High-pressure water flow type separation device for multi-particle-diameter microplastics in deposits or soil

A high-pressure water flow and separation device technology, applied in the preparation of test samples, etc., can solve the problems of low separation efficiency, incomplete separation of sediment and microplastic particles, lack of accuracy and scientificity of collection equipment and collection methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

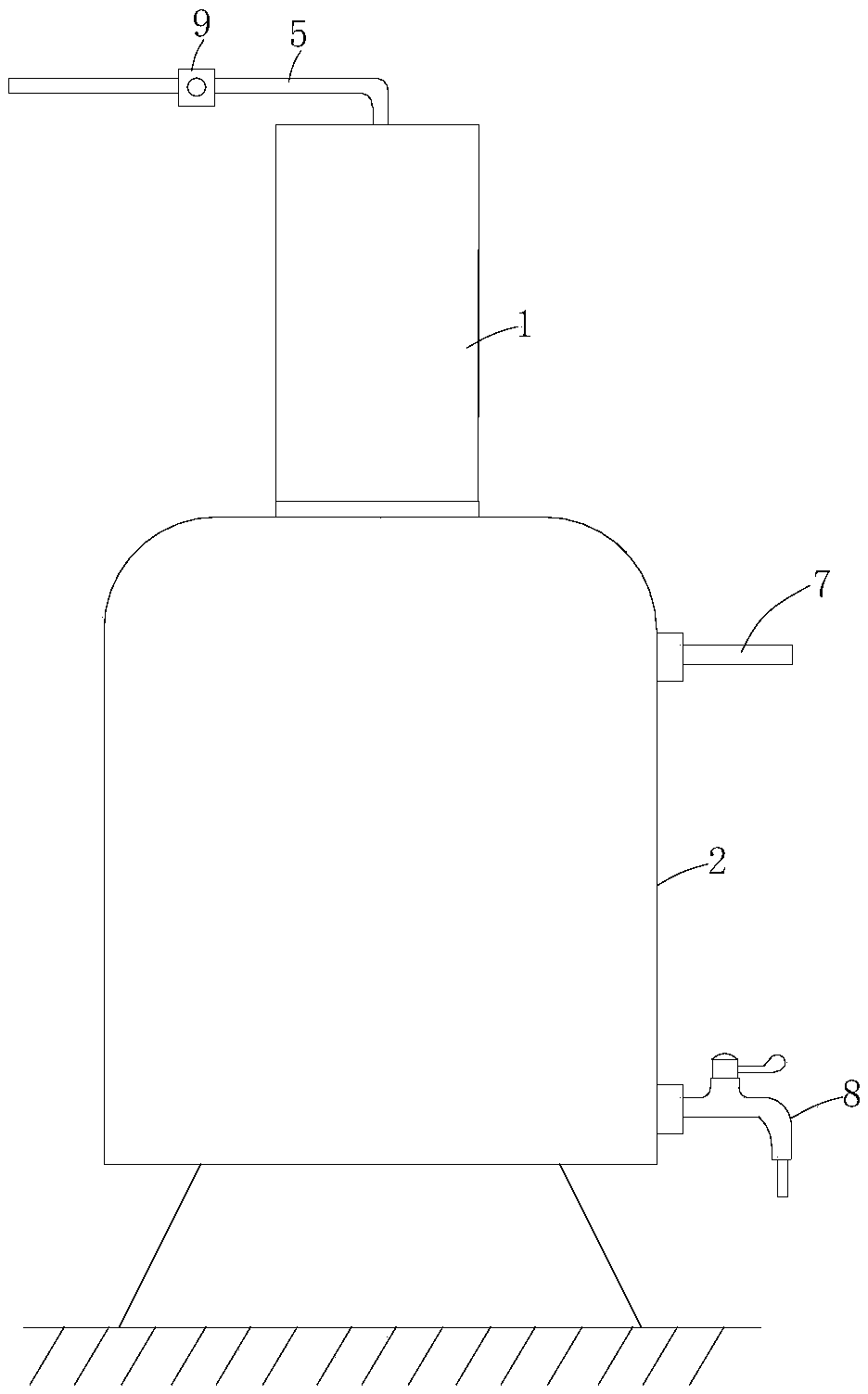

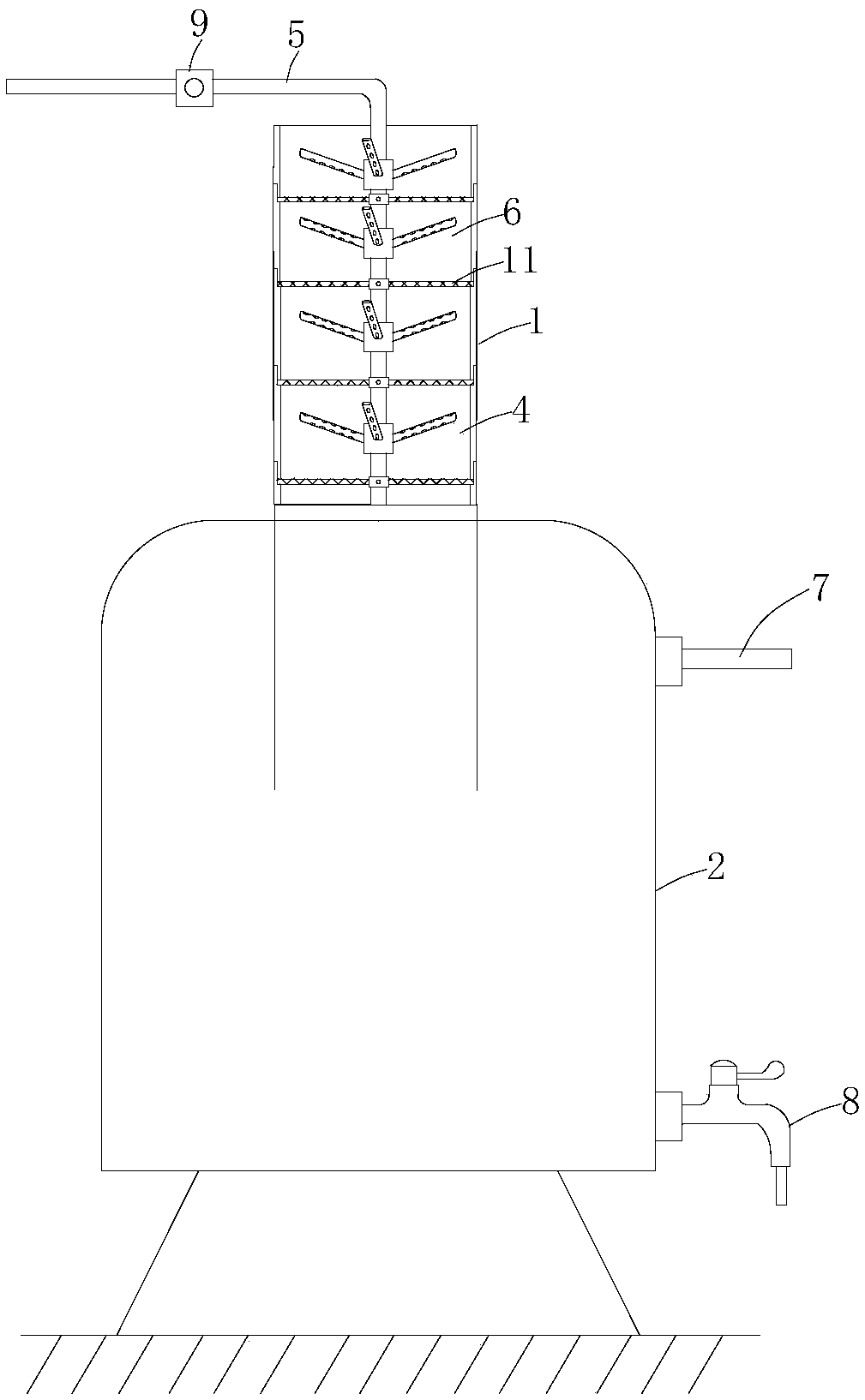

[0025] Such as Figure 1 to Figure 6 As shown, a high-pressure water flow type sediment or multi-particle size microplastic separation device in soil includes a filter box 1 and a waste liquid collection box 2 arranged at the bottom of the filter box 1, the top of the filter box 1 is sealed, and the inside of the filter box 1 A plurality of filter screens 11 spaced apart from each other are provided, and the filter box 1 is spliced by multi-stage frame units 3, and filter screens 11 are placed at the joints of adjacent frame units 3, and the frame unit 3 includes a vertical barrel wall 31, and the vertical barrel The two ends of the wall 31 are respectively provided with an upper connection part 32 and a lower connection part 33, and the vertical barrel walls 31 of the adjacent frame units 3 are quickly connected by the upper connection part 32 and the lower connection part 33, and the adjacent filter screens 11 A filter cavity 4 is formed between them;

[0026] The top of ...

