Feed preparing equipment

A feed and equipment technology, applied in the field of feed preparation equipment, can solve the problems of large floor space, low automation level, and increase the complexity of the process, and achieve the effect of saving plant space and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

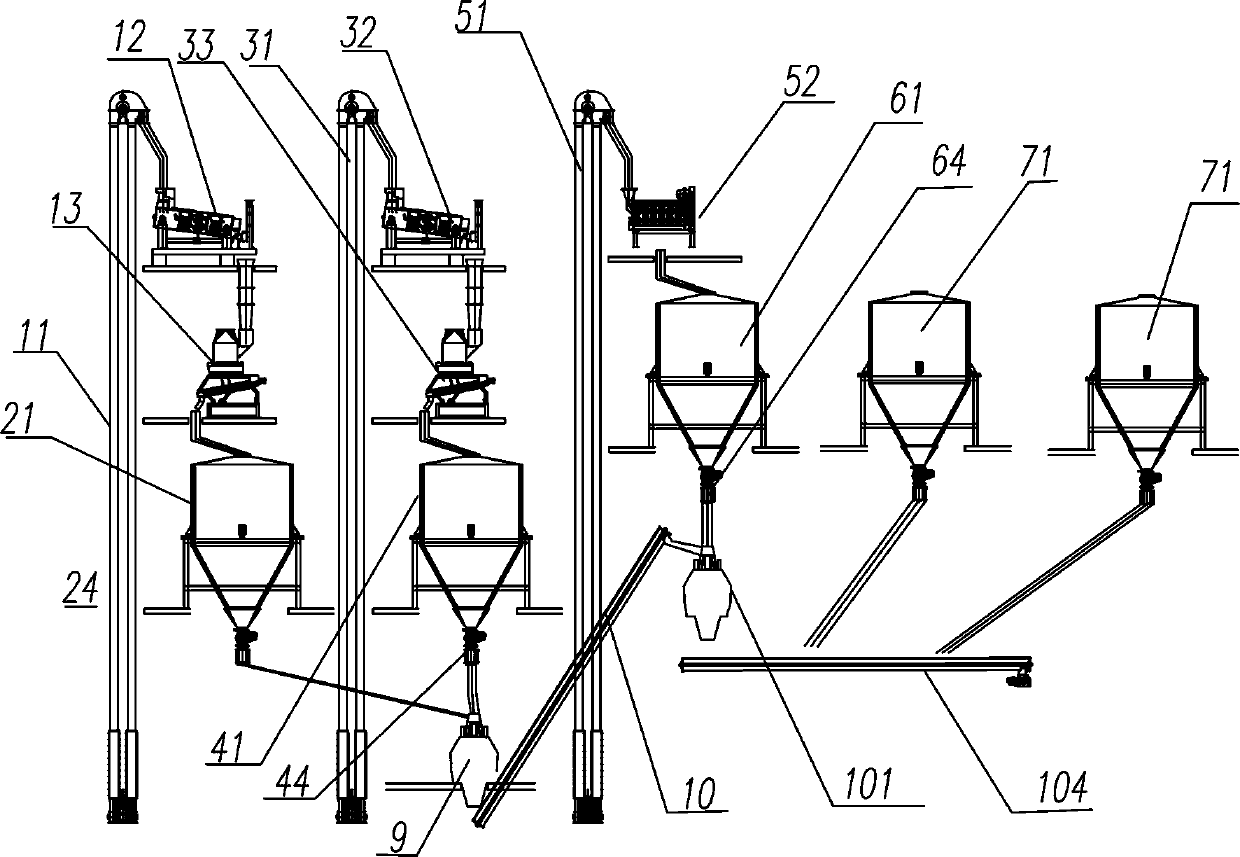

[0031] like figure 1 Among them, a kind of feed preparation equipment comprises corn flour purifying device 1, corn flour adding device 2, rice sugar powder purifying device 3, rice sugar powder adding device 4, fish bone meal purifying device 5, fish bone meal adding device 6, preferably, feed The preparation also includes a trace ingredient adding device 7;

