Water mixing valve

A valve and water mixing technology, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of low water output, low flow rate, and poor bathing of water heaters, so as to achieve comfortable water use, eliminate excessive pipe resistance, and be flexible The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

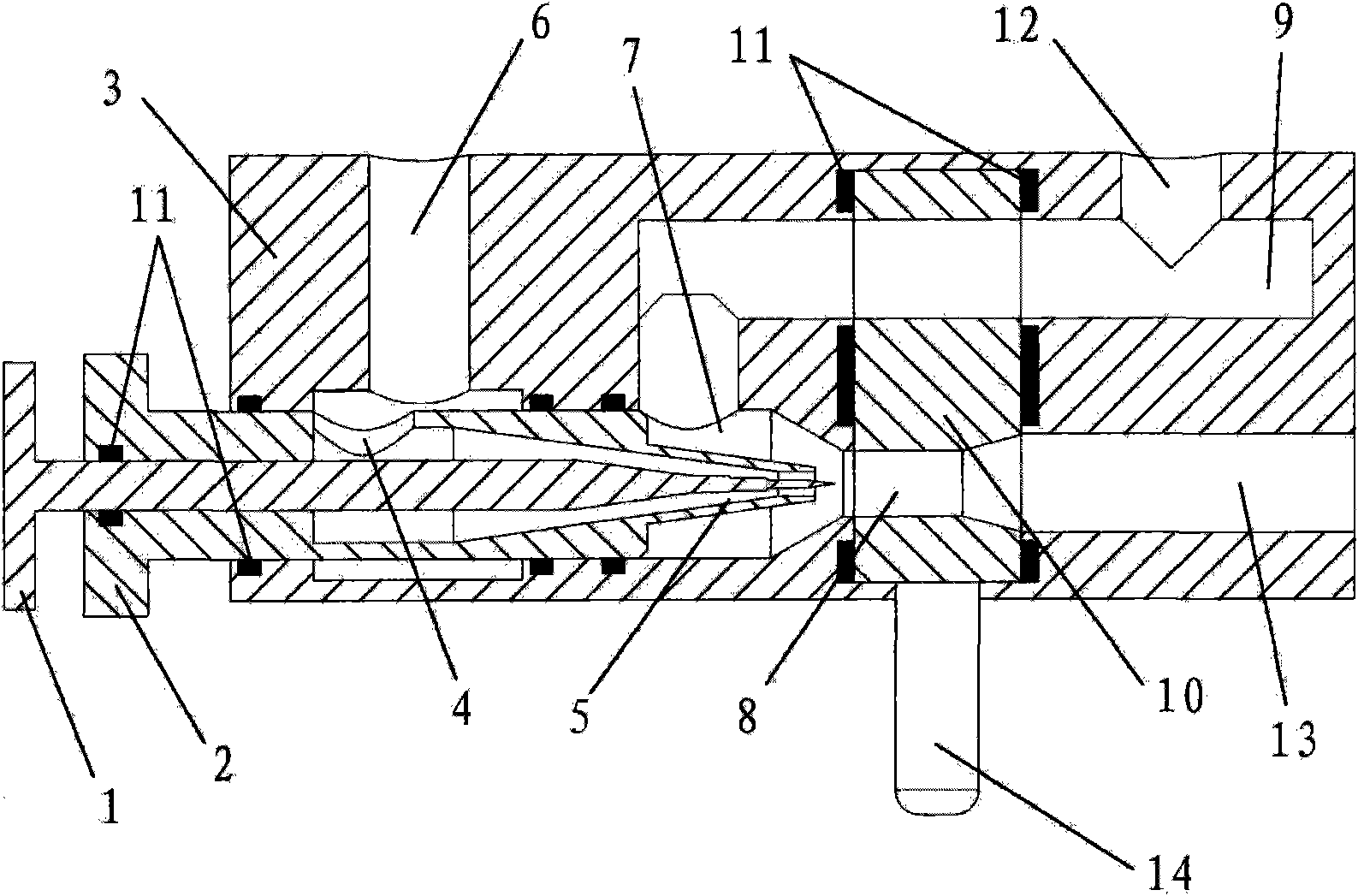

[0026] Such as figure 1 As shown, the water mixing valve of the present invention includes a valve body 3, and the valve body 3 is provided with three openings, which are respectively a valve body cold water inlet 6, a valve body hot water inlet 12, and a valve body water outlet 13. The water mixing valve also includes a nozzle 2 communicating with the cold water inlet 6 of the valve body. The nozzle 2 is provided with a nozzle cold water inlet 4 and a nozzle cold water outlet 5. By rotating the nozzle 2 axially, the relative position of the nozzle cold water inlet 4 and the valve body cold water inlet 6 can be adjusted, thereby controlling the flow through the nozzle. Invented mixing valve for cold water flow. Preferably, the nozzle 2 is roughly a cone shape, and the nozzle 2 is divided into a cone angle area and a straight section area, and the angle of the cone angle is greater than or equal to 0° and less than or equal to 90°; the length of the straight section area and t...