Embodiment 2

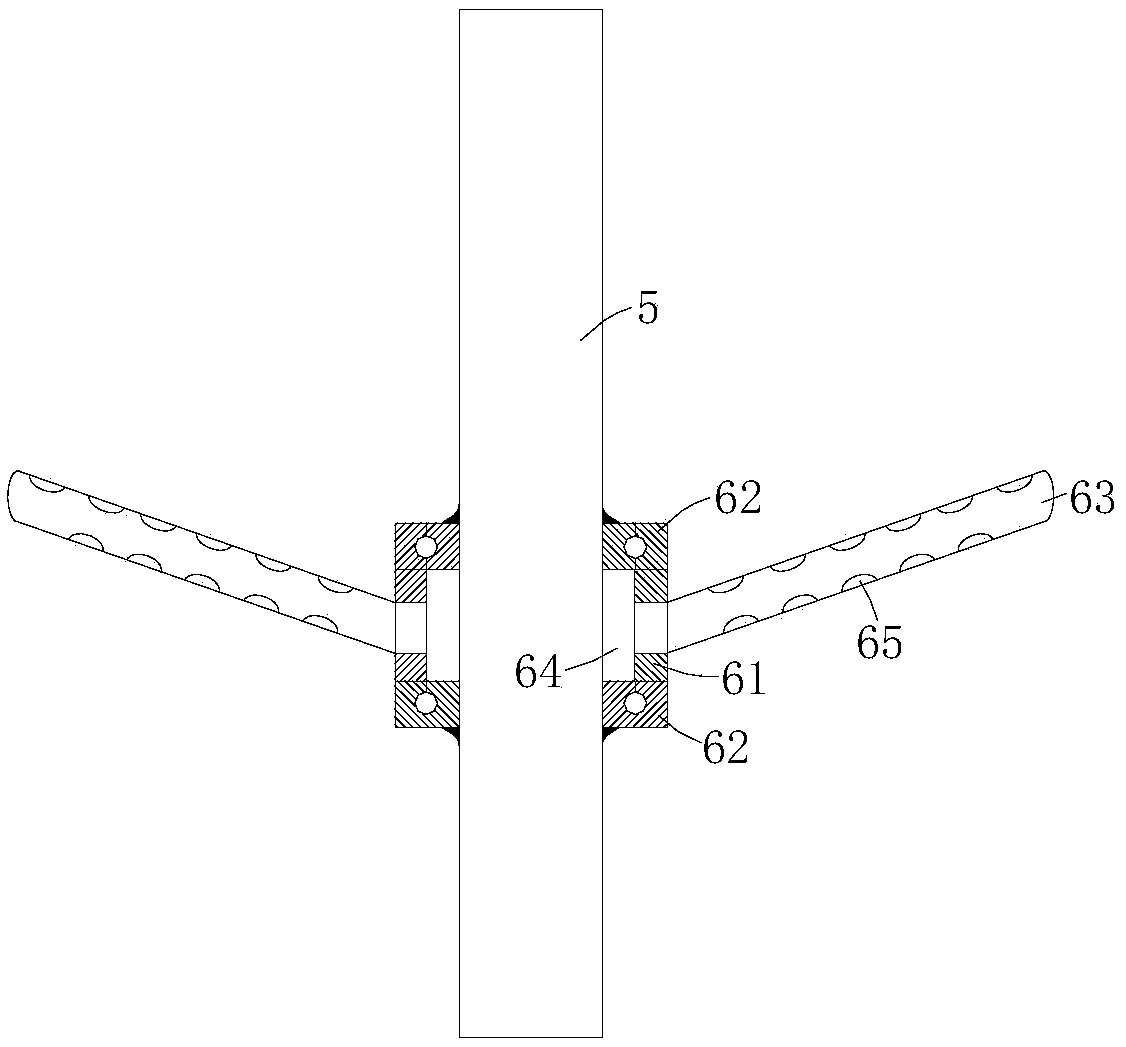

[0034] Such as Figure 7As shown, the difference between this embodiment and Embodiment 1 is that the inner wall of the rotating sleeve 61 in this embodiment is smooth, and the inclined power baffle 66 is not provided. In addition, the left side or the right side of the flushing water pipe 63 is provided with a water outlet 67. After the high-pressure water flow enters the flushing water pipe 63, while the water flow is ejected at high speed from the water outlet holes 65 on the upper surface and / or the lower surface of the flushing water pipe 63, the water flow will also flow from the left or right side of the flushing water pipe 63. The water outlet hole 67 on the surface is ejected, because only one side is provided with the water outlet hole 67 in the left side and the right side of the flushing water pipe 63, in this way, the force on the left and right sides of the flushing water pipe 63 will not be uniform, and the flushing water pipe 63 sides will not be uniform. Under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com