Constant-flow proportional air distribution ball valve

A constant flow, proportional technology, applied in the field of constant flow proportional ball valve, can solve the problems of inconvenient adjustment, complicated circuit, cumbersome structure, etc., and achieve the effect of convenient adjustment and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

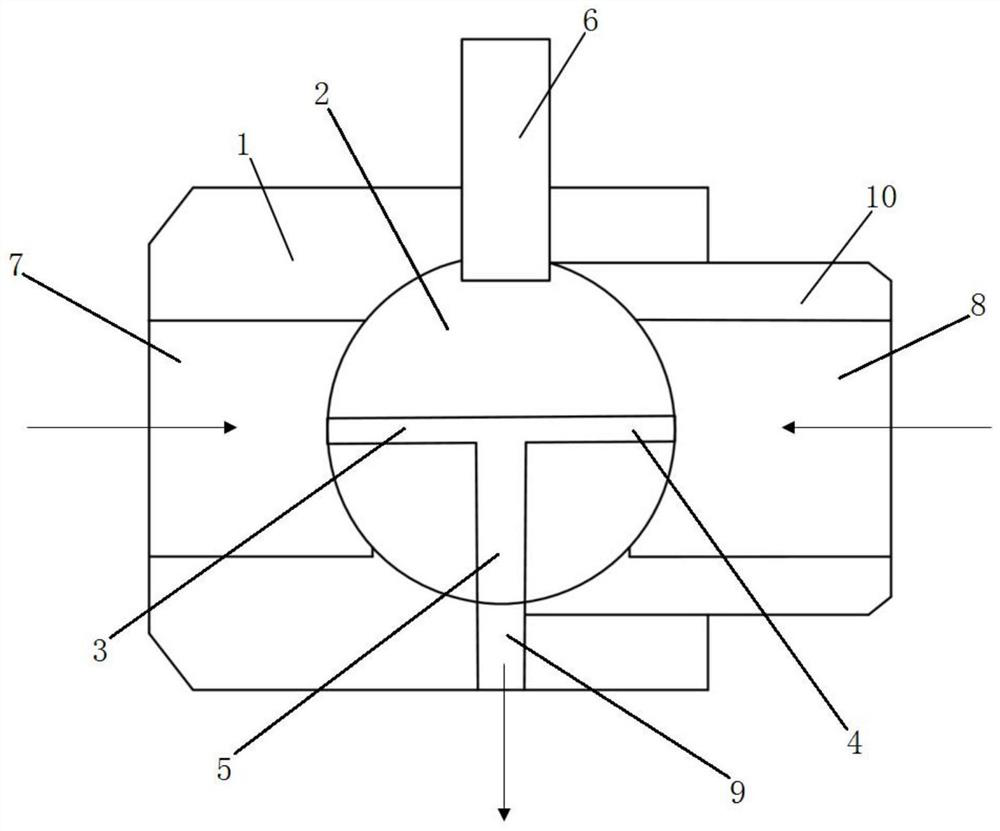

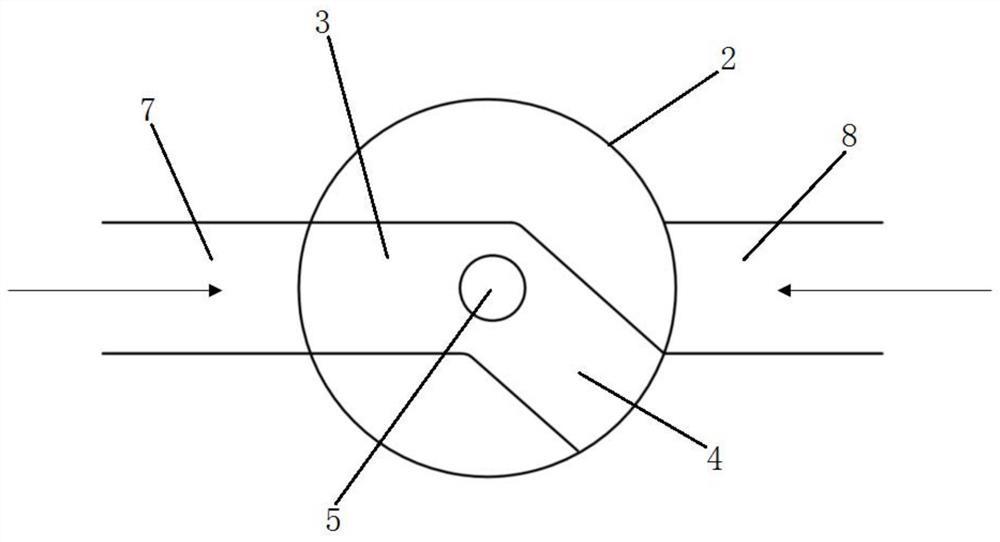

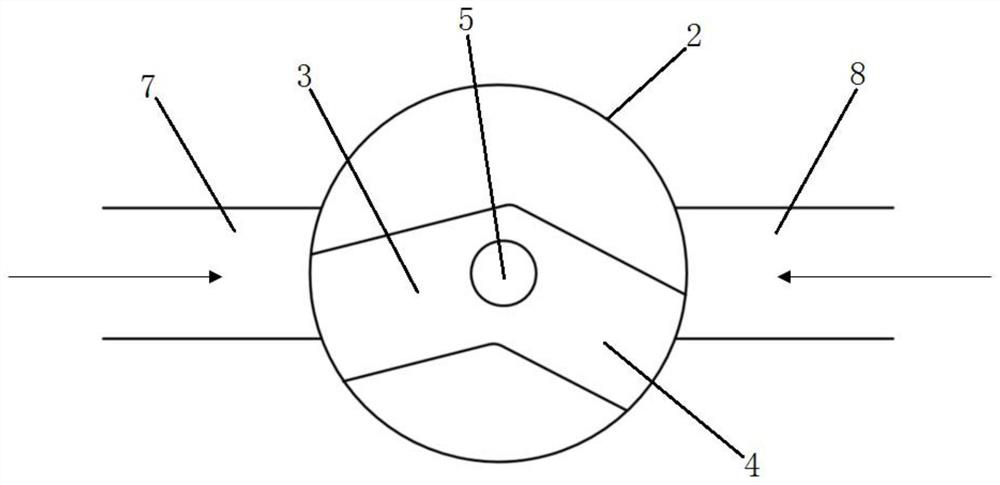

[0032] Such as figure 1 A fixed-flow proportional balloon valve shown includes a valve body 1 and a ball core 2 rotatably arranged inside the valve body 1. The valve body 1 is provided with a three-way channel for the valve body, and the ball core 2 is provided with a valve body The ball core three-way channel adapted to the three-way channel includes a first ball core air inlet channel 3, a second ball core air inlet channel 4, and a ball core air outlet channel 5 that are connected to each other. The first ball The core intake passage 3 and the second spherical core intake passage 4 form an angle with each other.

[0033] The valve body 1 is provided with a ball core installation cavity, and the ball core 2 is rotatably arranged in the ball core installation cavity. An adjusting handle 6 is inserted into the valve body 1, and the bottom of the adjusting handle 6 is connected with the top of the ball core 2.

[0034] The three-way passage of the valve body includes a first valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com