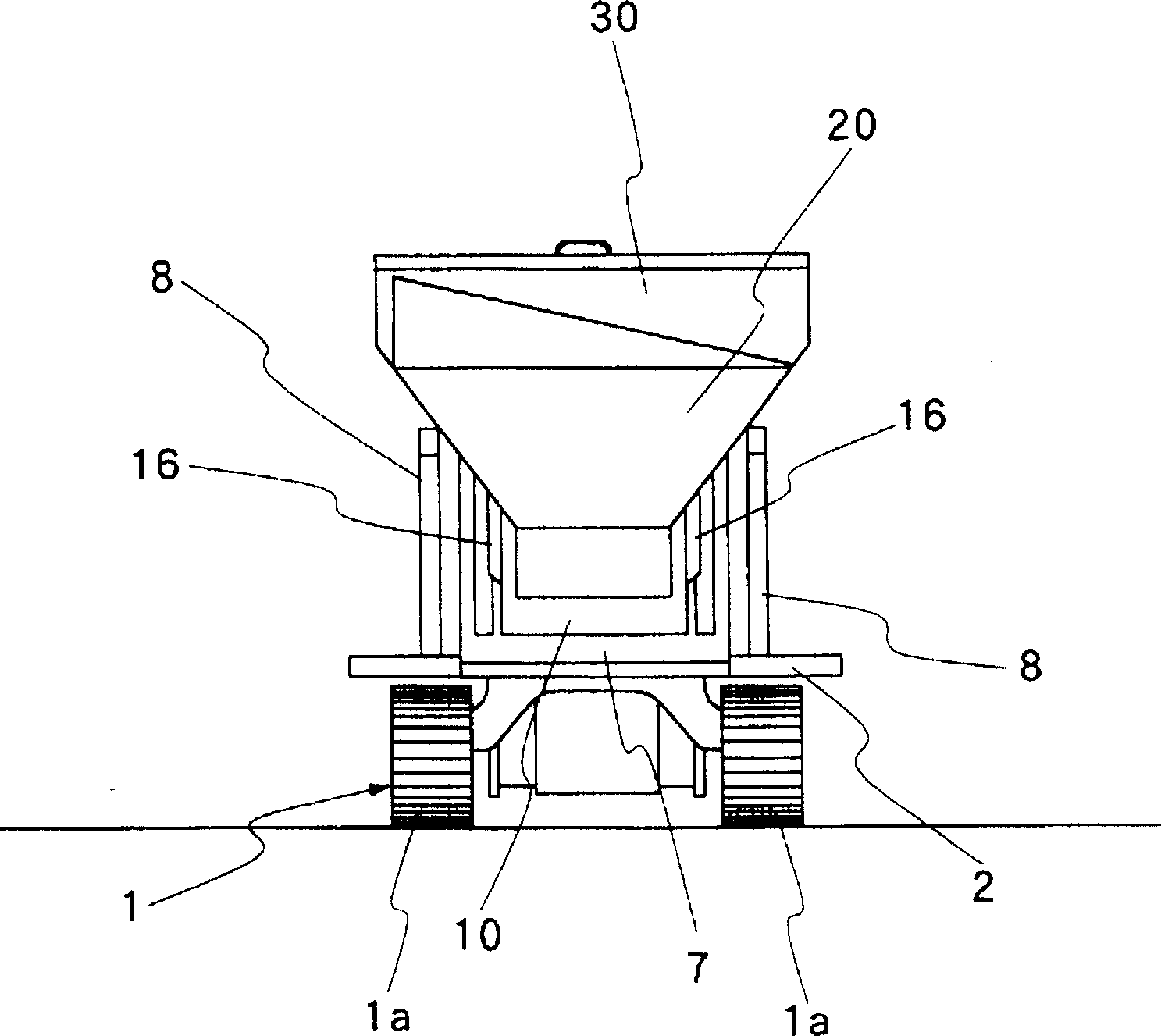

Self walking soil processing machine

InactiveCN1112958CEasy to handleImprove qualityRotary stirring mixersTransportation and packagingEngineering

A vehicular automotive soil treating machine having a main frame structure provided on an automotive drive means to support thereon a soil feeding stage including at least a soil hopper and an additive hopper, a soil processing stage including a soil processing trough which is internally provided with a mixing means for mixing soil and additive material while being transferred from one to the other end of the soil processing trough, and a processed soil discharging stage including a soil discharging conveyer. The soil processing trough is provided with an inlet opening on the upper side of its fore end portion and an outlet opening on the bottom side of its rear end portion.

Owner:NIHON KENKI CO LTD

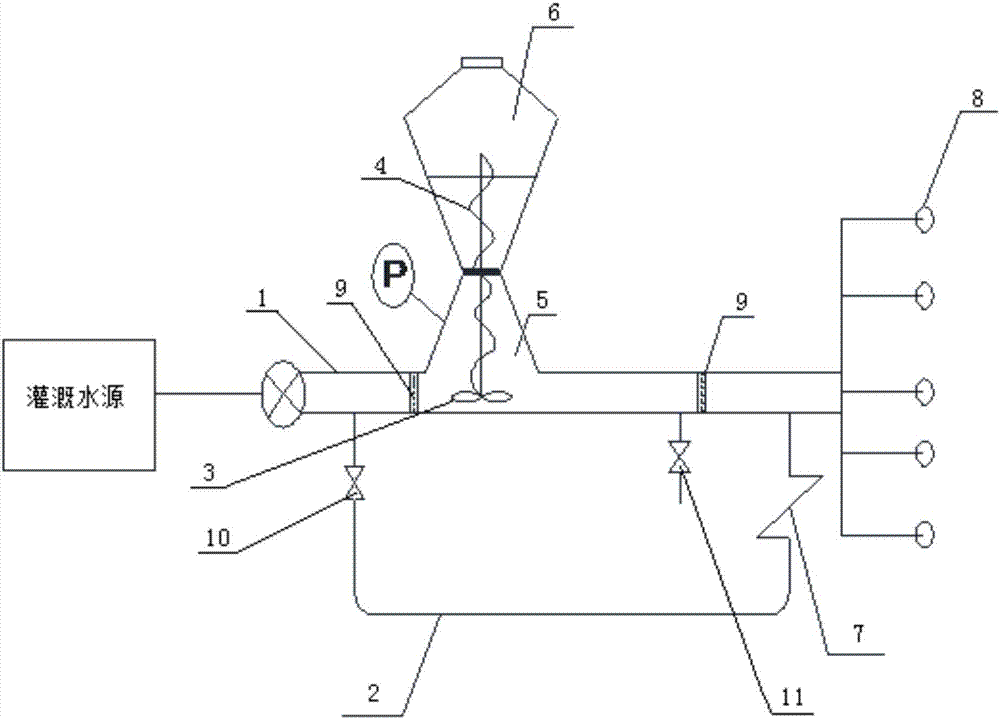

Irrigation system capable of adjusting water and fertilizer solubility

ActiveCN107969204AImprove spraying effectAdjust the mixing ratioPressurised distribution of liquid fertiliserSolubilityWater source

The invention discloses an irrigation system capable of adjusting water and fertilizer solubility. The irrigation system comprises a main water supply pipeline, wherein a water inlet of the main watersupply pipeline is connected with an irrigation water source, and a plurality of sprinklers are connected in parallel with a water outlet; a concentration adjusting bin is arranged between the waterinlet and the water outlet; the concentration adjusting bin is communicated with the main water supply pipeline; and the upper part of the concentration adjusting bin is provided with a chemical fertilizer bin. The irrigation system also comprises a spiral shaft, wherein the spiral shaft extends from the chemical fertilizer bin to the concentration adjusting bin; the lower part of the spiral shaftis connected with a driving blade which is arranged in the main water supply pipeline; and the driving blade can rotate under the push of water flow and drives the spiral shaft to rotate synchronously. The rotation of the spiral shaft can bring a chemical fertilizer into the concentration adjusting bin. The problems that in the prior art, irrigation and fertilization are carried out separately, asolution preparation process is tedious and waste is caused easily are solved. The irrigation system provided by the invention can fertilize crops while irrigating, uniformly dissolve a chemical fertilizer in water, and transport the chemical fertilizer to a farmland, thus saving the chemical fertilizer and achieving a good spraying effect.

Owner:NORTHWEST UNIV

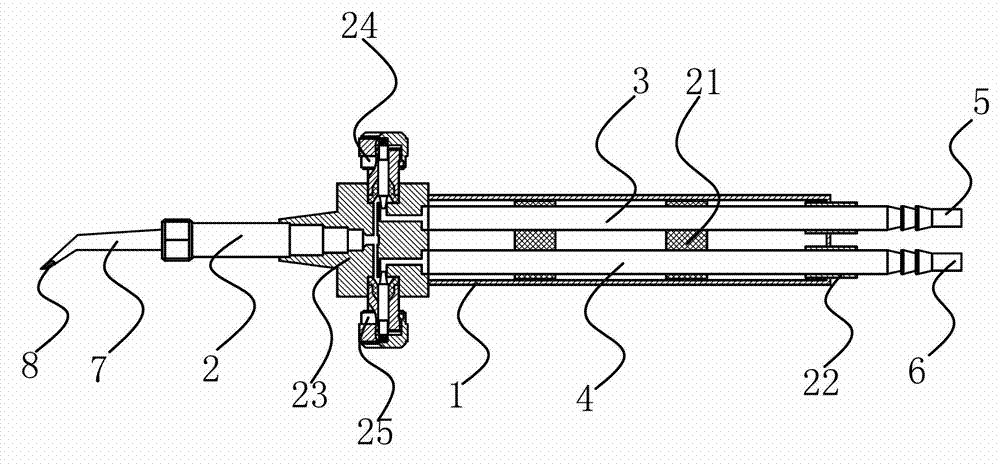

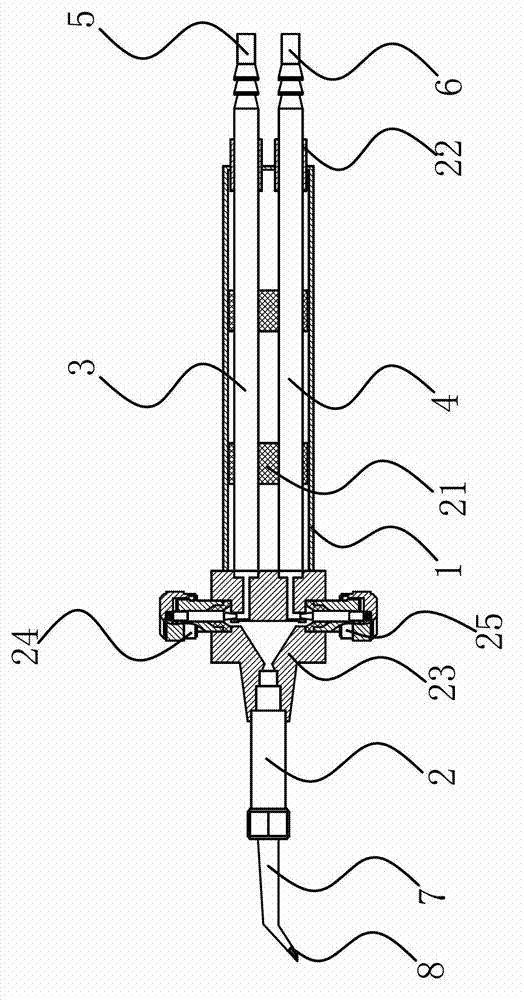

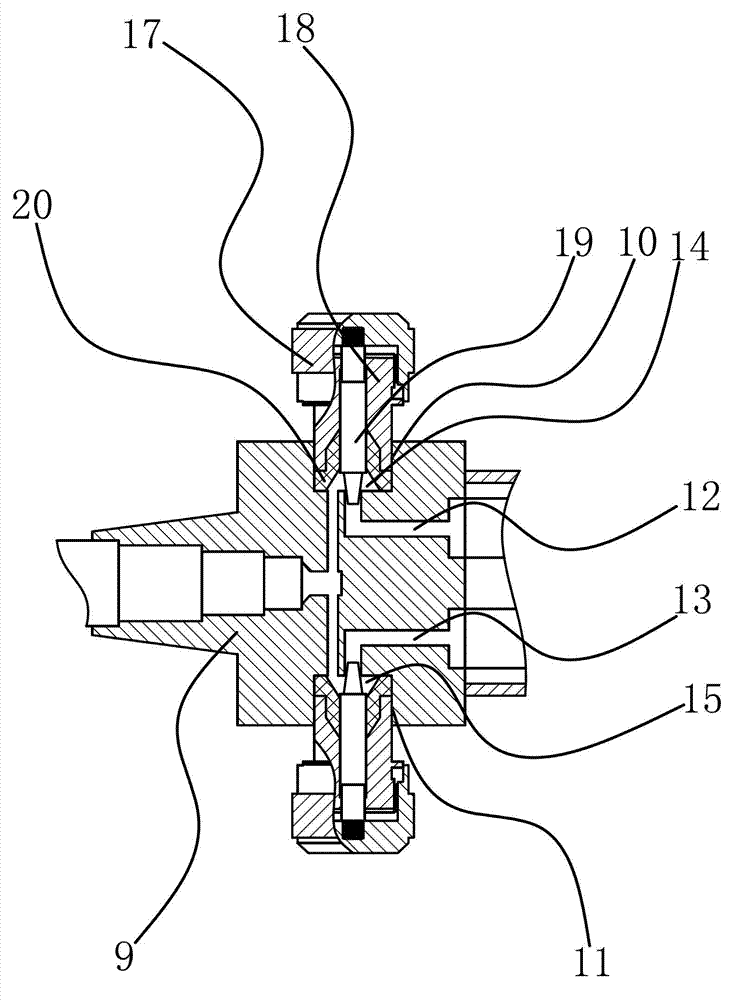

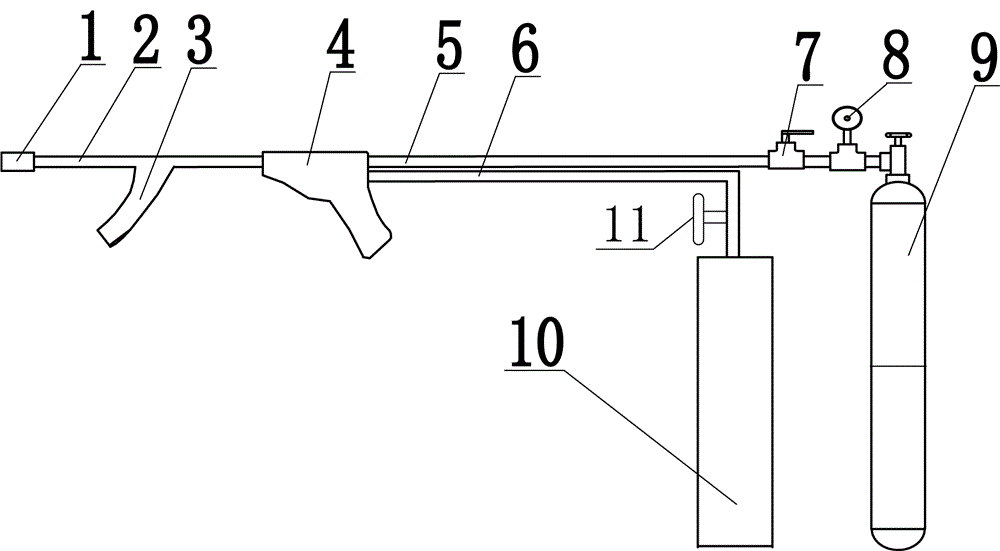

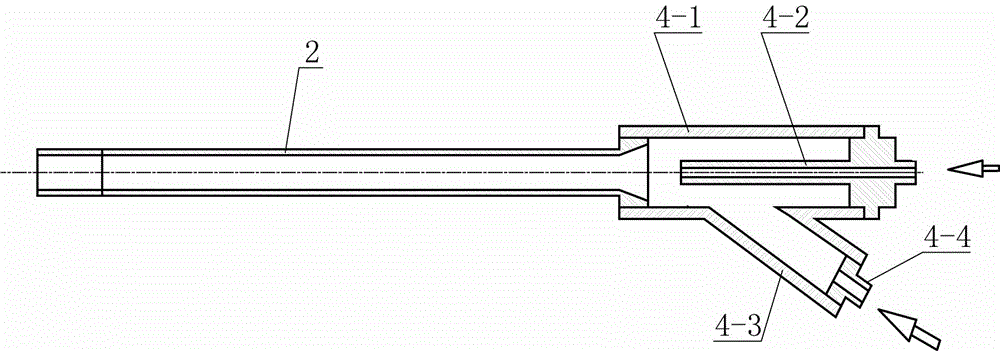

Novel oxyhydrogen flame gun

ActiveCN103075732AEasily adjust the mixing ratio at willAdjust the mixing ratioGaseous fuel burnerHydrogenEngineering

