Patents

Literature

33results about How to "Act as agitator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

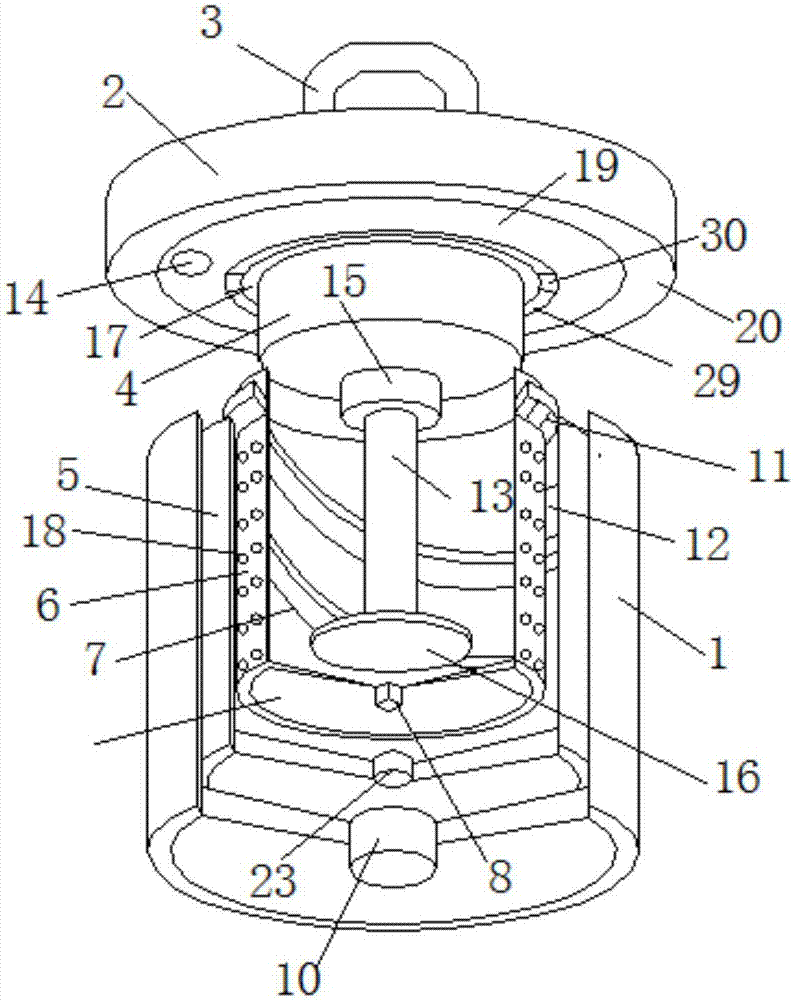

Separate uniform beating anti-blocking soymilk maker

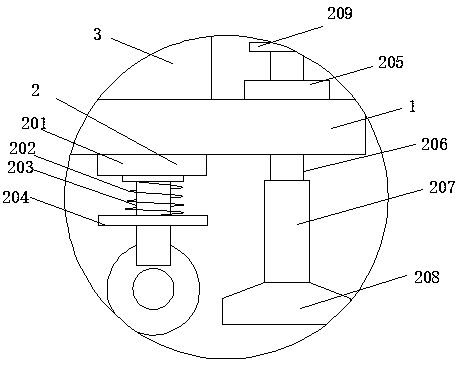

The invention provides a separate anti-clogging soymilk machine with uniform beating, which includes a soymilk body, and the soymilk body is covered with a soymilk machine cover. Finally, align the head of the insertion rod and insert it into the card slot, add an appropriate amount of soy products and water into the centrifuge tube, close the cover of the soymilk machine, and set the block of the centrifuge tube in the card slot, open The stirring motor of the soybean milk machine cover and the stirring knife of the stirring rod are used for cutting and stirring. The rotating motor drives the centrifuge to rotate. The bean dregs can be turned up and down, and the centrifugal action of the centrifuge separates the bean milk from the bean dregs. After beating, take out the centrifuge tube and discard the bean dregs, close the cover of the soy milk machine again, pour out the soy milk in the pulp container, and plug the outlet for a second time. The function of filtration is to filter the larger particles in the soy milk.

Owner:徐佩登

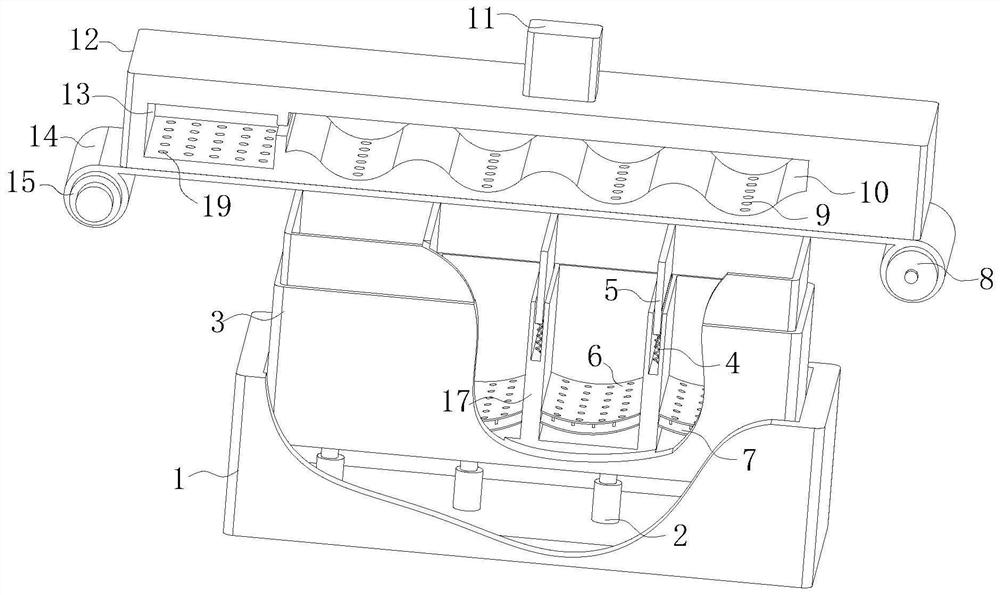

Uniform mixing device for vinyl acetate-acrylic latex paint production

PendingCN108465429ASimple structureEasy to useTransportation and packagingMixer accessoriesEngineeringRaw material

The invention relates to the technical field of latex paint processing equipment, in particular to a uniform mixing device for vinyl acetate-acrylic latex paint production. The uniform mixing device comprises a bottom plate, wherein moving devices are fixedly connected with the bottom of the bottom plate; fixed seats are fixedly connected with the two sides of the top of the bottom plate; side plates are fixedly connected with tops of the fixed seats, a push rod is fixedly connected with one side of each side plate, a grip is fixedly connected with one side of the push rod, a supporting plateis fixedly connected between the two side plates, a baffle plate is fixedly connected with the top of the supporting plate, and a mixing box is inserted in the supporting plate. The supporting plate fixedly connected between the two side plates is conveniently matched with hanging racks on two sides of the mixing box for placement of the mixing box, the limiting effect is realized under the matching with the baffle plate, raw materials are mixed through dual stirring under the matching of a first stirring device and a second stirring device, the purpose of uniform mixing is achieved, and the uniform mixing device for vinyl acetate-acrylic latex paint production is simple in structure, convenient to use and good in practical effect.

