Asphalt steam thermal cycle foaming system

A foaming system and heat cycle technology, applied in the field of asphalt production and processing, can solve the problems of waste of resources, imbalance of asphalt and water ratio, difficulty in controlling the amount of water injection, etc., and achieve the effect of improving utilization rate and quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

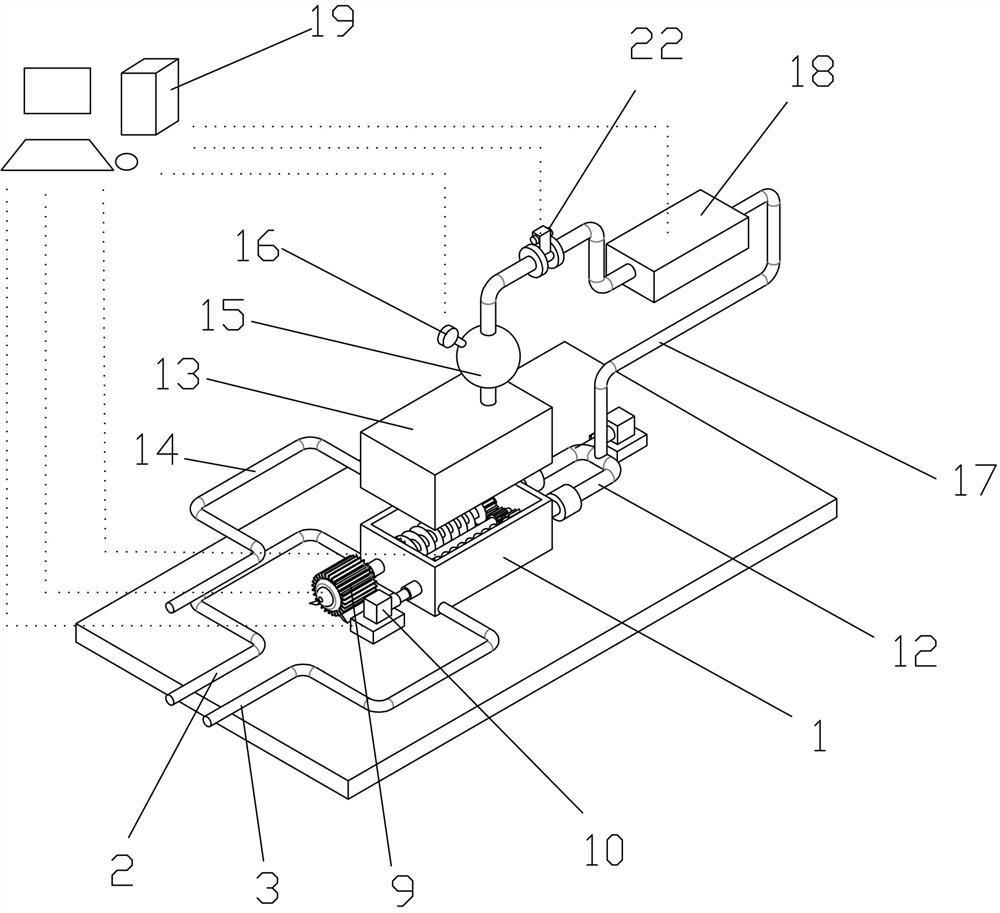

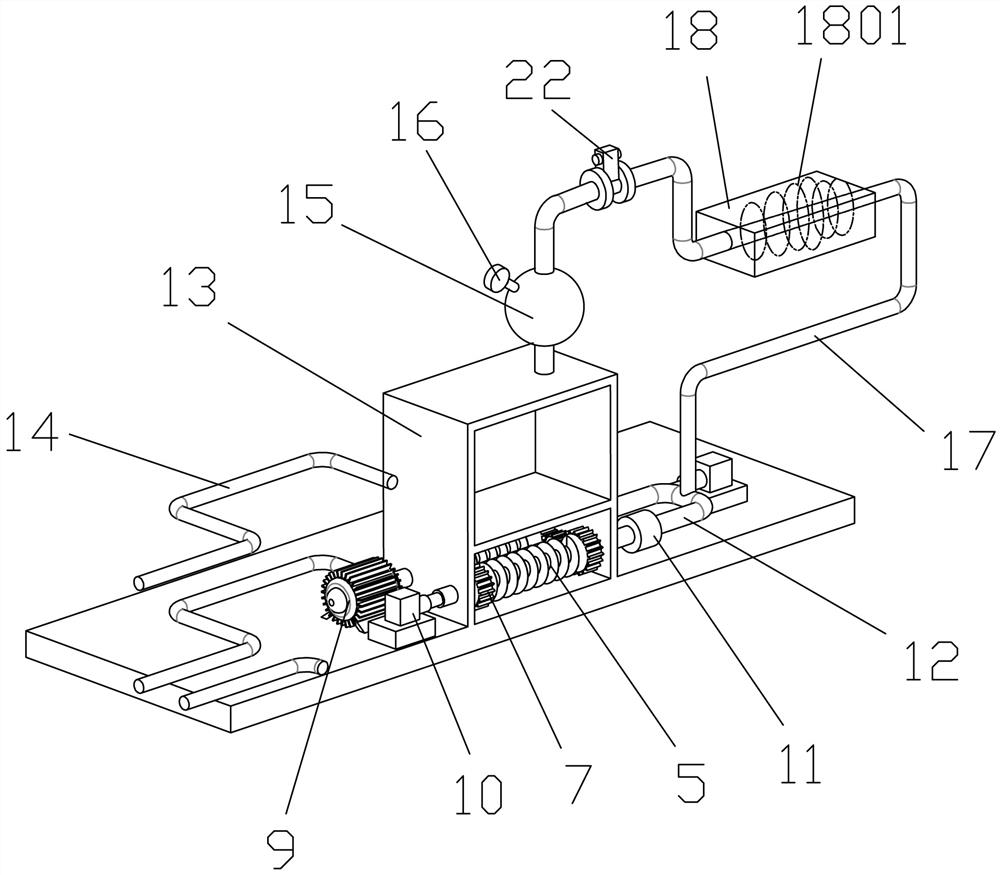

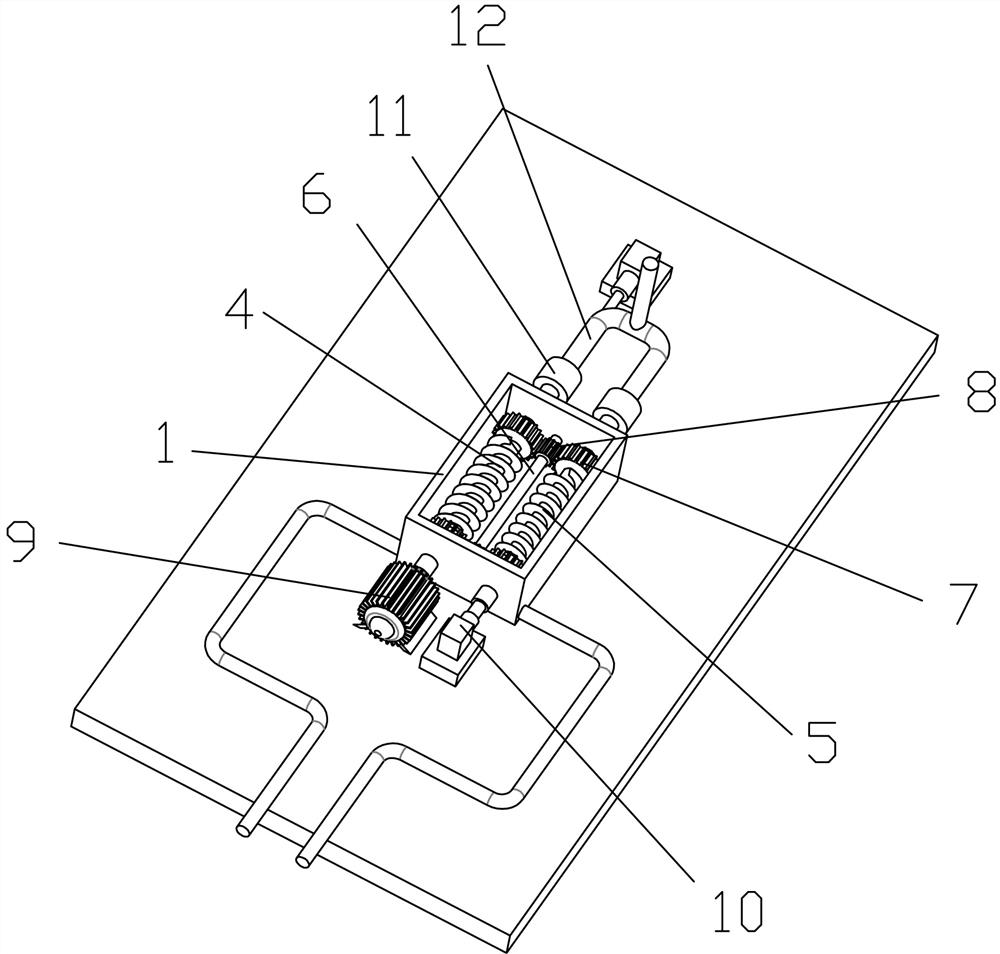

[0031] Such as Figure 1 to Figure 3 As shown, a bitumen steam thermal cycle foaming system includes a stirring device part and a steam device part, the stirring device includes a stirring box 1, and the stirring box 1 is provided with a first stirring rod 4 and a second stirring rod 5 for stirring Asphalt, the center line of the mixing tank 1 is provided with a connecting rod 6, the first stirring rod 4 and the second stirring rod 5 are respectively arranged on both sides of the connecting rod 6 in a symmetrical distribution, and the front and rear ends of the stirring rod are fixedly connected with transmission gears 7, The two ends of the connecting rod 6 are fixedly connected with a driven gear 8, the driven gear 8 drives the connecting rod 6 to rotate around the axis of the connecting rod 6, the transmission gear 7 drives the stirring rod to rotate around the axis of the stirring rod, and the first stirring rod 4 , between the second stirring rod 5 and the connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com