The invention relates to a novel oxyhydrogen flame gun, belonging to the field of machines. The flame temperature of the existing oxyhydrogen flame guns cannot be freely controlled. The novel oxyhydrogen flame gun comprises a gun barrel, a mixed gas delivery pipe, a gun nozzle fixedly mounted at the front end of the mixed gas delivery pipe, a hydrogen gas inlet pipe, an oxygen gas inlet pipe, a hydrogen gas inlet pipe connector, an oxygen gas inlet pipe connector and a regulating device, wherein the front ends of the hydrogen gas inlet pipe and the oxygen gas inlet pipe are both in sealed connection with the tail end of the regulating device, and the tail ends of the hydrogen gas inlet pipe and the oxygen gas inlet pipe are respectively connected with the hydrogen gas inlet pipe connector and the oxygen gas inlet pipe connector; the tail end of the mixed gas delivery pipe is in sealed connection with the front end of the regulating device; the gun barrel is sleeved outside the hydrogen gas inlet pipe and the oxygen gas inlet pipe and is fixedly mounted on the regulating device; and gas inflows of hydrogen and oxygen gases are respectively regulated through the regulating device, so as to control the mixture ratio of mixed gas of the hydrogen and oxygen gases. After the structure is adopted, the novel oxyhydrogen flame gun can be used for freely and easily regulating the mixture ratio of the mixed gas, and therefore the aim of regulating the flame temperature is achieved.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

High-pressure dried carbon dioxide powder fire extinguisher

InactiveCN104548433ATo achieve the purpose of fire extinguishingNo secondary disasterFire rescueCarbon dioxideMaterials science

The invention discloses a high-pressure dried carbon dioxide powder fire extinguisher. A dried powder self-sucking mechanism comprises a mixing pipe, wherein a dried powder suction pipe is connected to a pipe wall of the mixing pipe; a carbon dioxide injection pipe is arranged inside the mixing pipe; the front end of the mixing pipe is connected with a mixing injection pipe; the rear end of the carbon dioxide injection pipe extends out of the rear end of the mixing pipe and is connected with a carbon dioxide bottle by virtue of a high-pressure delivery pipe; and the outer end of the dried powder suction pipe is connected with a dried powder fire extinguishing agent tank by virtue of a connecting pipe. The pressure in the carbon dioxide bottle is 6-7MPa or below, and the injection distance of the fire extinguisher disclosed by the invention is about 20meters. The injection time can be regulated according to the loading capacity of the dried powder fire extinguishing agent tank and the carbon dioxide bottle and can be more than ten minutes and tens of minutes.

Owner:晏子俊

Rotary distributing device

InactiveCN106493012AAchieve cleanabilityTo achieve the effect of disinfectionMovable spraying apparatusLiquid spraying apparatusEngineeringMechanical engineering

The invention belongs to cleaning and sterilizing equipment in the field of cleaning and sterilizing, and relates to a rotary distributing device. The rotary distributing device comprises a shell and an inner core positioned in the shell, and is characterized in that the shell or the inner core is connected with a driving device, so that one of the shell and the inner core becomes a rotating piece, and the other one becomes a fixed piece; annular air delivering cavities and annular liquid delivering cavities are formed in a position where the shell is connected with the inner core in the peripheral direction; sealing bodies are arranged on the periphery of each annular liquid delivering cavity and the periphery of each annular air delivering cavity; the rotating piece is provided with air outlet tubes and liquid outlet tubes; the fixed piece is provided with air inlet tubes and liquid inlet tubes; each air inlet tube, the corresponding annular air delivering cavity and the corresponding air outlet tube communicate with one another; each liquid inlet tube, the corresponding annular liquid delivering cavity and the corresponding liquid outlet tube communicate with one another; and each air outlet tube and the corresponding liquid outlet tube are connected with the same sprayer. By the rotary distributing device, the problems that by existing cleaning equipment and existing sterilizing equipment, air and liquid cannot be mixed when the air and the liquid are about to be sprayed out, and high efficiency of using during distributing cannot be achieved are solved.

Owner:广州轻机机械设备有限公司

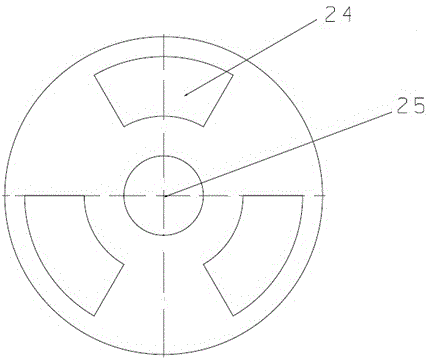

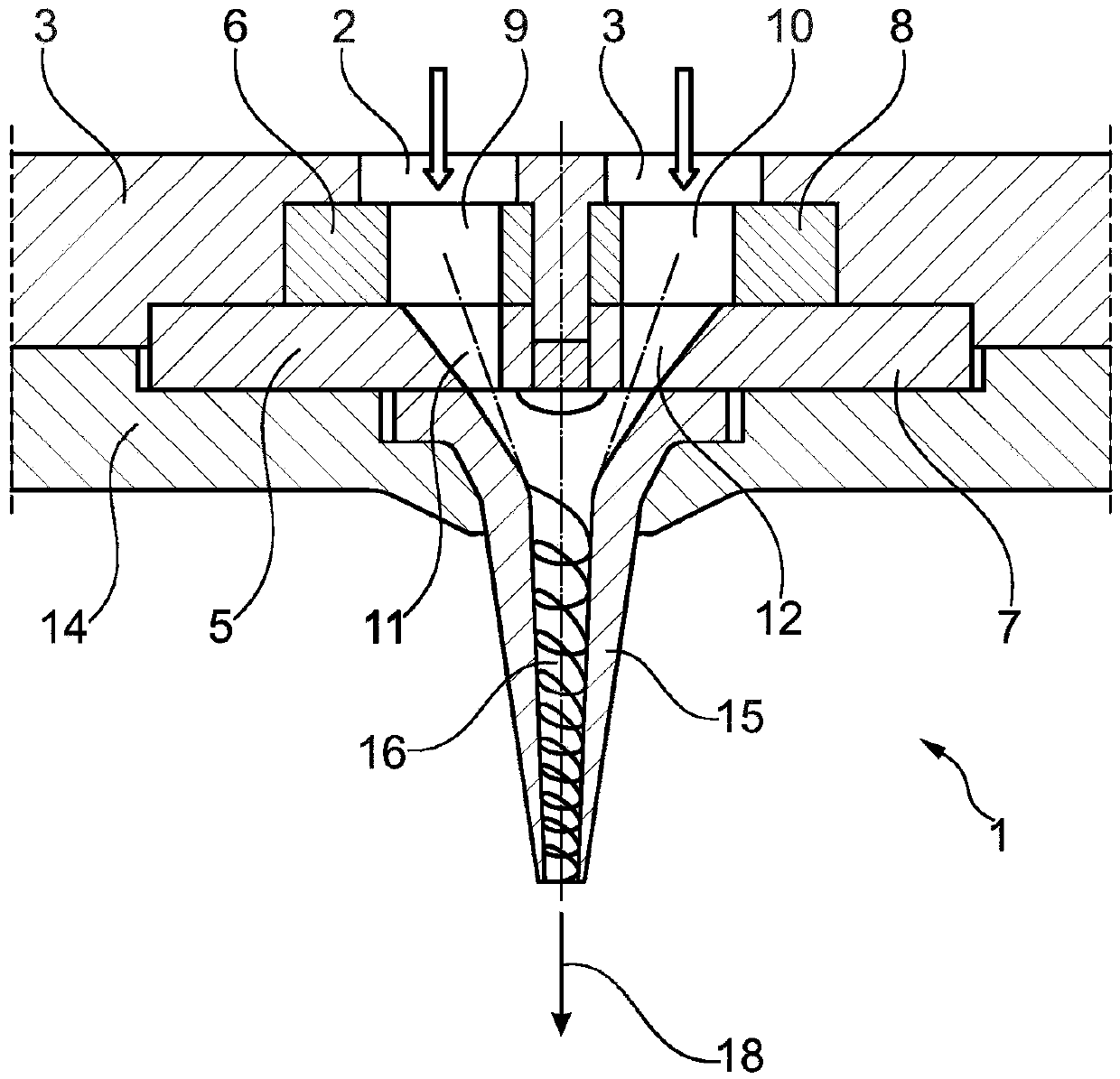

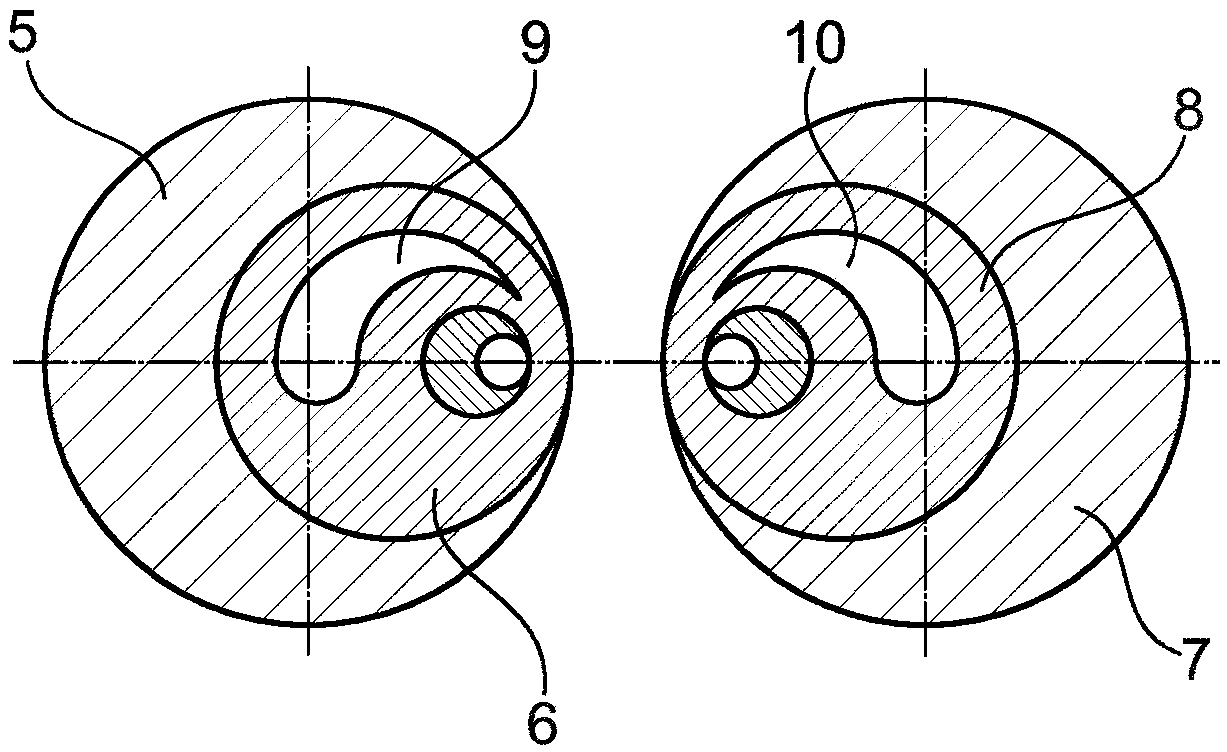

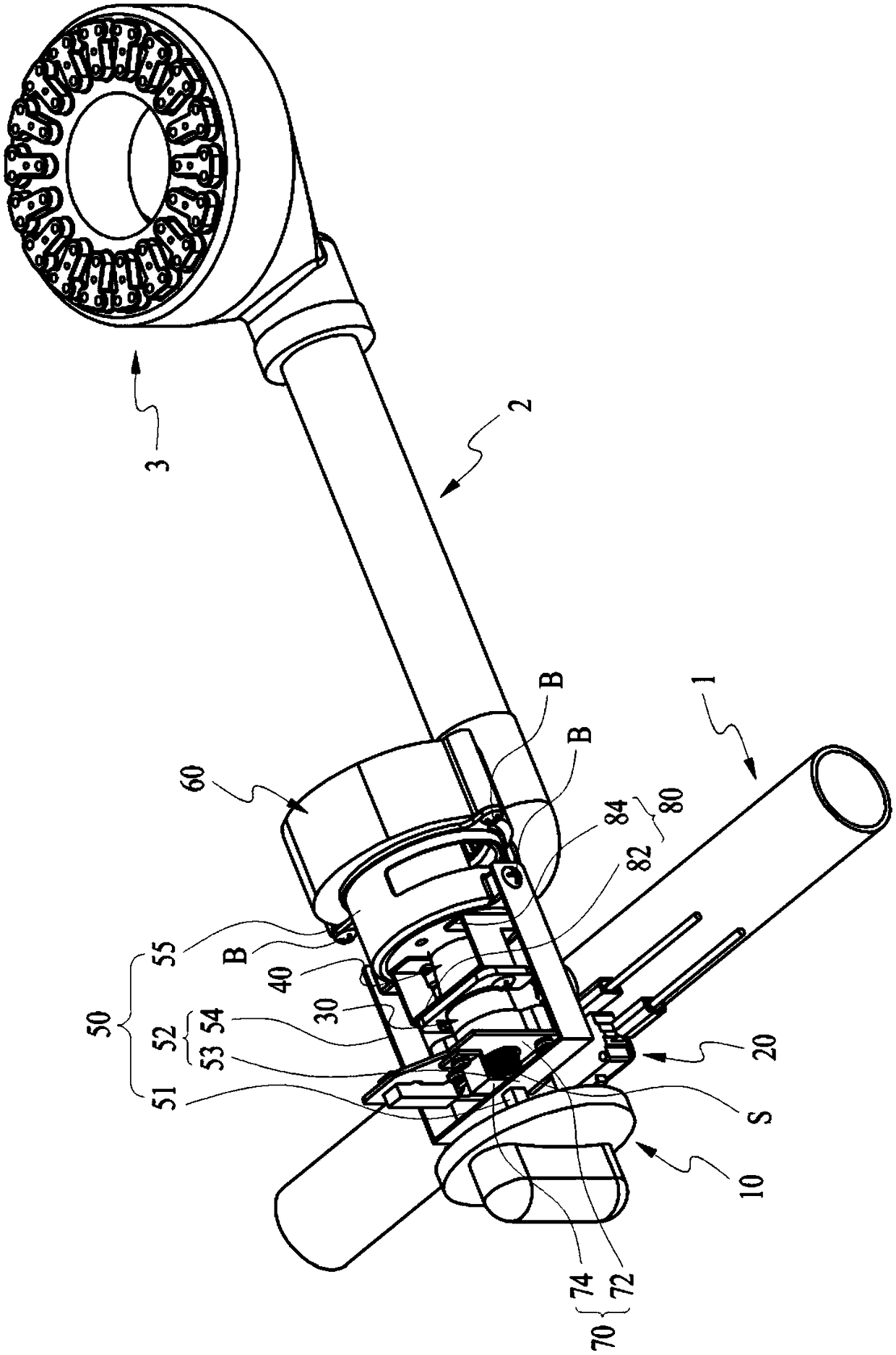

Mixing valve

ActiveCN109689220AAchieve zero closureEasy to adjustLiquid surface applicatorsFlow mixersRotational axisEngineering

The invention relates to a mixing valve (1) for mixing two coating agent components (e.g. a base and a hardener) to form a multi-component mixture, comprising two coating agent inlets (2) for supplying the two coating agent components, two coating agent valves (5-8) for controlling the coating agent flow through the two coating agent inlets (2, 3), as well as a coating agent outlet (4) for the delivery of the multi-component mixture in a specified outflow direction (18). The invention provides that at least one of the coating agent valves (5-8) is designed as a rotary slide valve having two plane-parallel valve disks (5-8) which are rotatable relative to each other about a rotational axis.