Owner:临沂市旭展化工有限公司

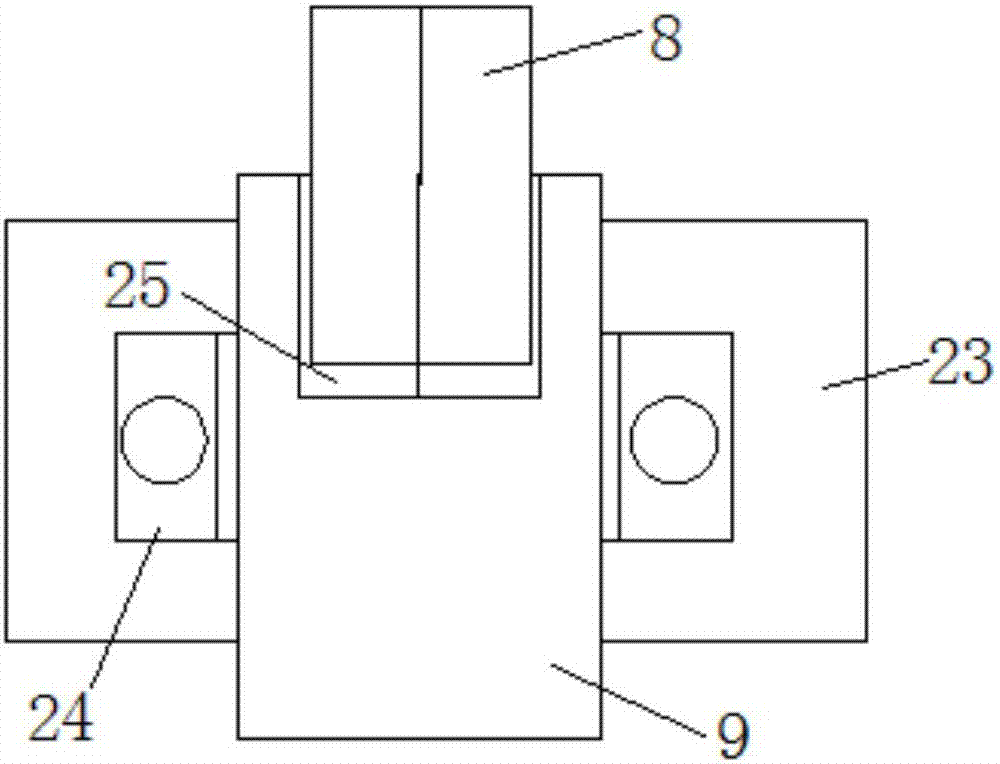

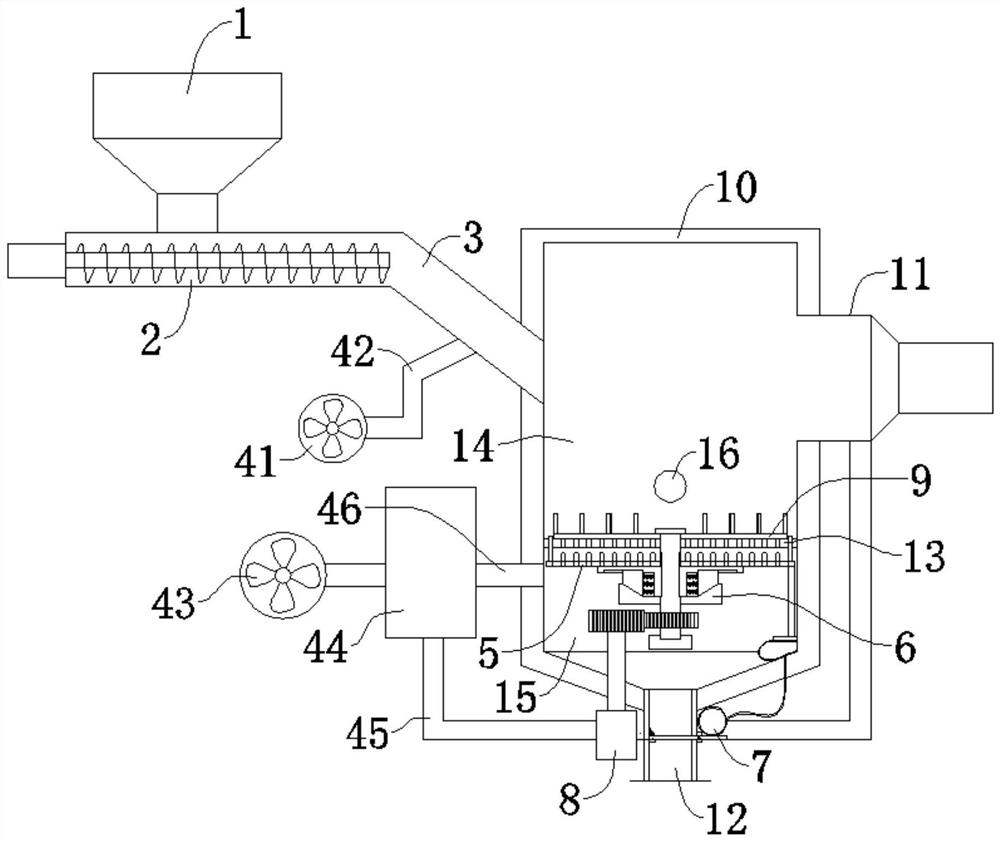

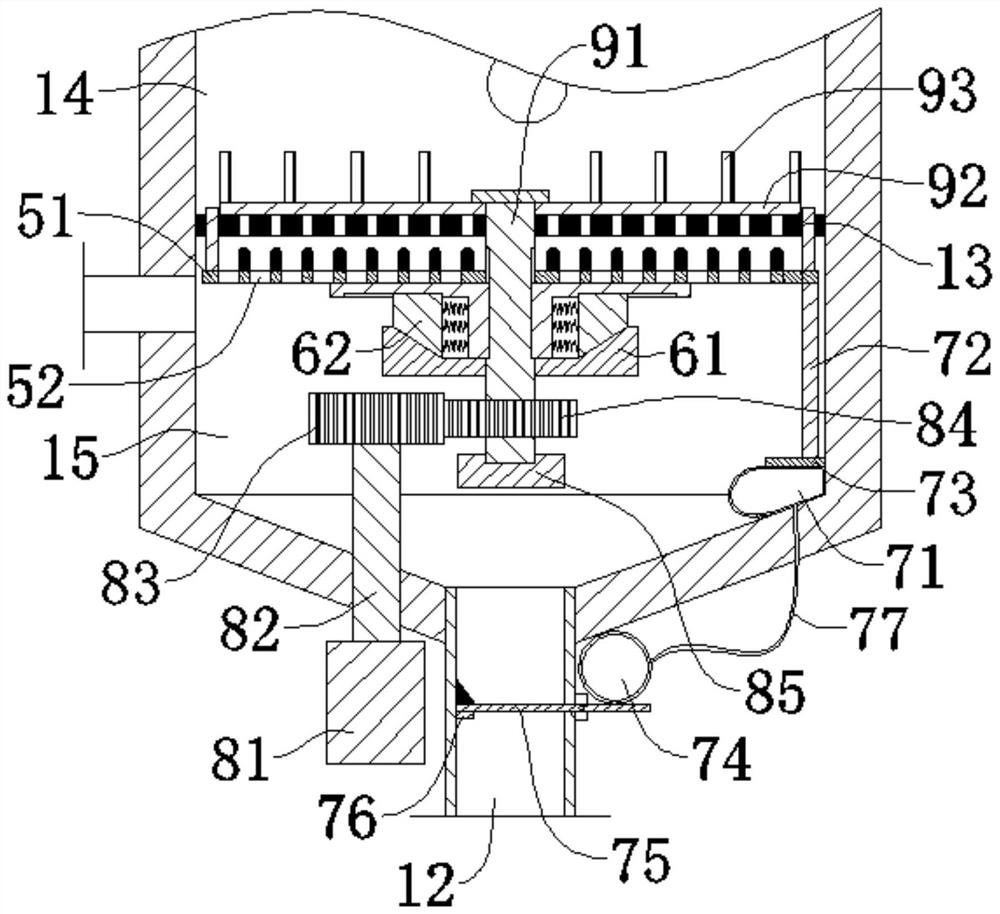

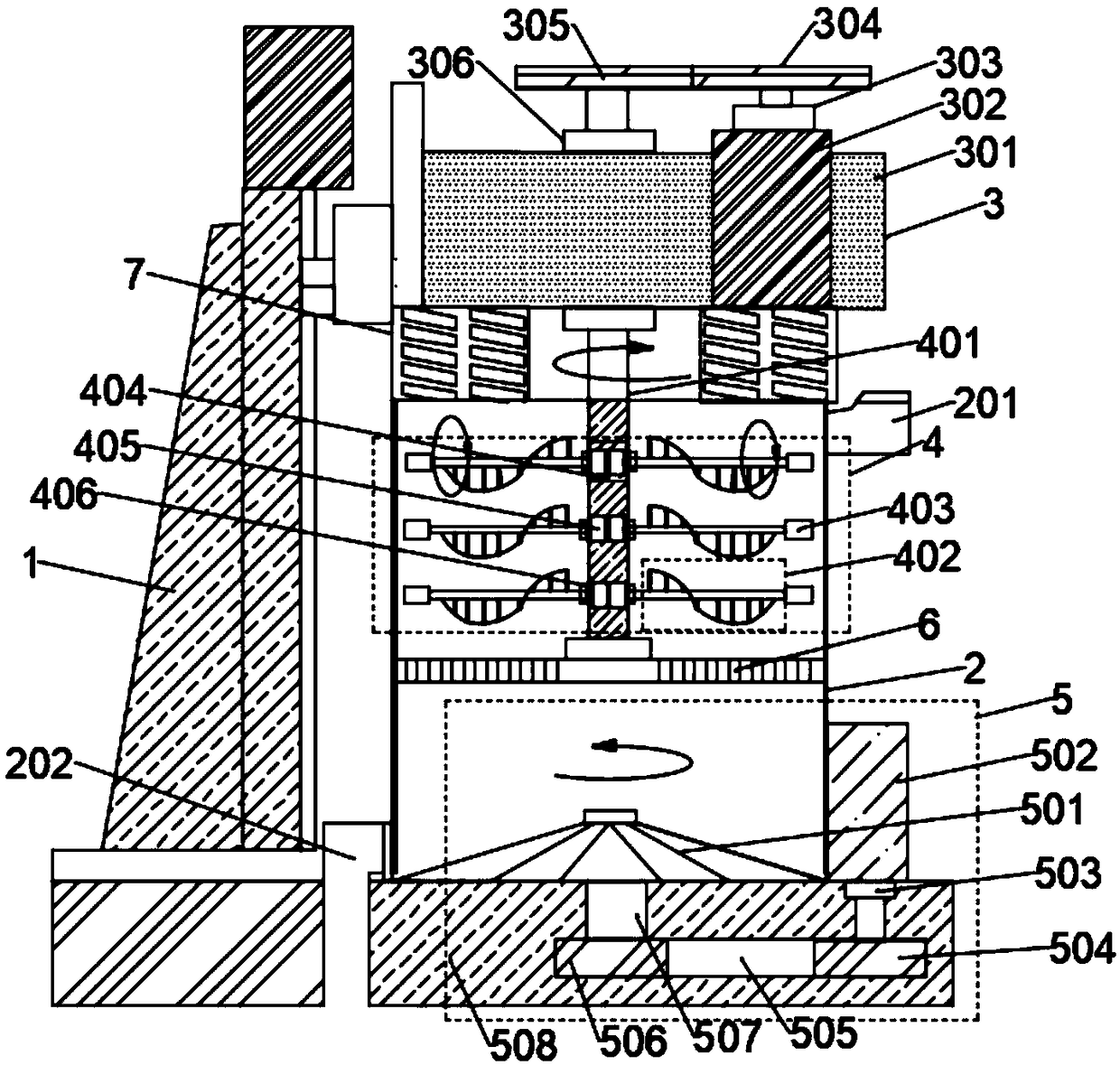

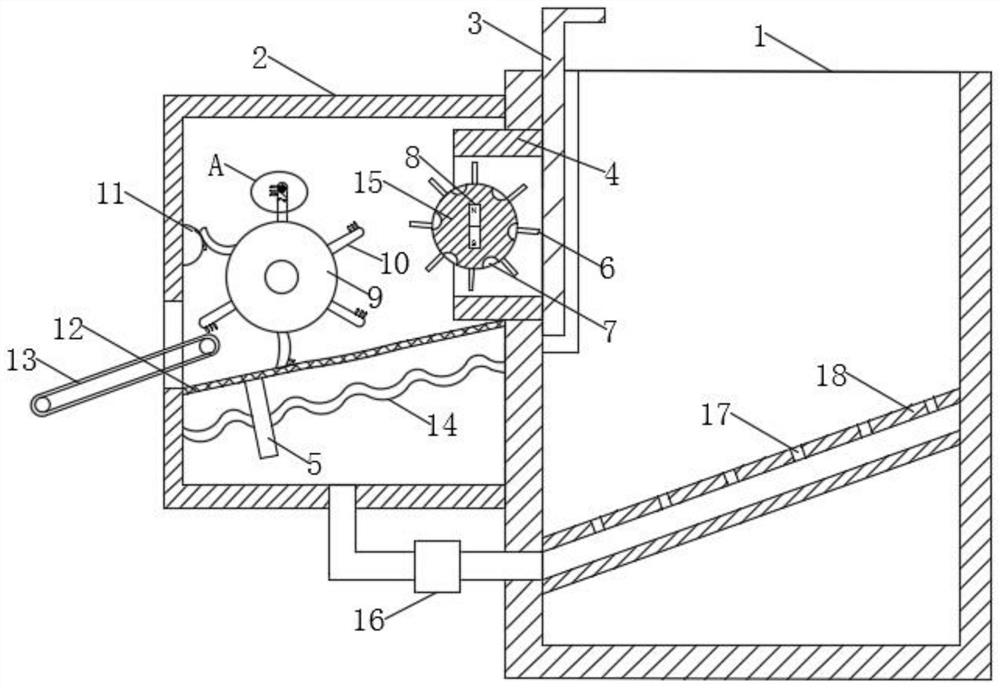

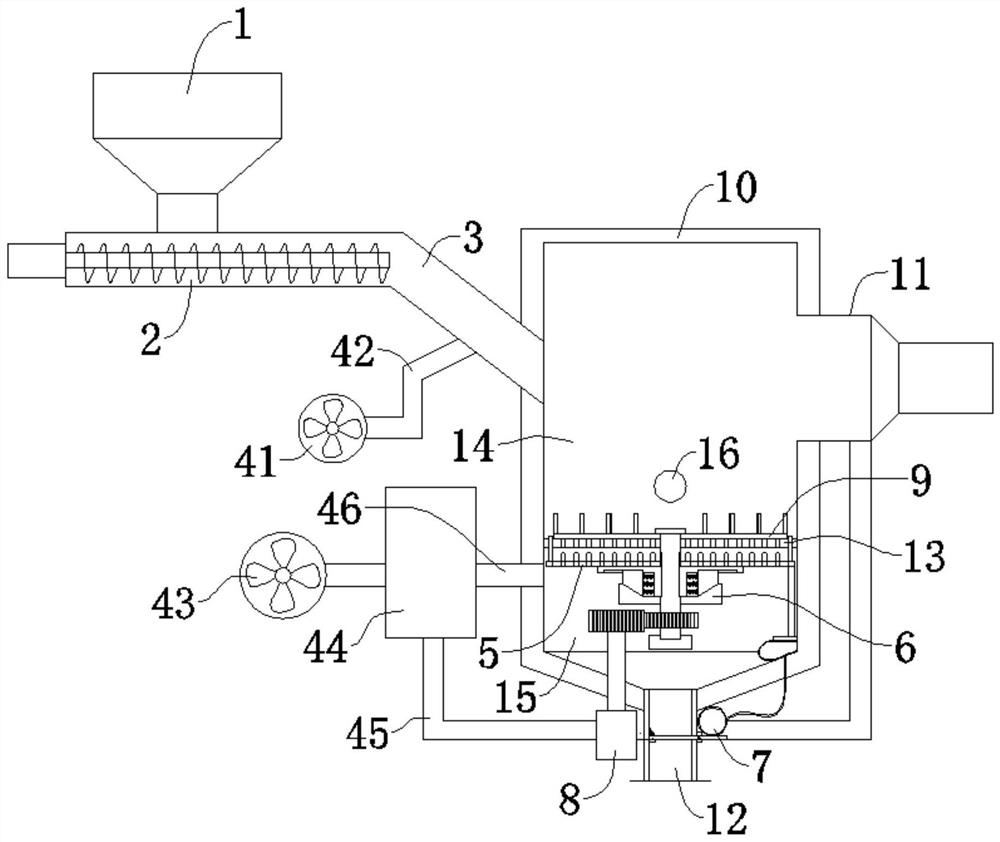

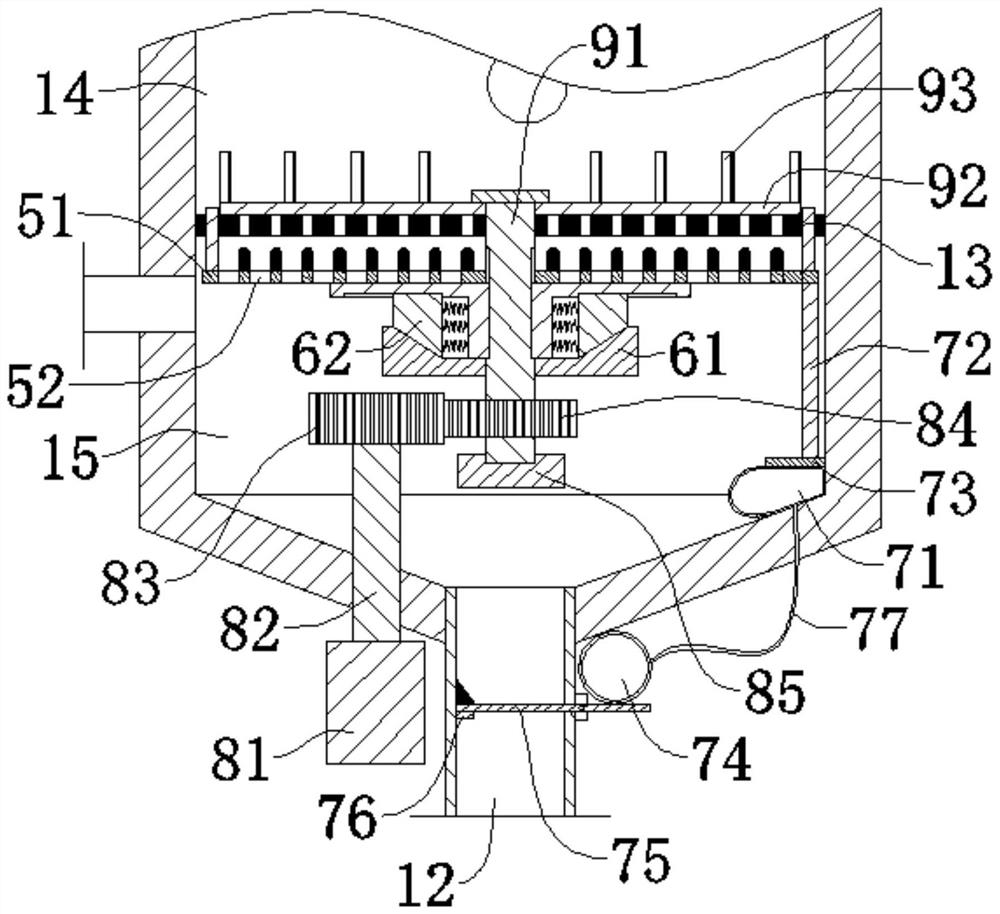

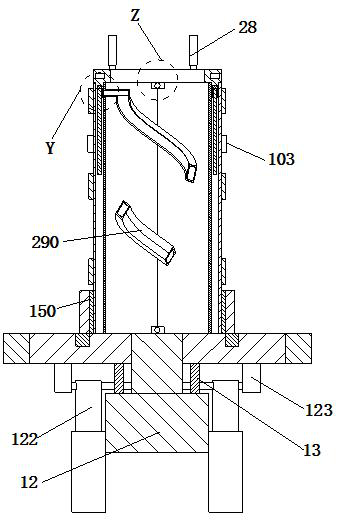

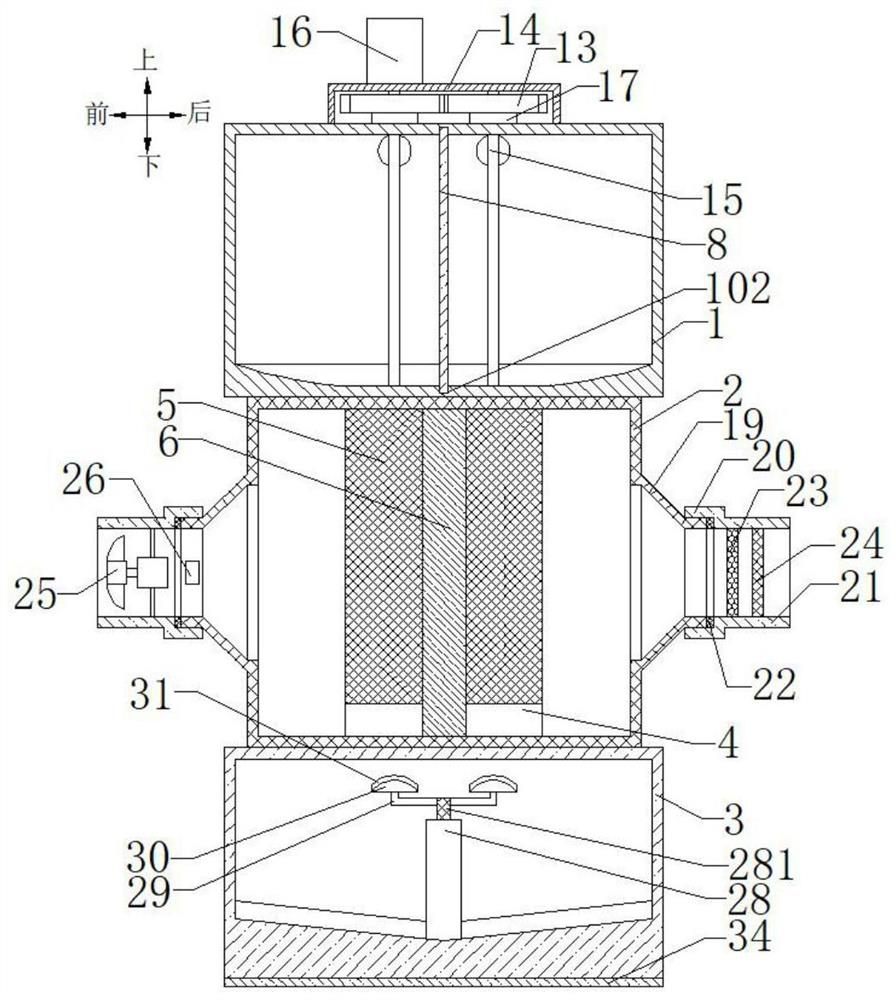

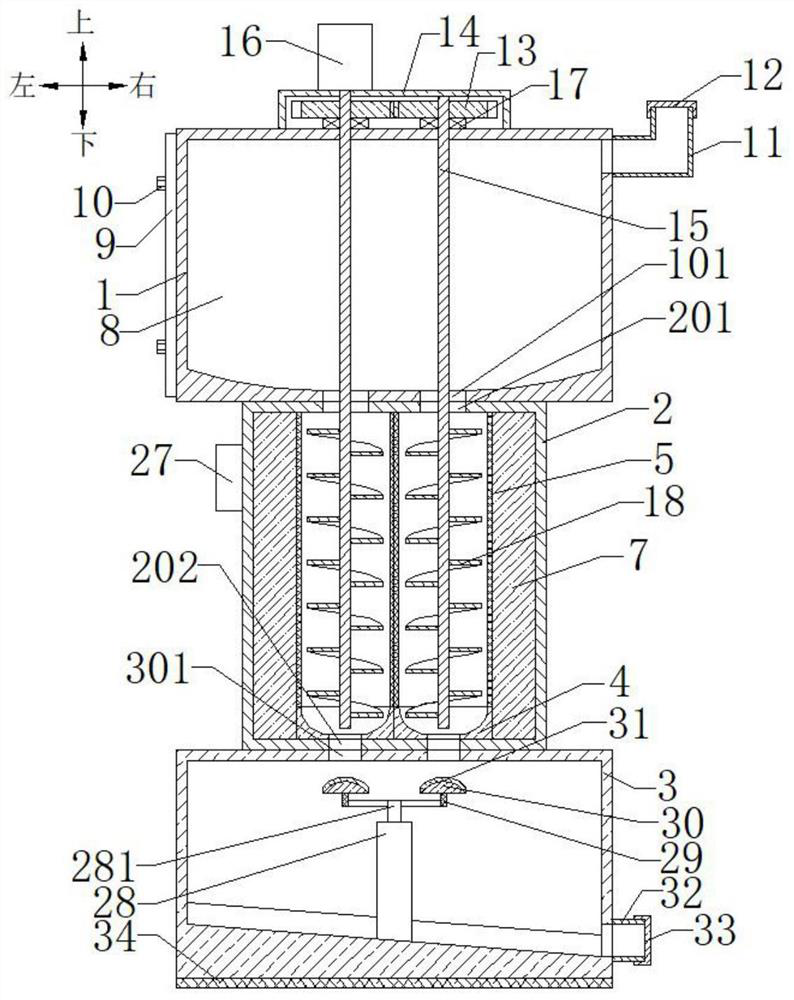

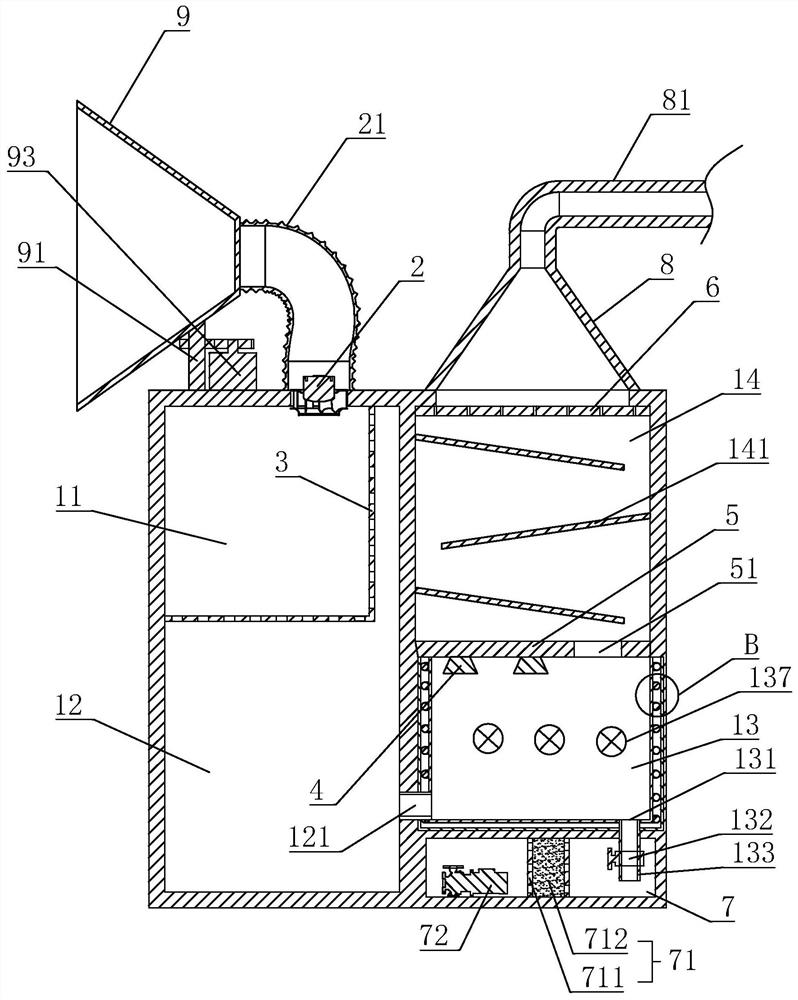

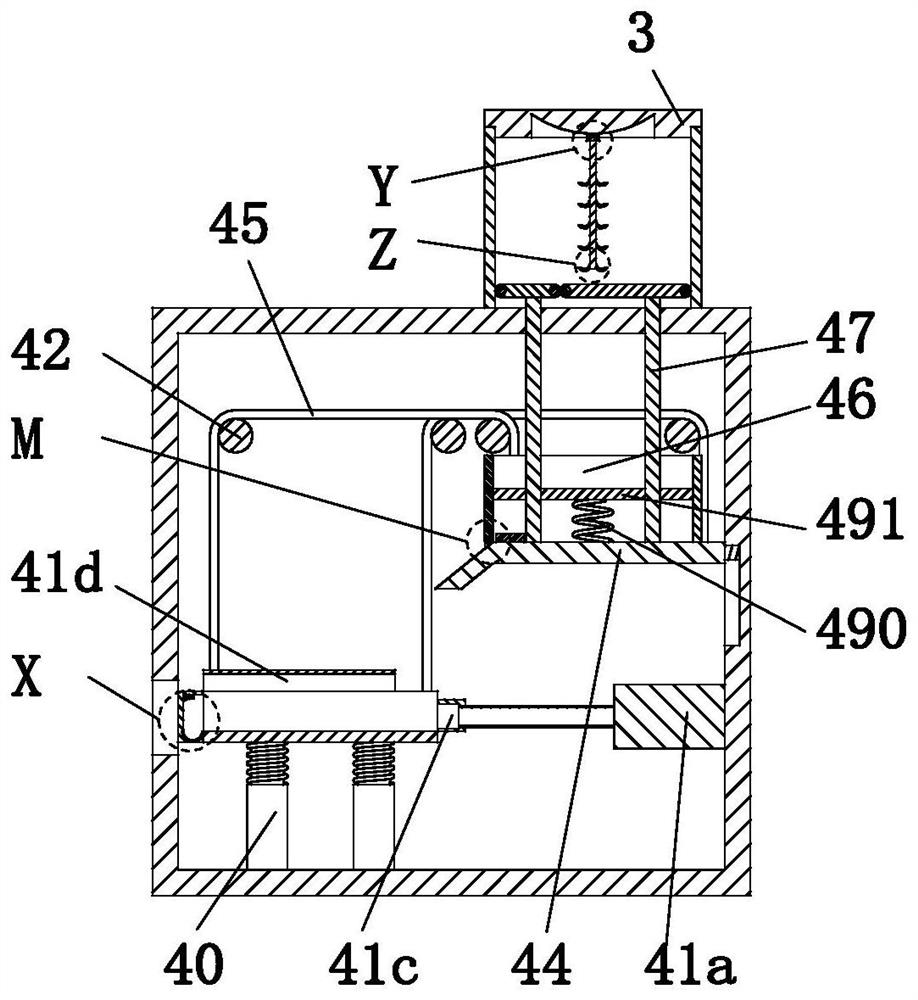

Biomass burner

ActiveCN112050193AIncrease contact areaReduce exposureSolid fuel combustionCombustion apparatusScrew conveyorBiomass burning

The invention discloses a biomass burner, and belongs to the field of biomass burning equipment. The biomass burner comprises a feeding hopper, a screw conveyor, a feeding channel, an air supply system and a burning furnace; the feeding hopper, the screw conveyor, the feeding channel and the burning furnace are connected sequentially; a bearing ring is fixed in the burning furnace; leakage holes are formed in the bearing ring; an anti-blocking assembly, a moving assembly, an ash discharging assembly, a driving assembly and a scattering assembly are arranged on the burning furnace; the scattering assembly comprises a spindle, a supporting rod and a scattering rod; the supporting rod is fixed to the spindle and makes contact with the top surface of the bearing ring; the scattering rod is fixed to the supporting rod; an ash discharging opening is formed in the bottom of the furnace bottom; the moving assembly is installed on the spindle; when the spindle rotates, the moving assembly pushes the anti-blocking assembly upwards, so that the anti-blocking assembly penetrates through the leakage hole, and the ash discharging assembly controls ash to be discharged through the ash dischargingopening; and the driving assembly is used for driving the spindle to rotate around the central axis of the spindle. The biomass burner has the advantages that fuel is scattered, the leakage holes areprevented from being blocked, discharging is convenient and the like.

