Stirring type synchronous separating device for multi-particle-size microplastics in sediment or soil

A technology of simultaneous separation and microplastics, which is applied in the separation of solids from solids by air flow, solids separation, sieving, etc. It can solve problems such as low separation efficiency, incomplete separation of sediment and microplastic particles, and simultaneous separation. , to achieve the effect of improving the collection and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

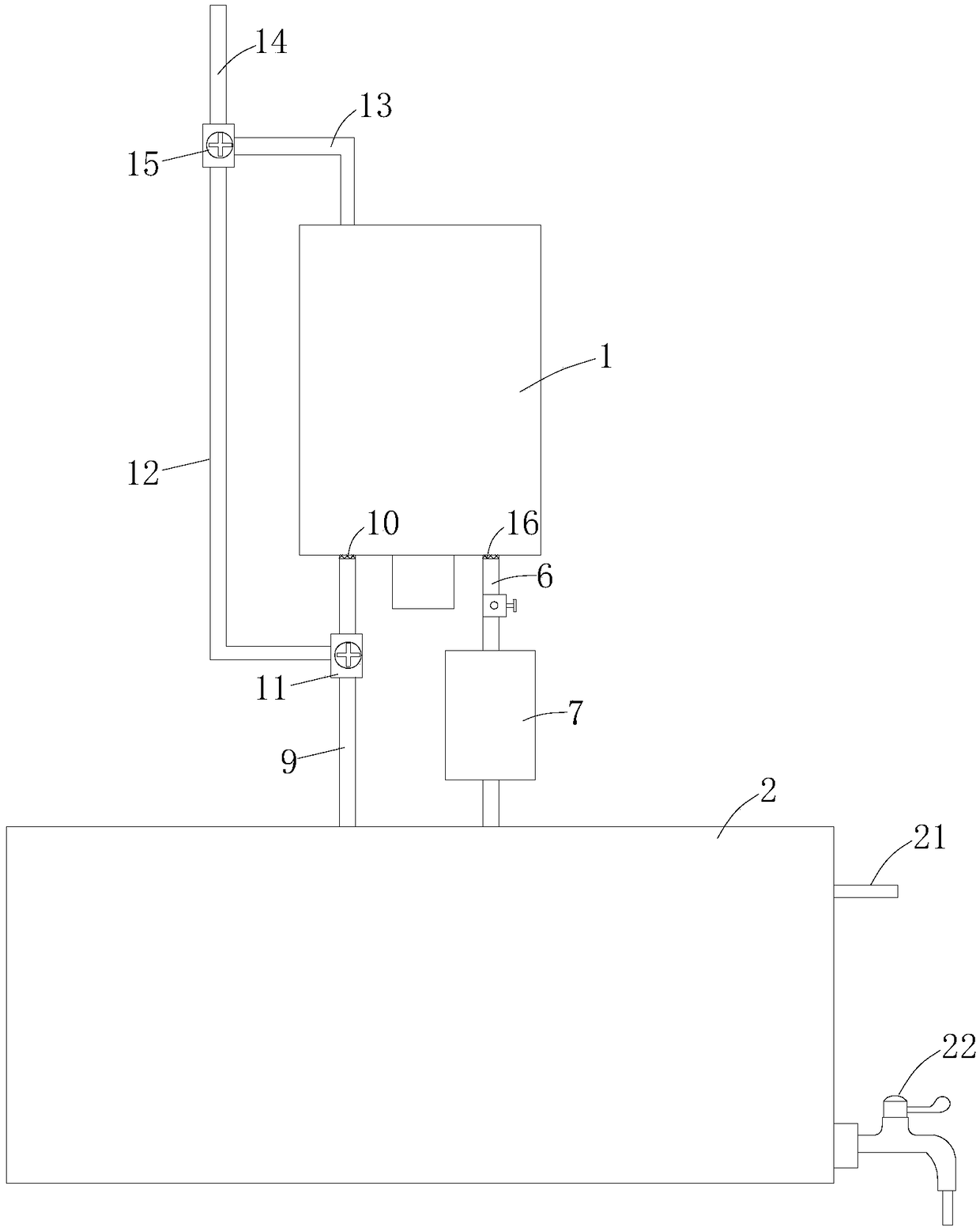

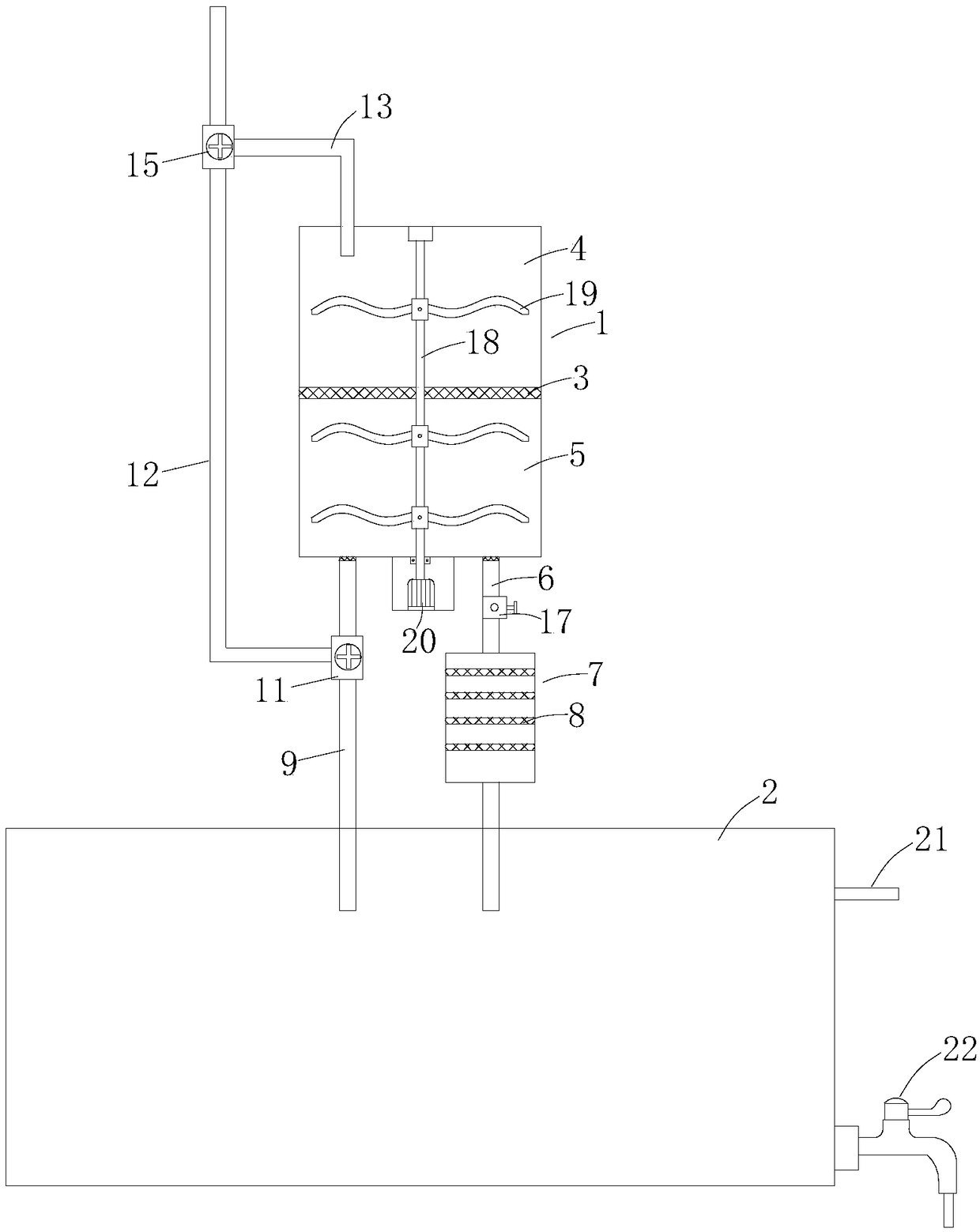

[0024] Such as figure 1 , figure 2 As shown, a simultaneous separation device for multi-particle size microplastics in agitated sediment or soil includes an agitated filter box 1, a waste liquid collection box 2 is provided at the bottom of the agitated filter box 1, and the agitated filter box 1 and the waste liquid collection box 2 are connected with a sediment separation mechanism and a microplastic separation and collection mechanism. The middle part of the stirring filter box 1 is provided with a primary filter 3, and the stirring filter box 1 is provided with a stirring mechanism. The primary filter 3 will stir the inner cavity of the filter box 1 It is divided into a sediment introduction chamber 4 and a sediment separation chamber 5 , and the ports of the sediment separation mechanism and the microplastic separation and collection mechanism are connected to the sediment separation chamber 5 .

[0025] The microplastics separation and collection mechanism includes a m...