Owner:DUERR SYST GMBH

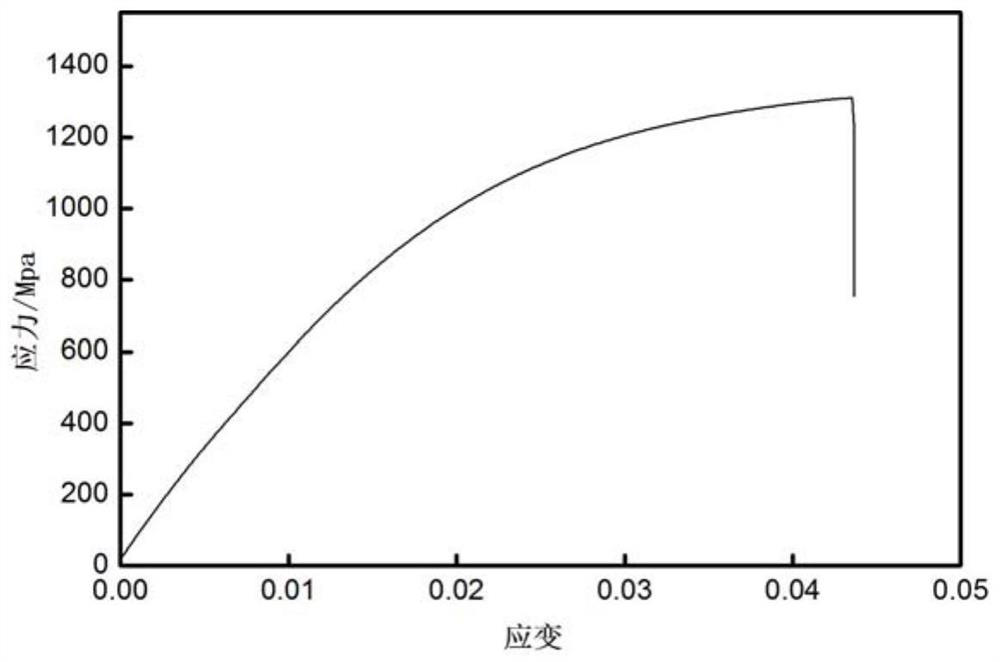

Double-phase high-entropy alloy and preparation method thereof

ActiveCN112746214AAdjust the mixing ratioControl ratioAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysDouble phase

The invention provides a double-phase high-entropy alloy. The alloy comprises a first alloy component in an FCC phase and a second alloy component in a BCC phase, wherein the first alloy component is FeCoCrNi, and the second alloy component is FeCoCrNiAl. The double-phase high-entropy alloy contains an FCC structure and a BCC structure in a proper proportion, and is excellent in comprehensive mechanical properties, high in hardness and strength, and good in plasticity and toughness. In addition, the invention further provides a preparation method of the double-phase high-entropy alloy. Through the method, the production period is short, parts in complex shapes can be directly formed, and the formed parts are high in precision and density, and have excellent comprehensive mechanical properties.

Owner:CENT SOUTH UNIV +1

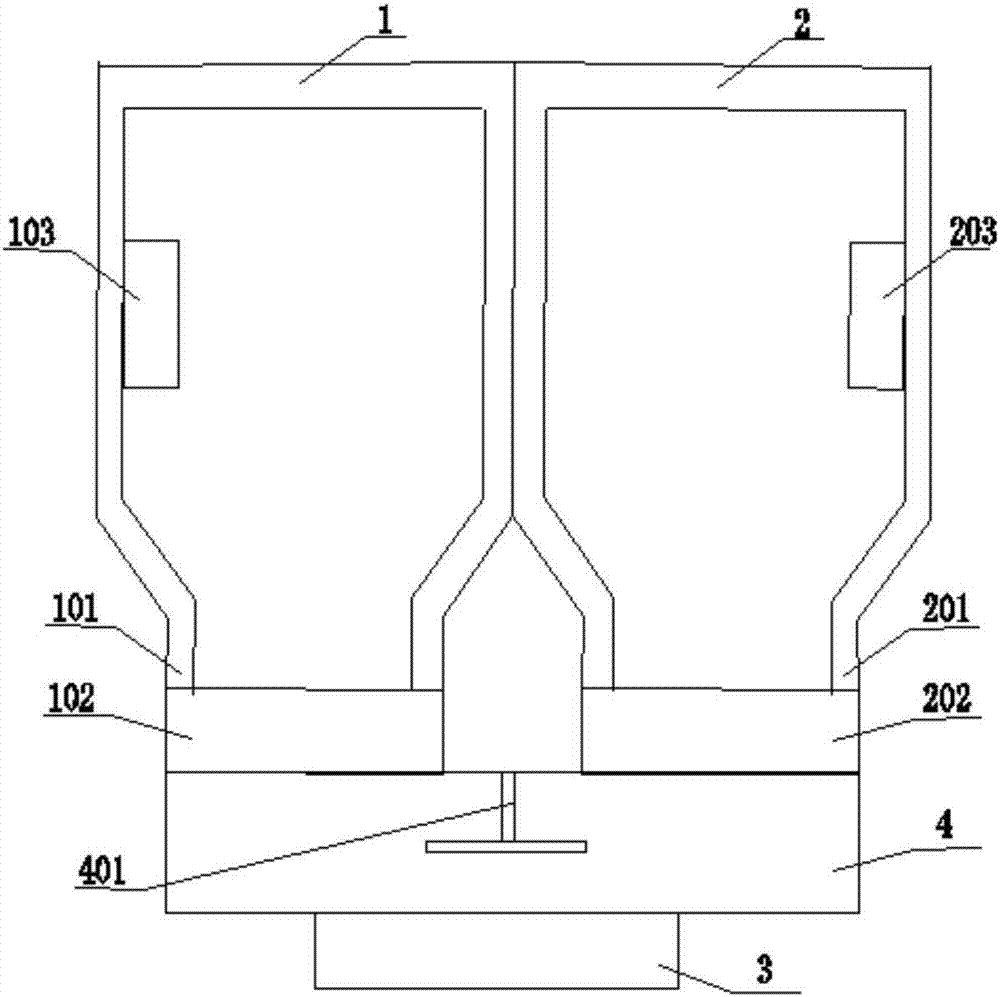

Milk powder can for mixing and brewing

The invention discloses a milk powder can for mixing and brewing. The milk powder can includes a first storage can, a second storage can and a collecting outlet, wherein the first storage can and the second storage can are arranged side by side; the bottom of the first storage can is provided with a first outlet, and the bottom of the second storage can is provided with a second outlet; the first outlet and the second outlet are each communicated with the collecting outlet. The milk powder can is novel in structure, separates milk powder to be stored, effectively ensures the quality of the milk powder, and facilitates mixing and brewing of the milk powder in the later stage.

