Slurry water flocculation treatment mixer and its application

A coal slime water and mixer technology, applied in the field of water treatment, can solve the problems of high disturbance intensity, low mechanical strength, prolong disturbance time, etc., and achieve the effect of wide popularization and application prospect, improving flocculation effect, and perfecting technological process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

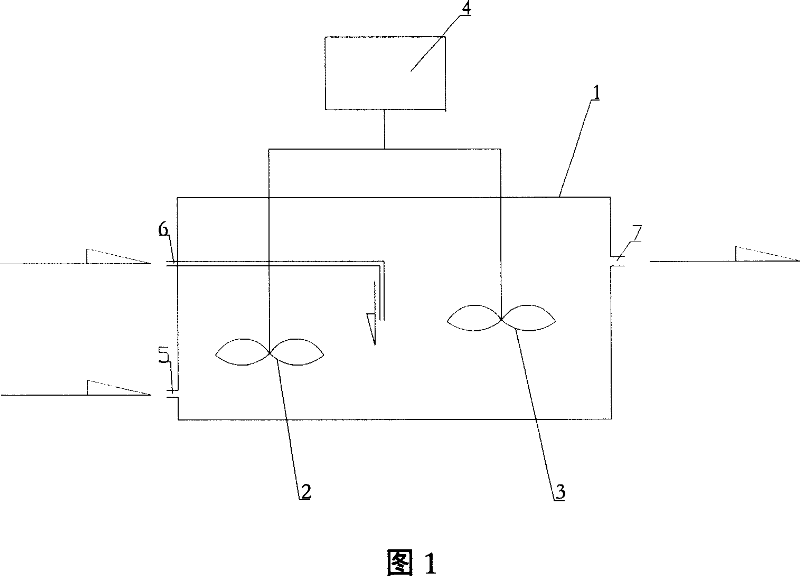

[0017] As shown in Figure 1, the mixer of the present invention includes a housing 1, which has a first-stage impeller 2 and a second-stage impeller 3, and the impellers 2 and 3 are driven by a motor 4; one side of the housing is provided with a coal slime water inlet 5 and flocculant dosing port 6, the other side of the shell is provided with a slime water outlet 7, the primary impeller 2 is close to the coal slime water inlet 5, the second impeller 3 is close to the coal slime water outlet 7, and the flocculant dosing port 6 passes through The pipeline is connected between the first-stage impeller 2 and the second-stage impeller 3 . The coal slime water inlet 5 is near the lower end of the mixer, and the coal slime water outlet 7 is near the upper end of the mixer.

Embodiment 2

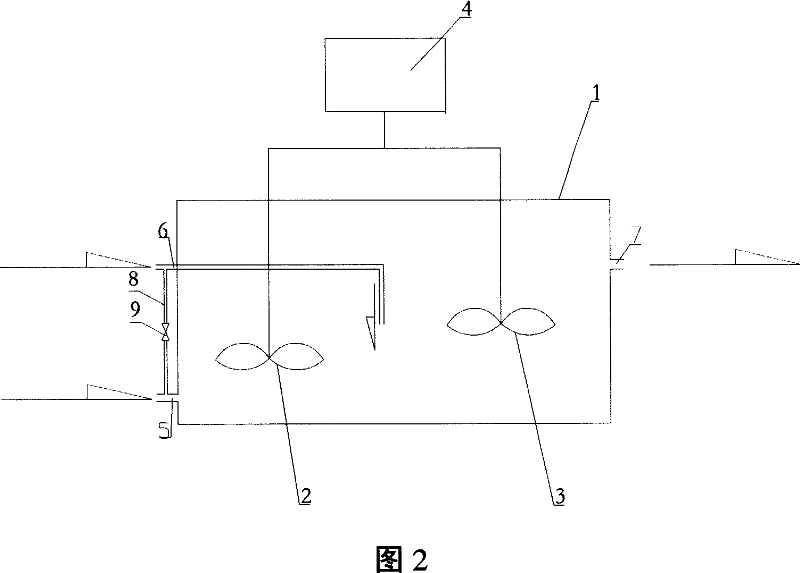

[0019] As shown in Figure 2, on the basis of embodiment 1, the present invention is provided with a pipeline 8 to link to each other with the coal slime water inlet place at the flocculant dosage opening place, is provided with a valve 9 on the pipeline, can regulate to enter coal slime water inlet like this the amount of flocculant. At the same time, according to the different properties of the slime water, it is convenient to change the dosing ratio of the flocculant and the partial mixing of the slime water. Embodiment 3 Determination of fractional administration and ratio thereof

Embodiment 3

[0019] As shown in Figure 2, on the basis of embodiment 1, the present invention is provided with a pipeline 8 to link to each other with the coal slime water inlet place at the flocculant dosage opening place, is provided with a valve 9 on the pipeline, can regulate to enter coal slime water inlet like this the amount of flocculant. At the same time, according to the different properties of the slime water, it is convenient to change the dosing ratio of the flocculant and the partial mixing of the slime water. Embodiment 3 Determination of fractional administration and ratio thereof

[0020] In this example, the design flow rate of the mixer is 1500m 3 / h, the impeller speed is controlled at 85rpm, the mixing time is 10s, and the power of the motor is 2.2KW. The flocculant is NPAM-7080 (Taiyuan Haichao Water Technology Co., Ltd.), dosage: 1mL (83.3g / t. coal); ss means initial slime water concentration (g / L); The first dosage refers to the amount of flocculant that enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com