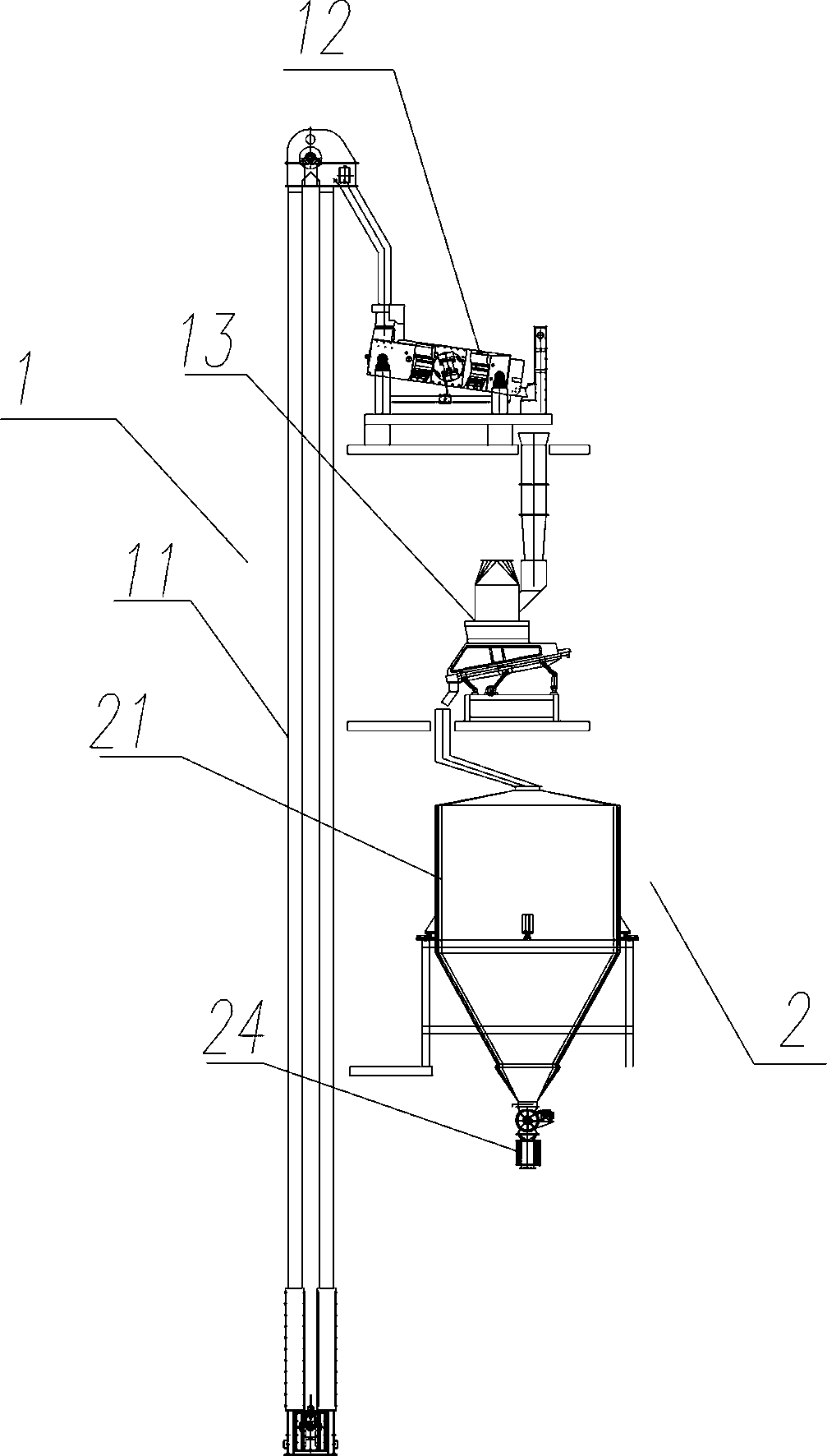

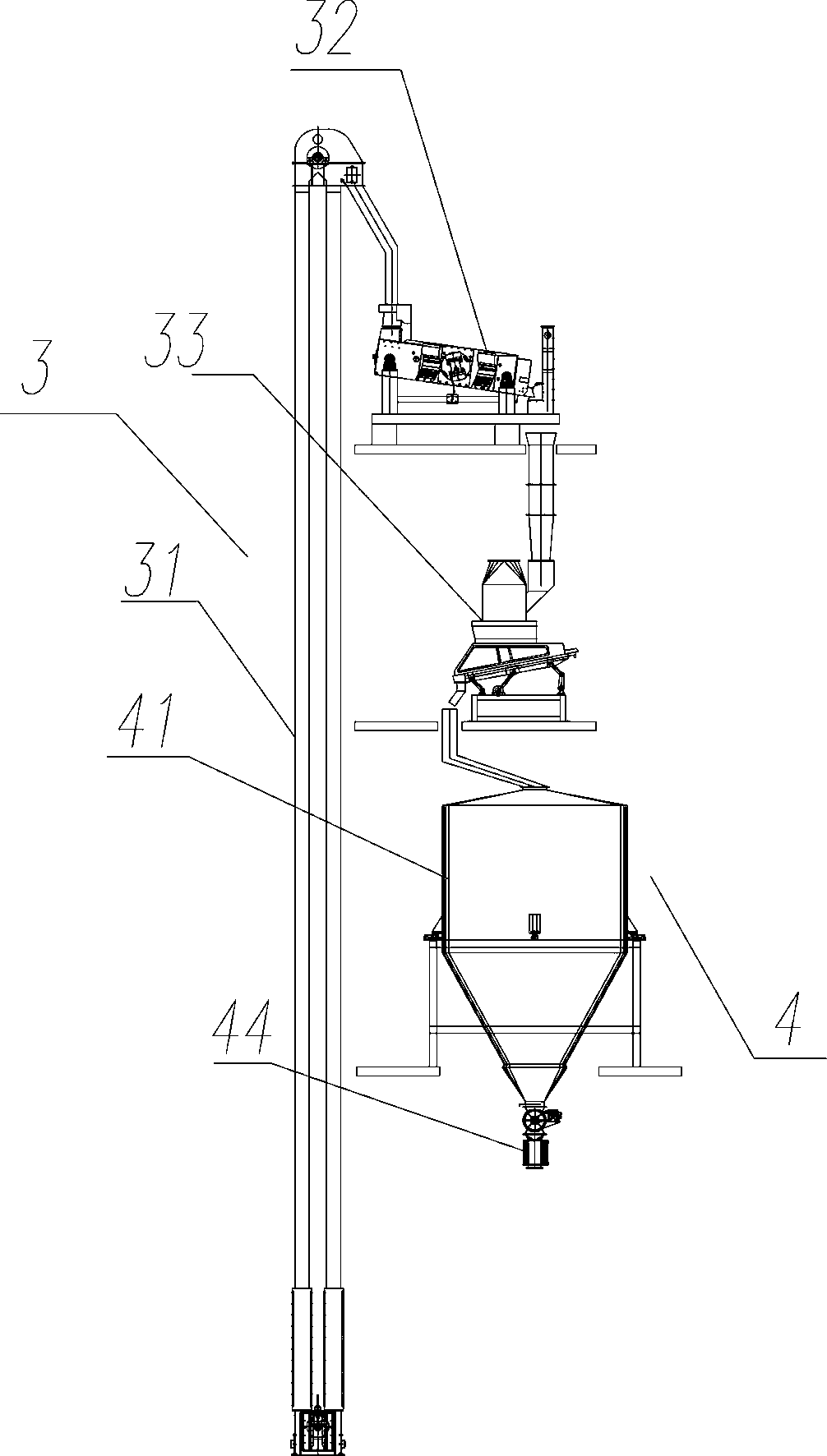

[0032] like figure 2 Among them, the corn flour purification device 1 comprises a corn flour hoist 11, a corn flour winnowing box 12, and a corn flour specific gravity destoner 13, and the corn flour hoist 11 upper port communicates with the corn flour winnowing box 12 inlets, The 12 outlets of the corn flour winnowing and miscellaneous removal box are connected with the 13 inlets of the corn flour specific gravity destoner machine;

[0033] Corn flour adding device 2 comprises corn flour cache device 21, corn flour flow control device 22, corn flour flow detection device 23, and corn flour flow control device 22, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com