Owner:亚月(武汉)智能科技有限公司

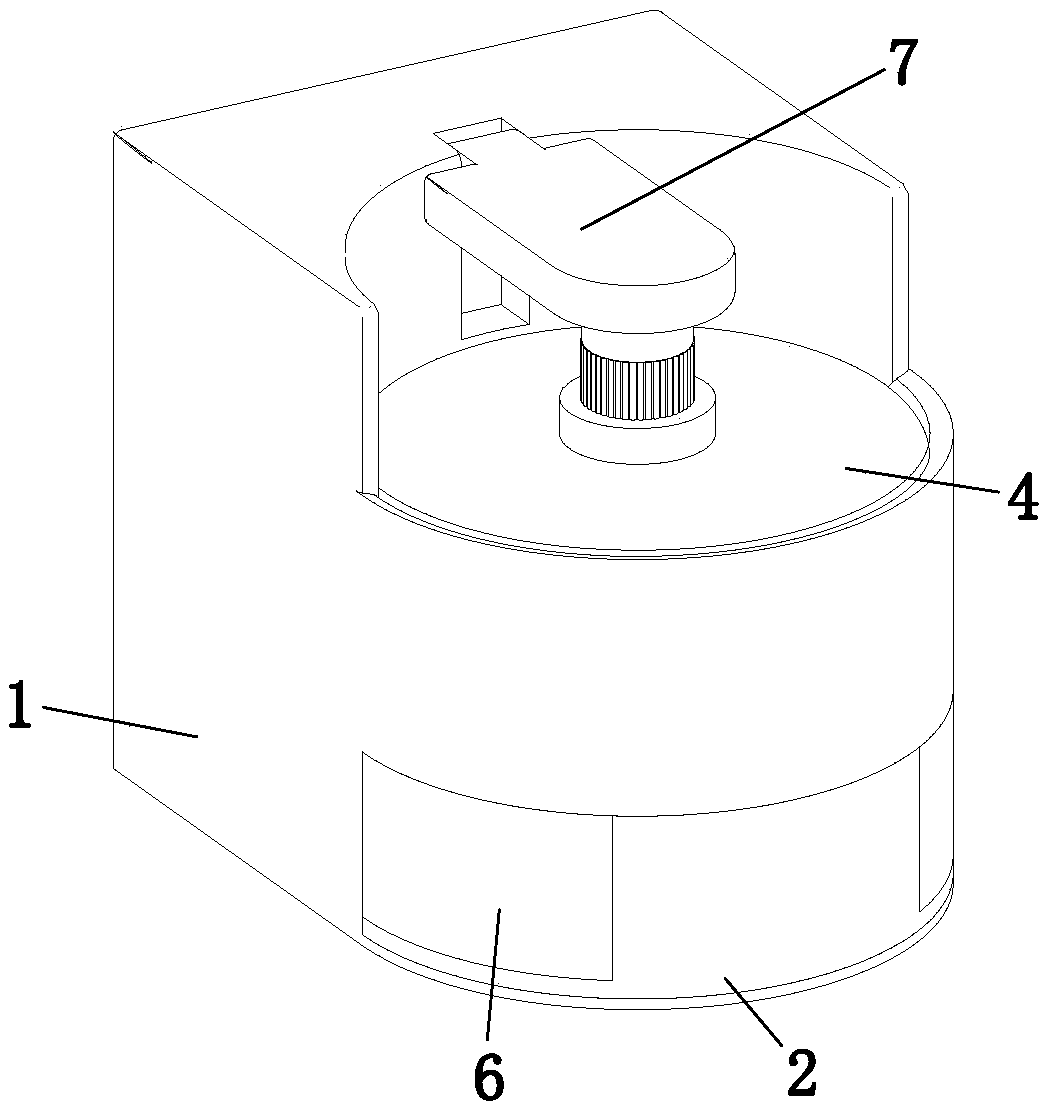

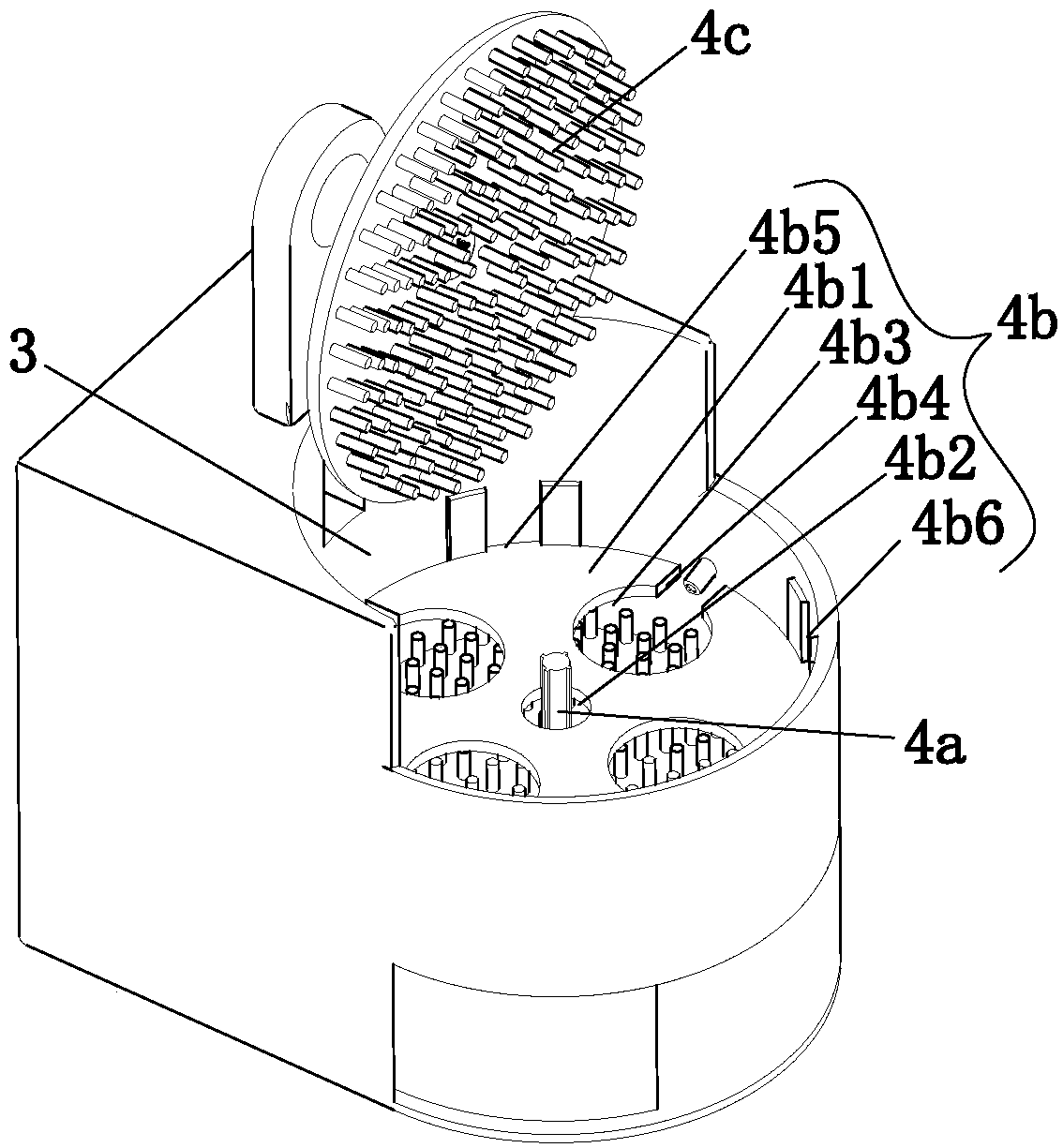

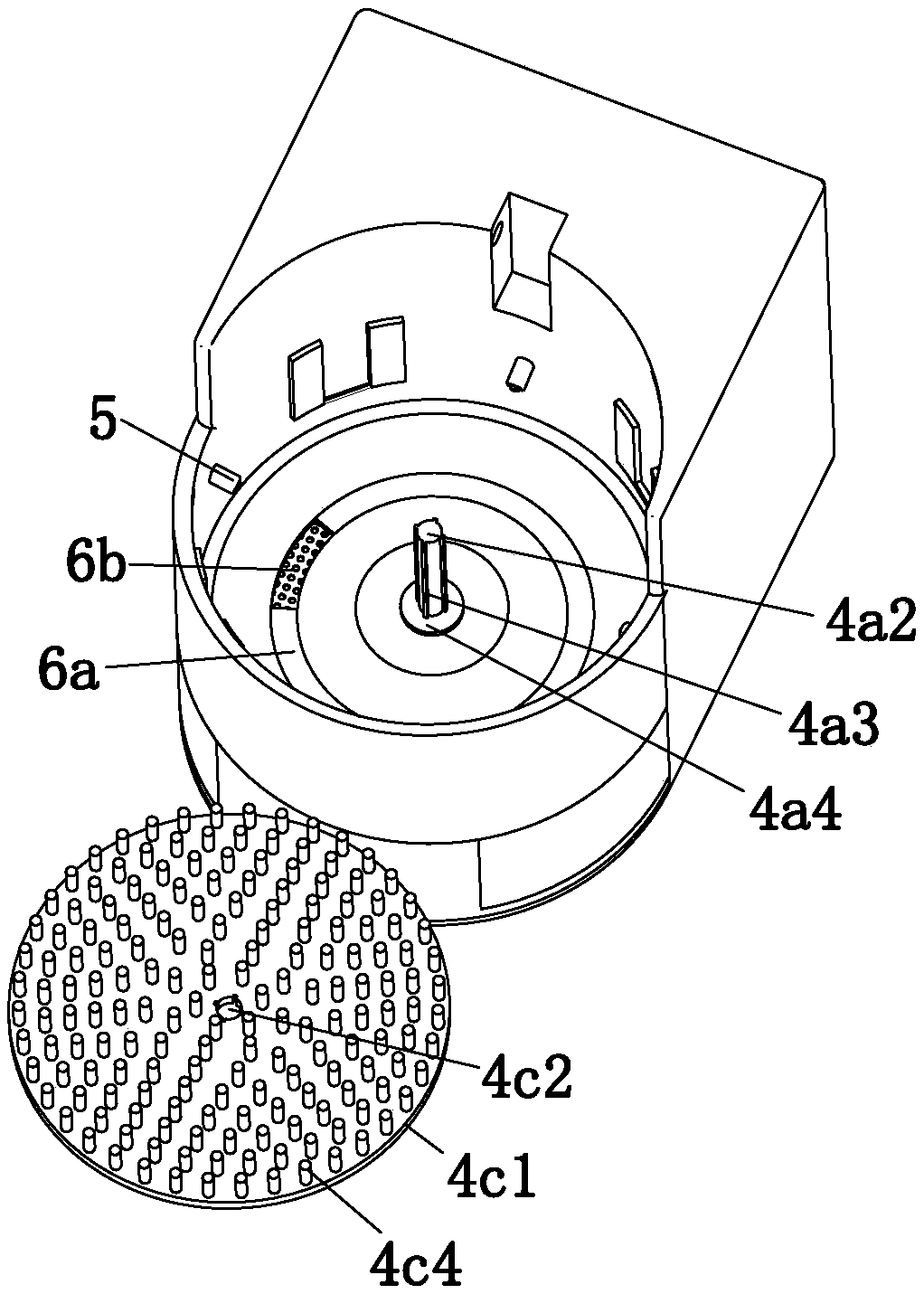

Polishing and washing device of collection walnuts

ActiveCN109366308AStrong applicabilitySolve grinding problemsGrinding machinesGrinding work supportsHigh pressureLiquid waste

The invention provides a polishing and washing device of collection walnuts, and belongs to the technical field of collection treating equipment. The polishing and washing device structurally comprises a base, two recovering tanks, a polishing cavity, a polishing mechanism, a washing mechanism and recovering mechanisms, wherein the two recovering tanks are arranged at the lower part of the base; each recovering mechanism is arranged in the corresponding recovering tank; the polishing cavity is formed in the middle part of the base; the polishing mechanism is arranged in the polishing cavity; the washing mechanism is arranged in the base; the polishing mechanism comprises a driving assembly, a fixing assembly and a polishing assembly; the driving assembly is arranged in the base; the fixingassembly and the polishing assembly are arranged in the polishing cavity; the washing mechanism comprises a washing assembly and a mixing assembly; and the washing assembly and the mixing assembly are arranged at the rear part of the base, and communicate with each other. Through the adoption of the polishing and washing device disclosed by the invention, the polishing efficiency of the collection walnuts can be improved; and through high-pressure water spraying, impurities in cracks of walnuts can be thoroughly washed, and besides, oil and water in waste liquid can be separated for recycling.