Embodiment 2

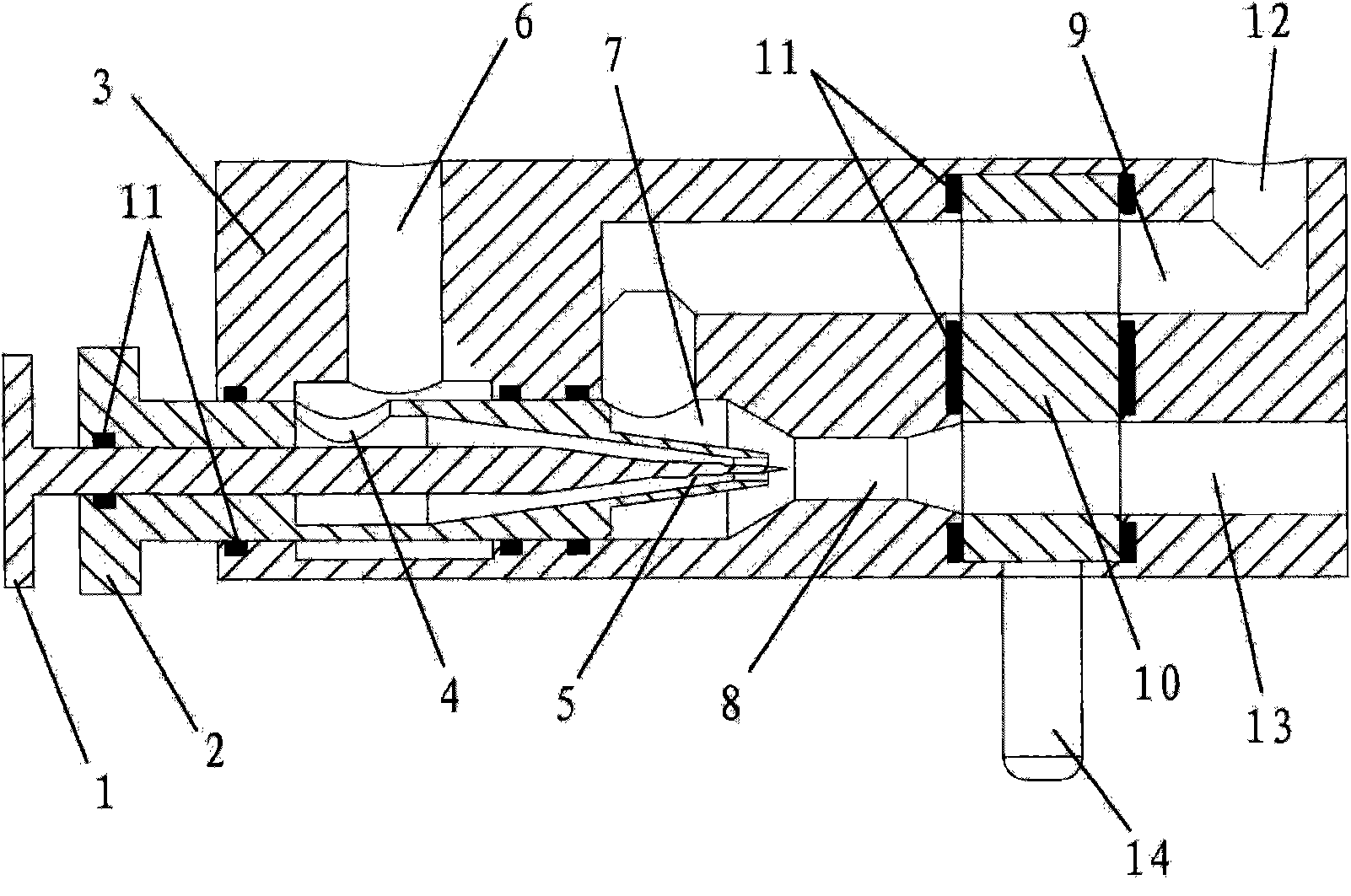

[0036] Such as figure 2As shown, the difference between this embodiment and embodiment 1 is: in embodiment 1, the double linkage valve 10 is set in the water mixing chamber 8, so the double linkage valve 10 is provided with a water mixing chamber Cavity 8 is a cavity corresponding to the shape; and in Embodiment 2, the double linkage valve 10 is set at the water outlet 13 of the valve body, so the double linkage valve 10 is provided with a common cylindrical cavity. Other technical features of embodiment 2 are the same as embodiment 1.

