Equipment and method for processing of koji-making

A kind of processing equipment and technology of mother koji, which is applied in the field of equipment for fully automatic koji making and processing operations, can solve the problems of insufficient production capacity, difficulty in achieving stable and uniform quality of koji cakes, and uneconomical problems, so as to ensure consistency and convenience Differentiated operations to ensure continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiment of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it after studying this description.

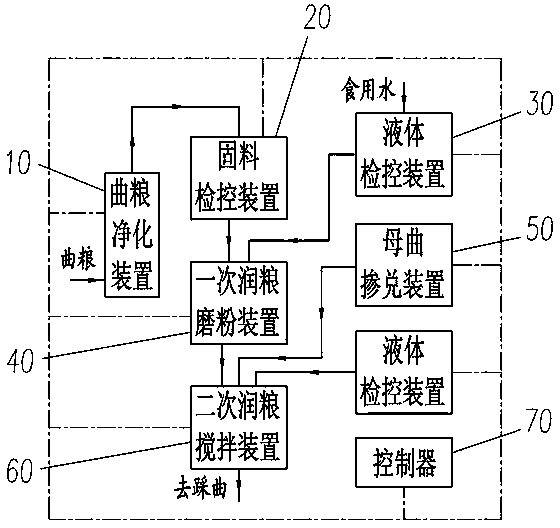

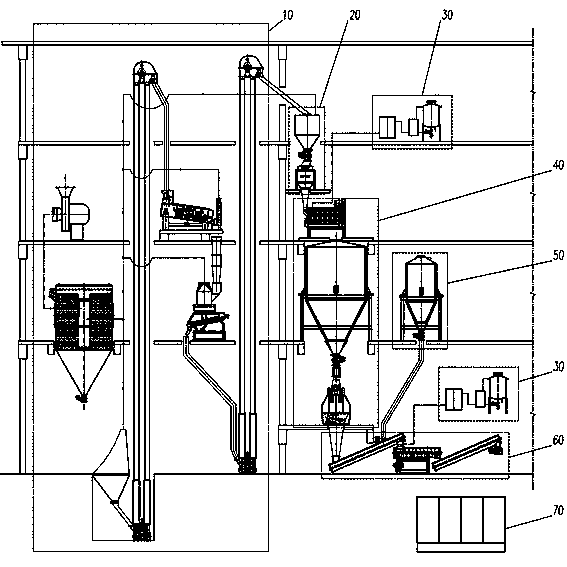

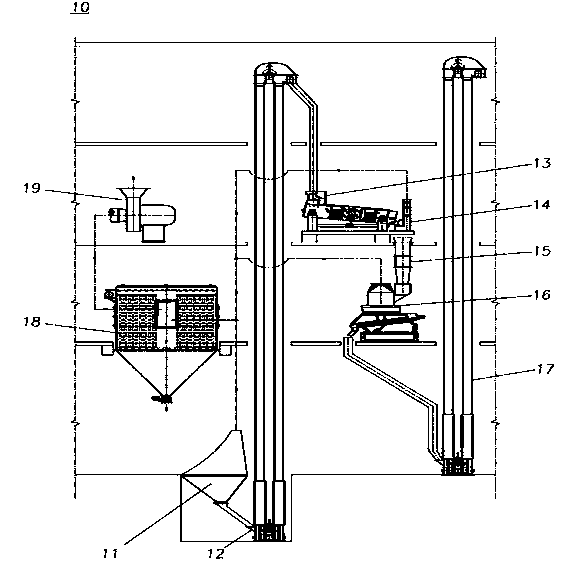

[0029] see figure 1 , and see in conjunction with figure 2 As shown, the present invention provides a kind of koji-making processing equipment, and this equipment is mainly made up of koji grain purification device 10, solid material inspection and control device 20, liquid inspection and control device 30, primary moisturizing grain milling device 40, mother koji blending device 50 and two The sub-moist grain stirring device 60 is composed of a controller 70, and the method in use is:

[0030] Step 1: Start the koji grain purification device 10 to purify the koji-making raw materials;

[0031] Step 2: Start the solid material detection and control device 20 to detect the flow rate and moisture of the koji grain for detection and measurement control, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com