Full-automatic integrated static mixing and filling machine

A static mixing device and static mixing technology, which are applied to the safety devices and packaging of liquid bottling and perfusion devices, can solve the problems of cumbersome process, low control precision and low work efficiency, and achieve high control precision and improve production efficiency. , the effect of small production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

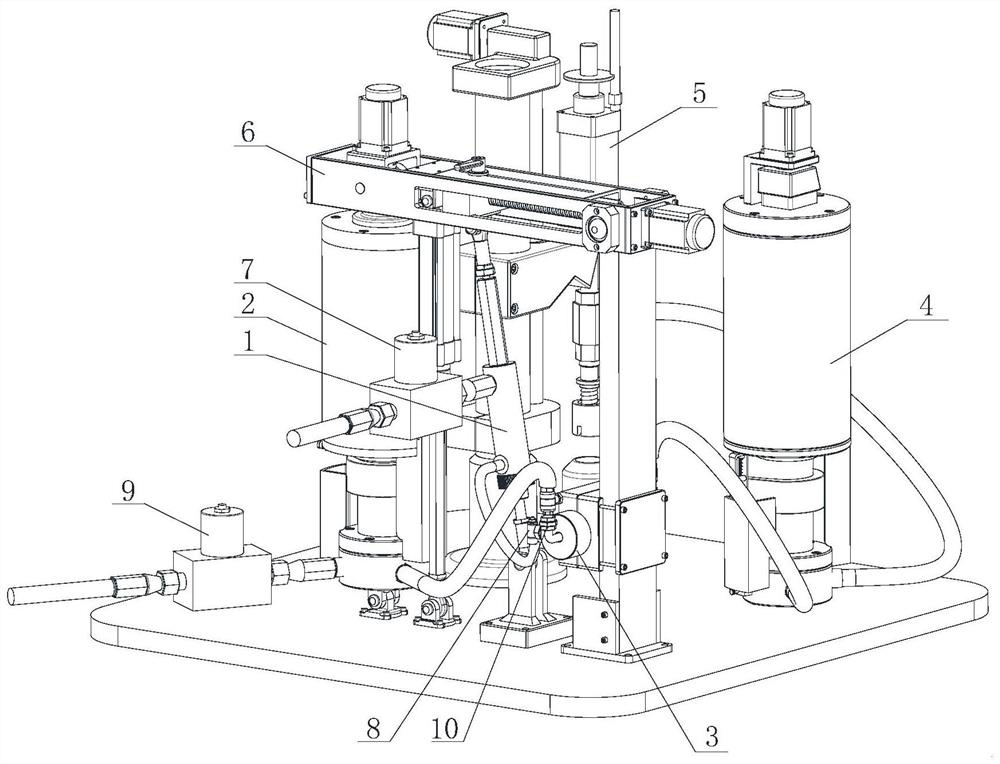

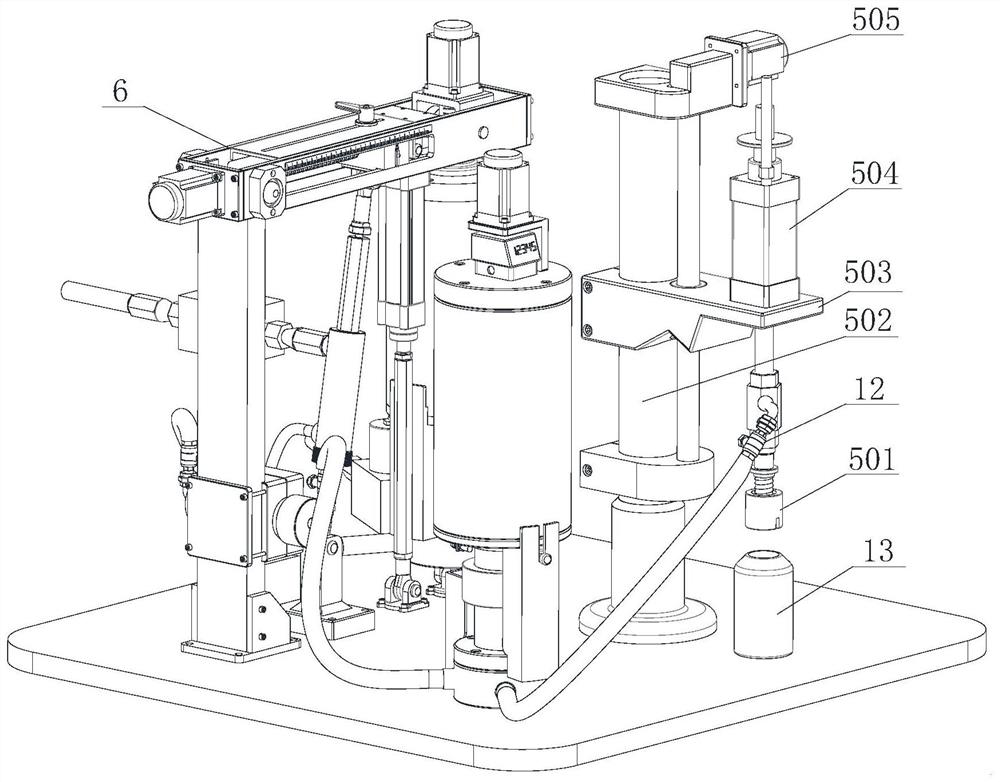

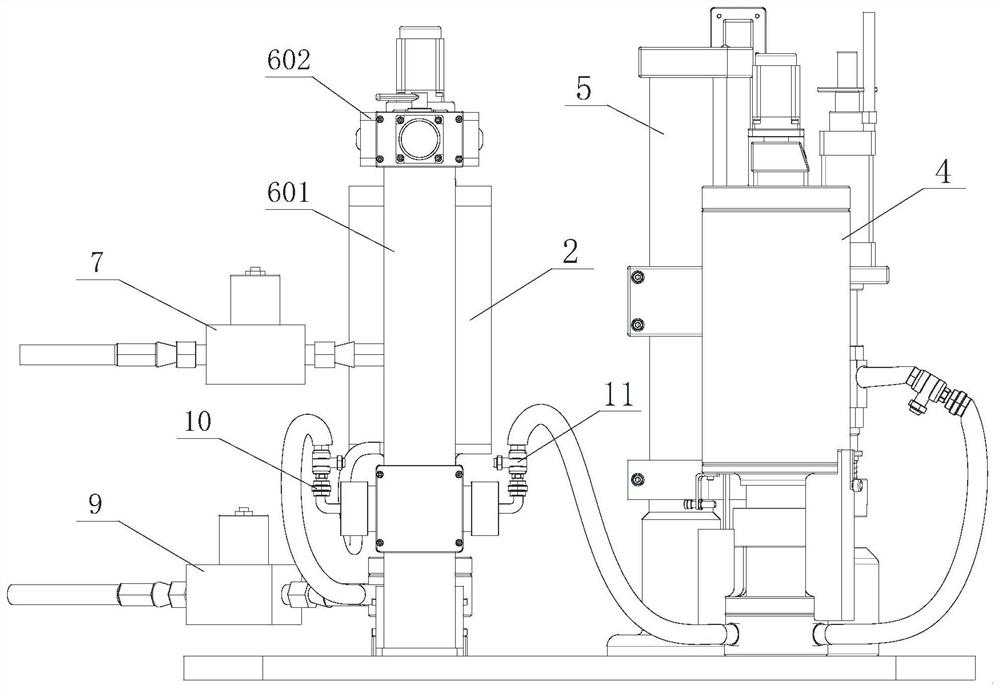

[0027] see Figure 1 to Figure 4 , fully automatic integrated static mixing filling machine, including A material quantitative extrusion device 1, B material quantitative extrusion device 2, static mixing device 3, mixed material constant pressure storage tank 4, filling execution The device 5 and the pressing device 6; the pressing device 6 includes a column 601, a pressing beam 602, and a reciprocating actuator 603; the column 601 is fixed on the worktable; the pressing beam 602 is hinged to the column 601 Above; the lower end of the reciprocating motion actuator 603 (in this embodiment, the reciprocating motion actuator 603 is a cylinder) is hinged to the work surface, and the upper end is hinged to the pressing beam 602, which can drive the pressing beam 602 to swing relative to the column 601; The upper ends of the A material quantitative extrusion device 1 and the B material quantitative extrusion device 2 are hinged with the down-pressing crossbeam 602, and the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com