Owner:衡阳衡锅锅炉有限公司

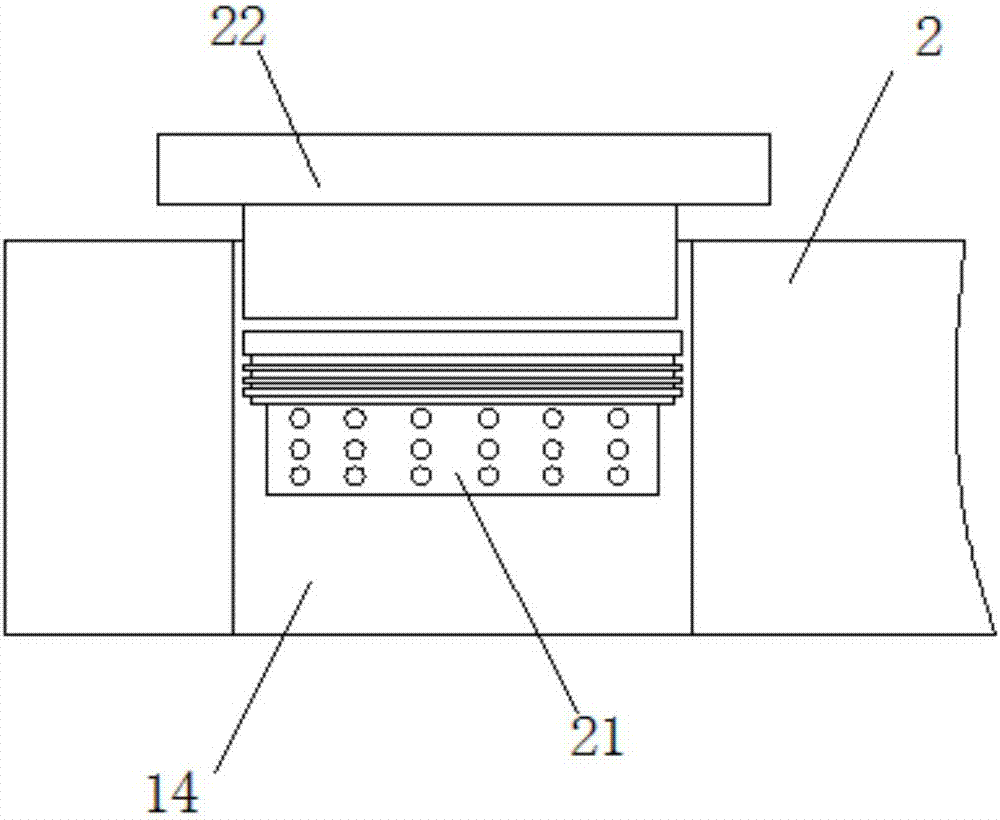

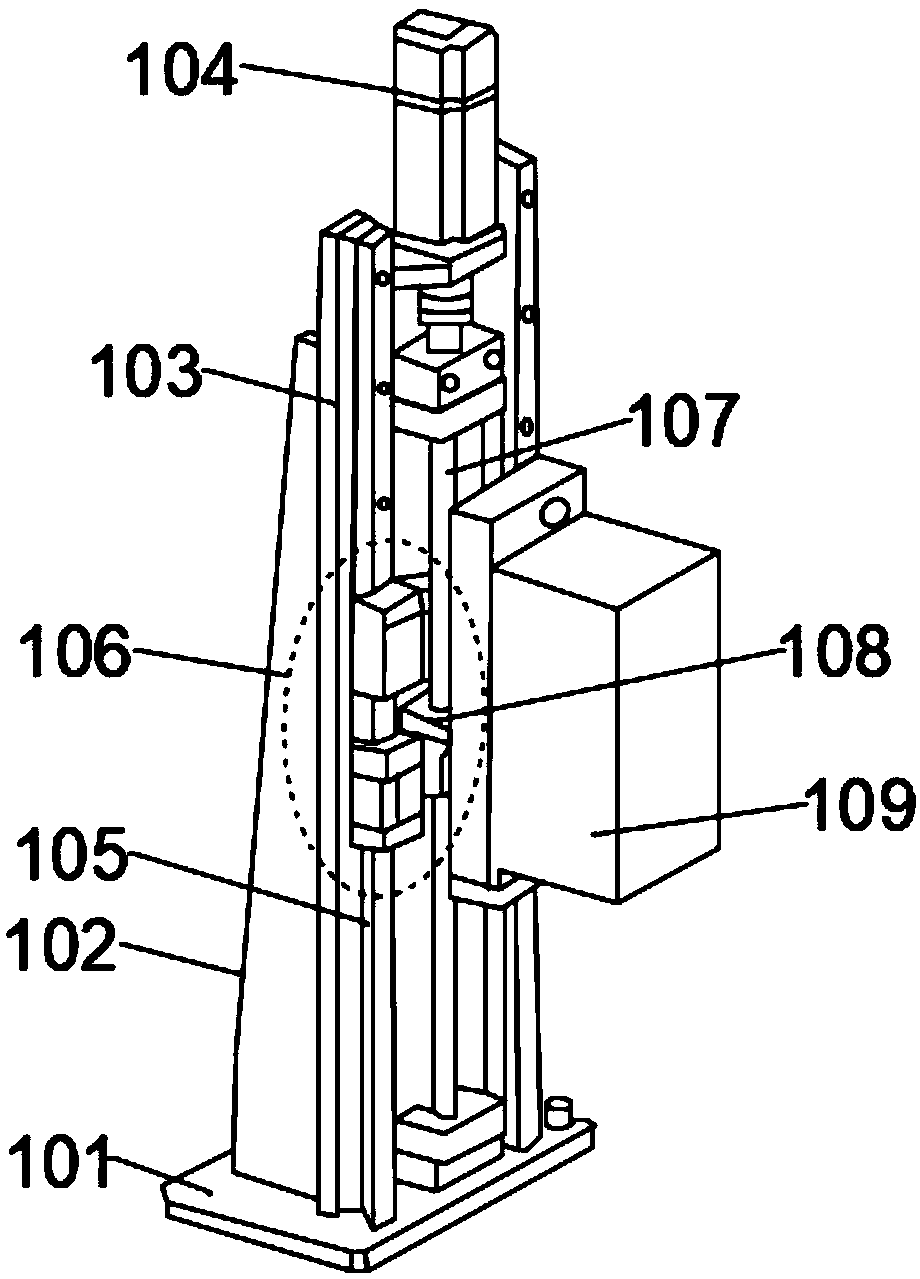

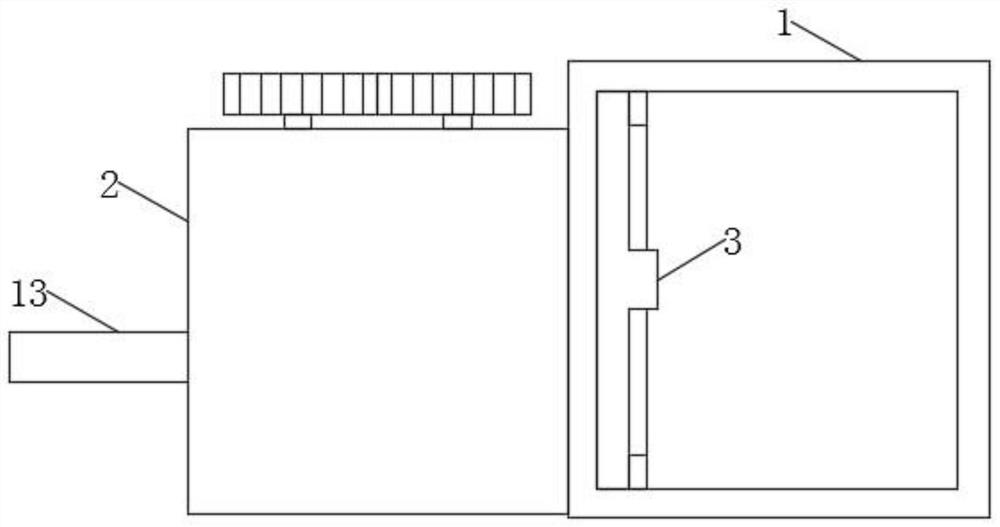

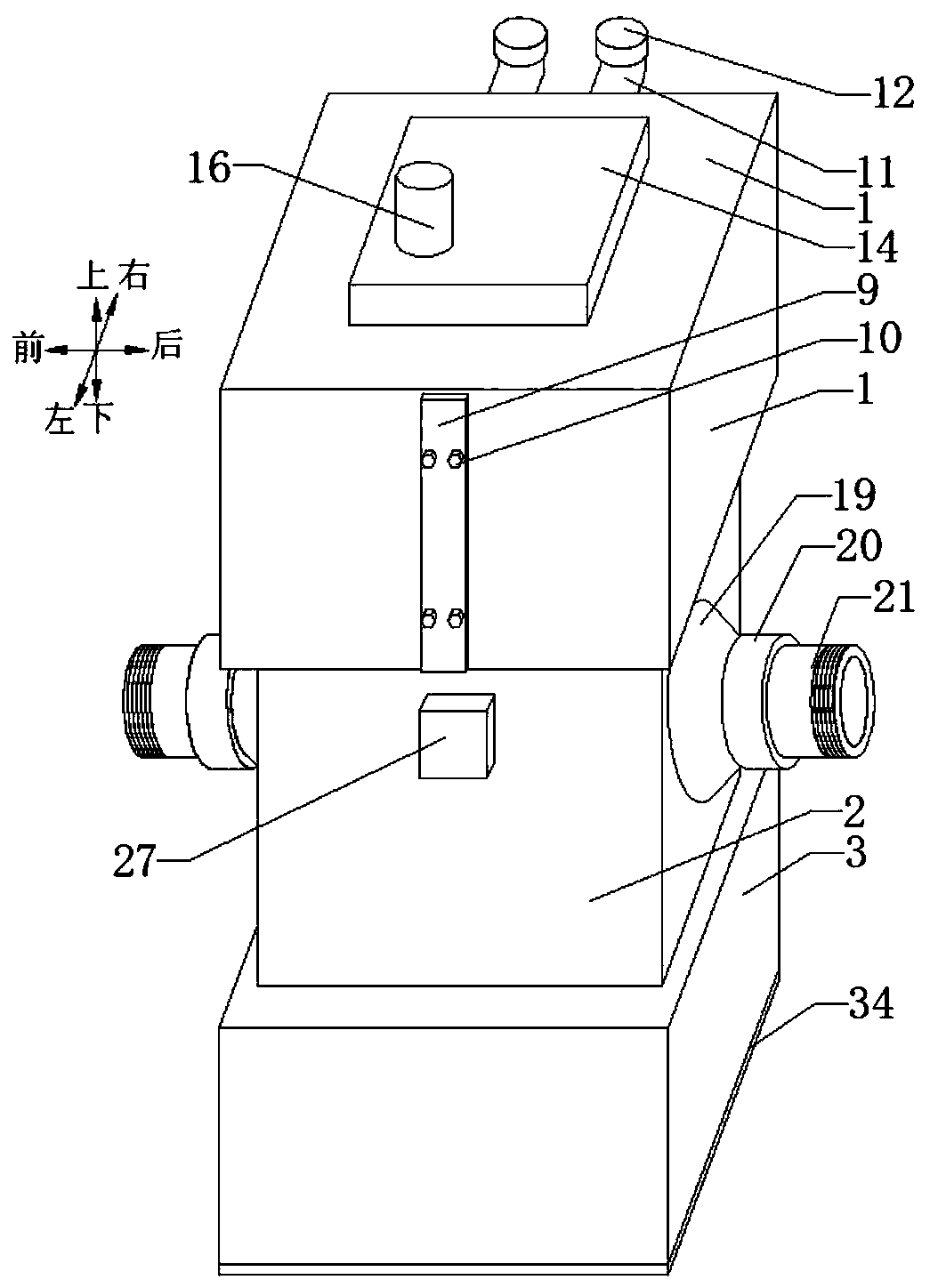

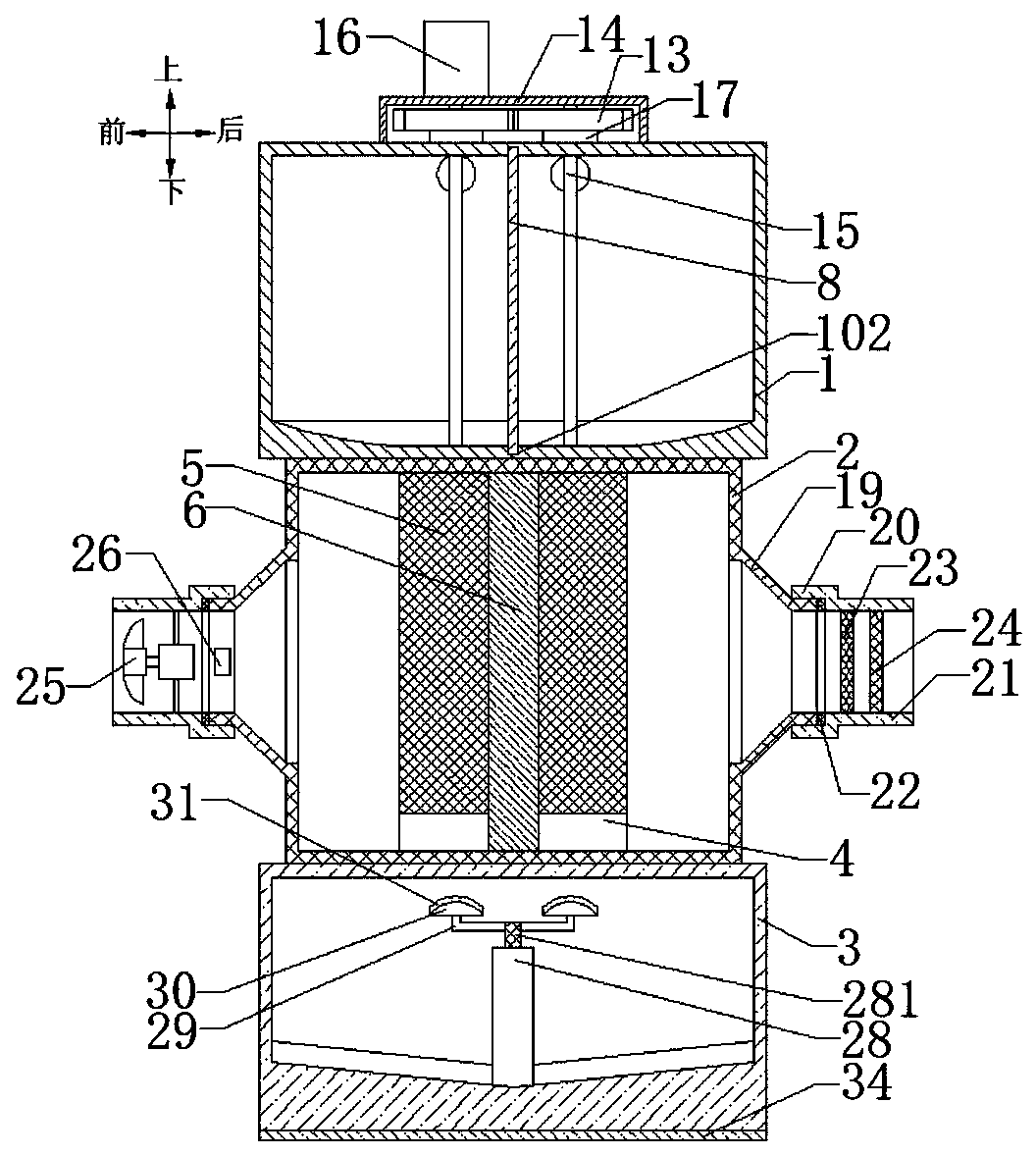

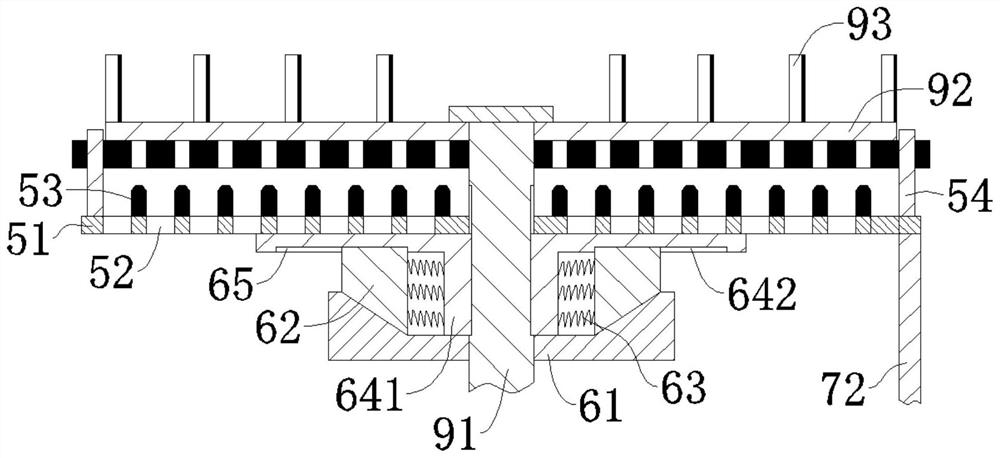

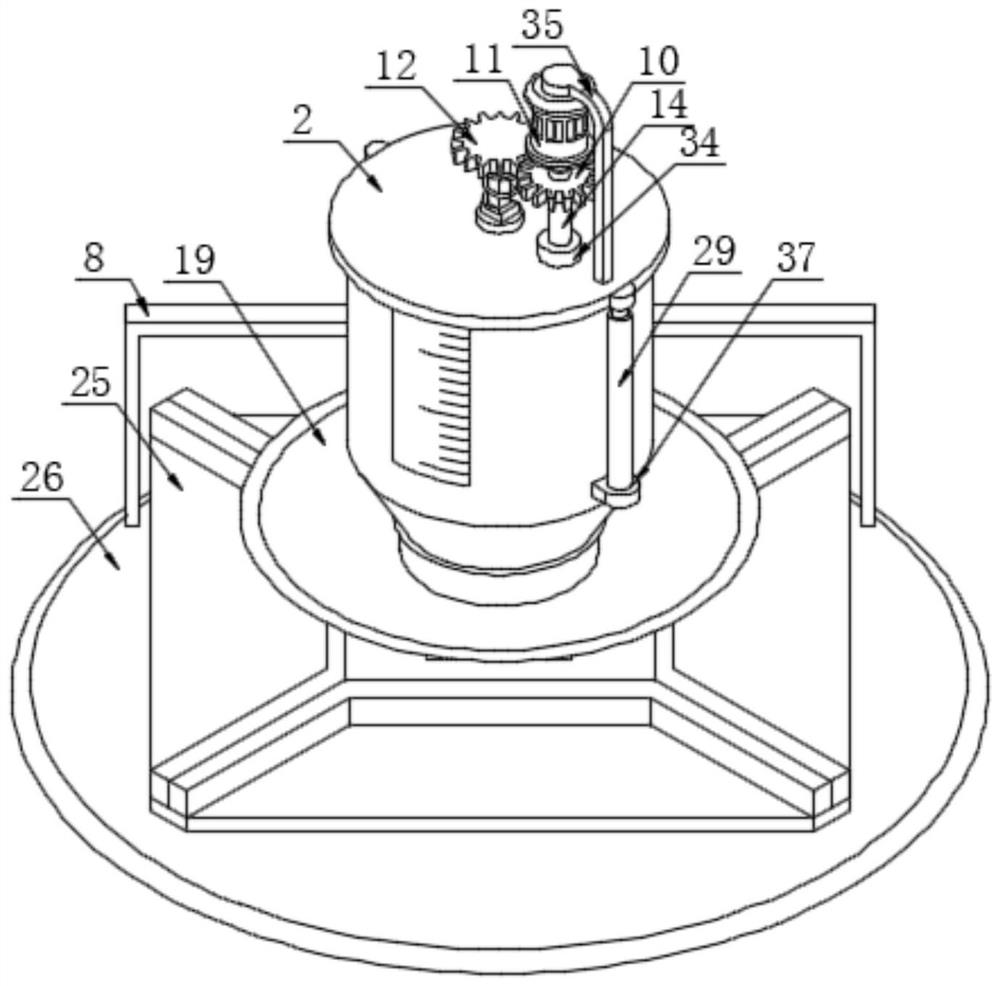

Building decorative coating stirring uniform mixing device

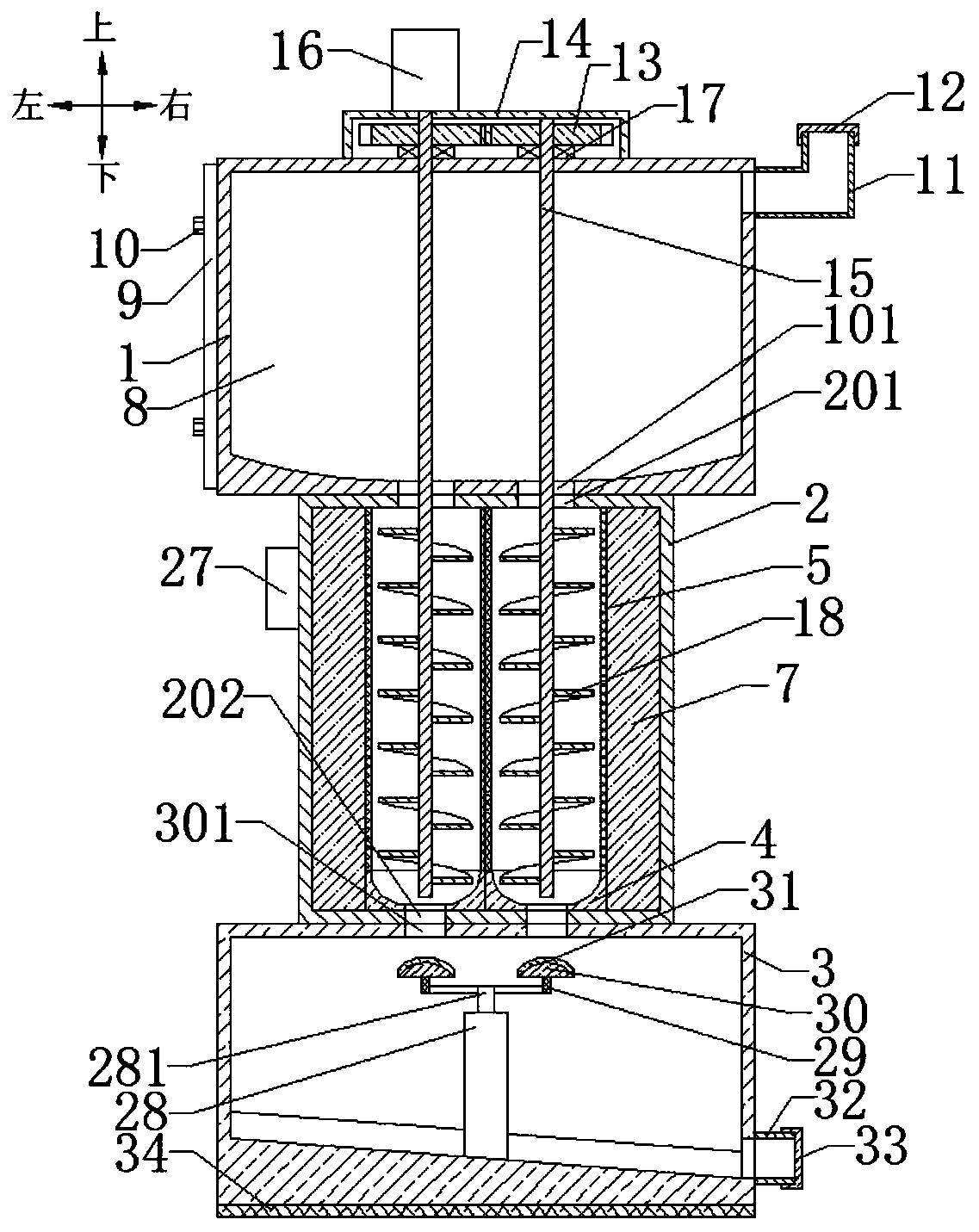

InactiveCN108927030AReduce stirring dead angleAct as agitatorRotary stirring mixersTransportation and packagingDistortionTransverse plane

The invention discloses a building decorative coating stirring uniform mixing device. The building decorative coating stirring uniform mixing device comprises a longitudinal adjusting device; the right side of the longitudinal adjusting device is provided with a stirring barrel; the upper end of the stirring barrel is provided with a stirring power assembly connected with the longitudinal adjusting device; a vertical omnidirectional stirring paddle is arranged in the stirring barrel; the lower end of the vertical omnidirectional stirring paddle is connected with an uniform sieve; a paint raising device is arranged right below the uniform sieve; the connection part of the stirring power assembly with the stirring barrel is provided with a damping connecting piece. In application, self rotation of a distortion paddle rod is driven, cutting of coating blocks is realized, and then stirring effect of coating in a vertical plane is achieved, coating transverse plane longitudinal plane three-dimensional stirring is realized, the rotating direction of a rotating vertical shaft and the rotating direction of a rotating bottom shaft are opposite, in-time stirring of raised coating is ensured,raising of stirred coating after precipitation is achieved, a virtuous circle is achieved, and stirring efficiency is increased greatly.

