Rotary distributing device

A technology of rotating distribution device and driving device, which is applied to spray devices, liquid spray devices, spray devices with movable outlets, etc. The effect of angle synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

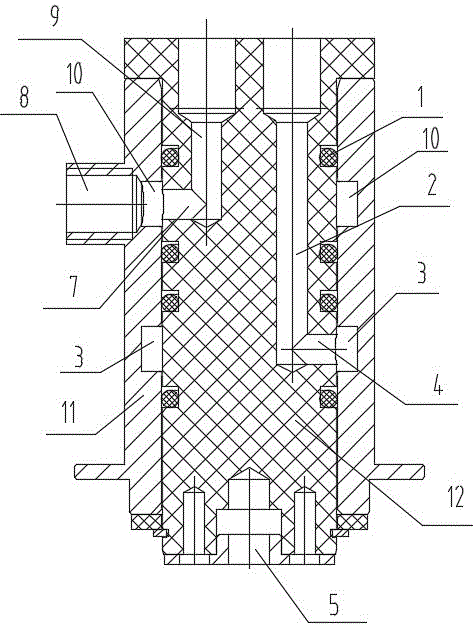

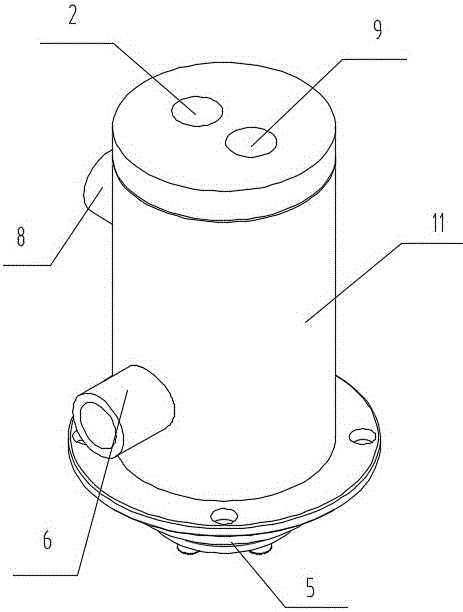

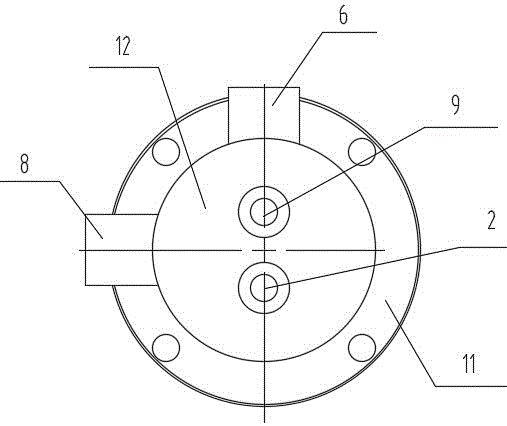

[0033] Such as figure 1 , 2 , 3 and 4 shown in the rotary distribution device, including a cylindrical shell 11 and a cylindrical core 12. The lower central axis of the inner core 12 is connected with the motor 5, and the motor 5 drives the inner core 12 to rotate inside the shell. The motor 5 is controlled by the control system to enhance the controllability of the motor. The cylindrical inner core 12 can have the largest contact area with the outer wall of the outer shell 11, and the inner core 12 is less likely to shake when it rotates in the outer shell.

[0034] A liquid inlet pipe 6 and an air inlet pipe 8 are arranged on the casing 11 . The liquid inlet pipe 6 is arranged below the air inlet pipe 8 . The liquid inlet pipe 6 is connected with an annular liquid delivery chamber 3 arranged inside the shell 11, and the annular liquid delivery chamber 3 is connected with a liquid delivery horizontal pipe 4 arranged in the inner core 12, and the liquid delivery horizontal...

Embodiment 2

[0042] In Embodiment 1, the liquid inlet pipe 6 is arranged horizontally, and forms an included angle of 60 to 75 degrees with the tangent direction of the connection point of the outer wall of the annular liquid delivery chamber 3, so that the liquid flows in the same direction in the annular liquid delivery chamber 3 when entering the liquid. , and form a centripetal force to move closer to the inner wall of the annular liquid delivery chamber 3, making it easier for the liquid to flow into the liquid delivery horizontal tube 4 arranged in the annular liquid delivery chamber 3, improving the efficiency of liquid delivery. The cross-sectional areas of the liquid inlet pipe 6 and the air inlet pipe 8 are larger than those of the liquid outlet pipe 2 and the air outlet pipe 9 respectively. The motor 5 in Embodiment 1 replaces the air motor.

Embodiment 3

[0044] In Example 1, the liquid feeding channel formed by connecting the liquid inlet pipe 6 , the annular liquid feeding chamber 3 , the liquid feeding horizontal pipe 4 , and the liquid outlet pipe 2 . The number of liquid delivery channels is greater than or equal to 2, that is, there are multiple liquid delivery channels. Some mixtures need to be prepared and used immediately to exert good disinfection and cleaning effects. If multiple substances are mixed in advance or mixed with air in advance, oxidation-reduction reactions will occur with each other and their performance will be reduced. When multiple liquids are required to be mixed at the spray head 16 , only a plurality of liquid delivery channels need be provided, and at this time, only a plurality of annular liquid delivery chambers 3 and annular air delivery chambers 10 are only required to be separately provided on the housing 11 . Corresponding horizontal liquid-feeding pipes 4 and liquid-outlet pipes 2 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com