Owner:马鞍山建腾新型建材有限公司

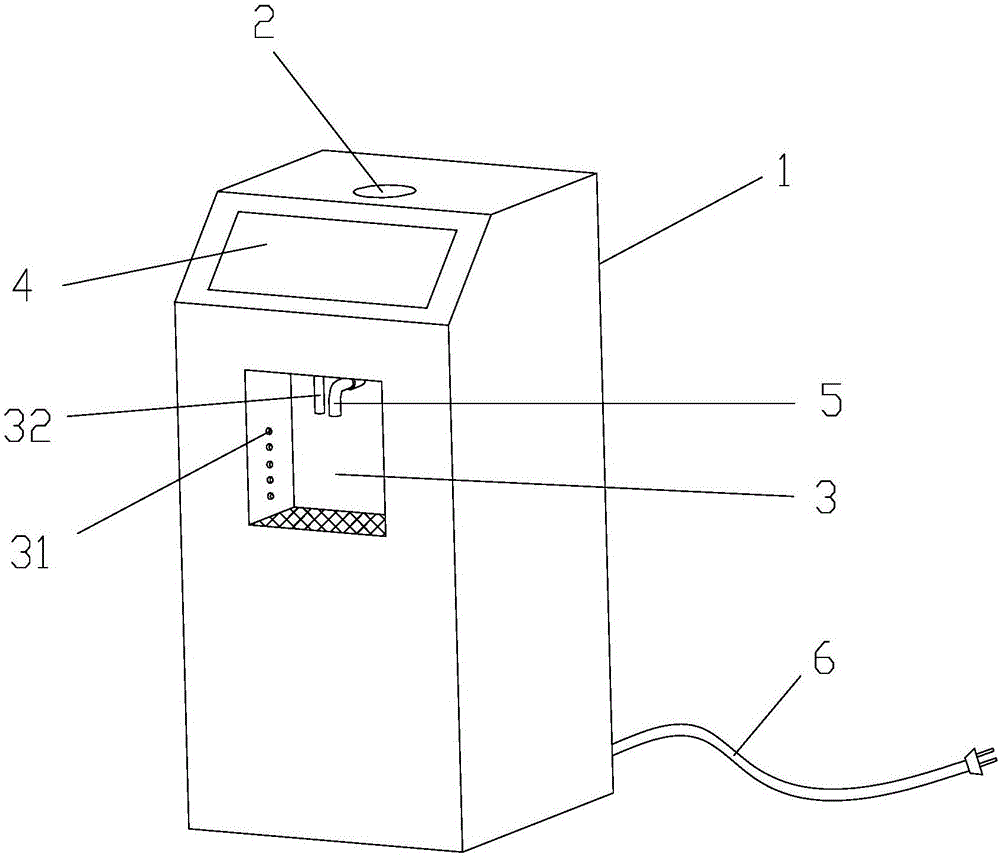

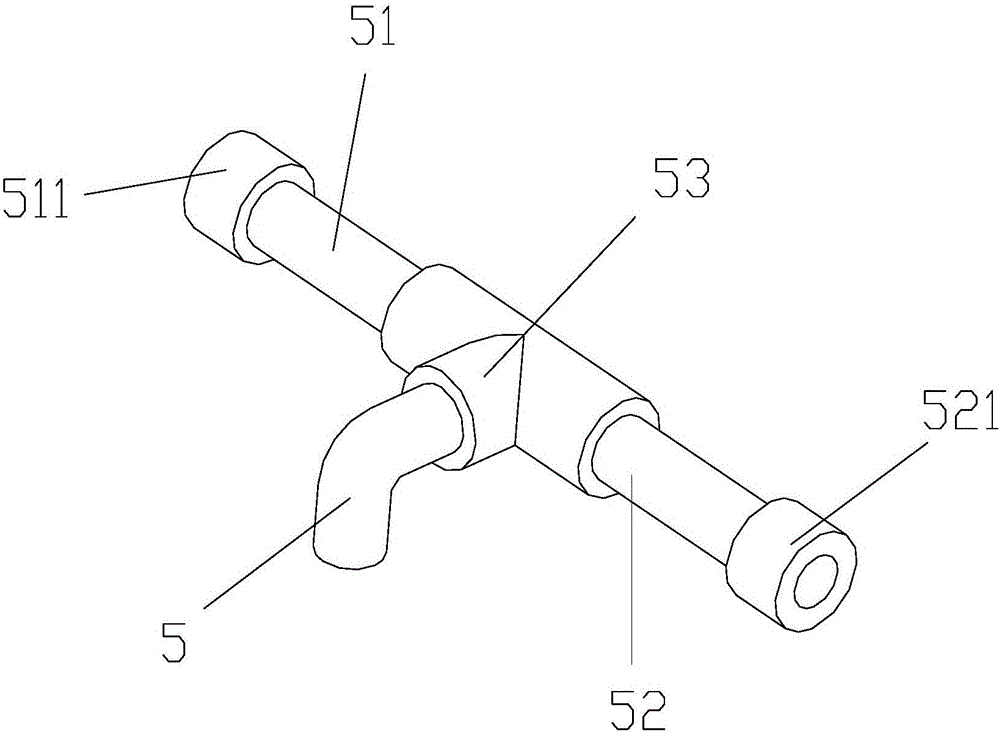

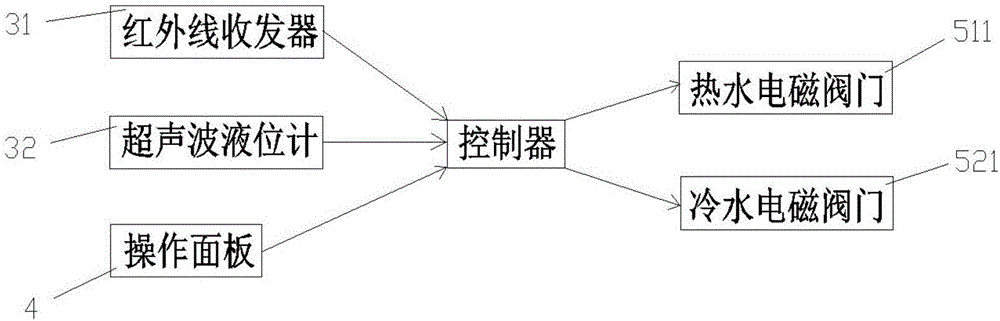

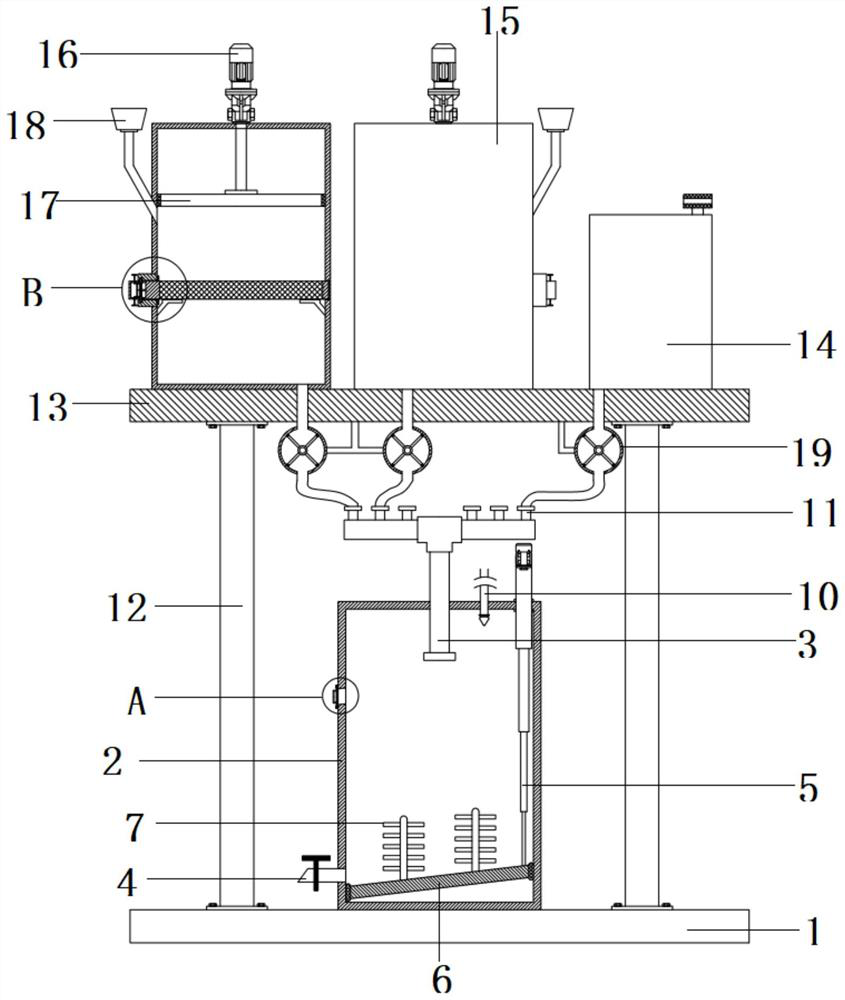

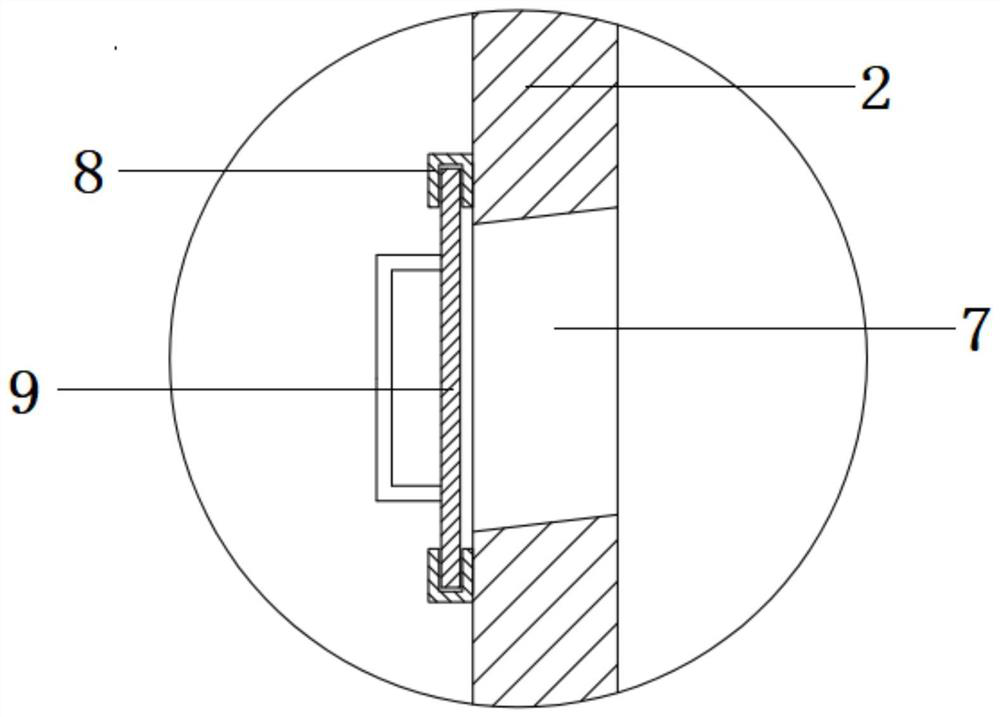

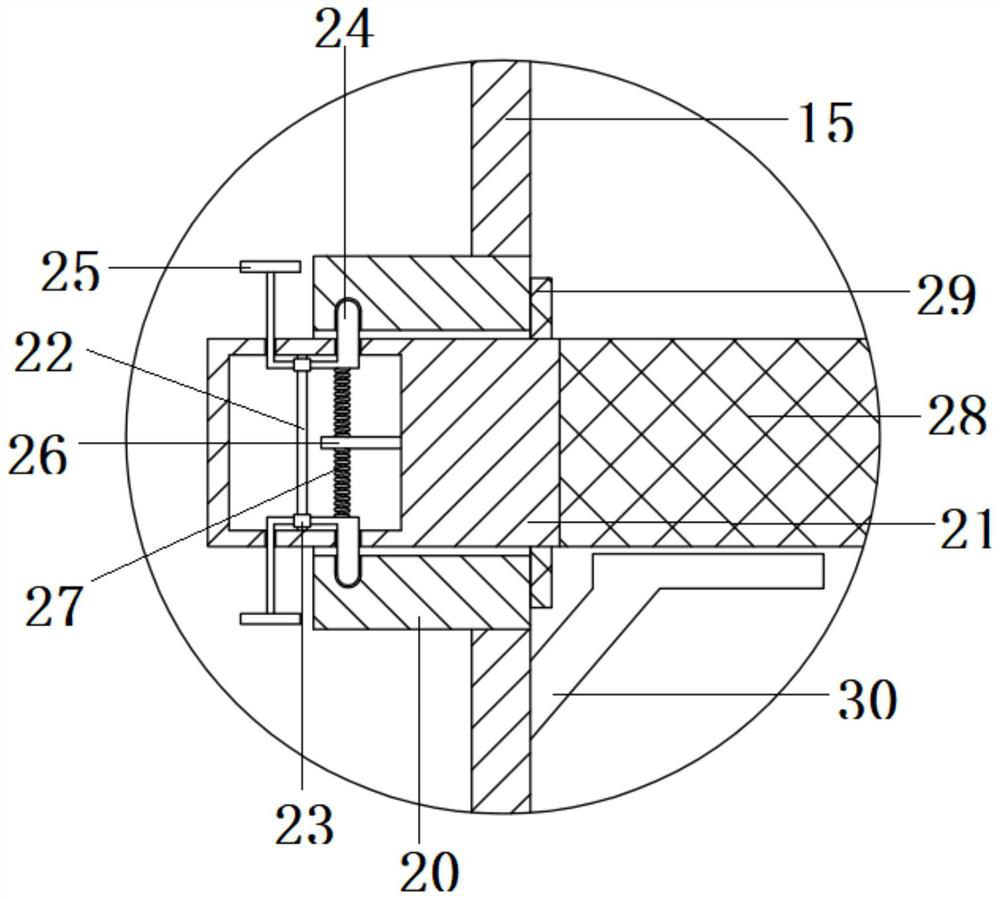

Intelligent water drinking device

The present invention relates to the field of logistics equipment, in particular to an intelligent drinking water device. The present invention adopts the following technical scheme: including a casing, a smart seat, a water tank, an operation panel, a water faucet and a water pipe; There are infrared transceivers and ultrasonic liquid level gauges; hot water pipes and cold water pipes are equipped with hot water electromagnetic valves and cold water electromagnetic valves respectively; faucets are equipped with flowmeters integrated with GSM modules. The advantages of the present invention are: the device can detect the height of the water cup and automatically fill it with water; the outlet water temperature of the device can be adjusted; when the bottled water is used up, the device will automatically send relevant information to the water supplier to notify it to deliver water, which is very intelligent .

Owner:FOSHAN XINGHUAYUAN MACHINERY EQUIP CO LTD

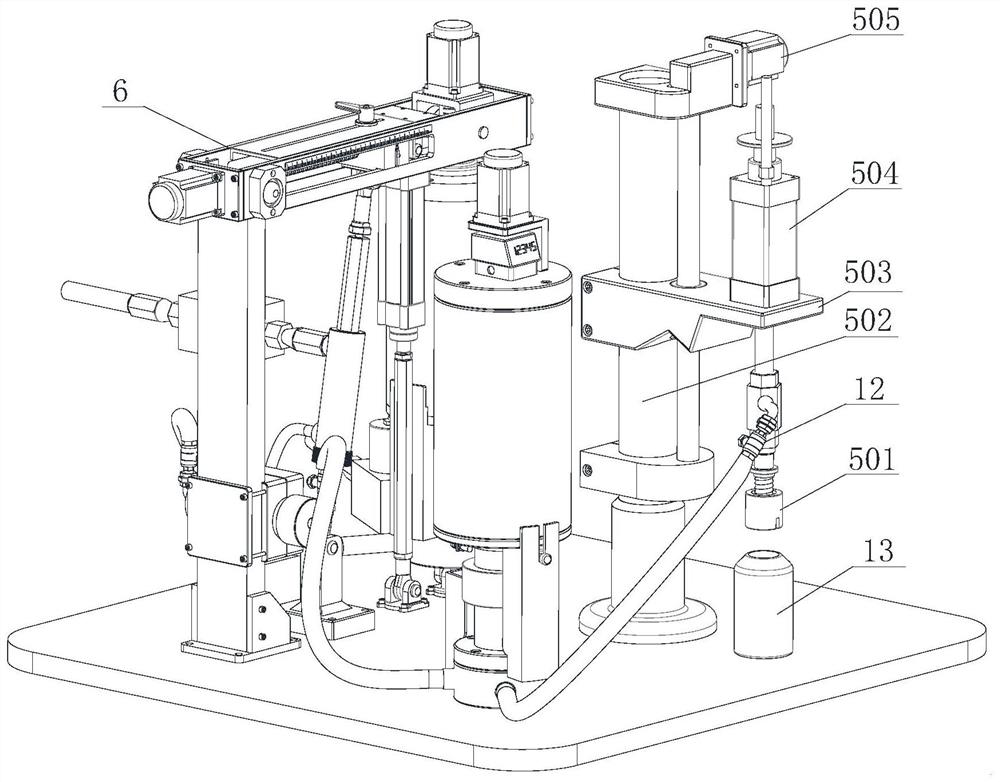

Mixed juice production system

InactiveCN111758968AQuick disassemblyEasy to cleanJuice extractionRotary stirring mixersHydraulic cylinderFruit juice

The invention discloses a mixed juice production system which comprises a bottom plate. A stirring tank is arranged at the top of the bottom plate, a liquid inlet pipe is arranged at the top end of the stirring tank, and a liquid outlet pipe is arranged at the bottom of the stirring tank. An electric push rod is arranged at the top end of the stirring tank in a penetrating mode, the free movable end of the electric push rod is connected to a sealing plate I, a stirring rod is arranged at the top of the sealing plate I, a through hole is formed in the inner wall of the stirring tank, and a sliding groove is formed in the outer side of the through hole. The sliding groove is internally and slidably connected with a baffle, a water spray head is arranged at the top end of the stirring tank ina penetrating mode, supporting rods with the bottom ends connected to the bottom plate are arranged on the two sides of the stirring tank, the top ends of the supporting rods are connected to a supporting plate, a liquid storage tank is arranged at one end of the top of the supporting plate, and a squeeze tank is arranged at the other end of the top of the supporting plate. The side wall of the squeeze tank is connected with a feeding hopper, a hydraulic cylinder is arranged at the top end of the squeeze tank, and a squeeze tank is arranged at the movable end of the hydraulic cylinder in a penetrating mode. The mixing ratio between different juices and trace elements can be conveniently and quickly adjusted, cleaning is convenient, the structure is simple, and use is convenient.

Owner:安阳市京膳堂饮料有限公司

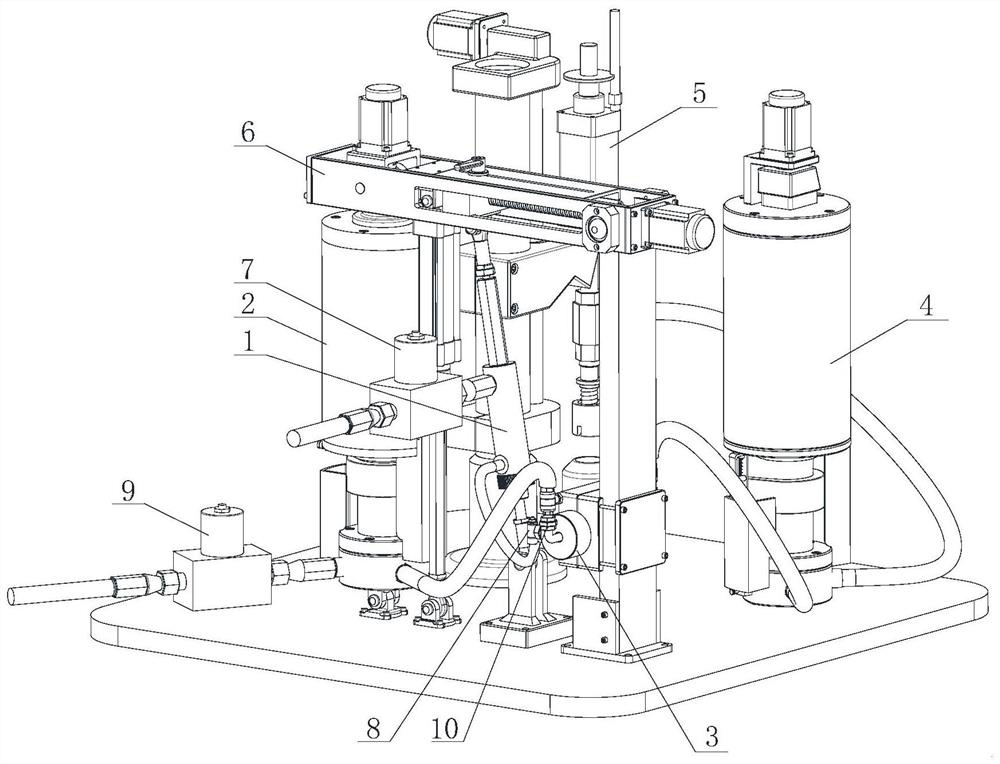

Full-automatic integrated static mixing and filling machine

ActiveCN112607688APrecisely control the mixing ratioHigh control precisionLiquid fillingSafety device in filling machineryControl engineeringProcess engineering

The invention discloses a full-automatic integrated static mixing and filling machine. The full-automatic integrated static mixing and filling machine comprises a material A quantitative extrusion device, a material B quantitative extrusion device, a static mixing device, a mixed material constant-pressure storage tank, a filling execution device and a pressing device, wherein the material A quantitative extrusion device and the material B quantitative extrusion device are both hinged to the pressing device, and materials are quantitatively extruded after the pressing device swings downwards by a certain angle; discharge ports of the material A quantitative extrusion device and the material B quantitative extrusion device are respectively connected with an input port of the static mixing device through a one-way valve and a pipeline; an output port of the static mixing device is connected with an input port of the mixed material constant-pressure storage tank through a one-way valve and a pipeline; and an output port of the mixed material constant-pressure storage tank is connected with an input port of the filling execution device through a one-way valve and a pipeline. The filling machine is compact in structure and small in occupied production space, and high-precision material matching can be achieved; and meanwhile, the automation degree is high, the labor intensity of workers is reduced, and the filling efficiency is improved.