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

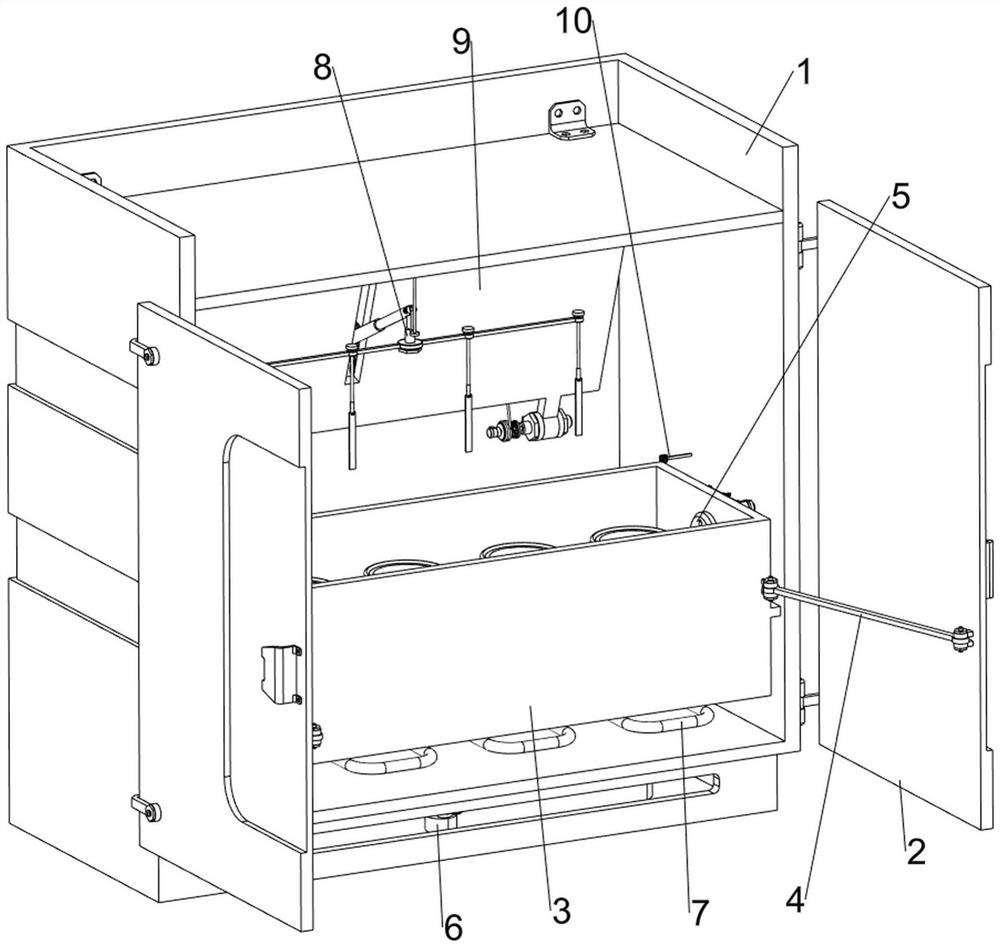

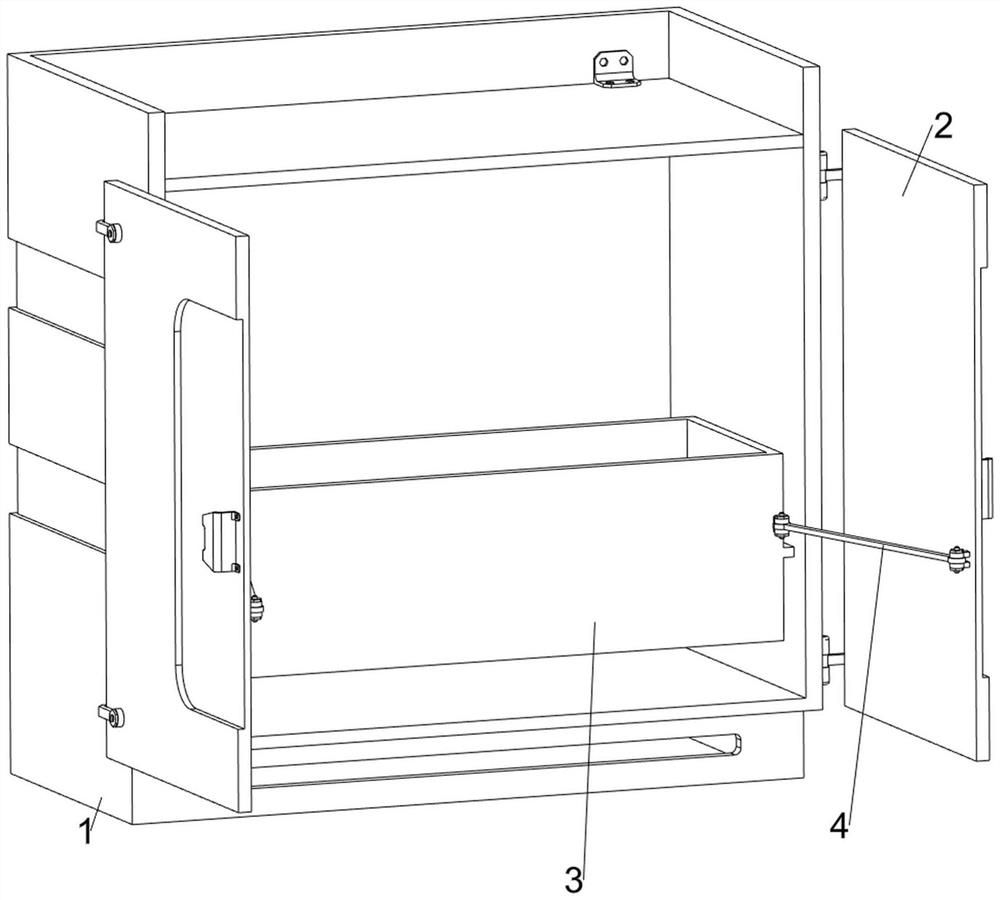

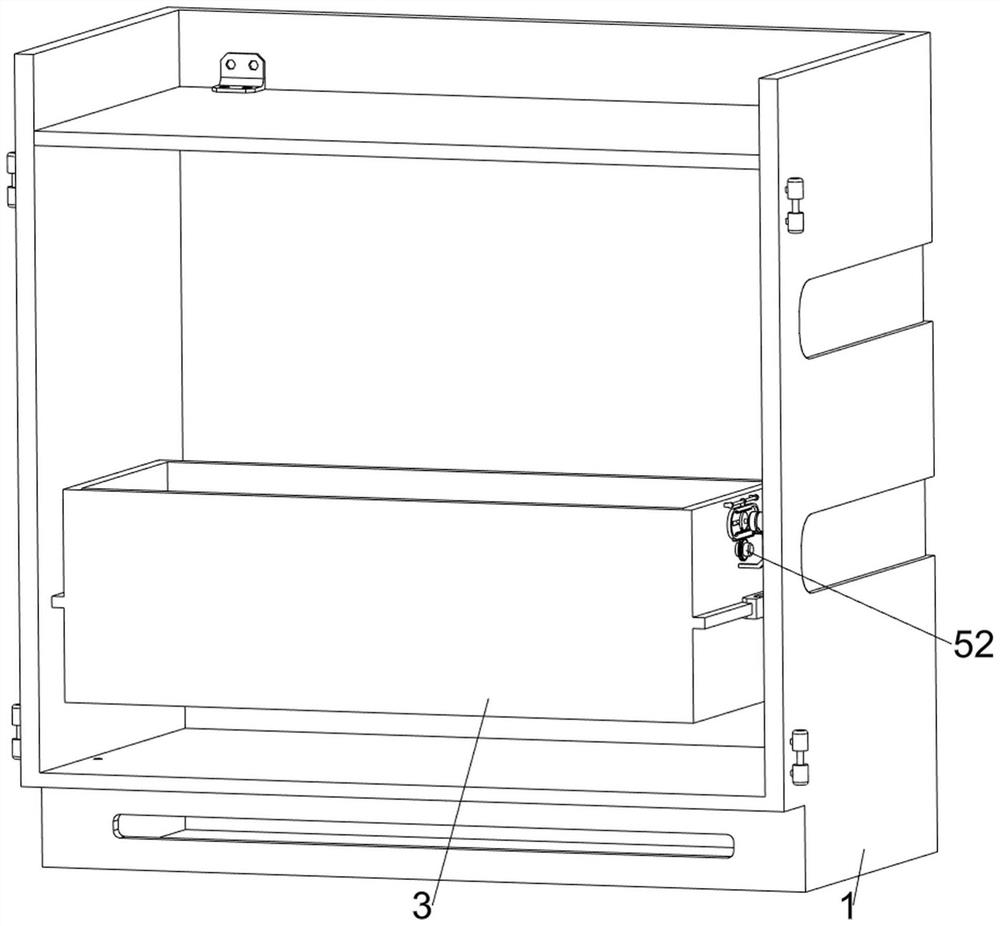

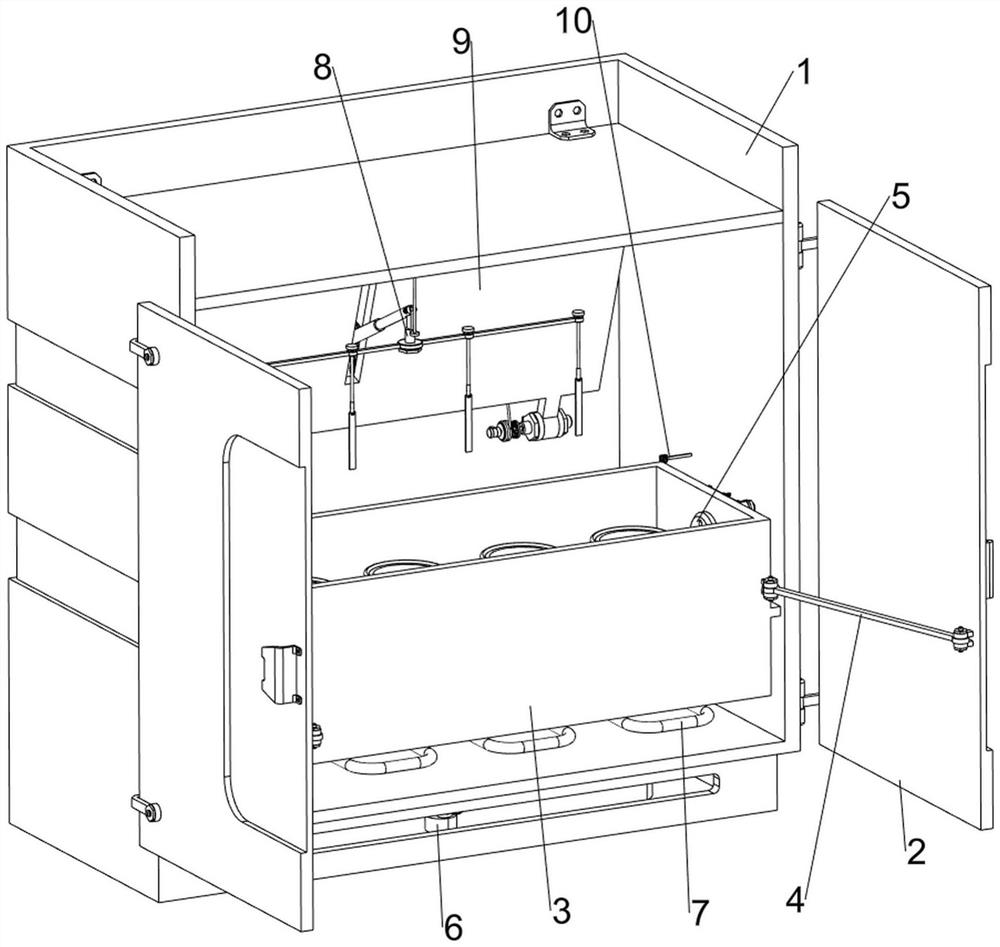

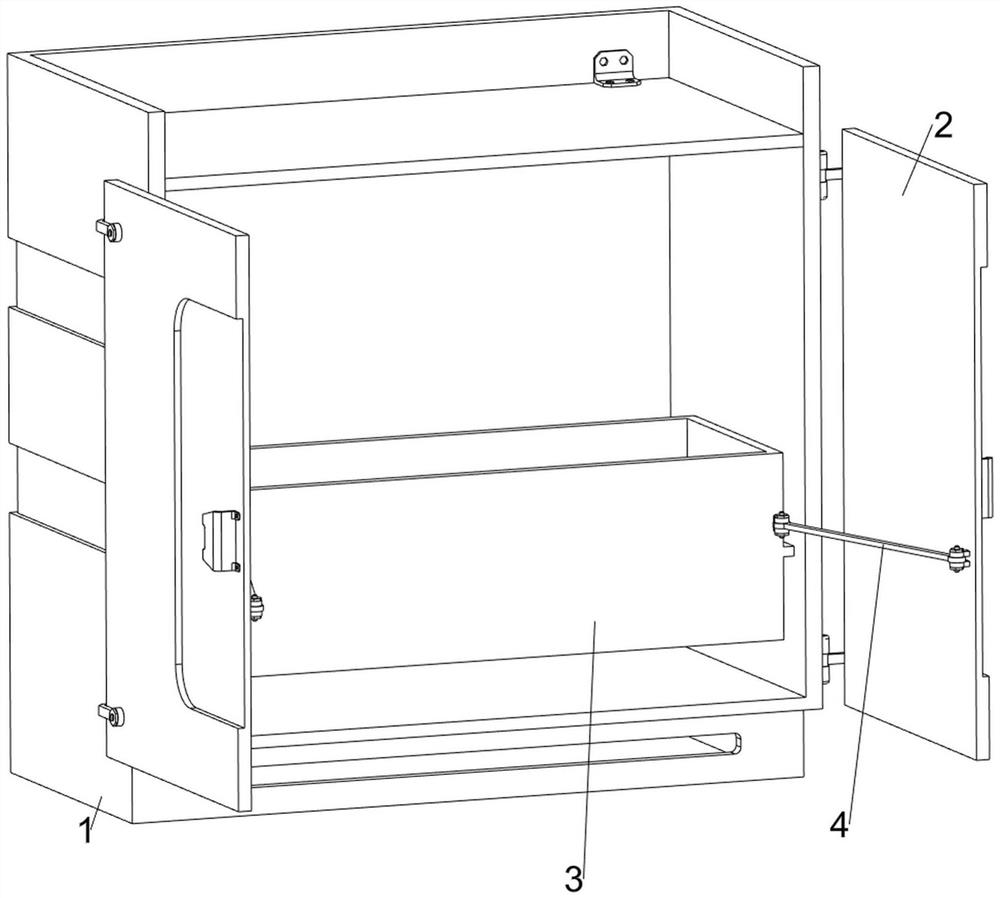

Microbial culture device for medical examination

InactiveCN114456915AFully contactedPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention relates to a microbial culture device, in particular to a microbial culture device for medical examination. The invention aims to provide the medical examination microorganism culture device capable of enabling microorganisms to be in full contact with air. The medical examination microorganism culture device comprises a frame, door plates, a sliding frame and the like, the front portions of the left side and the right side of the frame are rotationally provided with the door plates used for dust prevention, and the lower portion of the inner side of the frame is slidably provided with the sliding frame used for storing culture bottles. According to the device, an air pump is used as a driving force, a nozzle can spray sterile air into a sliding frame, a first driving motor is used as a driving force, a missing gear can be driven to rotate, so that a fluted disc can be driven to reciprocate back and forth, a culture bottle can be driven to shake back and forth back and forth, and microorganisms can be in full contact with the air; therefore, the growth is better.

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

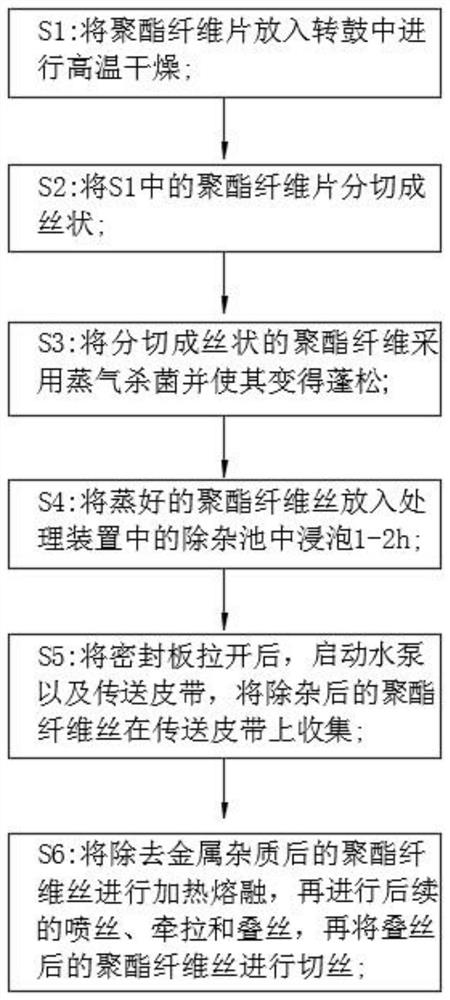

Production technology of polyester staple fibers

PendingCN111607828AImprove work efficiencySave human effortTextile treatment machine arrangementsFibre cleaning/opening machinesPolyesterFiber

The invention belongs to the technical field of fiber production, and particularly discloses a production technology of polyester staple fibers. A polyester fiber piece is processed by the productiontechnology according to the following steps that S1, the polyester fiber piece is put into a rotary drum to be subjected to high-temperature drying treatment; S2, the polyester fiber piece in the S1 is cut to be fibrous; S3, cut fibrous polyester fibers are sterilized by steam and can become fluffy; S4, the steamed polyester fibers is put into an impurity removal pool of a processing device and soaked for 1-2 hours; S5, after a sealing plate is pulled open, a water pump and a conveying belt are started, and the polyester fibers which are subjected to impurity removal are collected on the conveying belt; and S6, the polyester fibers which enable metal impurities to be removed are heated to be molten, then the follow-up fiber spraying operation, traction and fiber stacking operation are conducted, then the polyester fibers which are subjected to fiber stacking operation are cut, and therefore the polyester staple fibers can be obtained. According to the production technology, the polyester fibers are steamed to be fluffy, then the impurity removal pool is arranged, the metal impurities on the surfaces of the fluffy polyester fibers can be rinsed inside the impurity removal pool, andtherefore the working efficiency is improved.

Owner:程明

Filtering device for paper pulp

The invention relates to the field of paperboard production, and particularly discloses a filtering device for paper pulp. The filtering device comprises a seal cover, a pulp entering mechanism, a filtering disc and a collecting groove, filtering holes are formed in the filtering disc, a rotary shaft is fixed to the axis of the filtering disc, a rotating motor is fixed to the exterior of the sealcover, and a discharging pipe is communicated with the collecting groove; the pulp entering mechanism comprises an air-blowing pipe, a guiding pillar, a rotary barrel, a fixing barrel, an air-collecting pipe and a pulp entering motor; a seal plate is fixed to the opening of the fixing barrel; a plunger piston is fixed inside the fixing pipe, a spiral channel is formed inside the plunger piston, and the pulp entering pipe is communicated with the air-blowing pipe; the lower end of the guiding pillar is an inclined face, a clamping groove is formed in the lower end of the guiding pillar, the rotary shaft is fixed to the rotary barrel, and the pulp entering motor drives the rotary shaft; a partitioning plate is fixed inside the rotary barrel and divides the rotary barrel into a first cavity and a second cavity, and air inlets and air outlets are formed in the side wall of the rotary barrel; a first piston and a second piston are arranged in the first cavity and the second cavity, and a first piston rod and a second piston rod are fixed to the first piston and the second piston. In the scheme, workers are prevented from being scalded by the paper pulp.

