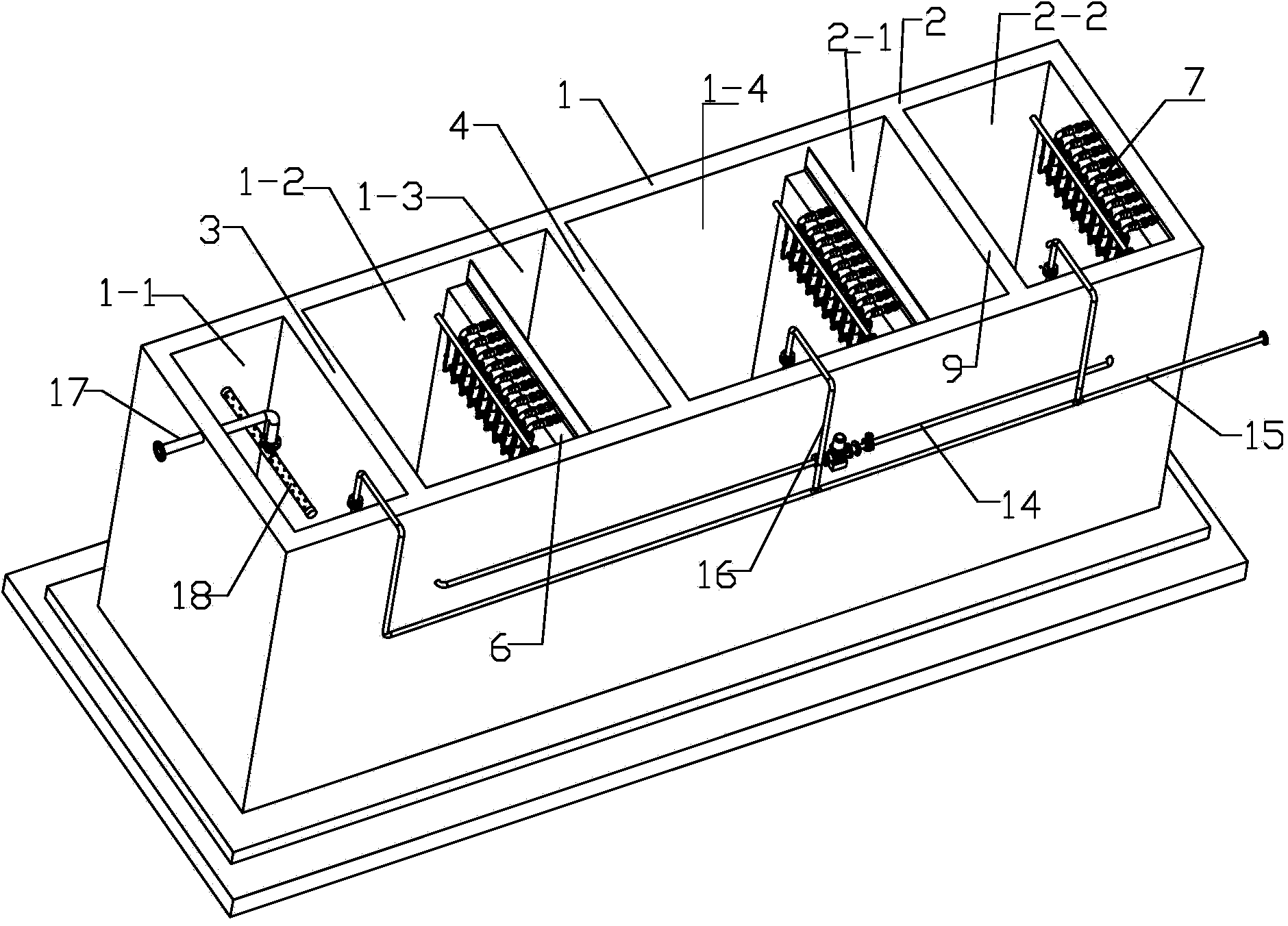

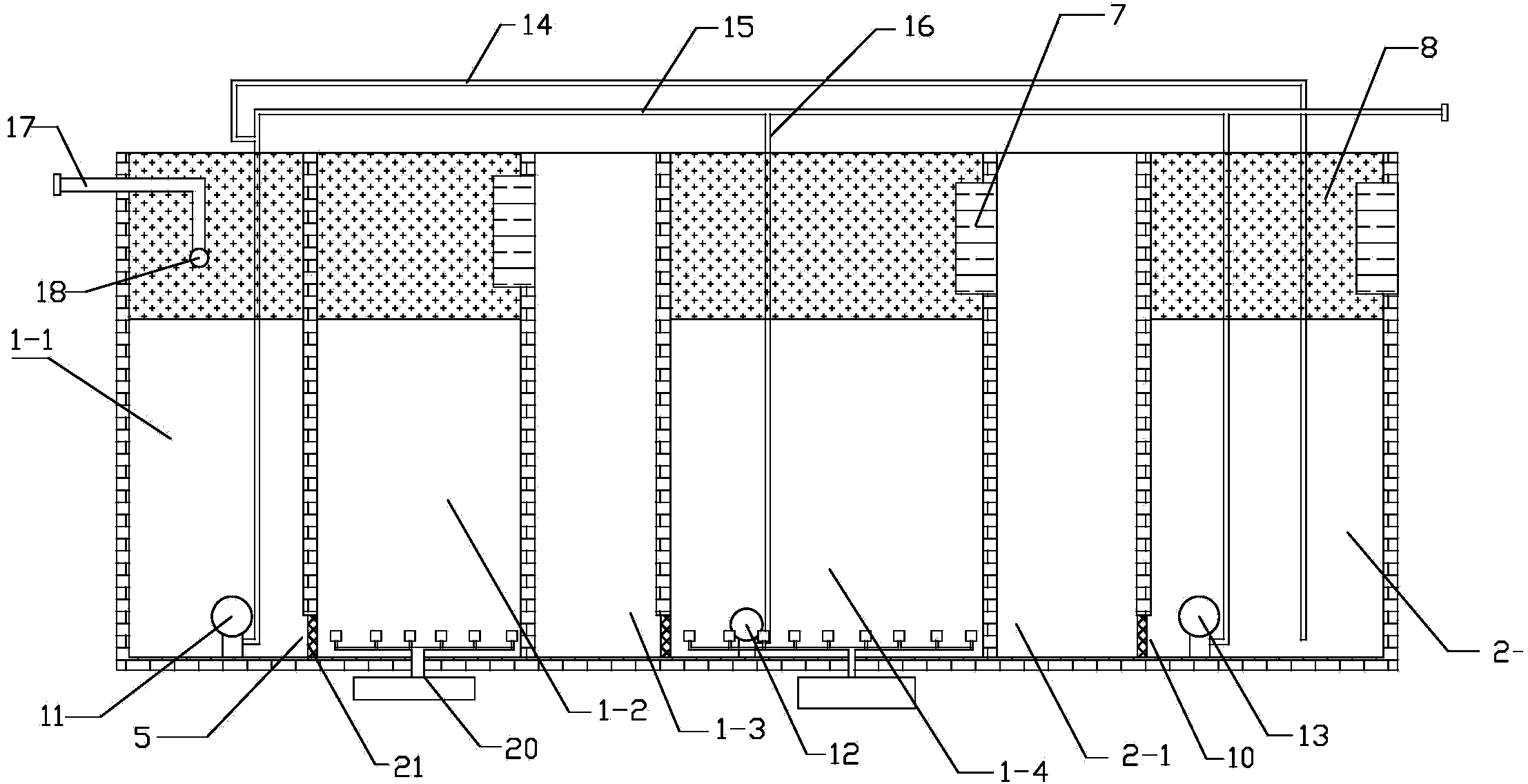

Horizontal type three-phase biological fluidized bed and sewage treatment method thereof

A biological fluidized bed, horizontal technology, applied in the field of sewage treatment process, can solve the problems of no more than 10,000 tons, shape and structure restrictions, easy blockage and hardening of biological fluidized bed, etc., to achieve the effect of increasing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