Embodiment 3

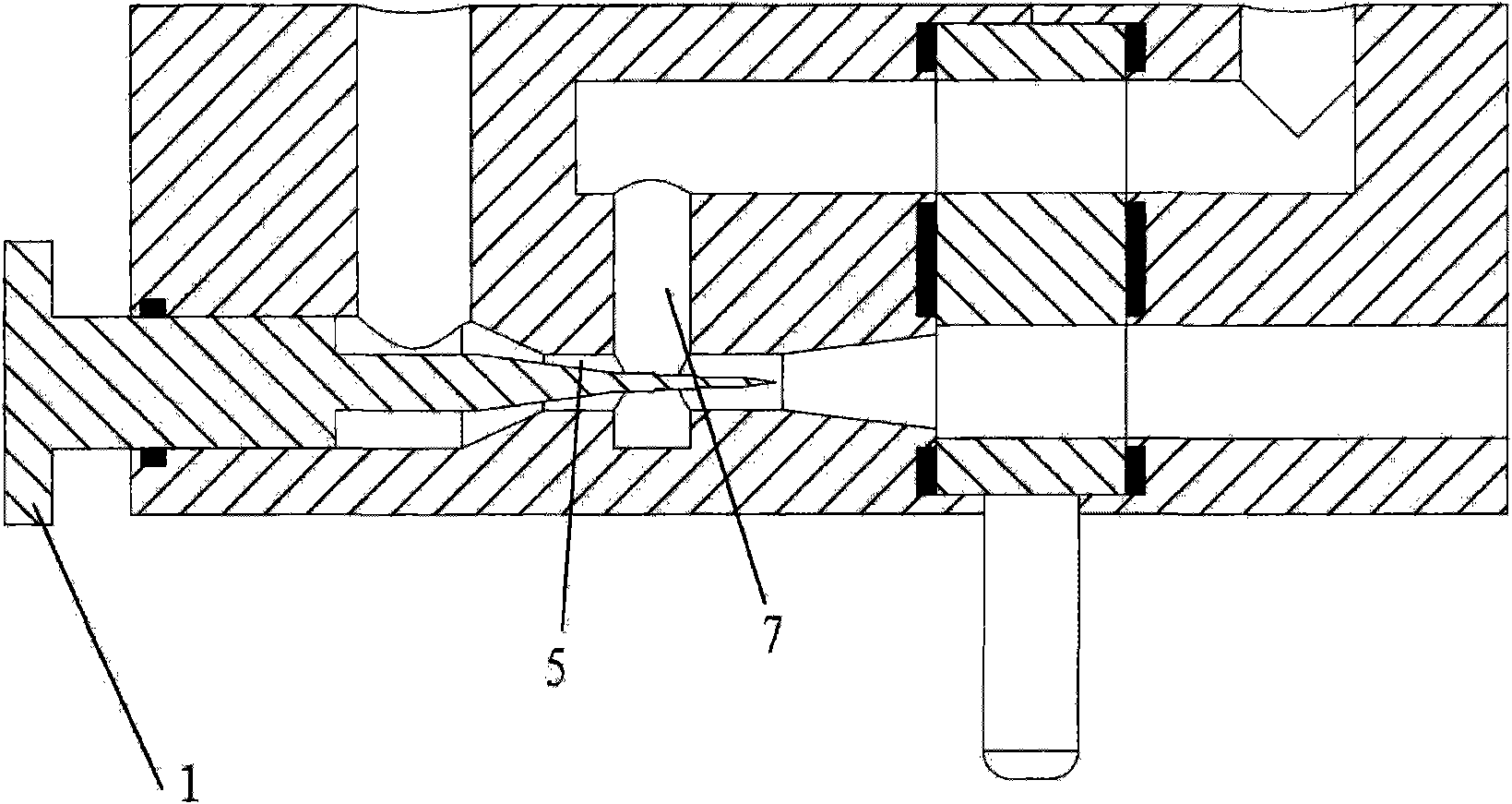

[0038] Such as image 3 As shown, the difference between this embodiment and embodiment 1 is that both the nozzle 2 and the water mixing chamber 8 are formed directly on the valve body 3, and the flow of cold water is adjusted by screwing in or out of the needle valve 1 . Other technical features of embodiment 3 are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com