Owner:ZHEJIANG LUDAO TECH CO LTD

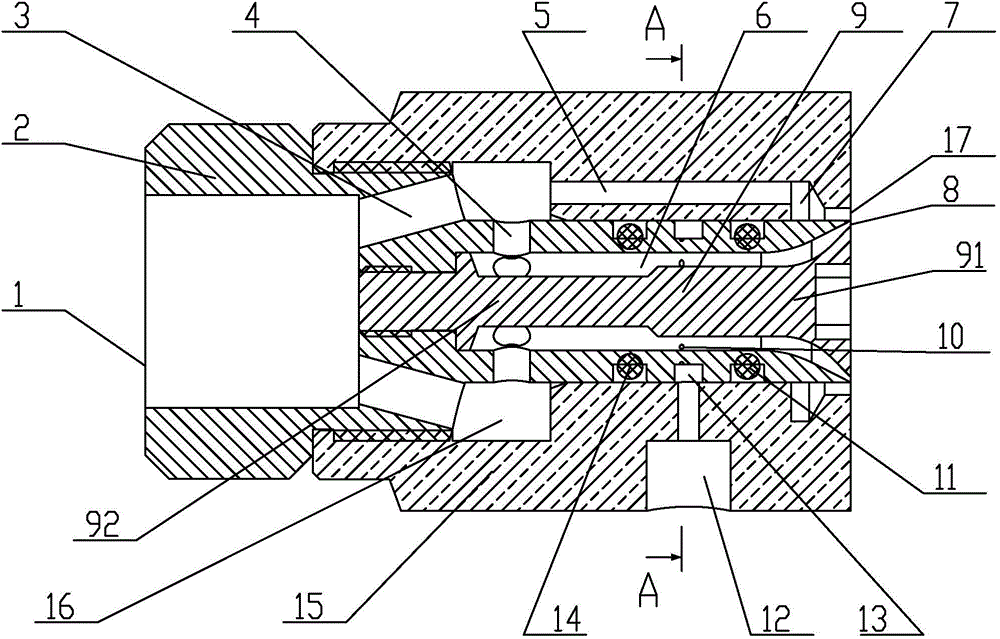

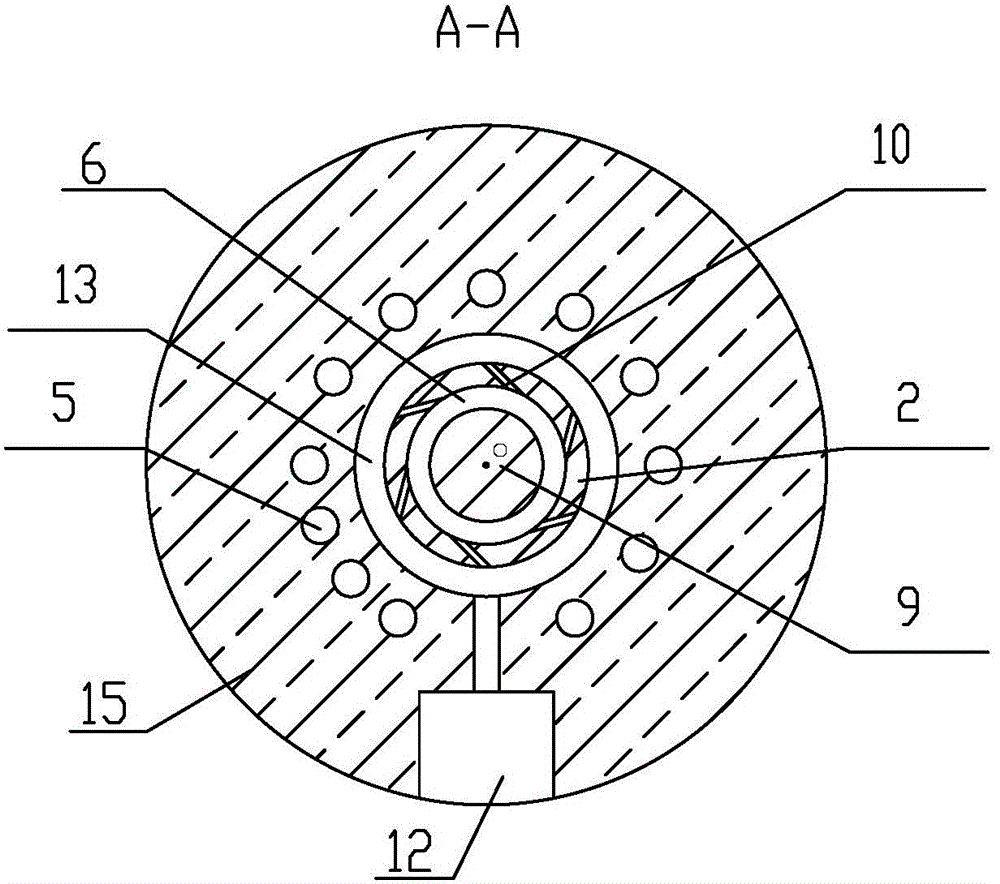

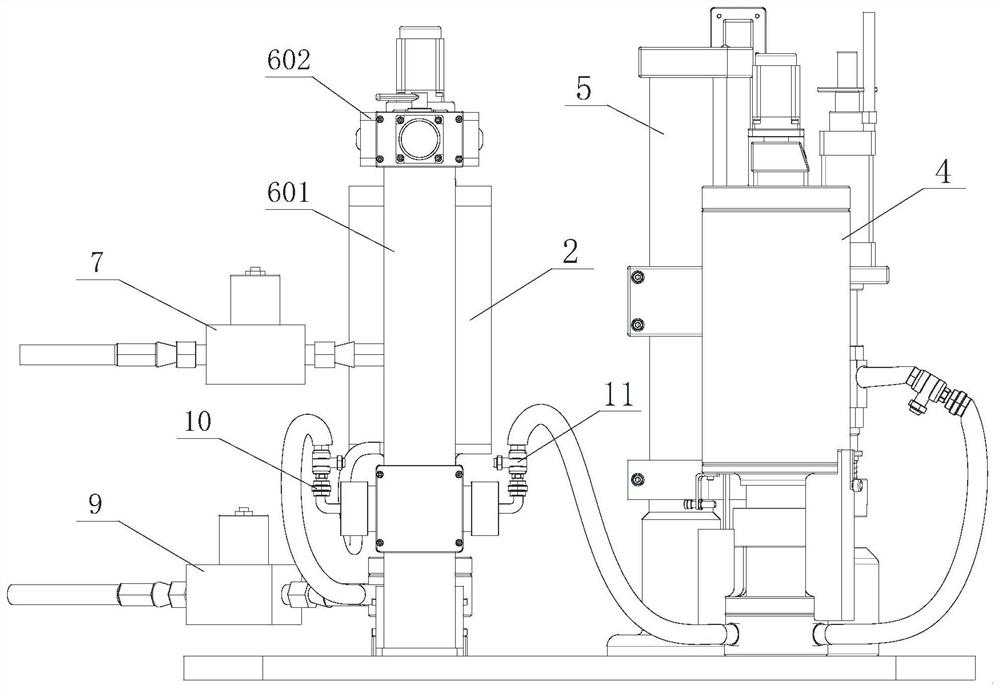

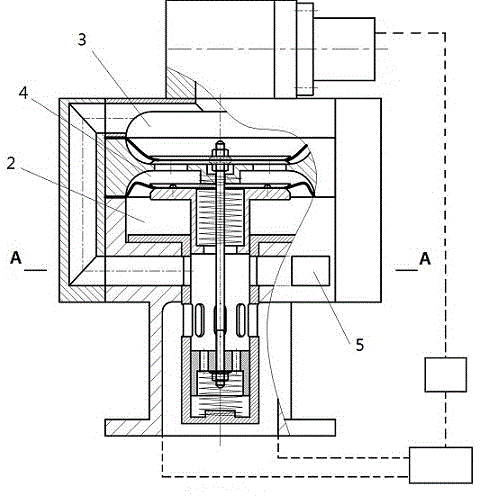

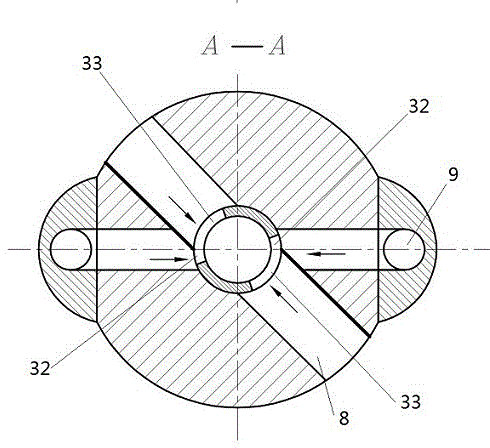

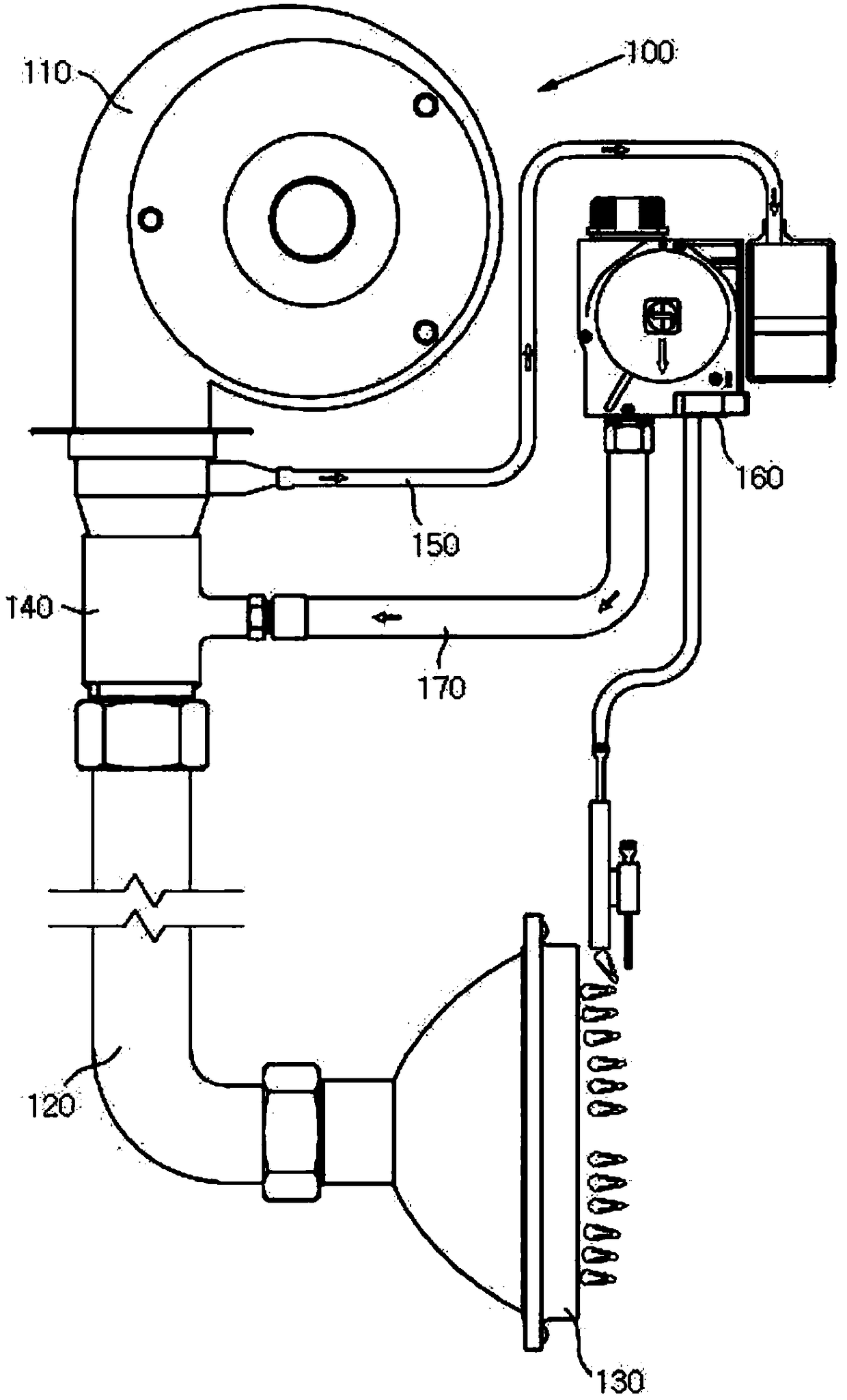

Load self-adaptation gas-fired device of gas engine

ActiveCN103511128AFix stability issuesSolve the problem of causing waste of gasInternal combustion piston enginesFuel supply apparatusThreaded rodMixed gas

The invention discloses a load self-adaptation gas-fired device of a gas engine. The load self-adaptation gas-fired device of the gas engine comprises an air channel, an air inlet, a gas channel, a gas inlet, a mixed gas channel, a mixed gas outlet, an upper diaphragm assembly, a lower diaphragm assembly, a gas chamber, a mixed gas chamber and an air chamber, wherein the gas chamber and the mixed gas chamber are separated by the upper diaphragm assembly, the air chamber and the mixed gas chamber are separated by the lower diaphragm assembly, the upper diaphragm assembly and a lower piston are fixedly connected into a whole through an adjusting threaded rod, the lower diaphragm assembly and an upper piston are fixedly connected into a whole through a pressure plate, metering holes are formed in a piston sleeve, and are used for input of air and gas and output of mixed gas, the metering holes are in a plugged or an open state along with movement of a piston head, and the upper diaphragm assembly and the lower diaphragm assembly can move vertically along with changes of air pressure, and drive the upper piston and the lower piston to move perpendicularly, so that the size of the air metering hole and the size of the gas metering hole are changed. The load self-adaptation gas-fired device of the gas engine can automatically provide the mixed gas with the appropriate amount according to the requirement of the gas engine, and can also automatically adjust the concentration of the mixed gas according to the requirement of load changes so that the purpose of improving power performance of the gas engine and the purpose of saving energy can be achieved.

Owner:重庆金之川动力机械有限公司

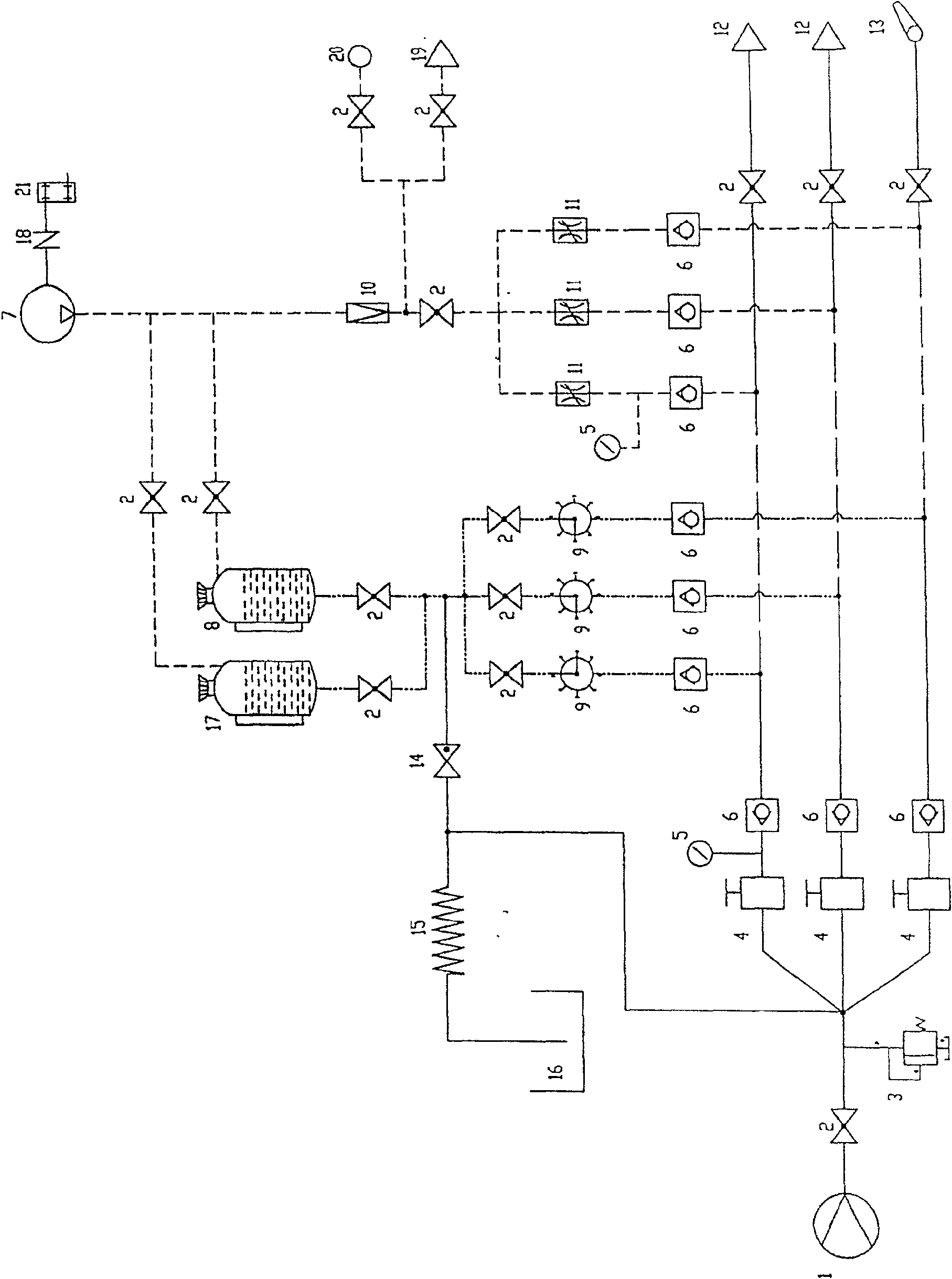

Hydrogen circulating pump test system for fuel cell engine and test method thereof

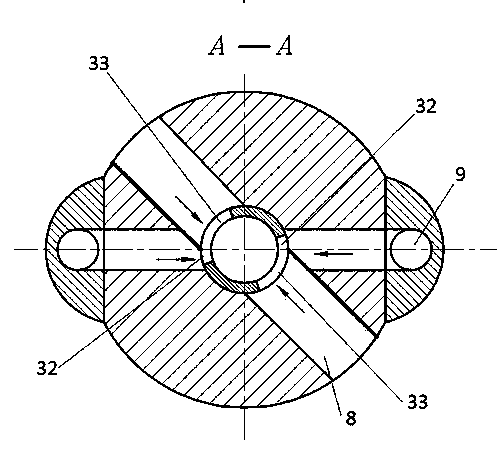

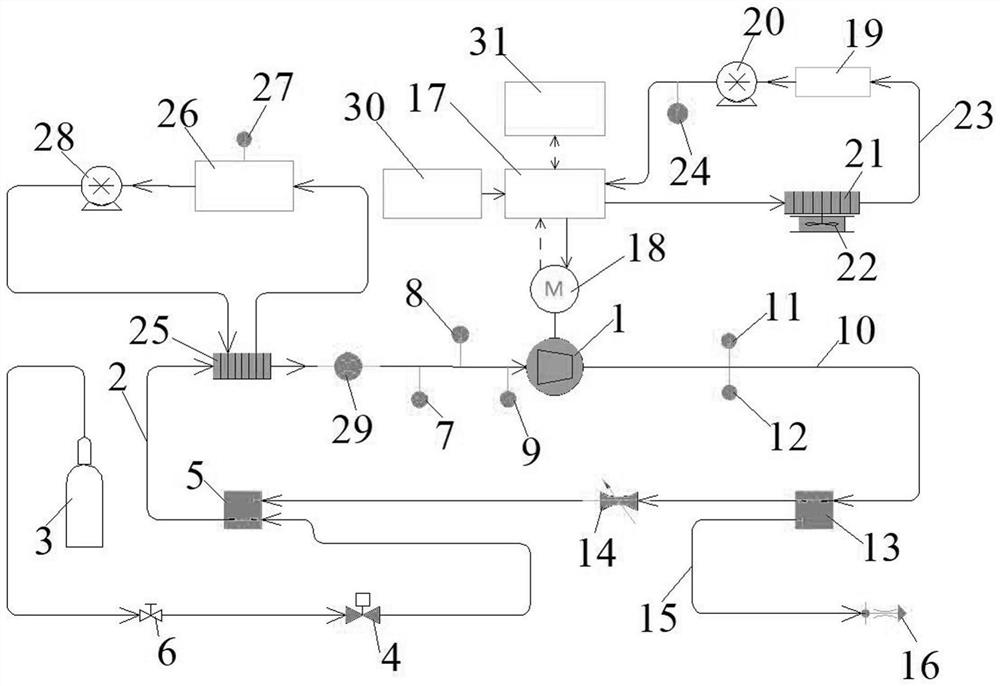

PendingCN114151321AReach a stressful environmentExtended service lifePump testingPositive-displacement liquid enginesTemperature controlFuel cells

The invention discloses a hydrogen circulating pump test system for a fuel cell engine and a test method thereof.The test system comprises a circulating pump, an inlet of the circulating pump is connected with a hydrogen source through a first pipeline, and a proportional valve, a first three-way valve and a temperature control heat exchange assembly are sequentially arranged on the first pipeline in the flow direction; a first pressure sensor, a first temperature sensor and a humidity sensor are arranged on the first pipeline at the downstream position of the temperature control heat exchange assembly, and a second temperature sensor, a second pressure sensor, a second three-way valve and a throttling valve are arranged on the second pipeline between an outlet of the circulating pump and the first three-way valve. The second temperature sensor and the second pressure sensor are located on the upstream of the second three-way valve and the throttling valve, and the second three-way valve is connected with the pressure release valve through a third pipeline. According to the test system, the circulating pump can completely simulate the running state environment of the fuel cell engine, and whether the hydrogen circulating pump for the fuel cell engine can meet the use conditions or not is evaluated under the condition of completely simulating the temperature, pressure and humidity environment conditions.