Owner:重庆云新包装有限公司

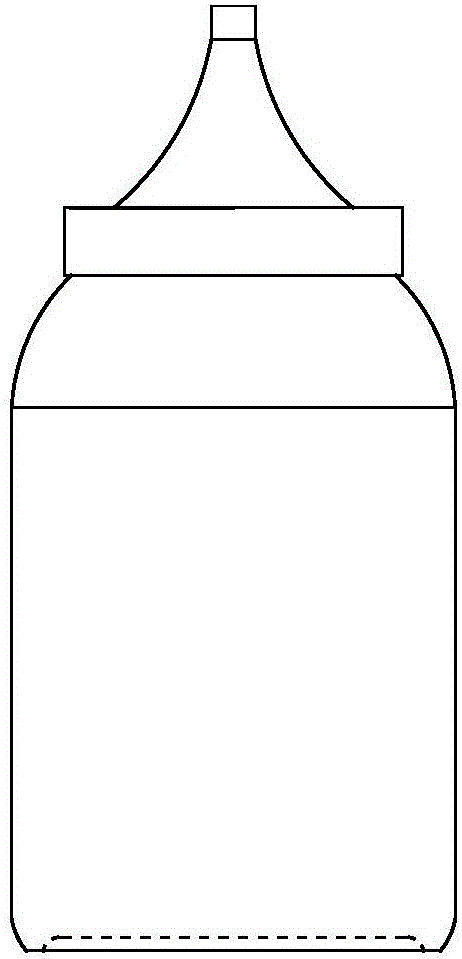

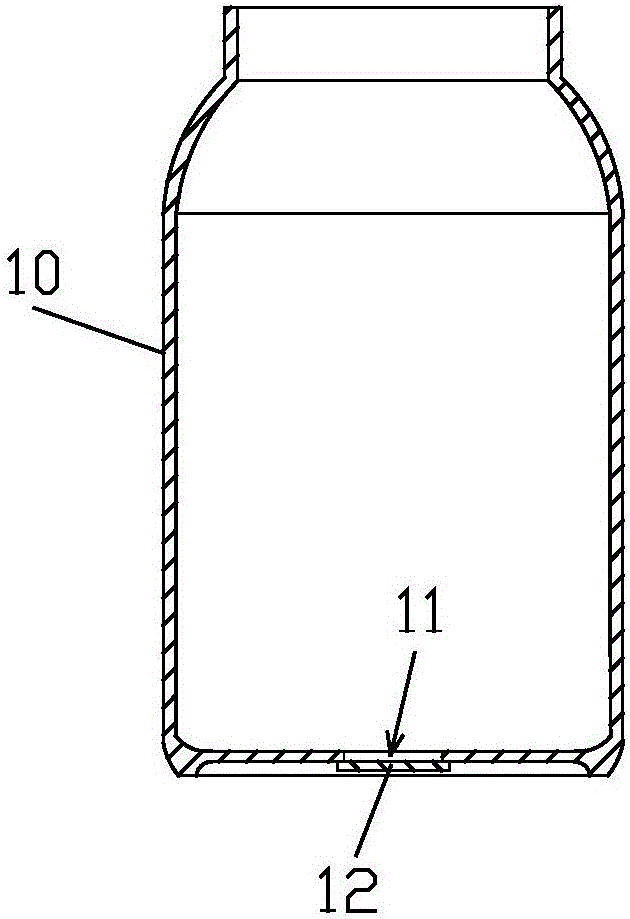

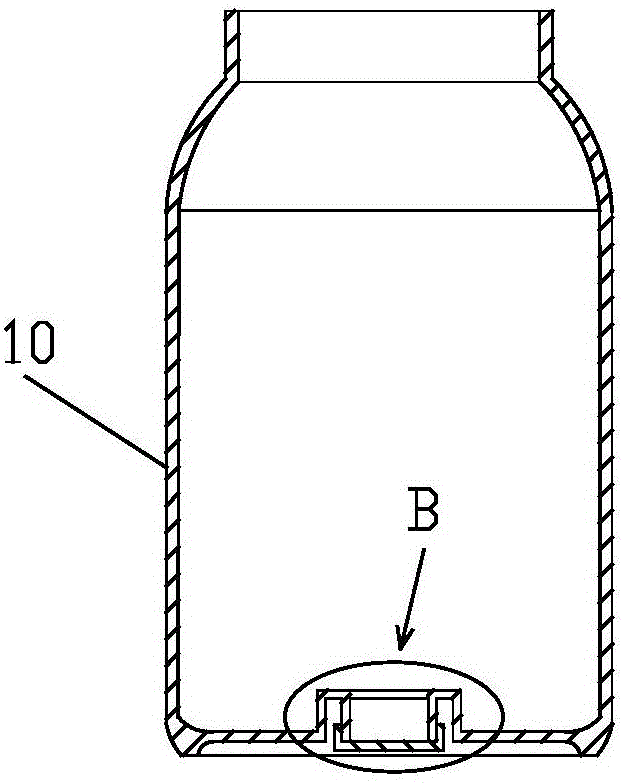

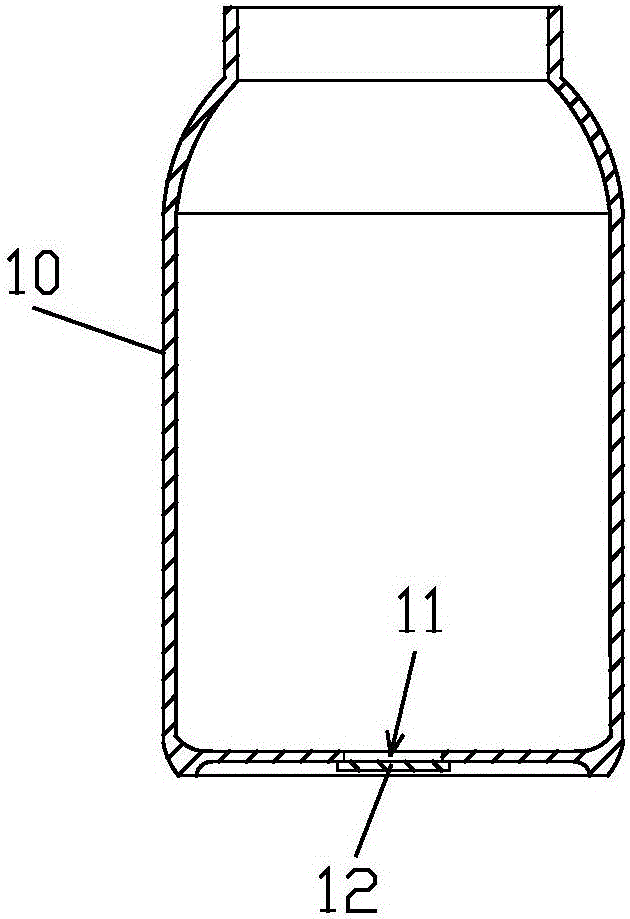

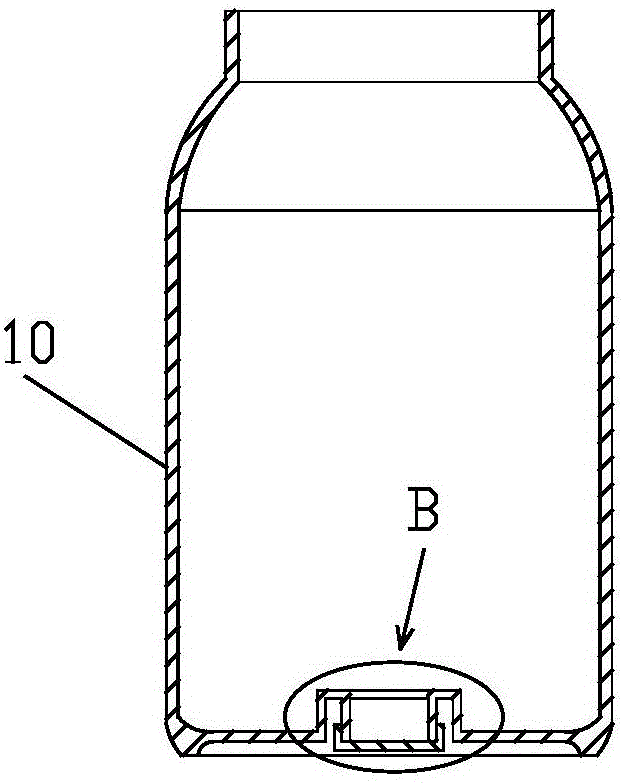

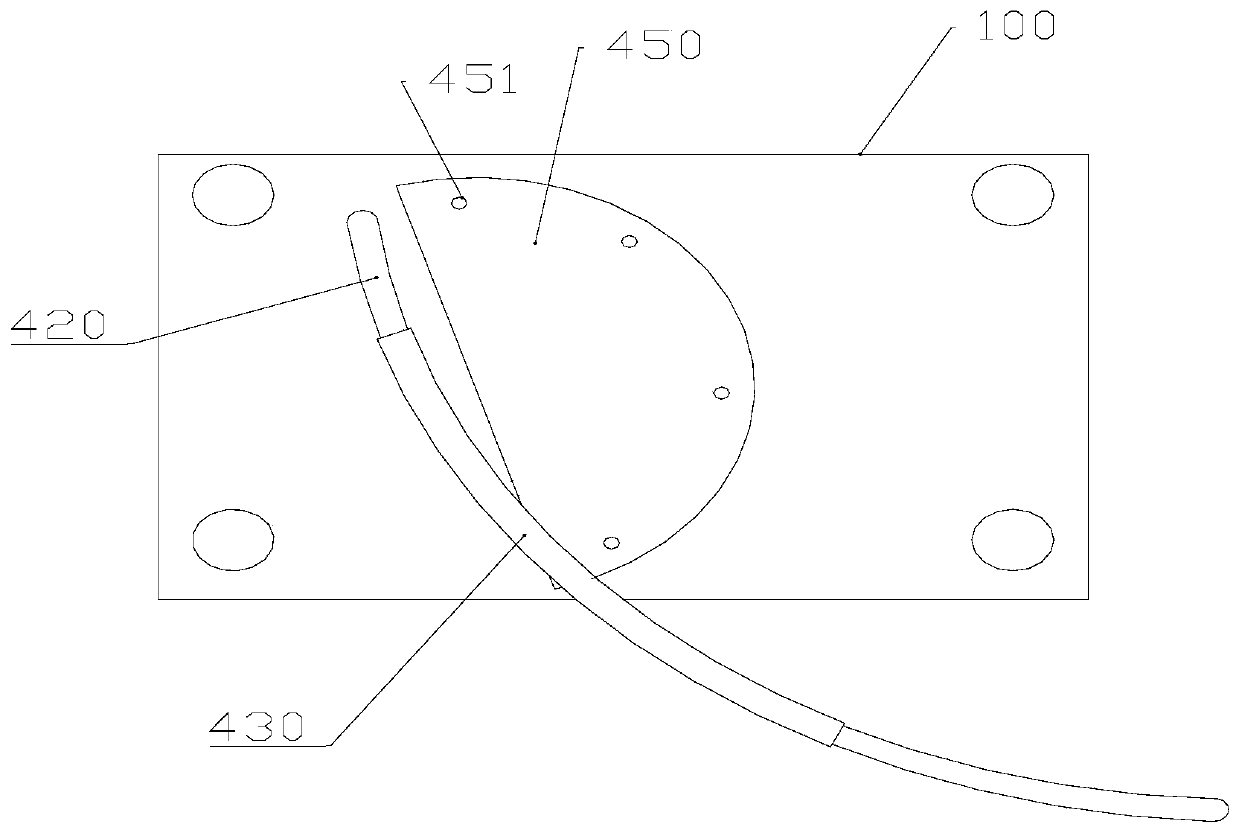

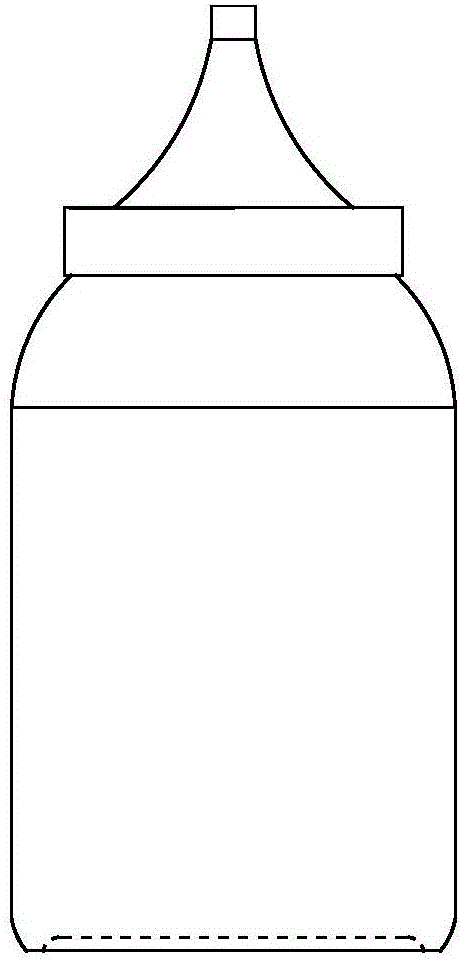

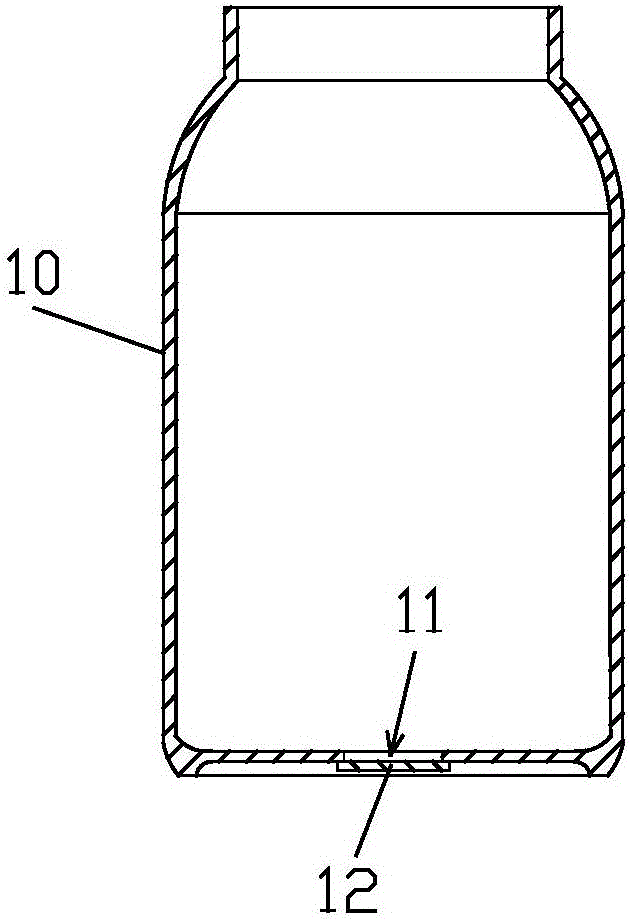

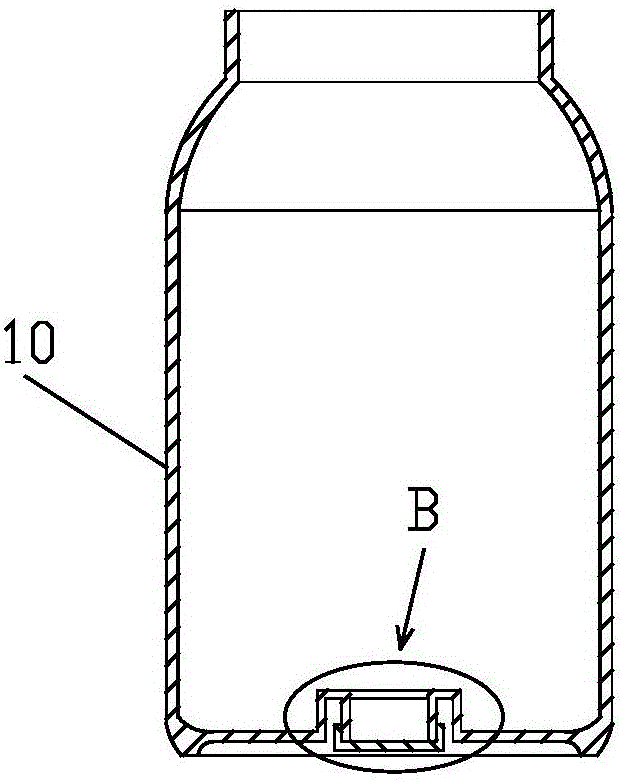

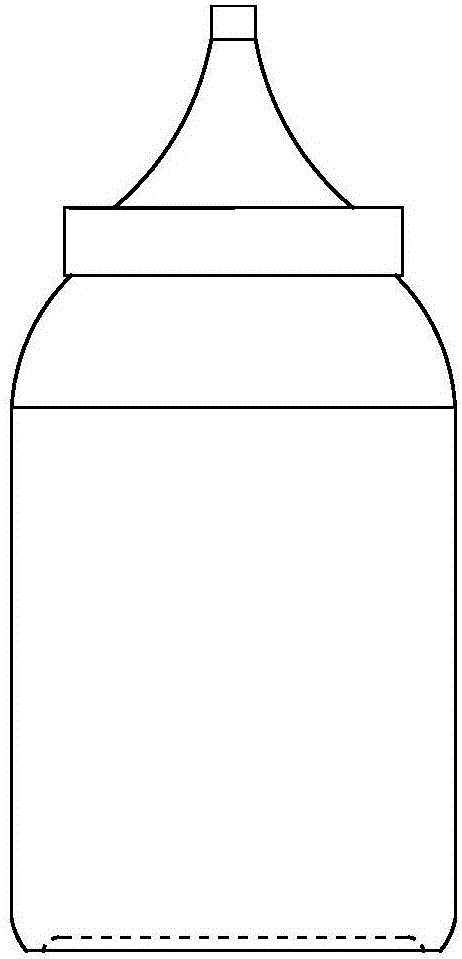

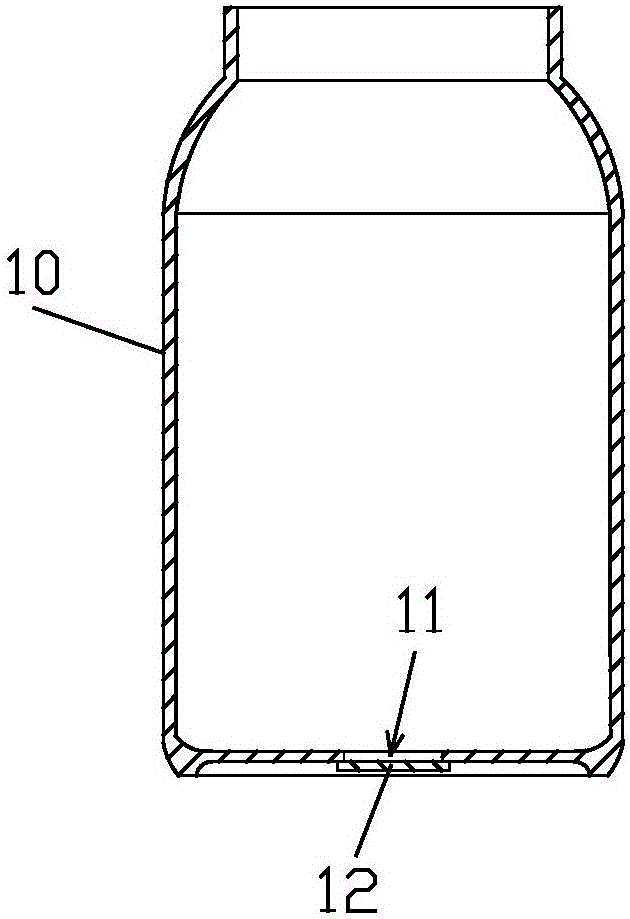

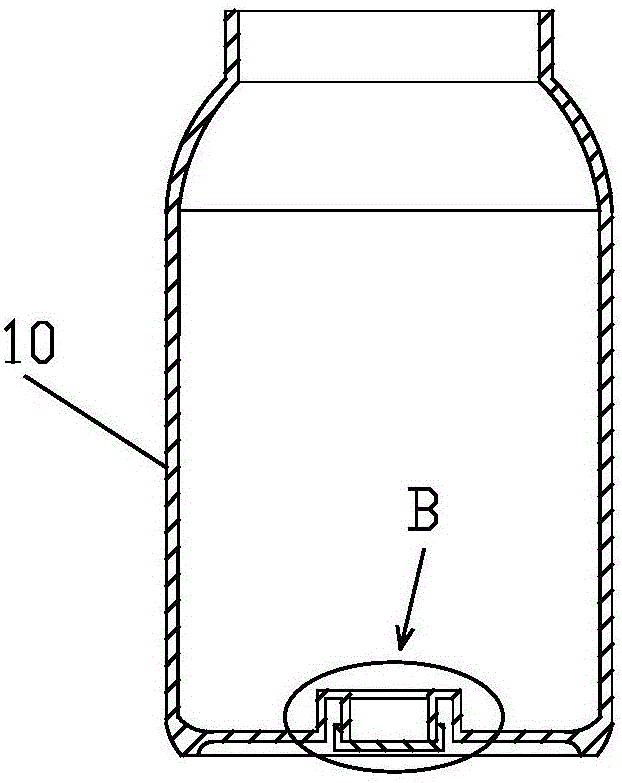

Toner bottle apt to add toner to toner cartridge

InactiveCN106773575ASolve the above-mentioned difficult problems that are eager to be solvedSolve the blockageElectrographic process apparatusEngineeringBottle

The invention relates to a toner bottle apt to add a toner to a toner cartridge. The toner bottle comprises a bottle body and a toner adding head. An insertion part allowing a strip piece to be inserted in the bottle body is arranged at the bottom of the bottle body, and the insertion part is plugged before the strip piece is inserted therein. The strip piece may be any one of a rod, a sheet, a tube, and a plate, and serves stirring as being inserted in the toner bottle when a toner is added. Thus, the problem of toner blockage at the toner adding head is solved, and reliable addition of the toner in the toner bottle to the toner cartridge is achieved. After the addition of the toner is finished, the strip piece is just pulled out and cleaned with tissue paper. In this way, the problem that the toner is prone to overflow to cause pollution and waste in a traditional solution may be avoided.

Owner:安徽智汇和科技服务有限公司

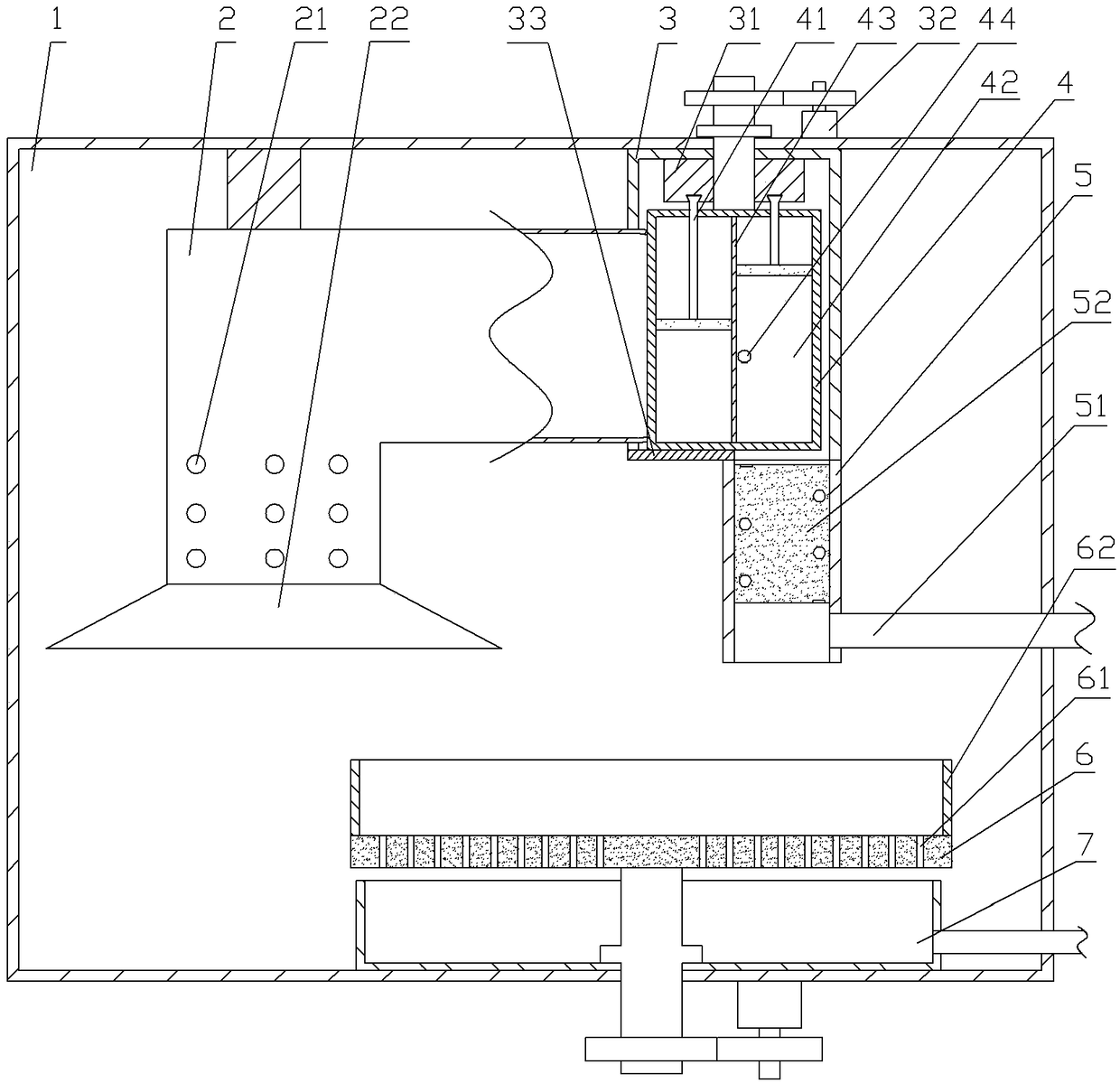

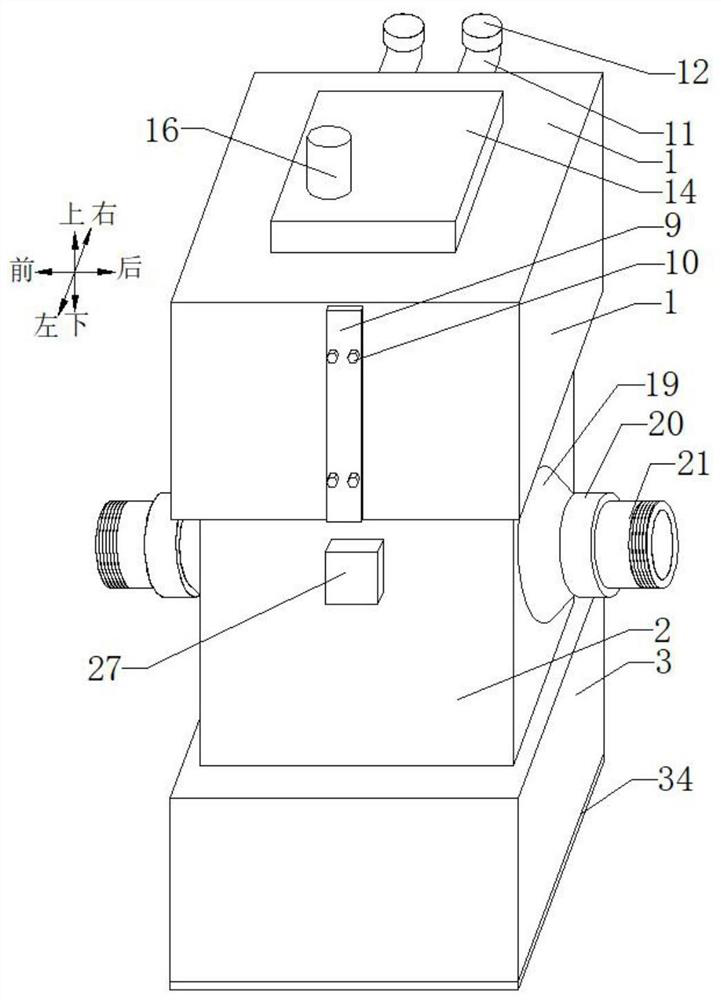

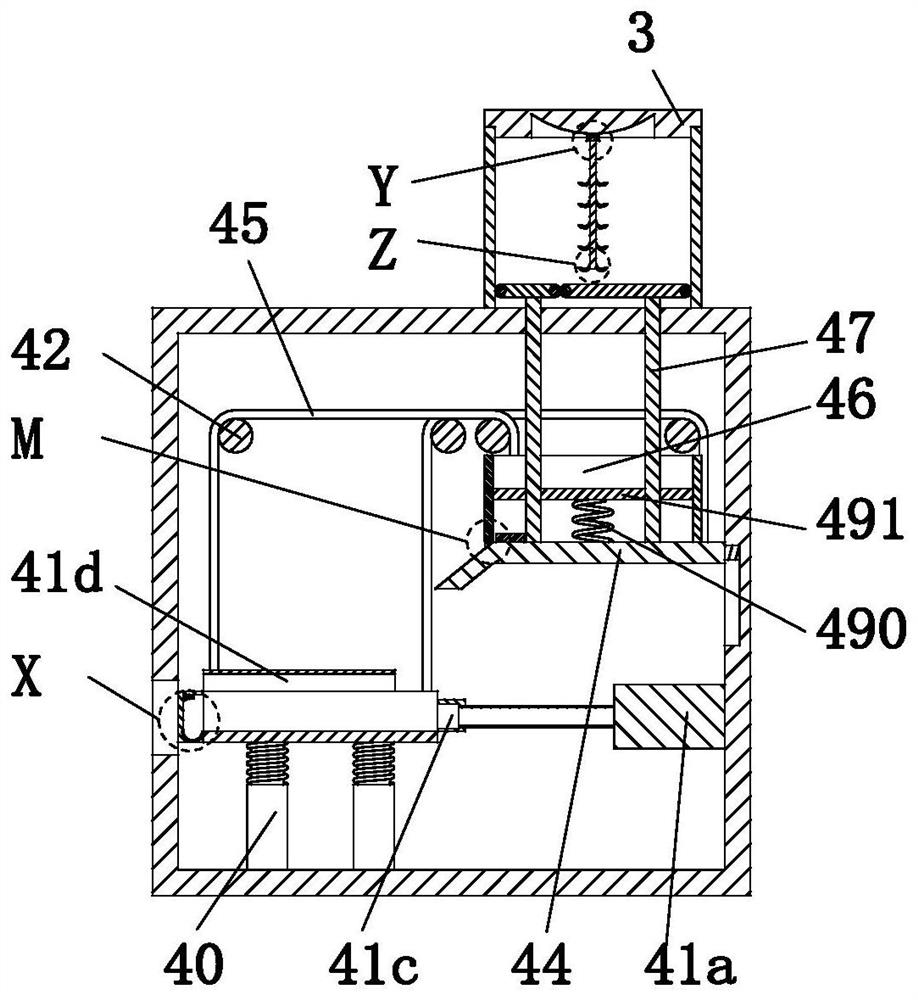

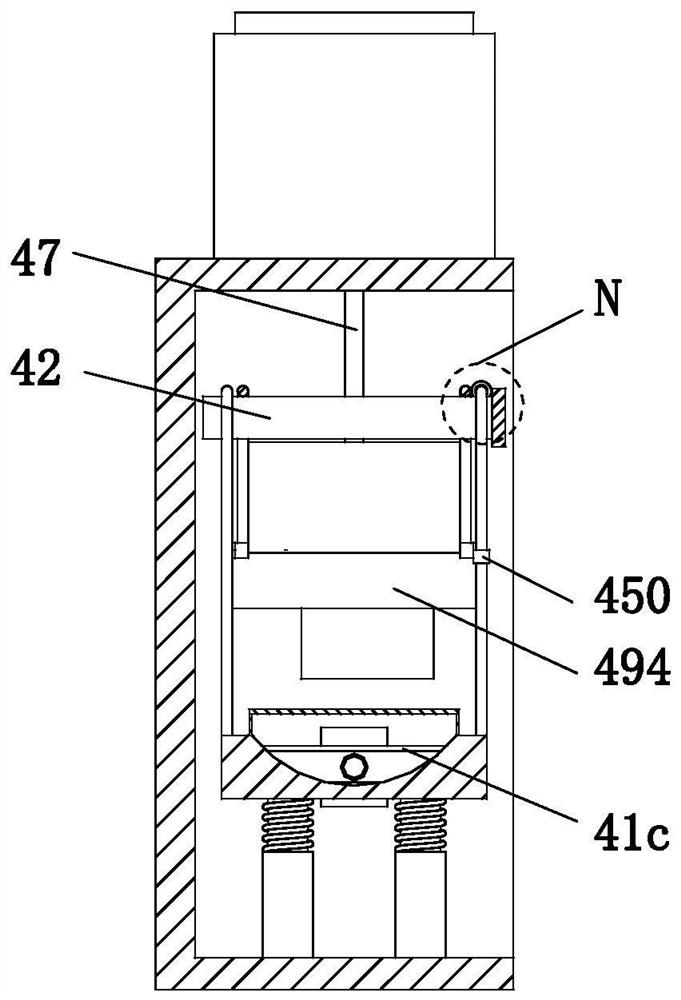

High efficiency air purification device capable of automatically adjusting using amount of molecular sieves

ActiveCN111503773AEasy to replaceGuaranteed work effectMechanical apparatusSpace heating and ventilation safety systemsMolecular sieveProcess engineering

The invention discloses a high efficiency air purification device capable of automatically adjusting the using amount of molecular sieves. The high efficiency air purification device capable of automatically adjusting the using amount of the molecular sieves comprises a material storage box, a purification box and a waste material box which are arranged in sequence from top to bottom; four cylinder seats which are arranged in a matrix are arranged in the purification box; a mesh cylinder is mounted at the upper end of each cylinder seat; second connecting blocks are connected between the fourcylinder seats as well as the mesh cylinders and the left side wall as well as the right side wall in the purification box; conical connecting pipes are mounted on the front side wall and the rear side wall of the purification box; connecting pipes are arranged at the heads of the conical connecting pipes; an activated carbon filtering net and a filtering net are arranged in the connecting pipe positioned at the front end; and a booster fan is arranged in the connecting pipe positioned at the rear end. Compared with the prior art, the high efficiency air purification device capable of automatically adjusting the using amount of the molecular sieves has the beneficial effects that air flow in the purification box can be driven to circulate through the work of the booster fan; the air flow is introduced into the purification box after being filtered through the activated carbon filtering net and the filtering net, and is exhausted after being treated by the molecular sieves in the cylinder seats and the mesh cylinders; and therefore, purification treatment of carbon dioxide and harmful substances in air is realized.

Owner:通用空气(辽宁)有限公司

Method for adding toner into printer

InactiveCN106842857ASolve the above-mentioned difficult problems that are eager to be solvedSolve the blockageElectrographic process apparatusBottleElectrical and Electronics engineering

The invention relates to a method for adding toner to a printer, which comprises taking out a toner bottle, removing a toner filling head on the toner bottle, removing a sealing film at the bottle mouth of the bottle body, and then reloading the toner filling head On the bottle body, insert the toner head into the toner chamber through the toner inlet on the toner chamber, turn the toner bottle upside down, and the toner in the toner bottle begins to flow into the toner chamber; The inserting part set on the bottom is inserted into the bottle body, the auxiliary device is rotated at intervals and the auxiliary device is drawn and inserted along the height direction of the bottle body, so that the toner in the bottle body completely flows into the toner powder bin; the auxiliary device is pulled out from the bottle body and wiped with a paper towel Keep it clean for use, remove the toner bottle that has been filled with powder, then close the toner inlet of the toner compartment, and reload the toner cartridge into the printer. The above solution can realize the rapid addition of toner to the printer, avoid the overflow of the toner during the adding process, and realize the cleaning and toner addition of the toner cartridge.

Owner:安徽智汇和科技服务有限公司

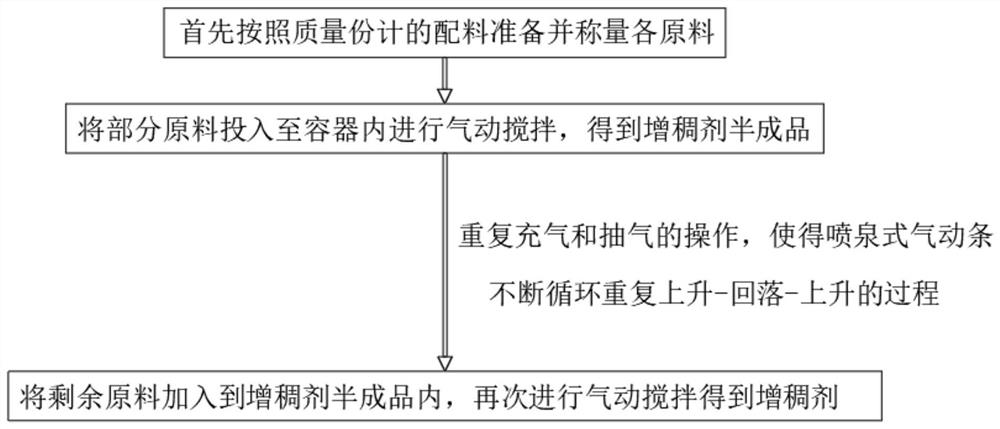

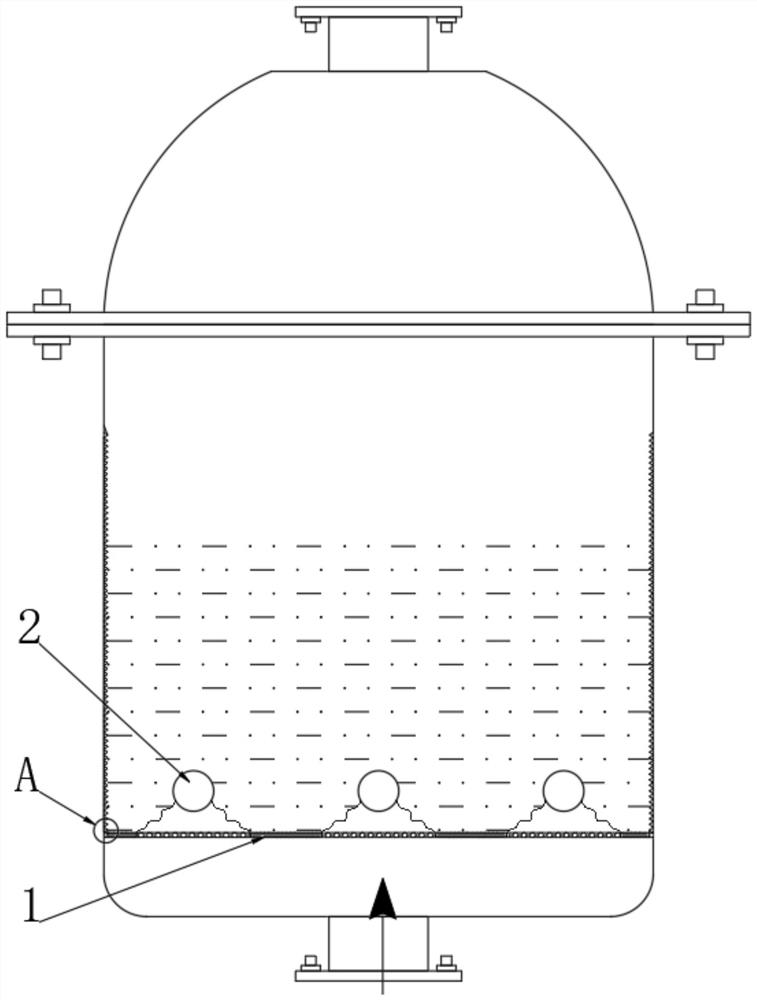

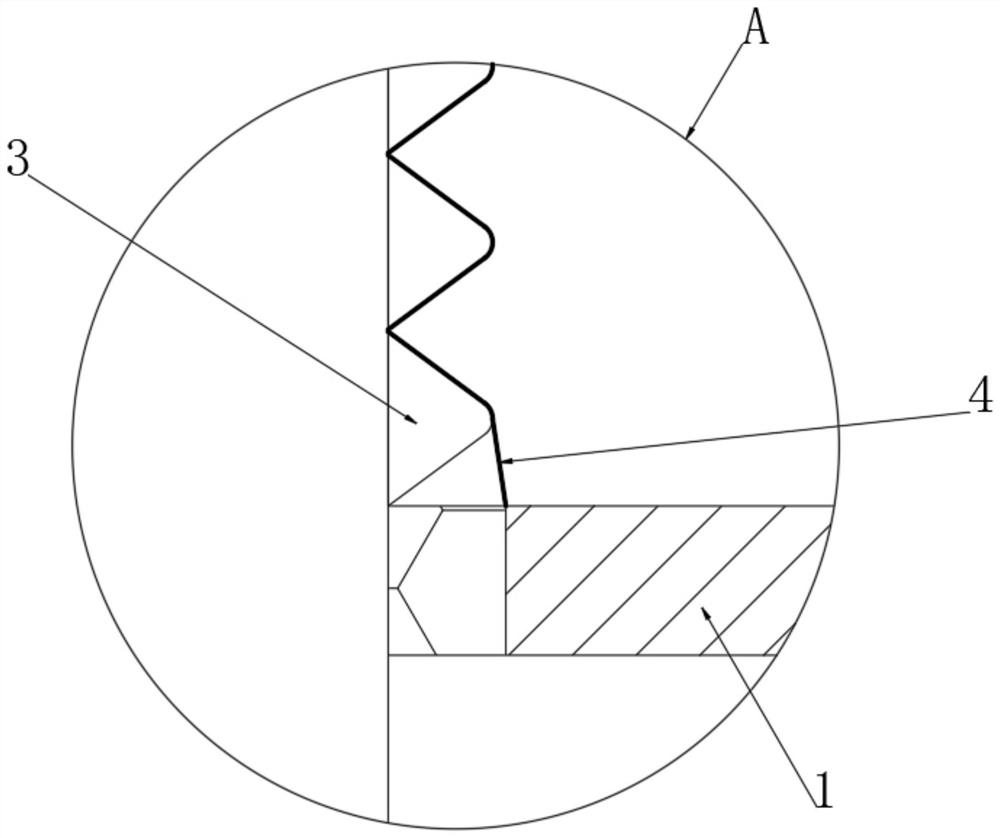

Efficient preparation process of thickening agent

PendingCN113105778AAchieving a stirring effectPrevent overflowTransportation and packagingMixersSurface tension forceProcess engineering

