Integrated oxidation ditch

An oxidation ditch and pond body technology, applied in the field of integrated oxidation ditch, can solve the problems of large area occupied by the sedimentation area, limited actual land saving area, and increased land occupation of the oxidation ditch, so as to increase the area of the sedimentation area and save the occupied area. The effect of reducing the floor area and operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

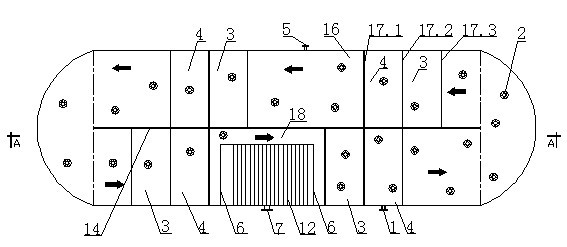

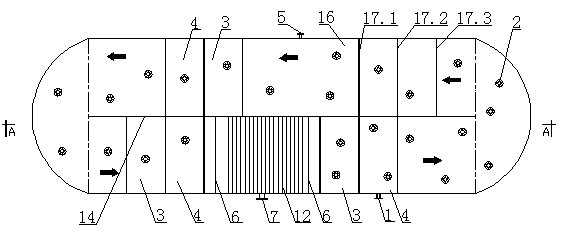

[0024] Embodiment 1: see figure 1 , 2 , The integrated oxidation ditch of the present invention is separated by a partition wall 14 to separate parallel symmetrical double ditch, with semicircular connections at both ends to form a circulating oxidation ditch. There are several groups in the single ditch, and each group is separated by interlaced partitions 17.1, 17.2 and 17.3 to form an upflow zone 3 and a downflow zone 4, followed by a biochemical zone 16, forming an oxidation ditch A 2 / O process, adding commercially available hollow wheel-shaped short tube suspension filler 2 accounting for 20% of the ditch volume in the oxidation ditch. A tubular microporous aerator 8 is installed at the bottom of the upflow zone 3, and a settling zone 12 separated by a partition wall 6 is built at the end of the oxidation ditch treatment process. The width of the settling zone accounts for 2 / 3 of the width of the oxidation ditch, leaving a circulation passage 18. There are asymmetric h...

Embodiment 2

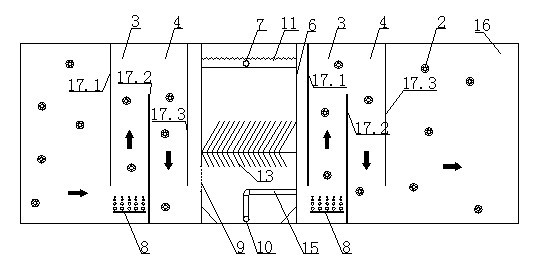

[0026] Example 2: see image 3 , 4 , as in Example 1, wherein the settling zone 12 is set at the same width as the oxidation ditch, the bottom of the settling zone is suspended, and a circulation flow channel 19 is reserved between the bottom of the settling zone, and the sedimentation and separation sludge can be discharged through the bottom mesh plate 20 and return with the circulating flow. The valve-controlled sludge discharge pipe 10 is set at the bottom of the sedimentation zone. The return flow and sludge discharge volume of sedimentation and separation sludge are controlled and distributed by 10 valves at the sludge discharge port according to the process requirements.

Embodiment 3

[0027] Embodiment 3: see Figure 5 , as embodiment 2 (also can be as example 1), below the upflow zone, downflow zone, and biochemical zone (the middle and lower part of the oxidation ditch) there is a partition plate 21 to separate the upper and lower layers, and the aeration device 8 is arranged at the bottom of the upper floor. 22 below the partition 21 is an anoxic zone, 23 behind the flow of the treatment liquid is an anaerobic zone, and 24 is an aerobic biochemical zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com