Owner:SHANGHAI CHONGSU ENERGY TECH CO LTD

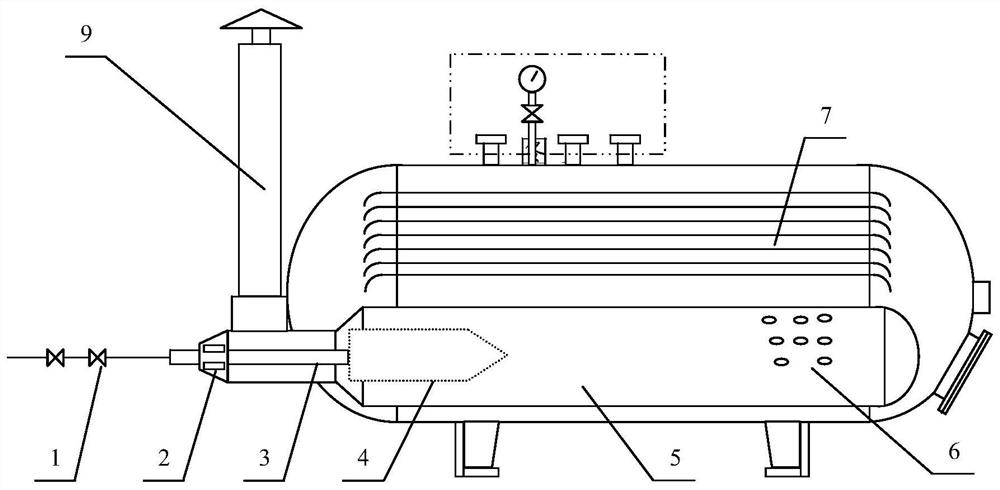

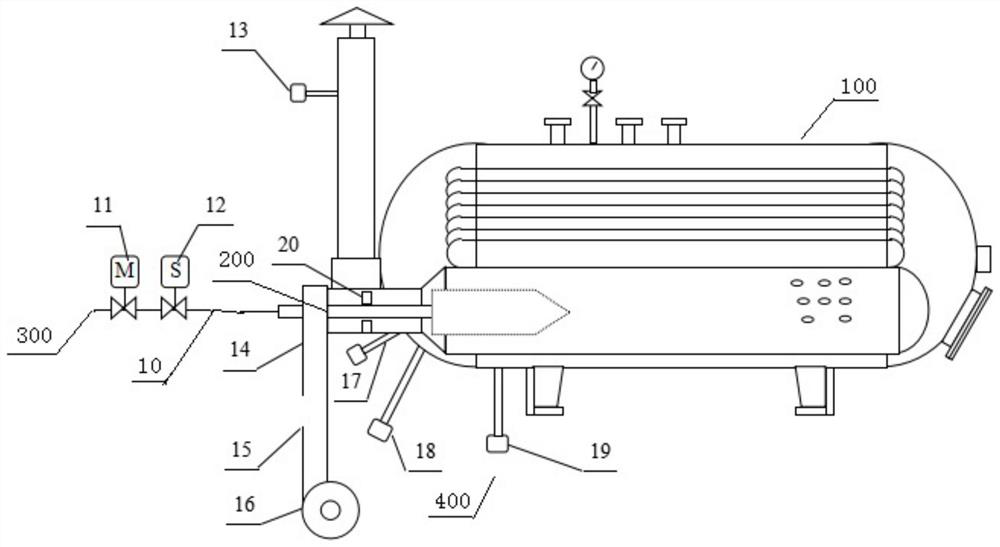

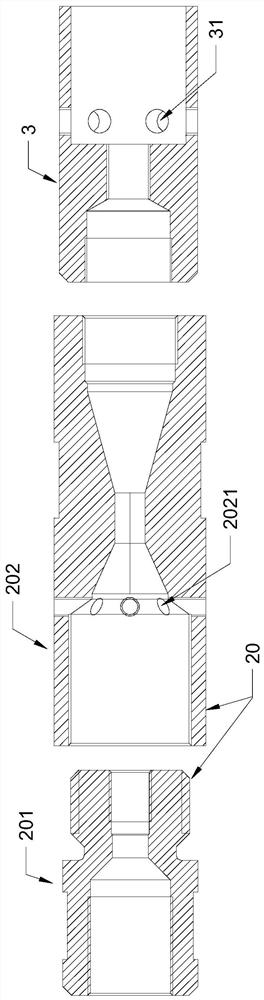

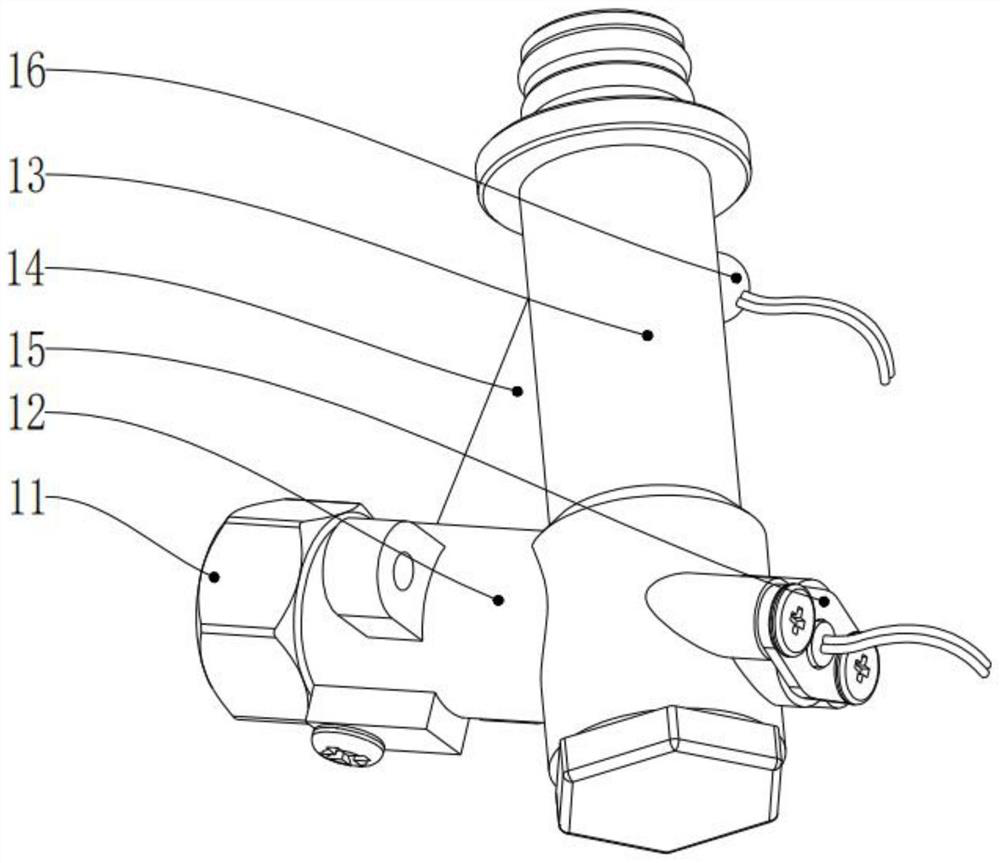

Flameout detection protection and re-ignition device for heating furnace

PendingCN111829191AEliminate accumulationEliminate deflagration accidentsFluid heatersElectric spark ignitersCombustible gasFlameout

The invention provides a flameout detection protection and re-ignition device for a heating furnace, and relates to the technical field of heating equipment. The technical problems that no detection means is used for fire extinguishing of the heating furnace, manual discovery is required and hidden dangers exist are solved. The flameout detection protection and re-ignition device for the heating furnace comprises a furnace body, a ventilation door and a chimney are arranged on the furnace body, and the flameout detection protection and re-ignition device further comprises a fire nozzle, a gassupply assembly and two fire extinguishing monitoring assemblies, wherein the fire extinguishing monitoring assemblies are installed in a premixing area and a flame area respectively; the device further comprises a sleeve type tee joint, a switching air valve and a high-pressure fan; a combustible gas sensor is arranged in the chimney; the self-pressurization high-energy high-frequency igniter isarranged in the furnace body and is close to the fire nozzle; and a flame stabilizer is arranged in the air inducing area. The flameout detection protection and re-ignition device disclosed by the invention has the characteristics of safety and capability of monitoring whether fire is extinguished in the heating furnace in real time and closing fuel gas in time or not.