The invention discloses an efficient preparation process of a thickening agent, and belongs to the field of preparation of thickening agents. In the preparation process, mechanical stirring in the prior art is replaced by pneumatic stirring operation, and by circulating inflation and exhaust operation; the stirring effect of fountain type rising-falling-falling-rising of the fountain type pneumatic strip in raw materials is achieved, overflow of internal air is effectively accelerated under the condition that external air is effectively prevented from being introduced, then the preparation efficiency is improved, meanwhile, when the fountain type pneumatic strip falls back, shrinkage pieces can also be tightly attached to the inner wall of a bearing plate, at the moment, the surface tension of the two is greatly changed, bubbles adsorbed on the surfaces of the two are exploded, the situation that the bubbles adsorbed on the inner wall of a container are difficult to eliminate in the prior art is effectively avoided, overflow of the bubbles in the raw materials is further accelerated, the air content in the finished product of the thickening agent is effectively reduced, and the quality of the finished product of the thickening agent is better.

Owner:徐鹏

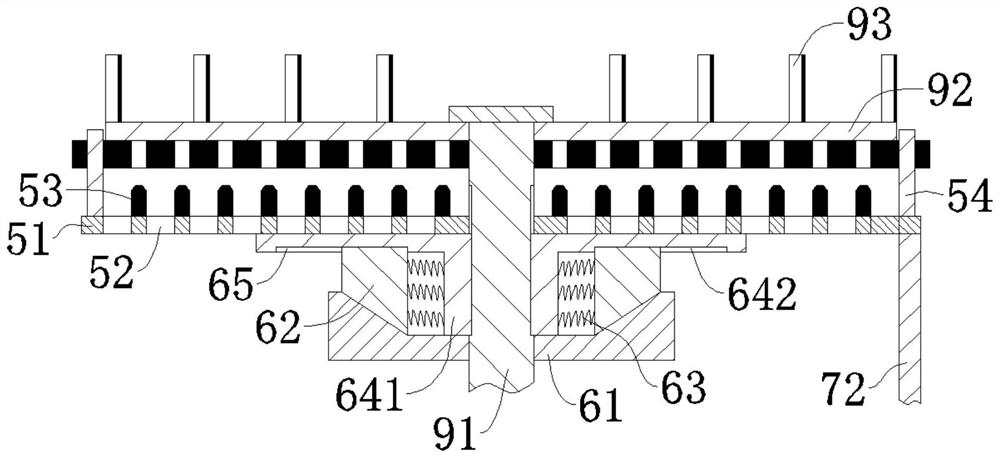

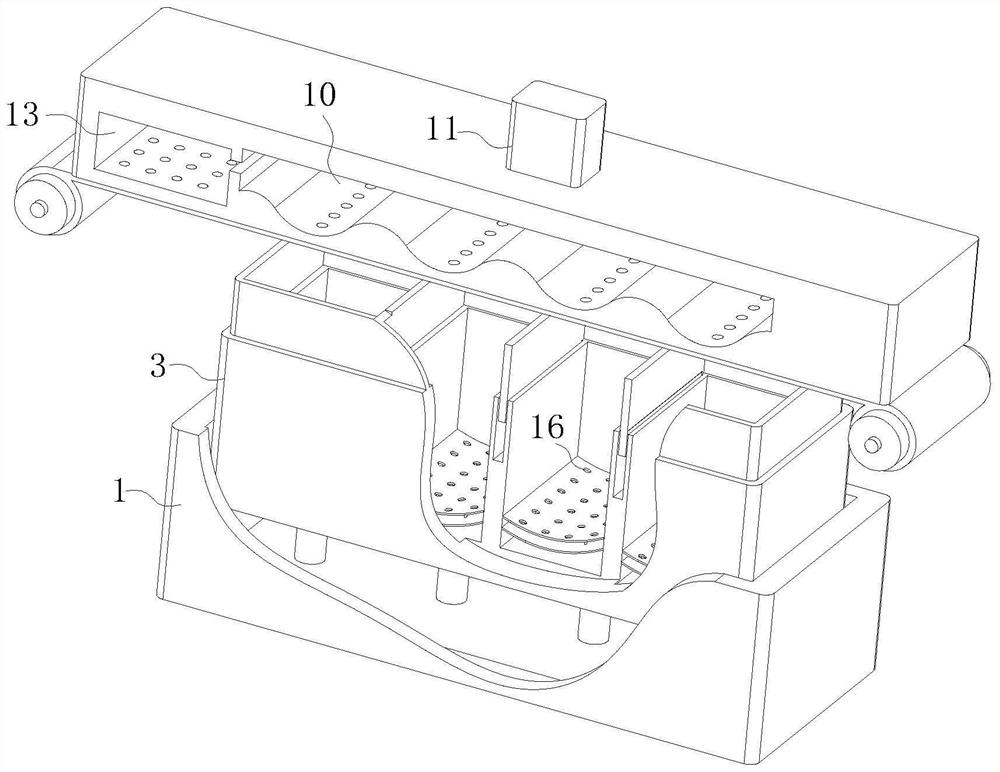

Textile fabric space dyeing machine

InactiveCN111876946APlay the role of pre-dryingAvoid wastingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsHydraulic cylinderEngineering

The invention belongs to the technical field of space dyeing machines, and particularly relates to a textile fabric space dyeing machine which comprises a bottom limiting box, a large dyeing pool anda winding roller. A hydraulic cylinder is fixedly arranged on the inner wall of the bottom of the bottom limiting box. The top of the hydraulic cylinder is fixedly connected with the bottom of the large dyeing pool. The interior of the large dyeing pool is divided into a plurality of dye pools through partition plates. A rectangular groove is formed at the edge of the top of each dye pool. The bottom of each rectangular groove is fixedly connected with the bottom of a concentric-square-shaped movable plate through a spring. A lower rubber elastic membrane is fixedly arranged at the bottom of each dye pool. The large dyeing pool is driven by the hydraulic cylinder to move up and down, the concentric-square-shaped movable plates are driven to move downwards in the rectangular grooves when the large dyeing pool moves upwards, then gas in the rectangular grooves is extruded into a bottom cavity of the lower rubber elastic membranes to enable the liquid levels in the dye pools to move upwards, and then the textile fabric body is dyed; and by means of the dyeing manner, the textile fabric body is just wet by the dye, and then the purpose of saving the dye can be achieved.

Owner:宿州市悦然纺织有限公司

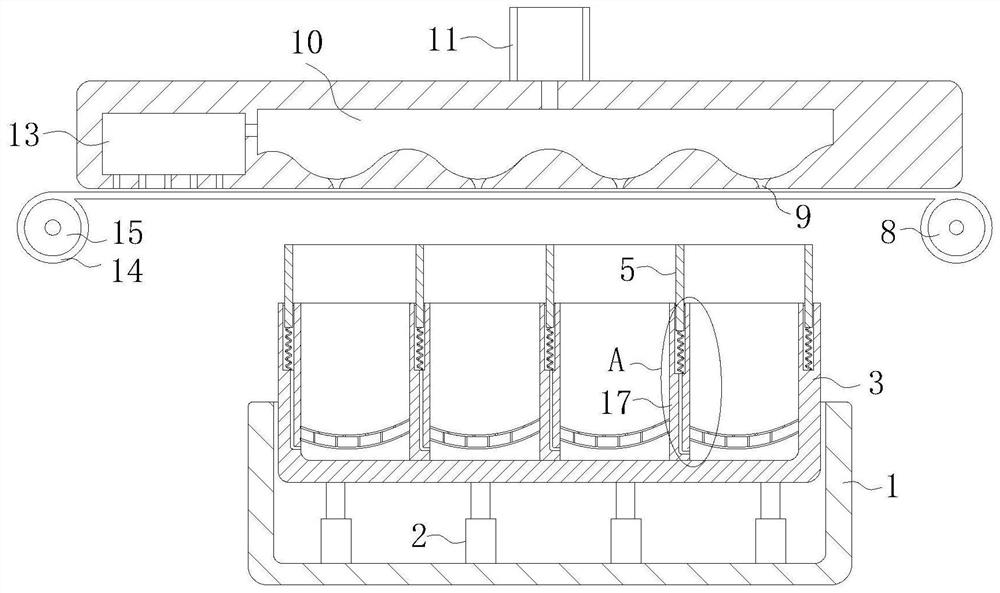

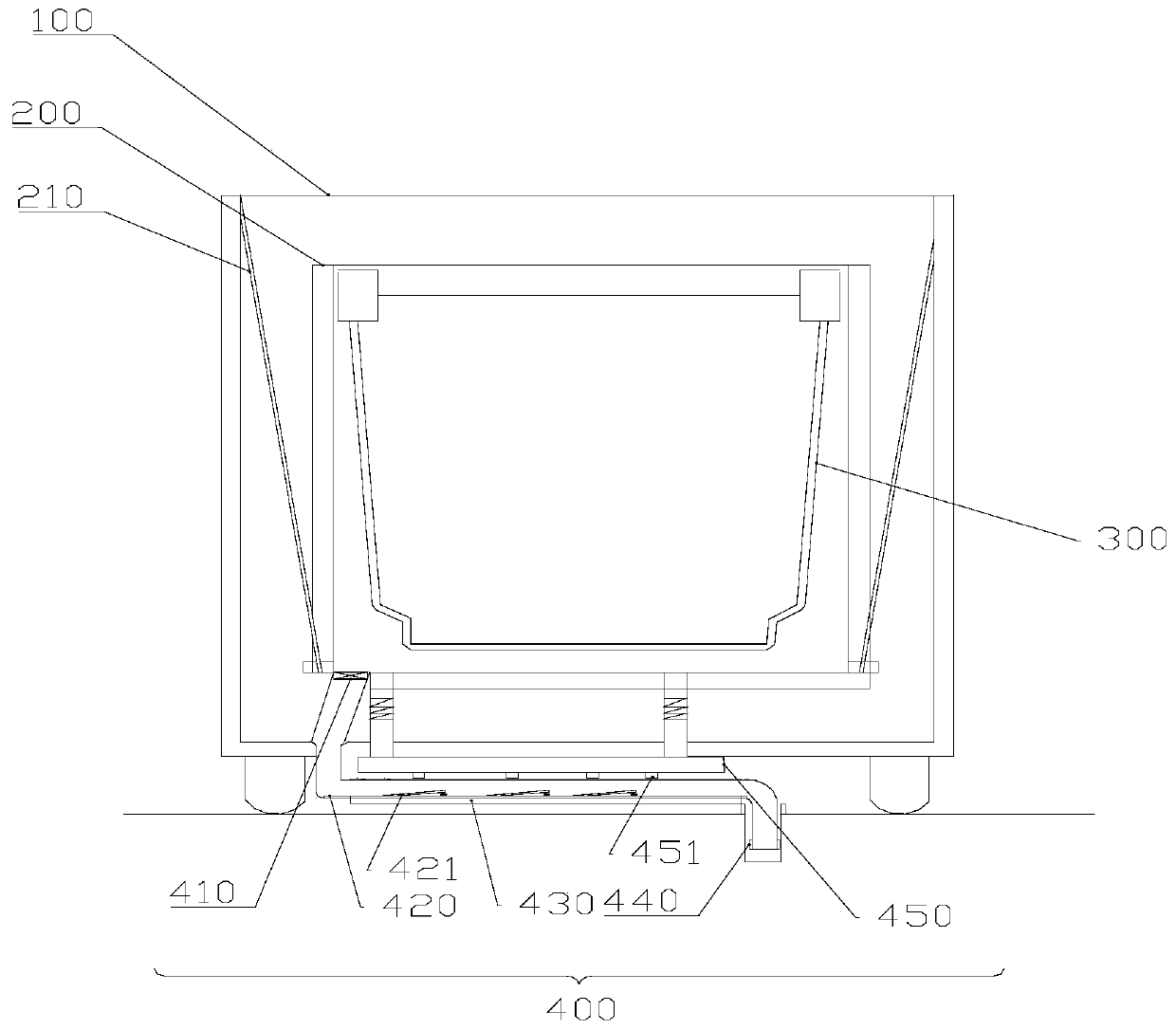

Clothes washing machine

ActiveCN108221292AImprove featuresAvoid blockingOther washing machinesTextiles and paperWater storageElectric machinery

The invention relates to a washing device of textiles and in particular to a clothes washing machine. The clothes washing machine comprises a housing and a drainage pipe. The drainage pipe is dividedto an elastic layer in an inner layer and a ferromagnetic net layer packaging the elastic layer. The outer wall of the tail part of the drainage pipe is fixedly provided with a heavy ring. The clotheswashing machine further comprises a dredging mechanism. The dredging mechanism comprises a vibrating plate, an elastic connecting rod, a plurality of electromagnets and an electromagnet controller. The elastic connecting rod passes through one end of the housing and is fixedly connected with a water storage outer barrel, and the other end is fixedly connected with the vibrating plate. The vibrating plate is positioned below the housing. The electromagnets are fixed on the lower end face of the vibrating plate. The electromagnet controller is used for starting the electromagnets one by one while a motor is driven to be started, and closing the electromagnets while a drainage valve is started. The provided clothes washing machine is capable of automatically cleaning the blocked drainage pipe.