Embodiment 2

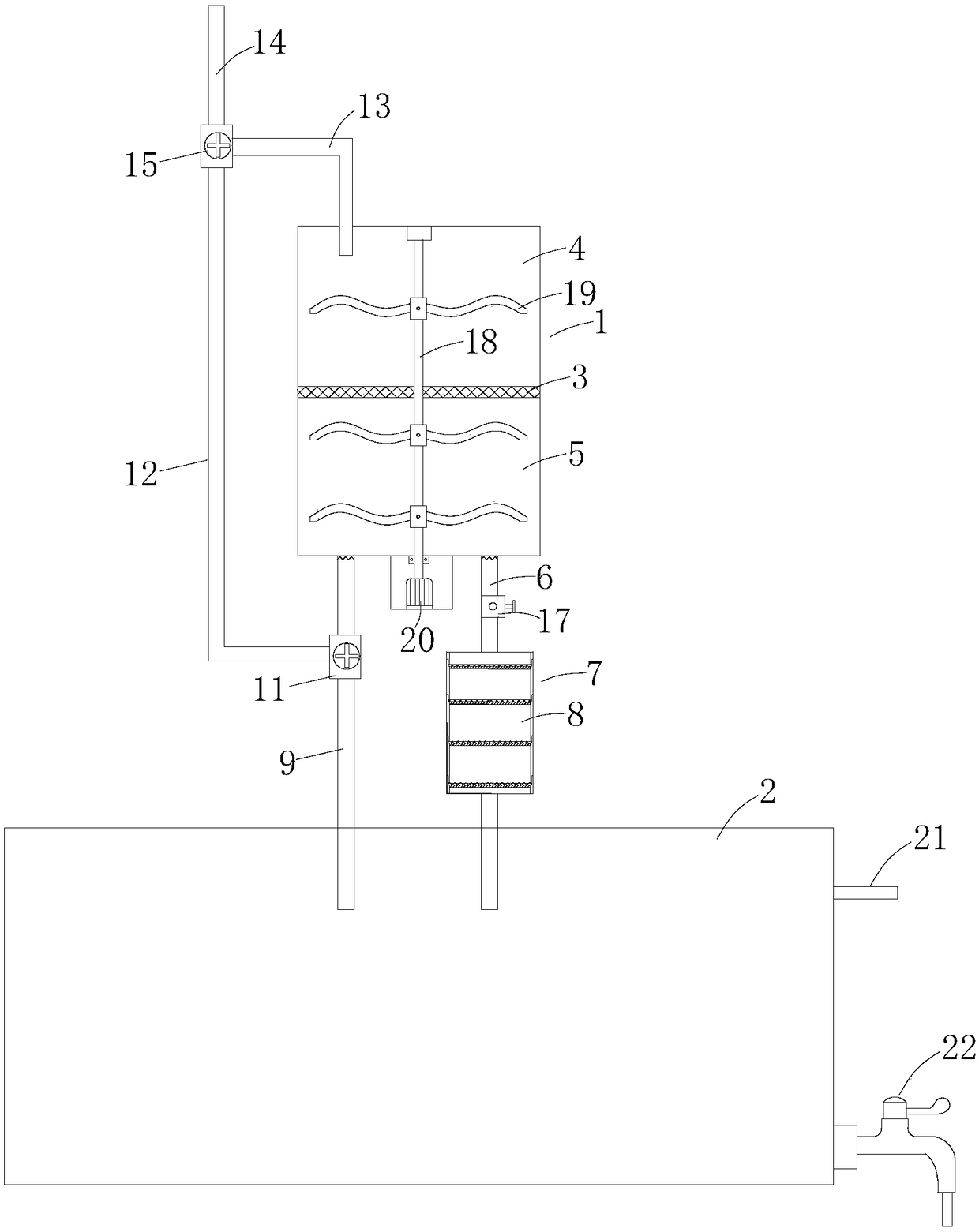

[0032] Such as Figure 3 to Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the microplastic collection box 7 is spliced by multi-stage frame units 71, and the junction of adjacent frame units 71 is provided with a microplastic filter screen 8, and the frame unit 71 includes a vertical The barrel wall 72, the two ends of the vertical barrel wall 72 are respectively provided with an upper connecting portion 73 and a lower connecting portion 74, and the vertical barrel walls of adjacent frame units 71 are quickly connected by the upper connecting portion 73 and the lower connecting portion 74, The connection method can be threaded or clamped. The advantage of this structure is that the number of microplastic filter screens 8 in the microplastic collection box 7 can be changed arbitrarily, and after the collection of microplastics is completed, the microplastic collection box 7 can quickly Dismantling is convenient for taking out the microplas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com