Automatic logistic conveying device for machining end face of lift guide rail

An end face processing and conveying device technology, applied in metal processing and other directions, can solve the problems of work quality affected by differences in employee responsibility, difficulty in ensuring product stability, and low enthusiasm for equipment maintenance, so as to reduce product bump defects and reduce moving. With the number of flips, the effect of reducing human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

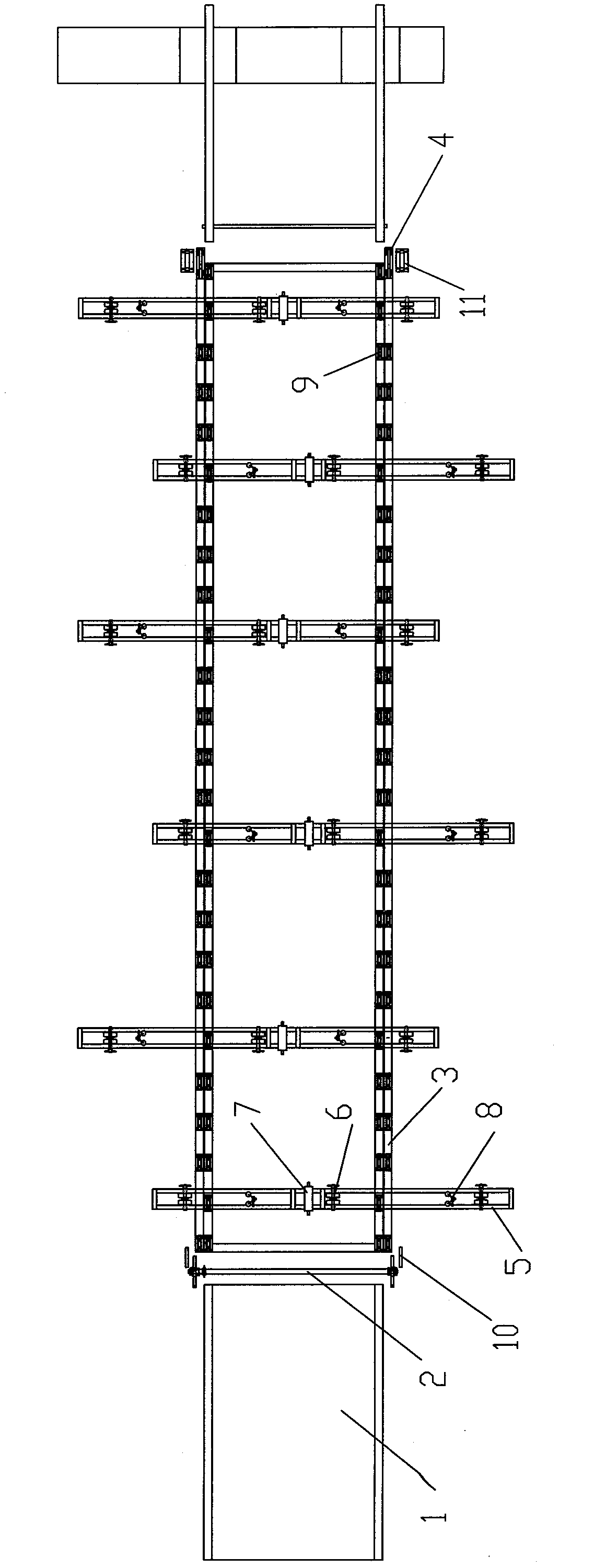

[0022] Such as figure 1 The shown automatic logistics conveying device for the end surface processing of elevator guide rails includes a feeding rack, which is different in that the output end of the feeding rack used in the present invention is provided with a feeding turning mechanism. At the same time, the output end of the feeding turning mechanism is provided with a step fixing frame. Moreover, a discharge turning assembly is arranged at the output end of the stepping fixed frame. Correspondingly, the machine bed loading and unloading racks are distributed on the stepping fixed frame.

[0023] In view of a preferred embodiment of the present invention, in order to facilitate the transmission of the elevator guide rail, a feeding wheel and a processing support wheel are arranged on the loading and unloading rack of the machine tool. At the same time, considering that the subsequent processing will not be affected by deflection during the elevator guide rail transportatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com