Owner:宁波梦居智能科技有限公司

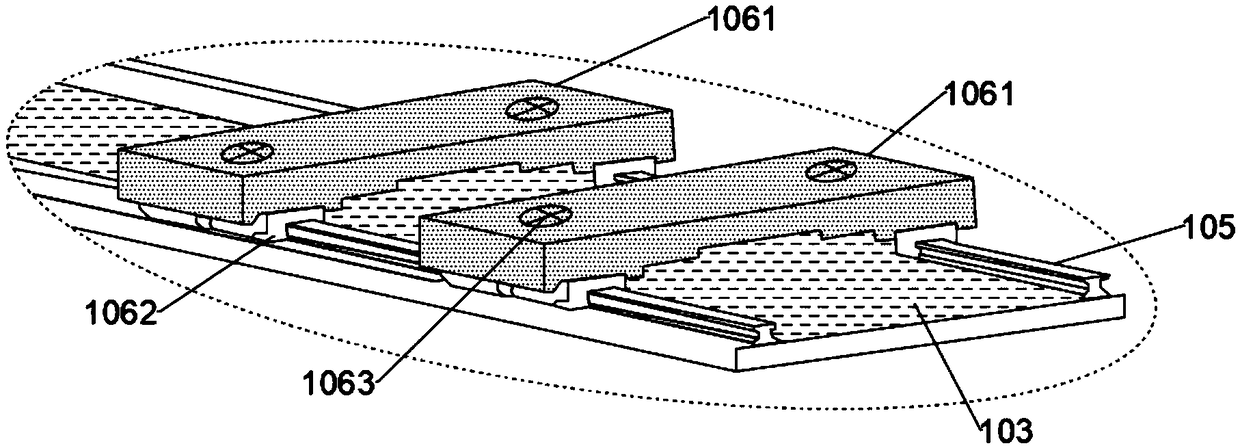

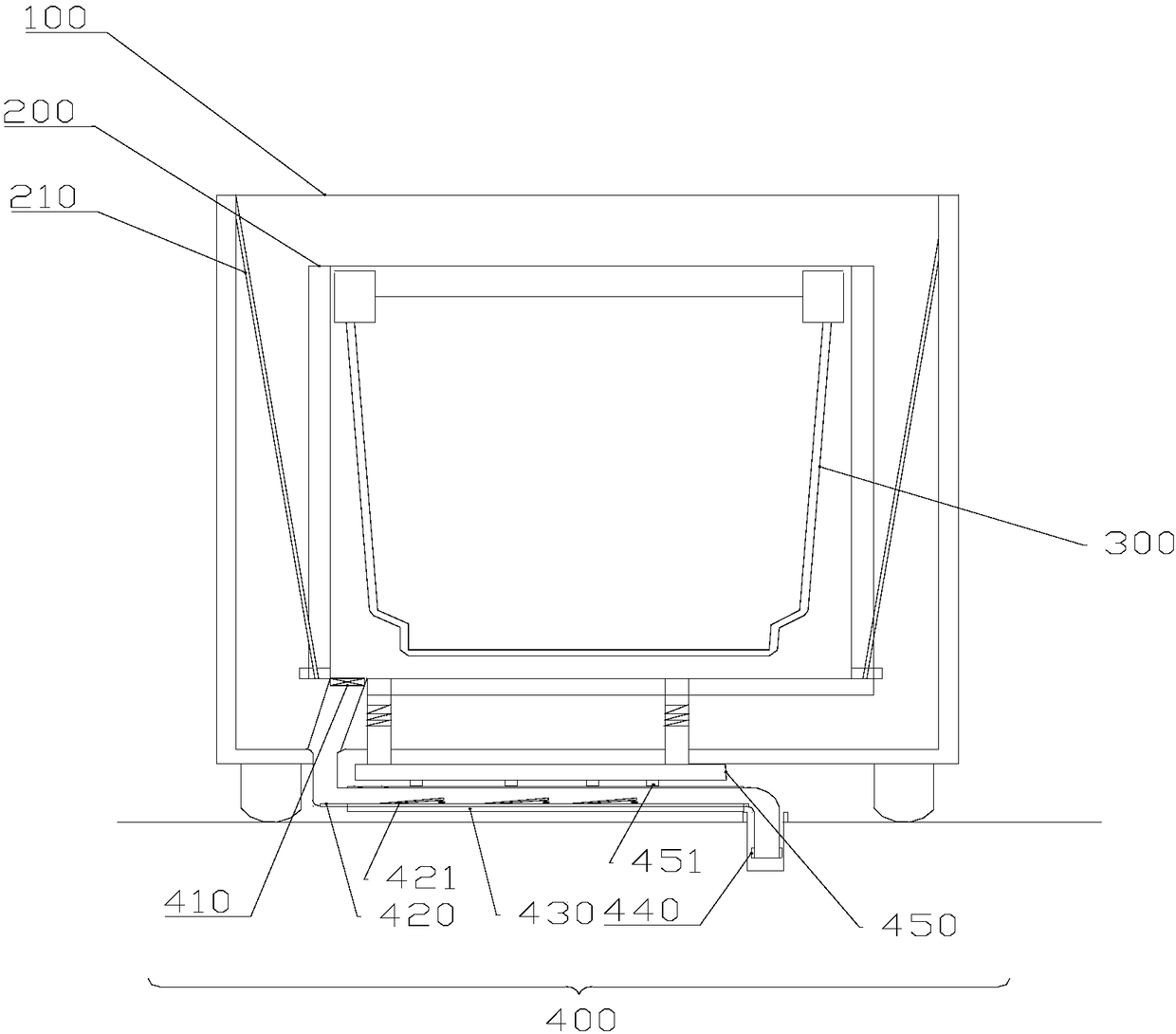

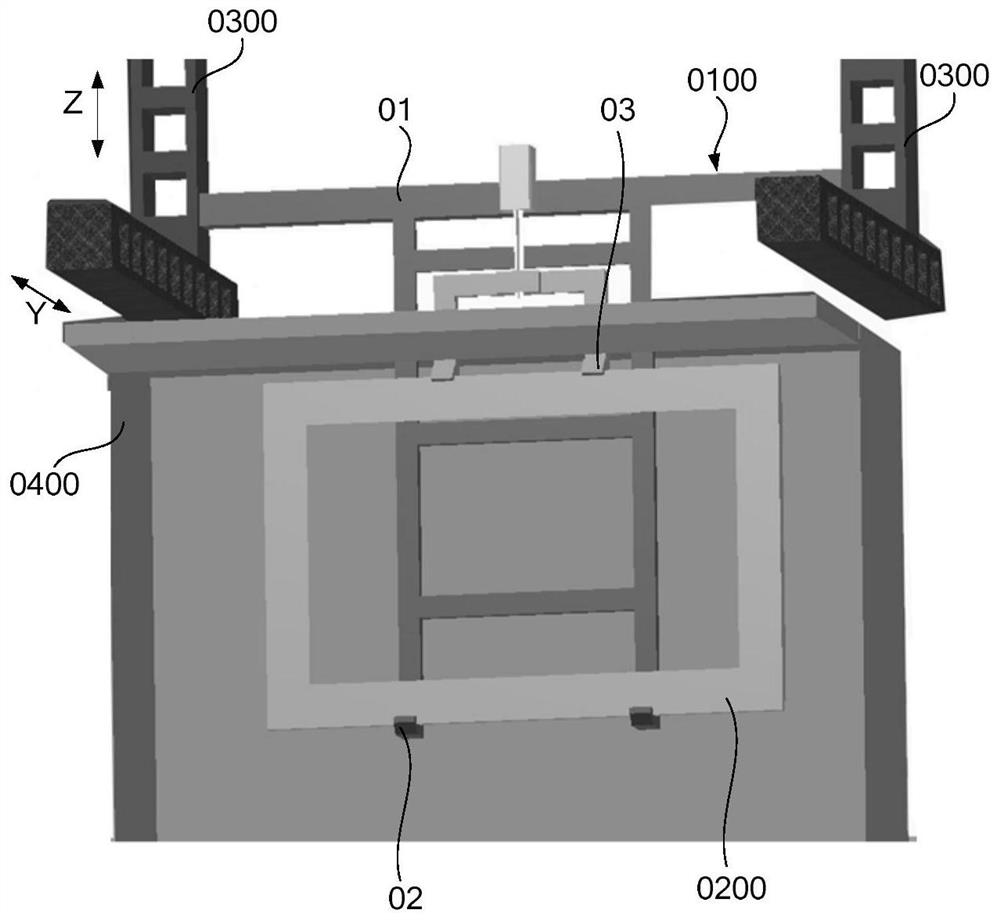

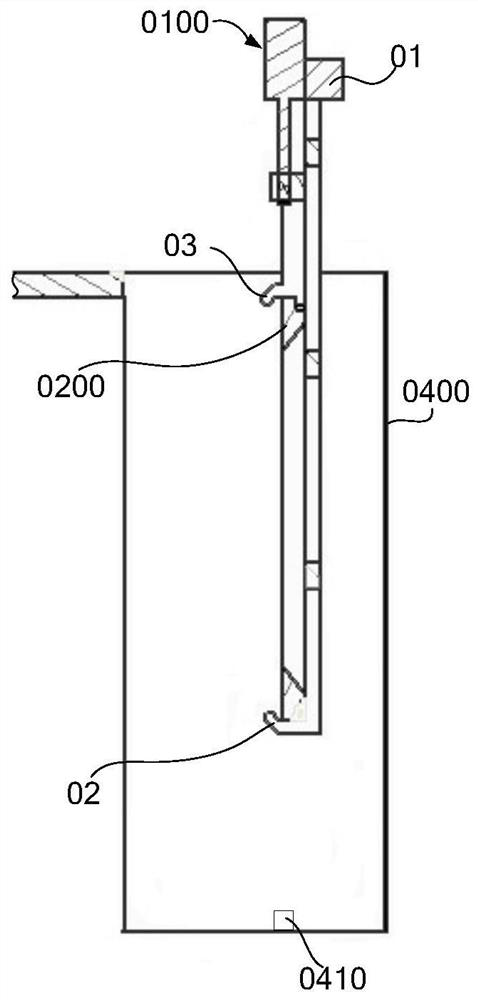

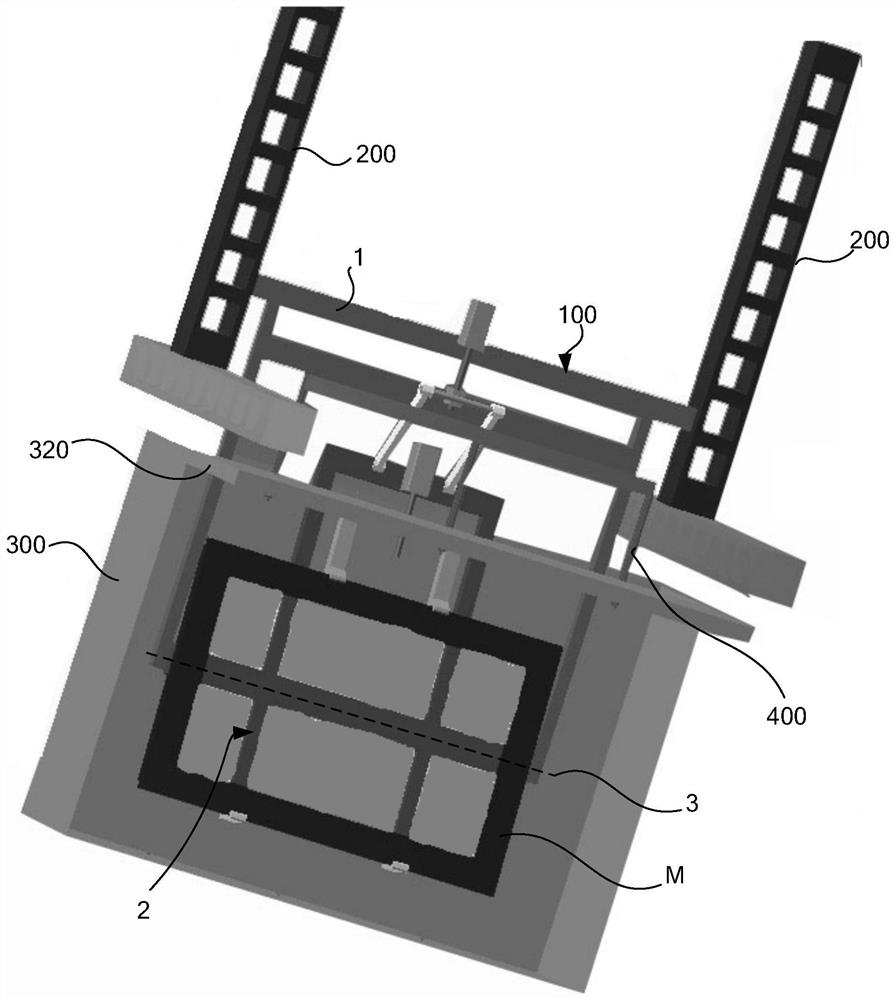

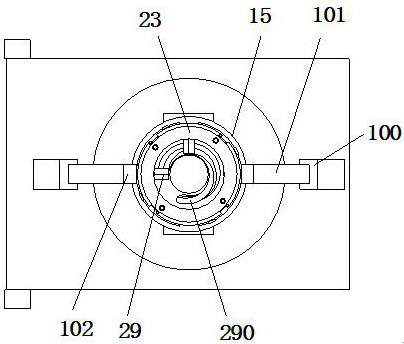

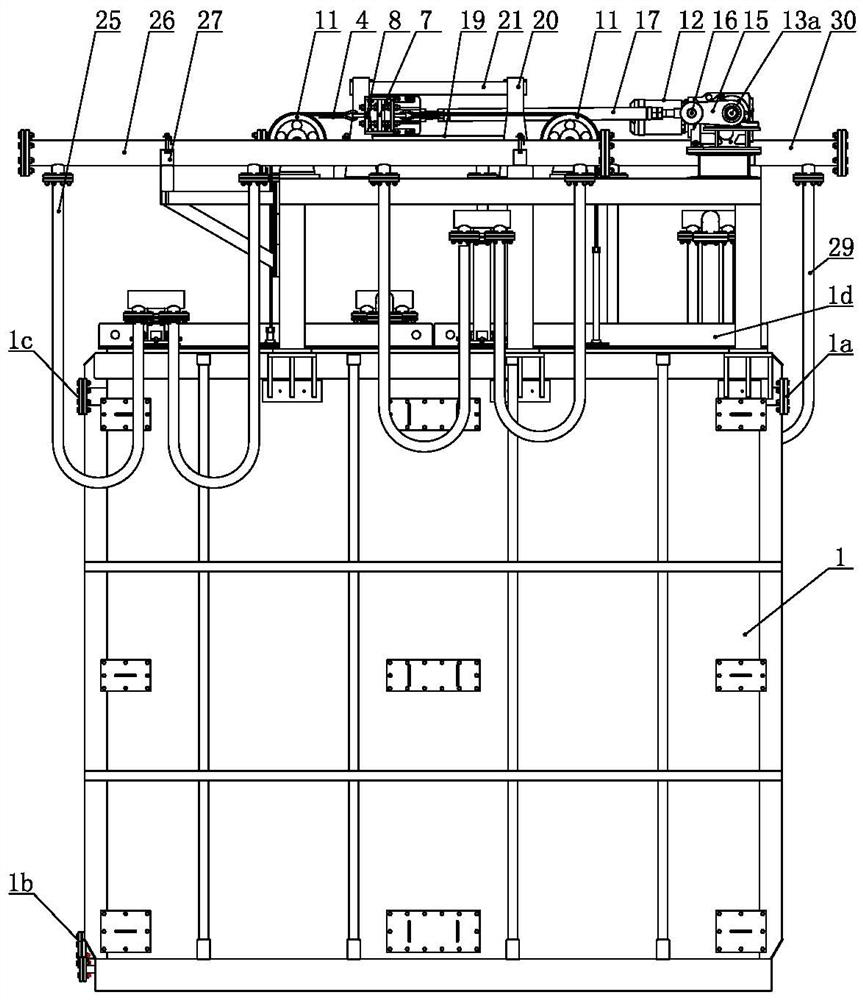

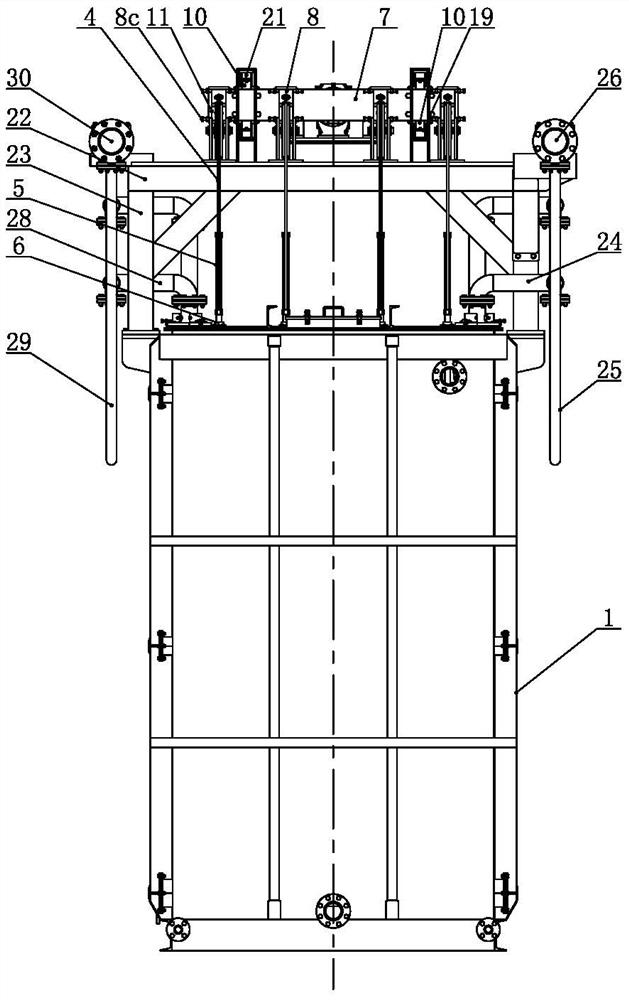

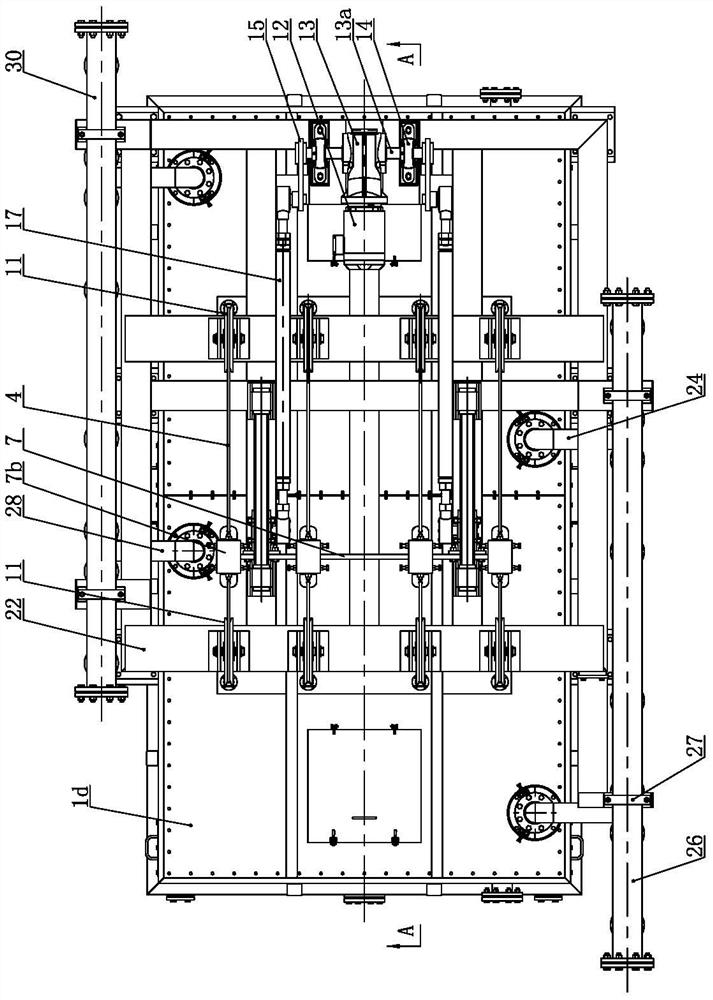

A jig for a mask plate, a mask plate cleaning system and a method for cleaning the mask plate

ActiveCN107526247BEasy to cleanAvoid blockingFlexible article cleaningOriginals for photomechanical treatmentStructural engineeringMechanical engineering

The invention discloses a clamp for a mask, a mask cleaning system and a method for cleaning the mask, relates to the technical field of mask cleaning equipment and aims to solve the problem of poor mask cleaning effect of an existing mask cleaning system. The clamp for the mask comprises a hanging frame, a fixing frame and a first driving device, wherein the fixing frame is used for fixing the mask and is rotationally connected with the hanging frame, and the rotating central axis extends in the transverse direction of the fixing frame; the first driving device is fixed on the hanging frame, connected with the fixing frame and used for driving the fixing frame to rotate relative to the hanging frame. The invention can be used for cleaning the mask.

Owner:BOE TECH GRP CO LTD +1

a biomass burner

ActiveCN112050193BReduce exposureIncrease contact areaSolid fuel combustionCombustion apparatusEnvironmental engineeringMechanical engineering

Owner:衡阳衡锅锅炉有限公司

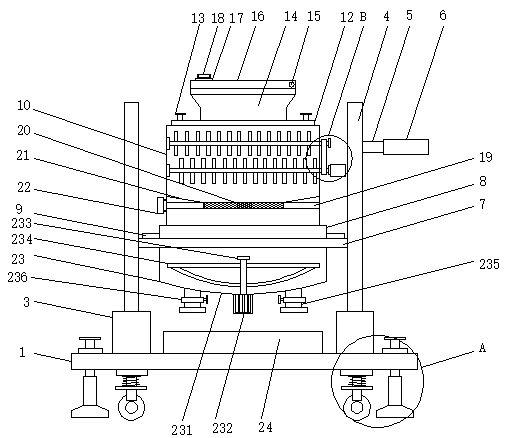

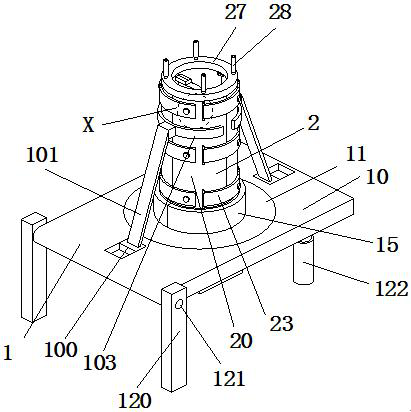

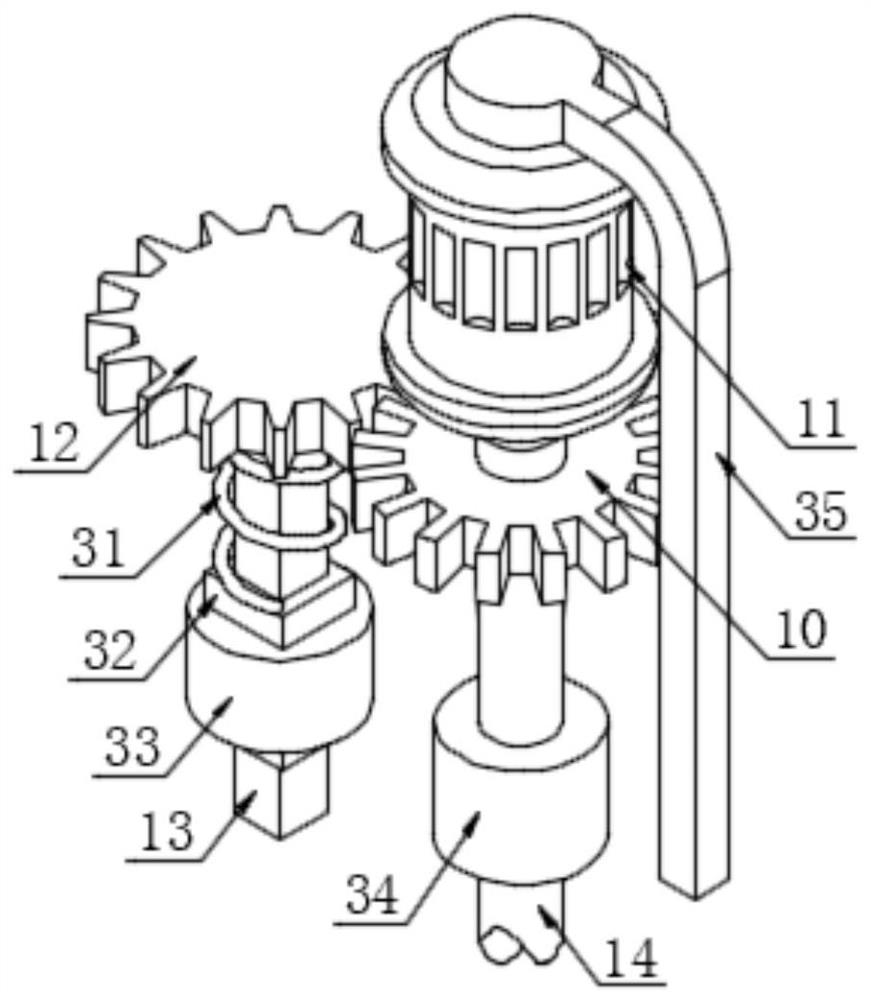

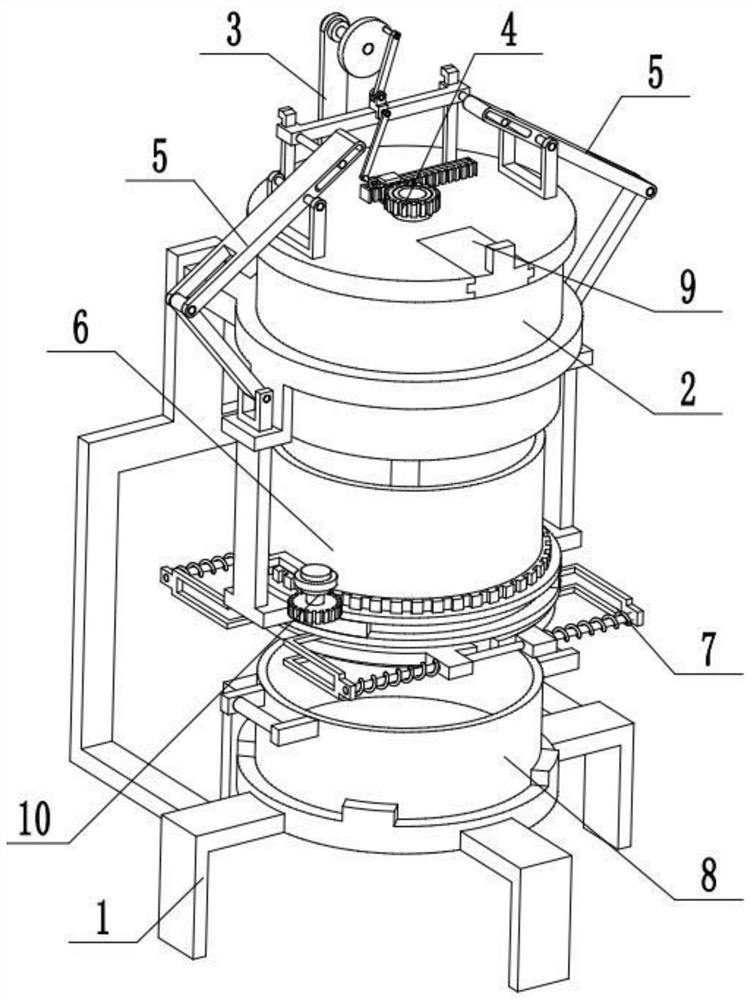

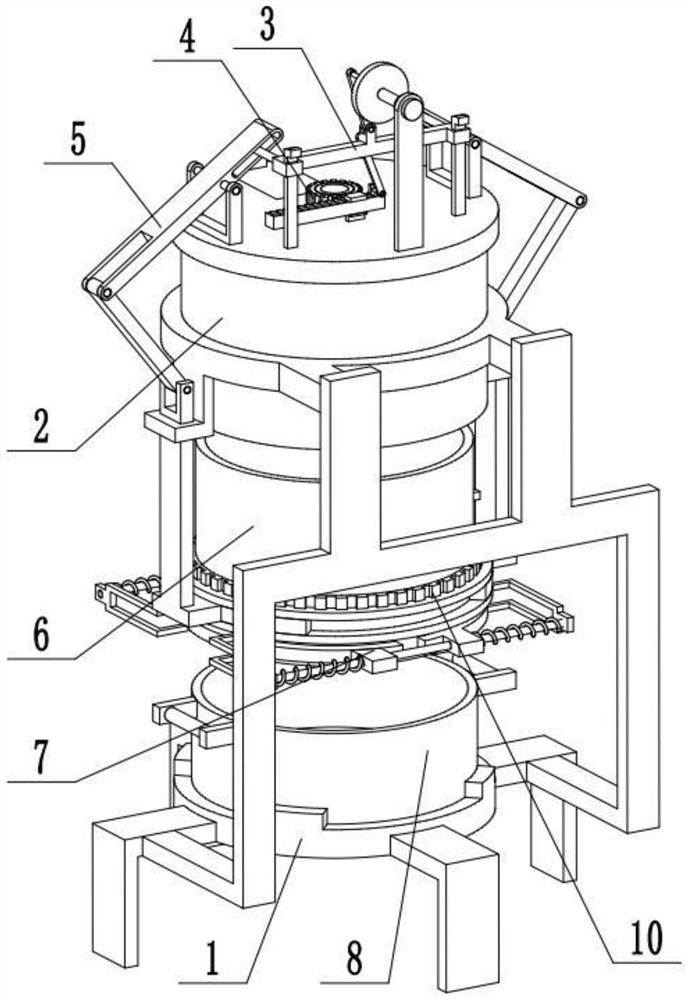

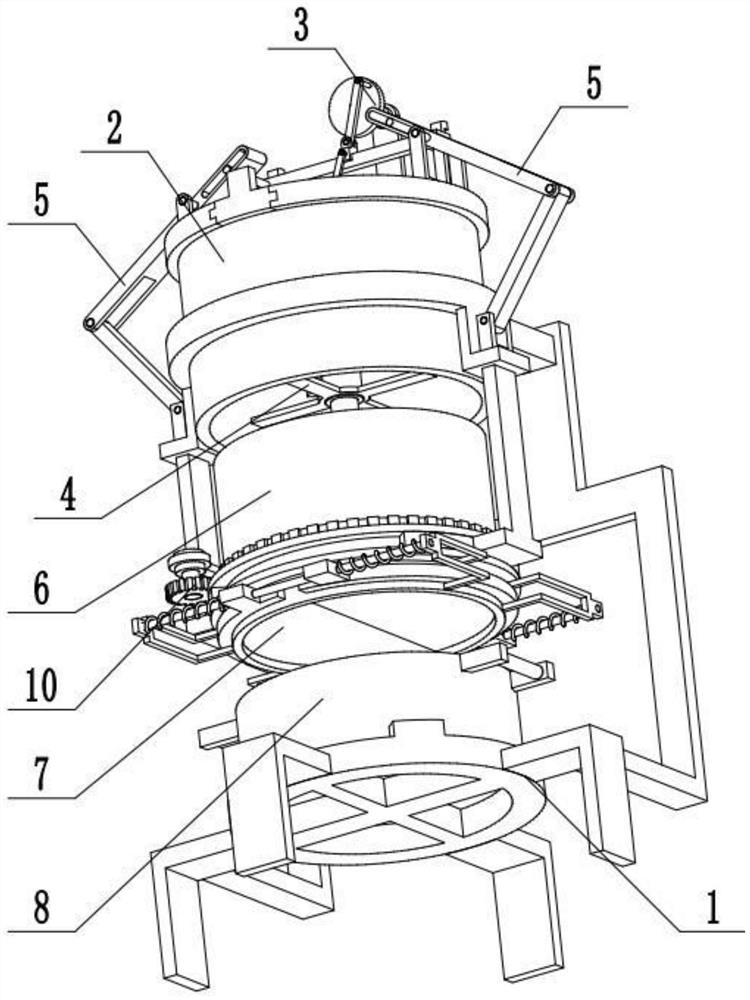

A vertical centrifugal casting equipment for manufacturing twisted sheet tubes

The invention relates to a vertical centrifugal casting equipment for manufacturing twisted sheet tubes, which includes an auxiliary manufacturing mechanism and a forming mechanism. The upper middle part of the auxiliary manufacturing mechanism is provided with a forming mechanism, and the auxiliary manufacturing mechanism is arranged on the existing ground. The invention adopts the design concept of combined splicing to carry out the vertical centrifugal casting of twisted sheet tubes. The auxiliary mechanism set up can use the centrifugal force to vibrate the casting material. At the same time, the casting material can also be shaken up and down. The combination of the reciprocating shaking treatment can greatly reduce the existence rate of air bubbles, thereby improving the forming quality of the twisted sheet tube. The combined splicing method adopted by the forming mechanism can realize the recycling of the structure, which in turn is conducive to reducing the production cost.