Owner:王佐芹

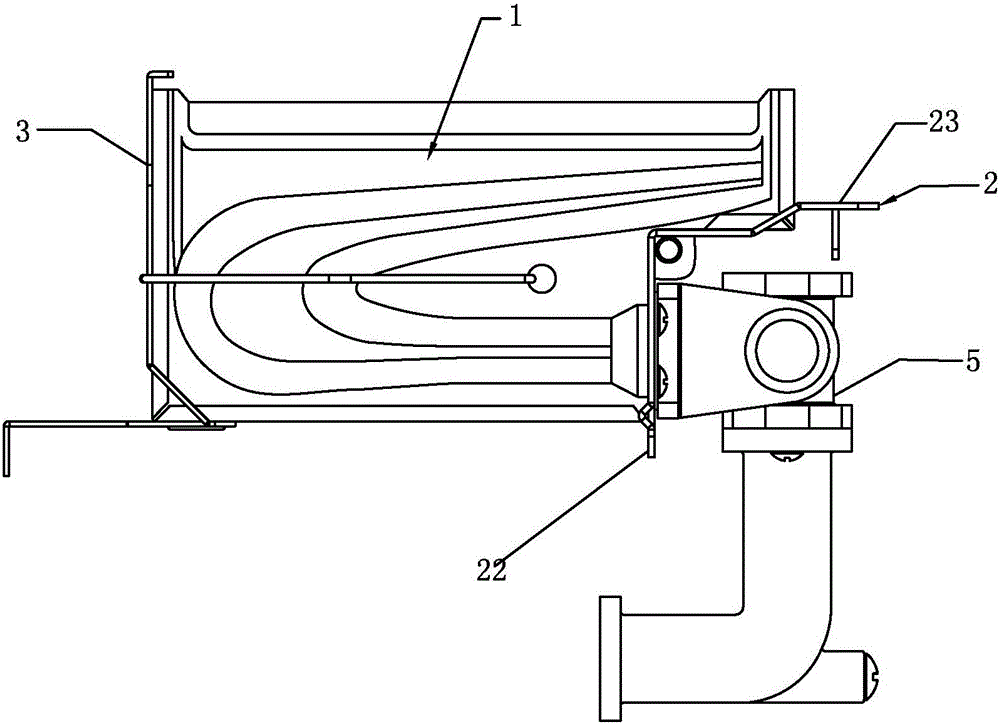

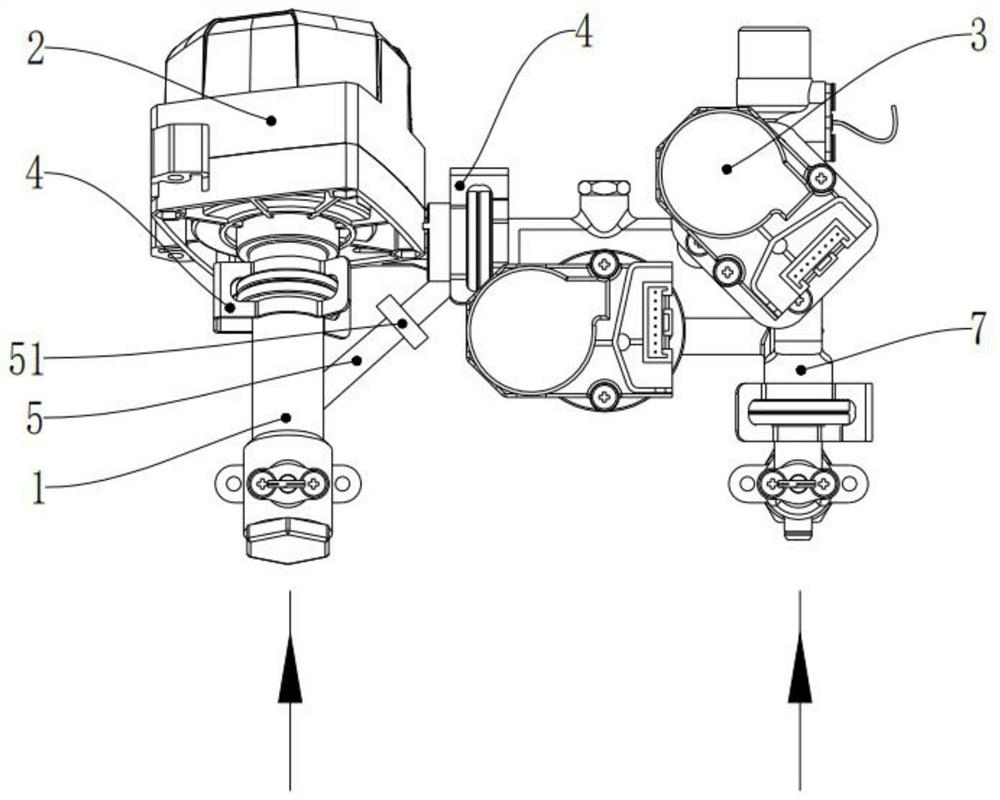

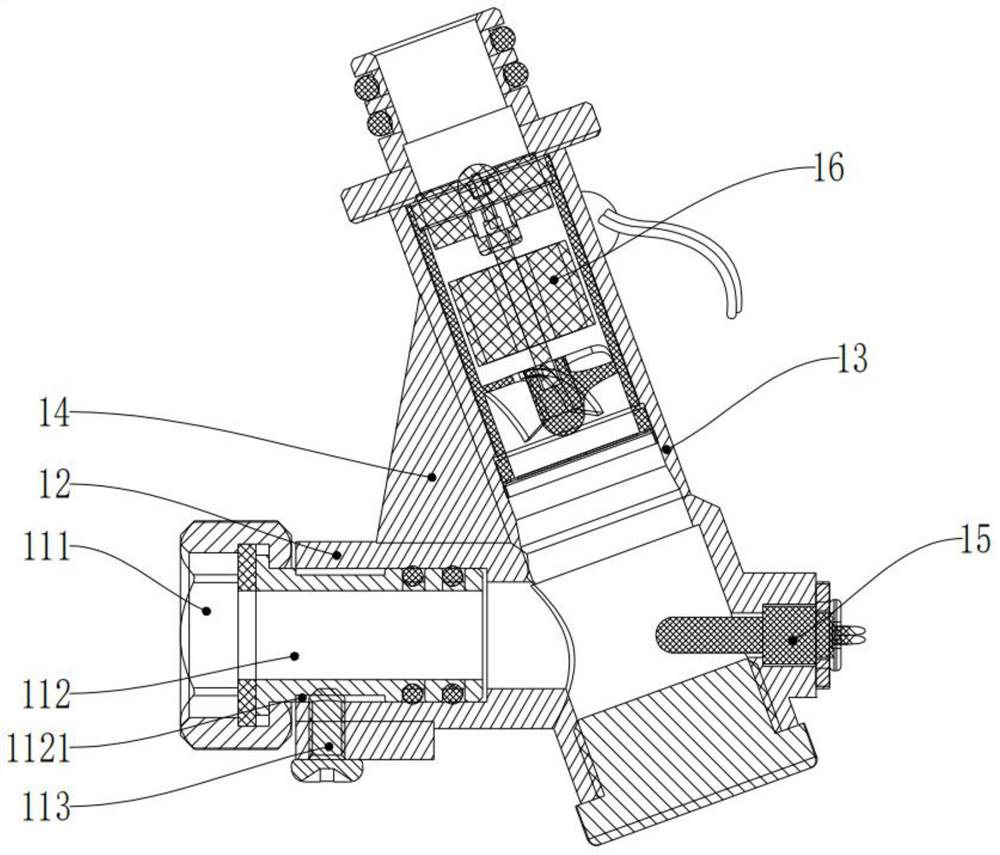

Water mixing device and shower system thereof

PendingCN112815536AImprove versatilityImprove structural stabilityFluid heatersThermodynamicsEngineering

A water mixing device comprises a shower hot water connector, a water mixing valve and a shower cold water connector. The water mixing valve is provided with a cold water pipeline, a hot water pipeline and a water mixing pipeline. The hot water pipeline is communicated with the shower hot water connector. The shower hot water connector is used for introducing hot water. The shower hot water connector comprises a first adjusting part, a hot water inlet section and a hot water outlet section. The first adjusting part is slidably installed at one end of the hot water inlet section and can stretch out and draw back in the length direction of the hot water inlet section, and the other end of the hot water inlet section fixedly communicates with the hot water outlet section. The hot water outlet section is obliquely arranged. According to the water mixing device, the installation position of the water mixing device is adjusted, the water mixing device can adapt to the installation positions of different bathroom hot water inlet pipes, and the adjustable amount is large. The other objective of the invention is to provide a shower system using the water mixing device, so that hot water can circulate in a water path, a zero cold water mode is realized, and the water pressure can be adjusted.

Gas engine load adaptive gas device

ActiveCN103511128BAdjust the size of the air intakeAdjust the mixing ratioInternal combustion piston enginesFuel supply apparatusThreaded rodMixed gas

The invention discloses a load self-adaptation gas-fired device of a gas engine. The load self-adaptation gas-fired device of the gas engine comprises an air channel, an air inlet, a gas channel, a gas inlet, a mixed gas channel, a mixed gas outlet, an upper diaphragm assembly, a lower diaphragm assembly, a gas chamber, a mixed gas chamber and an air chamber, wherein the gas chamber and the mixed gas chamber are separated by the upper diaphragm assembly, the air chamber and the mixed gas chamber are separated by the lower diaphragm assembly, the upper diaphragm assembly and a lower piston are fixedly connected into a whole through an adjusting threaded rod, the lower diaphragm assembly and an upper piston are fixedly connected into a whole through a pressure plate, metering holes are formed in a piston sleeve, and are used for input of air and gas and output of mixed gas, the metering holes are in a plugged or an open state along with movement of a piston head, and the upper diaphragm assembly and the lower diaphragm assembly can move vertically along with changes of air pressure, and drive the upper piston and the lower piston to move perpendicularly, so that the size of the air metering hole and the size of the gas metering hole are changed. The load self-adaptation gas-fired device of the gas engine can automatically provide the mixed gas with the appropriate amount according to the requirement of the gas engine, and can also automatically adjust the concentration of the mixed gas according to the requirement of load changes so that the purpose of improving power performance of the gas engine and the purpose of saving energy can be achieved.

Owner:重庆金之川动力机械有限公司

Automatic feeding stirrer with proportion being adjustable

InactiveCN108943403AAdjust the mixing ratioEasy to operateDischarging apparatusMixing operation control apparatusBiochemical engineeringGate valve

The invention discloses an automatic feeding stirrer with the proportion being adjustable. The automatic feeding stirrer comprises a base and a stirring tank. A stand column is arranged above the right side of the base. A spiral feeding mechanism is fixed to the stand column. A first discharging bin and a second discharging bin are arranged above a feeding barrel. A support is arranged at the lower side of the stirring tank, wherein the stirring tank is supported by the support. A discharging pipe is arranged at the lower side of the stirring tank. The bottom of the discharging pipe is provided with a first valve. A material containing tank is located below the discharging pipe. The stirring tank is internally provided with a rotating rod and stirring rods, wherein the stirring rods are connected with the rotating rod. The automatic feeding stirrer is provided with the spiral feeding mechanism, and materials can be better delivered to a feeding opening of a machine body; the automaticfeeding stirrer is provided with two material bins which communicate with a feeding barrel of the spiral feeding mechanism, and the two types of materials can be mixed in the feeding process; operation is more convenient to conduct, and manpower is saved; and the automatic feeding stirrer is provided with three gate valves, and the discharging speed and the mixing ratio of the two types of materials can be adjusted.

Owner:张祖红

Air proportional controller for gas burners

InactiveCN106958812BEvenly adjust the mixing ratioAdjust the mixing ratioGaseous fuel burnerElectricityProportional control

The invention relates to an air proportional control device for a gas burner, and specifically relates to an air proportional control device for a gas burner, and the air proportional control device can proportionally adjusts inflow of air with an opening of an air valve, so as to improve burning efficiency. The air proportional control device comprises a rotary knob which is configured to rotate to a required angle, a micro switch which is adjacent to the rotary knob, an air valve, a gas delivery pipe, an air flow regulator, and a mixing housing. When the rotary knob is rotated, the micro switch contacts with the inner surface of the rotary knob to connect with an electric contact. The air valve is electrically connected with the micro switch, and when the electric contacts of the micro switch are connected with each other, the air valve is opened to receive gas. The gas delivery pipe is hollow and is communicated with the air valve, and the gas delivery pipe transmits the gas flowing in the air valve. The air flow regulator is connected with the rotary knob, and when the rotary knob is rotated, flow of inflow air is proportionally regulated with flow of the gas transmitted in the air valve according to the rotation angle of the rotary knob. The mixing housing is connected with the air flow regulator, and an inner space is formed, and air and the gas transmitted from the air flow regulator and the gas delivery pipe are mixed in the inner space.

Owner:PASECO

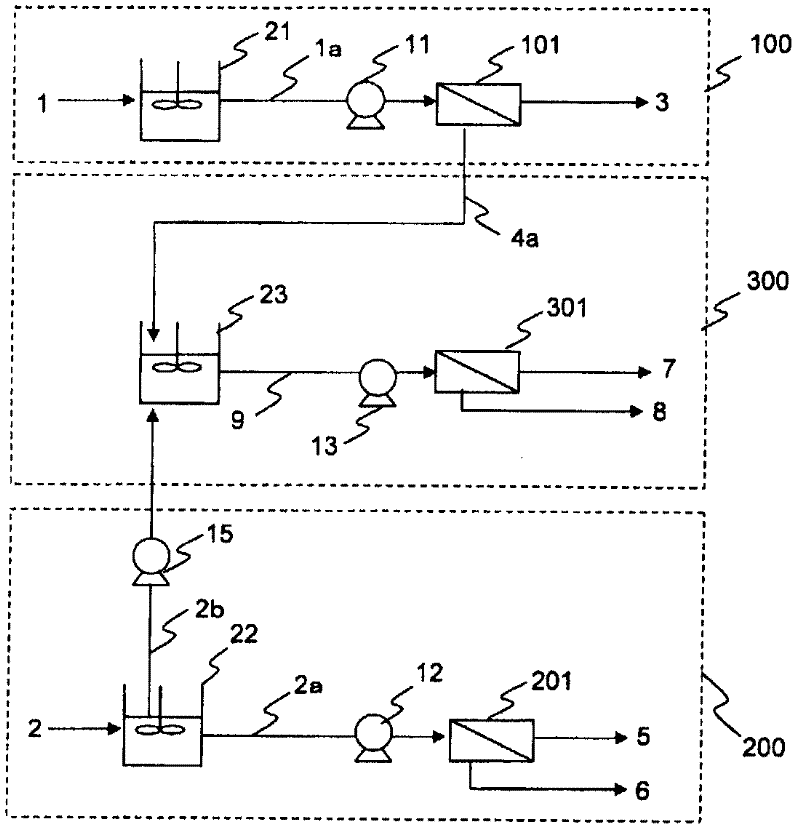

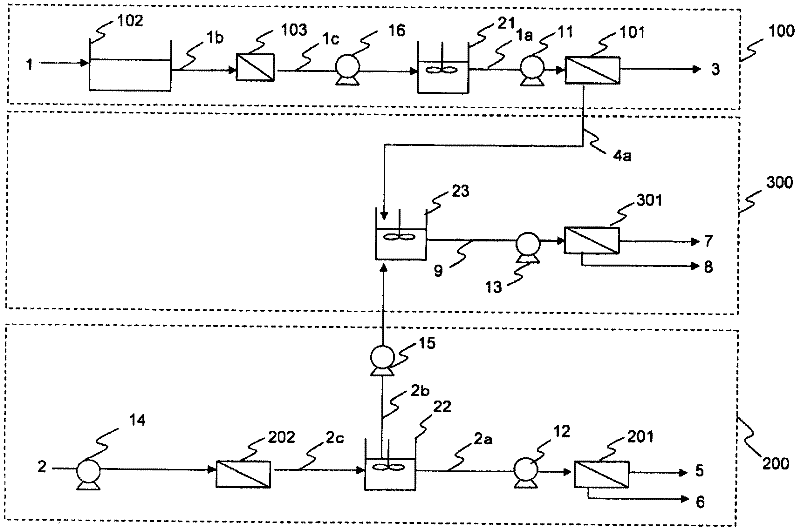

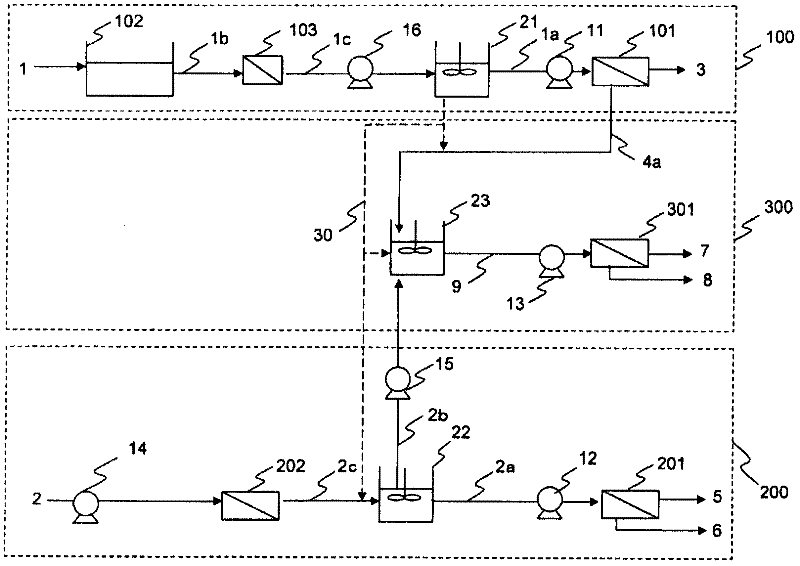

Water production system and operation method therefor

ActiveCN102596822AExtend your lifeReduce processMembranesSeawater treatmentWater productionSemipermeable membrane

Disclosed are: a water production system which is provided with a semi-permeable membrane treatment process (A100) for subjecting water (A1) to be treated to semi-permeable treatment to produce membrane permeated water (A3) and concentrated water (A), a semi-permeable membrane treatment process (B200) which is equipped with a water (B)-to-be-treated branching means for branching water (B2) to be treated into two or more kinds of water, and subjects water (B) to be treated to the semi-permeable membrane treatment to produce membrane permeated water (B5) and concentrated water (B6), and a semi-permeable membrane treatment process (C300) which is equipped with a first water mixing means for mixing water (B) to be treated, which has been branched by the water (B)-to-be-treated branching means with at least part of the concentrated water (A); produced in a semi-permeable membrane treatment step (A), and subjects the mixed water to the semi-permeable membrane treatment to produce membrane permeated water (C7) and concentrated water (C8), thereby producing flesh water from a plurality of kinds of raw water which differ in osmotic pressure utilizing complex water treatment technology in which a plurality of membrane units using a semi-permeable membrane are disposed, and which can ensure the necessary quantity of production water, and accommodate an upsized system while responding to change in the water intake quantity of raw water; and an operation method therefor.

Owner:TORAY IND INC

Constant-flow proportional air distribution ball valve

InactiveCN111637251AEasy to adjustAdjust the mixing ratioSleeve/socket jointsPlug valvesEngineeringMechanics

The invention relates to a constant-flow proportional air distribution ball valve. The constant-flow proportional air distribution ball valve comprises a valve body and a ball core rotationally arranged in the valve body, a valve body three-way channel is formed in the valve body, and a ball core three-way channel matched with the valve body three-way channel is formed in the ball core; the ball core three-way channel comprises a first ball core air inlet channel, a second ball core air inlet channel and a ball core air outlet channel which are in communication with one another; and an included angle is formed between the first ball core air inlet channel and the second ball core air inlet channel. According to the constant-flow proportional air distribution ball valve, compared with the prior art, the mixing proportion of two premixed fluids can be conveniently and linearly adjusted, and the output flow of mixed fluid can be kept stable.

Owner:SHANGHAI TIANKE CHEM INSPECTION +1

Compressed air foam fire-extinguishing apparatus

The invention discloses a pressure-air fire fighting foam device for vehicle-carrying in the fire-fighting safety facilities technique domain, which comprises the following parts: water pump, bipeltate liquid container, air compressor, wherein the air feed end of air compressor connects to admission port of bipeltate liquid container through valve controlling conduit line; the bipeltate liquid conduit line form the exit of bipeltate liquid container passing through valve controlling conduit line and pressure pipe line from water pump conduit line passing through valve controlling conduit line converge for water bipeltate mixing flow conduit line; the compressed air conduit line form air feed end of air compressor passing through valve controlling conduit line and water bipeltate mixing flow conduit line converge for compressed air bipeltate liquid conduit line connecting to fire-fighting spraying device. The invention realizes that the compressed air bipeltate mixes free, which possesses steady system pressure.

Owner:南京消防器材股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com