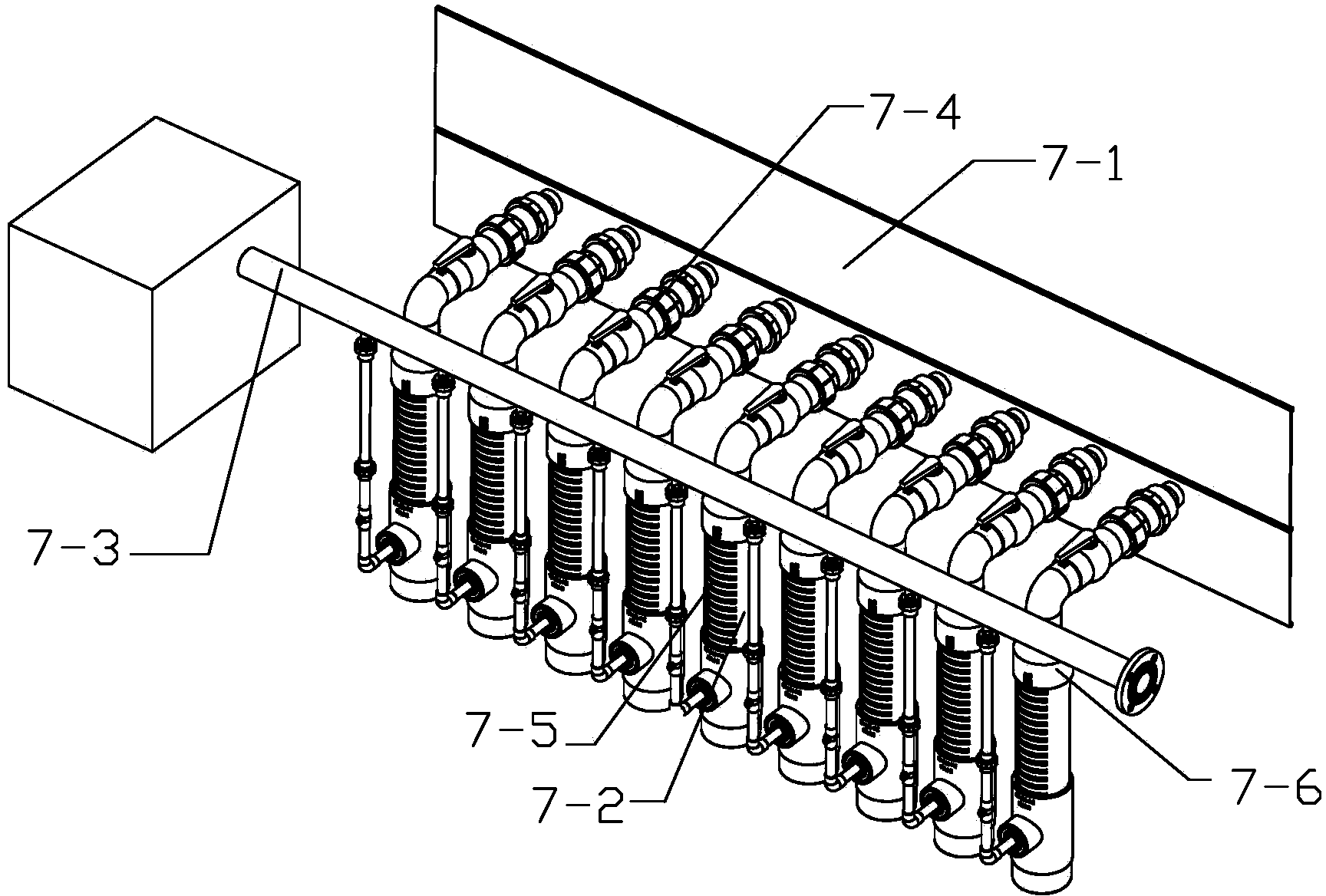

[0052] Example 1: Catering and accommodation sewage is discharged into the regulating tank of the sewage treatment station, the influent water volume is 100 tons / day, and the water quality is as follows: water temperature 8.5 ° C, pH 7.8, suspended solids, 59 mg / l; chemical oxygen demand 159 mg / l ; Biochemical oxygen demand 50mg / l; ammonia nitrogen 14.4mg / l; total phosphorus 0.81mg / l; hydraulic retention time 6 hours. The water in the regulating tank of the sewage treatment station is lifted to the horizontal three-phase fluidized bed described in the present invention by a lifting pump for purification treatment. The biological filler selected in the treatment process is produced by Dalian Shengyuan Water Treatment Equipment Development Co., Ltd. The biological filler of model BM-5 has a diameter of 25mm, a height of 8mm, and a specific gravity of 0.95g / cm 3 Above, specific surface area ≥ 500m 2 / m 3 , porosity ≥ 95%, the specific process is as follows:

[0053] (1) After ...

Embodiment 2

[0058] Embodiment 2: The catering and domestic sewage of middle school students in the student education base is discharged into the regulating pool of the sewage treatment station. The influent water volume is 300 tons / day, and the water quality is as follows: suspended solids, 242mg / l; chemical oxygen demand 286mg / l; biochemical oxygen demand Amount of 47.7mg / l; ammonia nitrogen 18.1mg / l; total phosphorus 1.58mg / l; hydraulic retention time 9 hours. After adopting the horizontal three-phase biological fluidized bed of the present invention to carry out sewage treatment, the effluent water quality is as follows: suspended solids, 37mg / l; chemical oxygen demand 47mg / l; biochemical oxygen demand 5.8mg / l; ammonia nitrogen 2.03mg / l; total phosphorus is 0.41mg / l, and the effluent reaches the first-class A standard value in Table 1 of the National GB18919-2002 "Pollutant Discharge Standards for Urban Sewage Treatment Plants".

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com