Owner:江苏双勤新能源科技有限公司

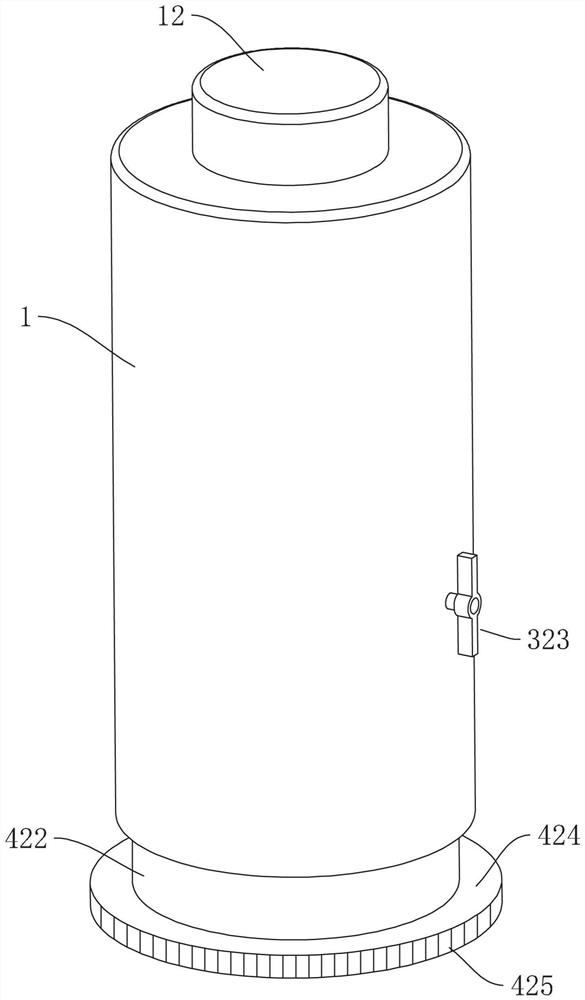

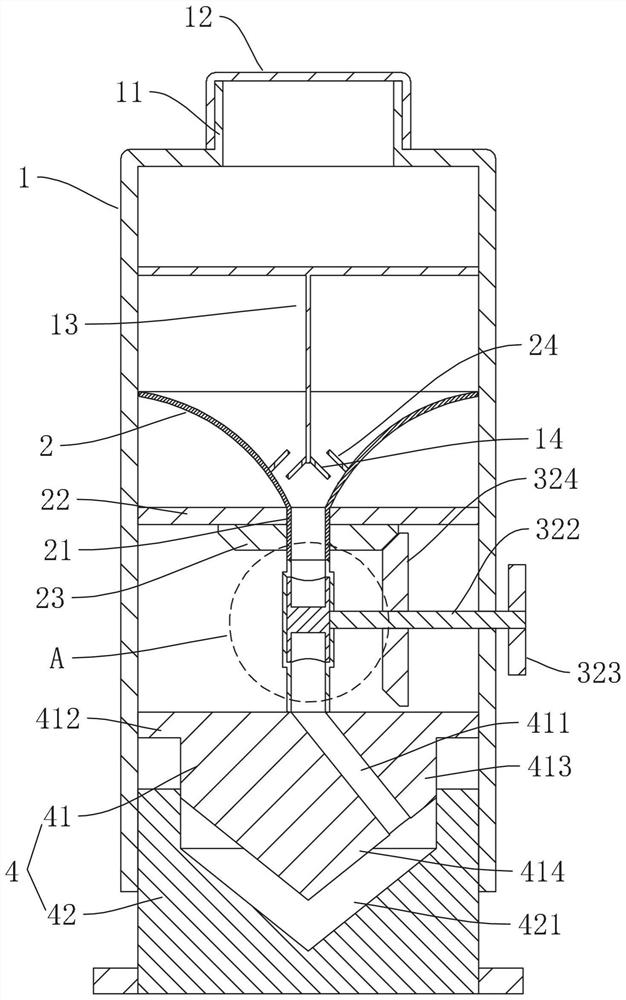

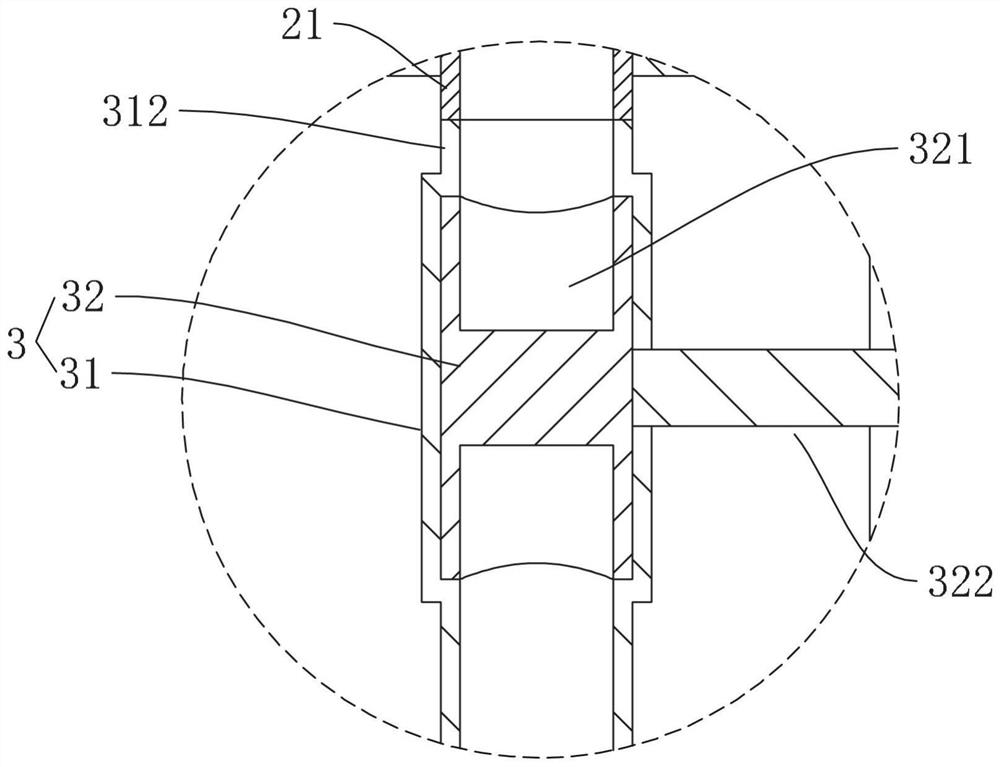

Quantitative medicine taking grinder

ActiveCN114453107AEasy to operateImprove efficiencyPharmaceutical containersMedical packagingPhysicsEngineering

The invention relates to the field of tablet grinding devices, and discloses a quantitative medicine taking grinder which comprises a medicine bottle with an opening in the lower side and a bottle cap arranged on the medicine bottle and further comprises a medicine leaking plate, a quantitative medicine guiding assembly and a grinding assembly. The medicine leaking plate is installed in the medicine bottle and is of a big-end-up horn mouth structure, and the lowest position of the medicine leaking plate is fixed and communicated with a medicine leaking pipe. The quantitative medicine guiding assembly comprises a shell and a medicine distributing wheel, the shell is fixed in the medicine bottle, the shell is located on the lower side of the medicine leaking pipe and communicated with the lower end of the medicine leaking pipe, the medicine distributing wheel is rotationally installed in the shell, a medicine containing groove capable of containing quantitative tablets is formed in the medicine distributing wheel, and a rotating rod is fixed to the center of the medicine distributing wheel. The end, away from the medicine distributing wheel, of the rotating rod penetrates out of the medicine bottle. The grinding assembly comprises an upper grinding body and a lower grinding body. According to the tablet grinding device, people can take tablets quantitatively and conveniently, the tablets do not need to be taken out before being ground, the problem that the tablets are polluted is avoided, operation is very convenient, and efficiency can be improved.

Owner:潍坊市第二人民医院

A high-efficiency air purification device that can automatically adjust the amount of molecular sieve

ActiveCN111503773BTimely replacementEase of discharge exportMechanical apparatusSpace heating and ventilation safety systemsMolecular sieveActivated carbon filtration

The invention discloses a high-efficiency air purification device capable of automatically adjusting the amount of molecular sieve, which comprises a storage box, a purification box and a waste box arranged up and down in sequence, and four cylinder seats arranged in a matrix are arranged in the purification box, and the upper end of the cylinder seat is A net cylinder is installed, and a second connection block is connected between the four cylinder seats and the left and right side walls of the purification box. The front and rear sides of the purification box are equipped with conical connecting pipes, and the head of the conical connecting pipe is set There is a connecting pipe, an activated carbon filter screen and a filter screen are arranged in the connecting pipe at the front end, and a booster fan is arranged in the connecting pipe at the rear end; compared with the prior art, the beneficial effect of the present invention is: the work of the booster fan can Drive the circulation of the airflow in the purification box, the airflow passes through the activated carbon filter and the filter, then enters the purification box, and is discharged after being treated by the cylinder seat and the molecular sieve in the mesh cylinder, so as to realize the purification of carbon dioxide and harmful substances in the air.

Owner:通用空气(辽宁)有限公司

a washing machine

ActiveCN108221292BRealize self dredgingImprove featuresOther washing machinesTextiles and paperLaundry washing machineElectric machinery

The invention relates to a washing device of textiles and in particular to a clothes washing machine. The clothes washing machine comprises a housing and a drainage pipe. The drainage pipe is dividedto an elastic layer in an inner layer and a ferromagnetic net layer packaging the elastic layer. The outer wall of the tail part of the drainage pipe is fixedly provided with a heavy ring. The clotheswashing machine further comprises a dredging mechanism. The dredging mechanism comprises a vibrating plate, an elastic connecting rod, a plurality of electromagnets and an electromagnet controller. The elastic connecting rod passes through one end of the housing and is fixedly connected with a water storage outer barrel, and the other end is fixedly connected with the vibrating plate. The vibrating plate is positioned below the housing. The electromagnets are fixed on the lower end face of the vibrating plate. The electromagnet controller is used for starting the electromagnets one by one while a motor is driven to be started, and closing the electromagnets while a drainage valve is started. The provided clothes washing machine is capable of automatically cleaning the blocked drainage pipe.

Owner:宁波梦居智能科技有限公司

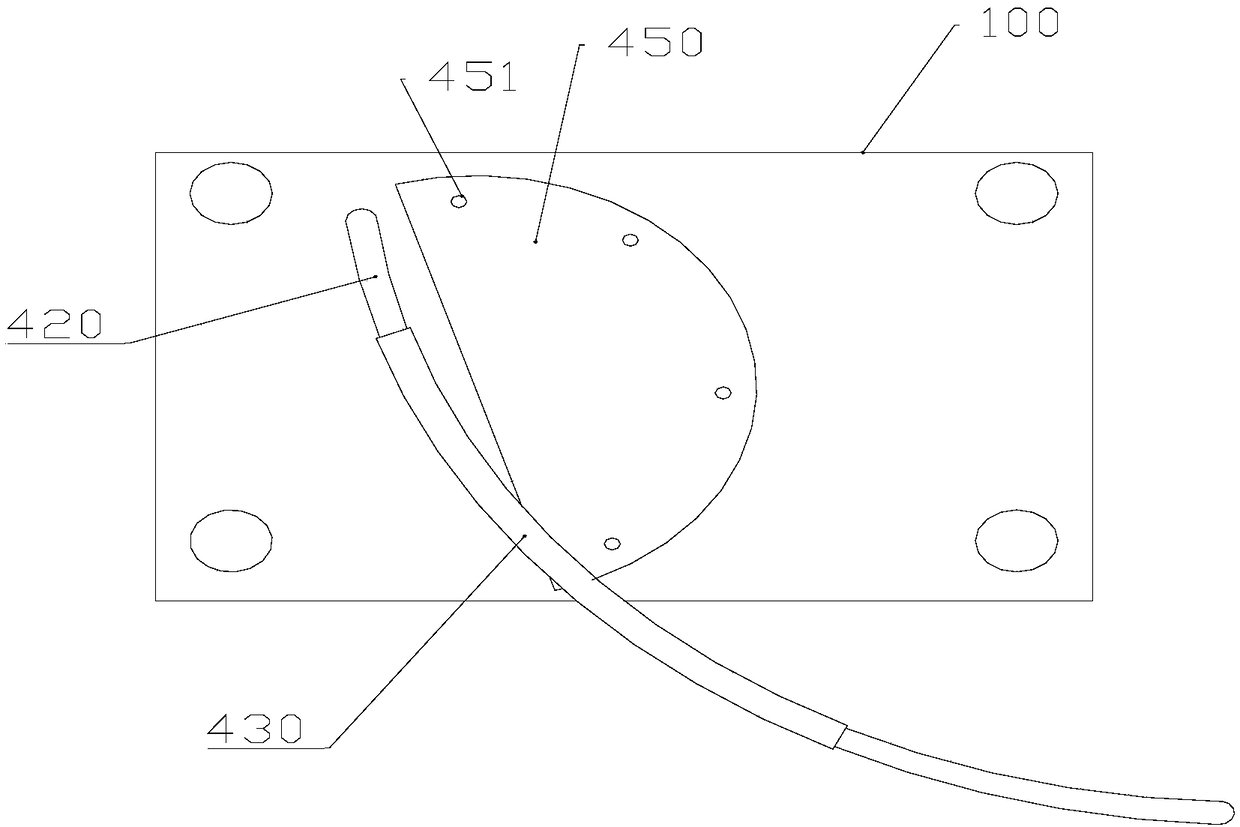

A cooling crystallization box

ActiveCN112619198BAvoid destructionPut an end to blankSolution crystallizationHeat exchange cooling cystallizationVertical tubeEngineering

The invention relates to a cooling crystallization box. The upper end of the square box is provided with a top cover, the upper part of the right side wall of the box is provided with an oil inlet, the lower part of the left side wall is provided with an oil outlet, and the inner cavity of the box is provided with two square cooling tube bundles. The two square cooling tube bundles can reciprocate vertically respectively. Each row of square cooling tube bundles includes four vertical pipes parallel to each other. Standpipe 1, vertical pipe 2, vertical pipe 3 and vertical pipe 4 stand in the four corners of the rectangle in turn, vertical pipe 1 and vertical pipe 3 are diagonal distribution, the top of standpipe 1 is connected with an upwardly extending tube bundle inlet pipe, the top of standpipe 3 is connected with an upwardly extending tube bundle outlet pipe, and there are multiple left confluences extending along the front and rear directions between standpipe 1 and standpipe 2 Horizontal pipes, vertical pipe four and vertical pipe three are connected with multiple right confluence horizontal pipes extending in the front and back directions, and the left confluence horizontal pipes on the same floor are respectively connected to the right confluence horizontal pipes through multiple cooling branch pipes extending horizontally to the right . The crystallization box integrates cooling and stirring, has a large cooling area, and has no heat exchange blind area.

Owner:MYANDE GRP CO LTD

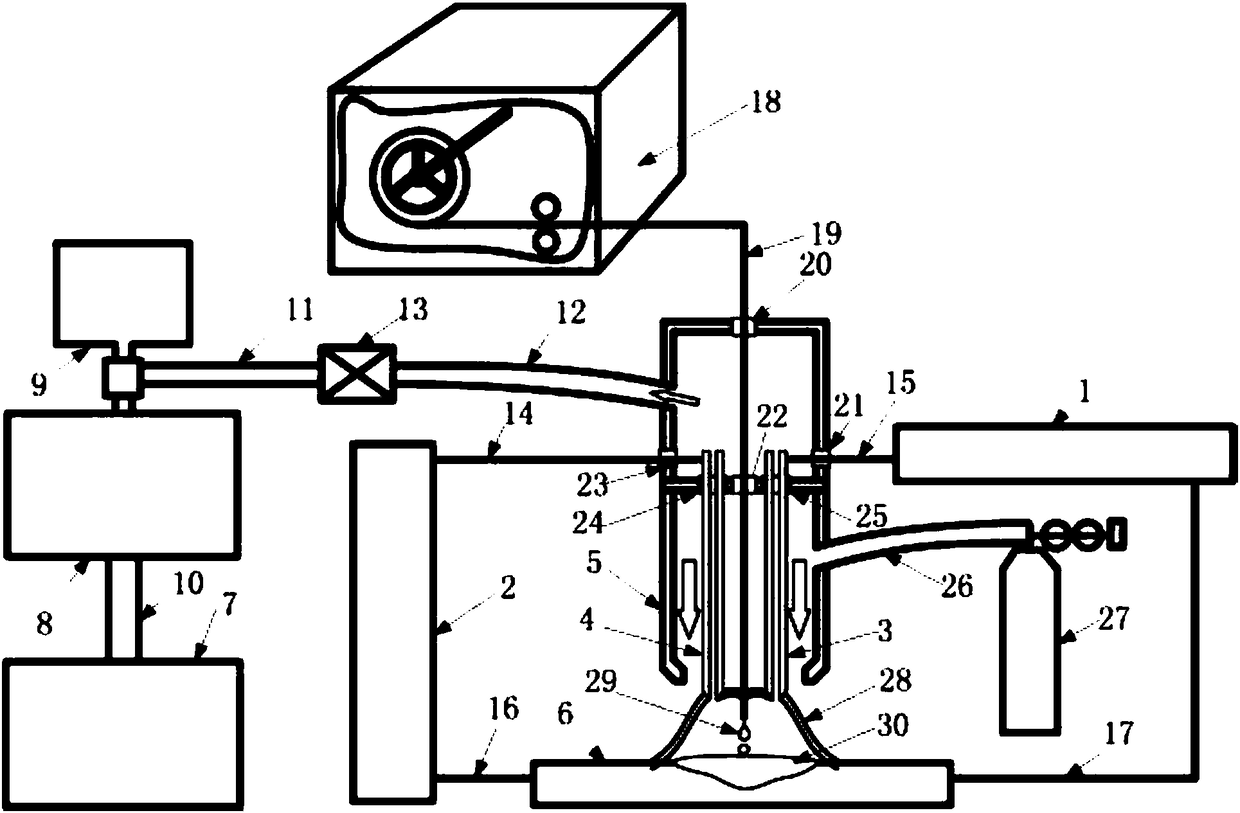

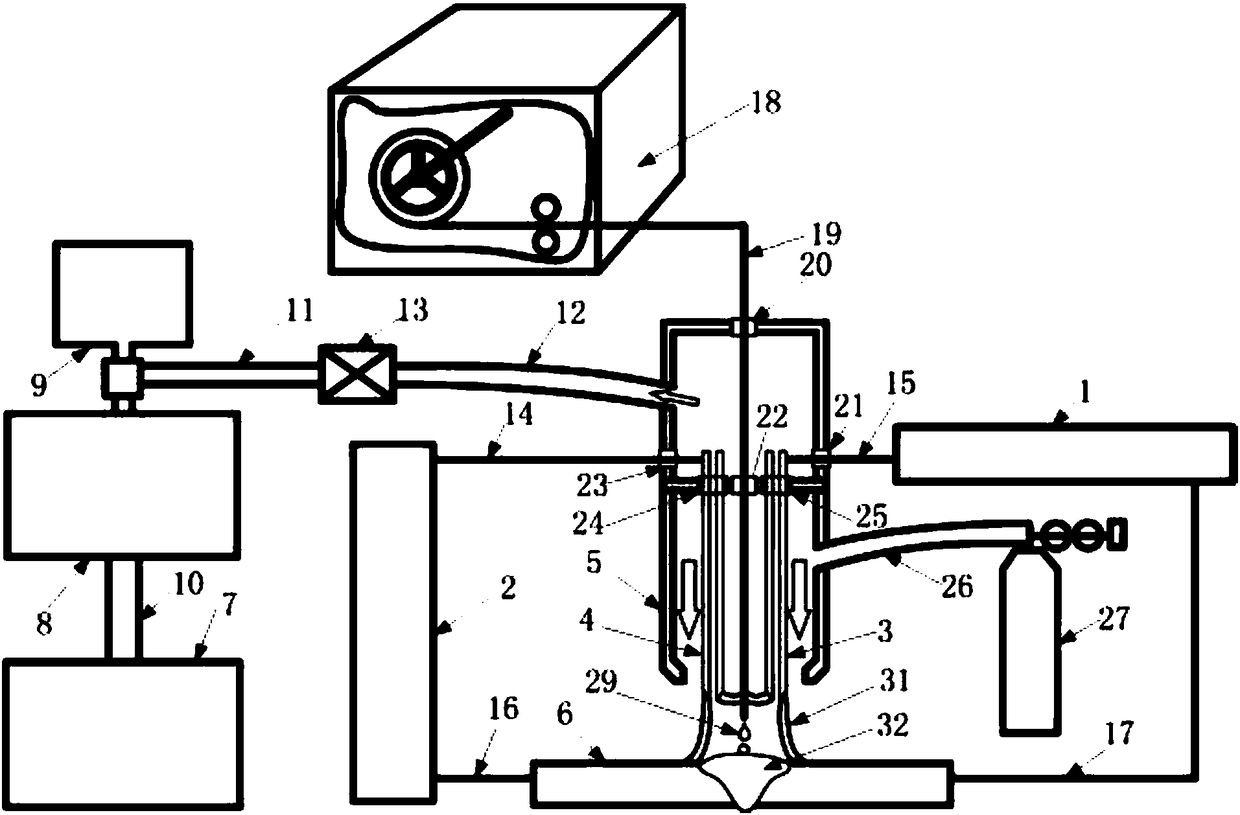

Double Center Negative Pressure Arc Filling Wire Welding Method

ActiveCN105478969BRealize restraintAspect ratio heightArc welding apparatusHigh energyWelding power supply

The invention belongs to the field of welding methods, and discloses a dual-center negative pressure electric arc wire filling welding method. Two identical hollow tubular cathodes are arranged, and two sets of welding power sources and control systems are connected with the cathodes. Gas in an electric arc center area is extracted away through a gas extractor, so that pressure of the area is lowered, a certain pressure difference exists between the gas in the electric arc center area and gas outside electric arcs, the two arcs are compressed at the same time under the action of barometric pressure, and a high-energy-density constrained electric arc is formed. Welding wires are vertically fed from the position between two electrodes, electric arc heat is absorbed for melting to form molten drops, and the molten drops are transited to a melting pool. According to the welding method, the current bearing capacity is increased, and the welding speed is increased. By means of the formed high-energy-density electric arc, penetrability on a workpiece is increased, the interference action of the two electric arcs is weakened, part of electric arc heat is extracted away through gas extracting, the heat influence area range is narrowed, and welding deformation is relieved. The position between the two electrodes is filled with the welding wires, the interference action of the two electric arcs can be balanced, and the welding defects such as undercut and melting pool collapsing brought by high-energy beam welding can be overcome.

Owner:BEIJING UNIV OF TECH

Dust Suppression Device for Suppressing Dust in Construction Sites

Owner:江苏建宇建设集团有限公司

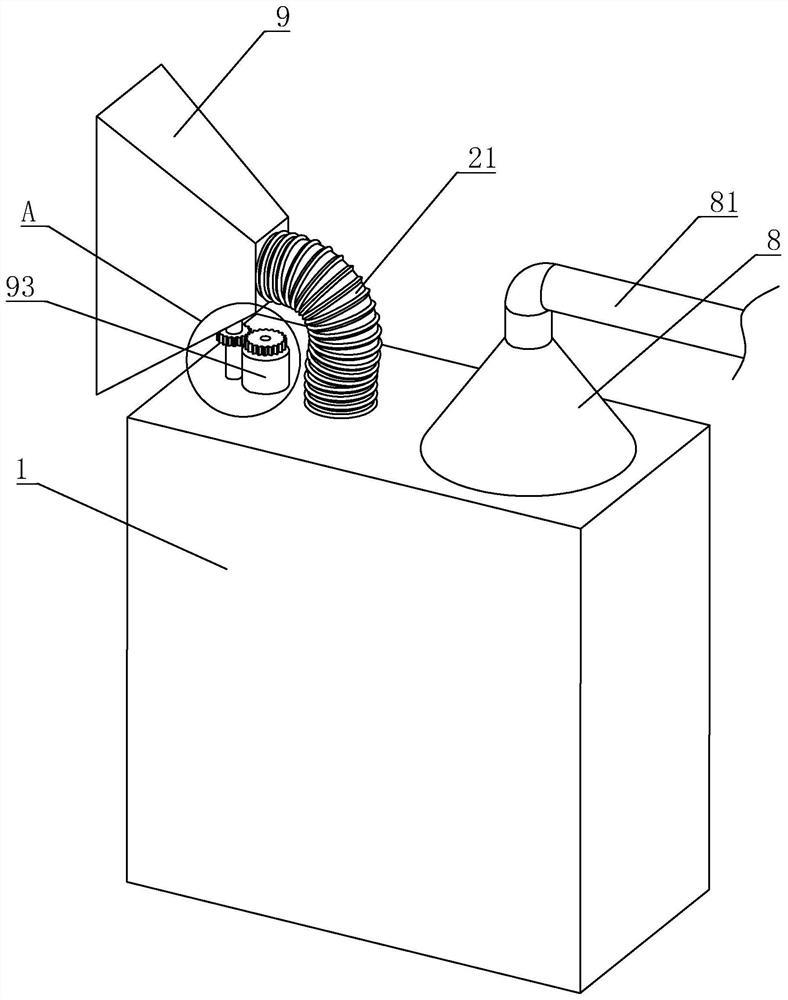

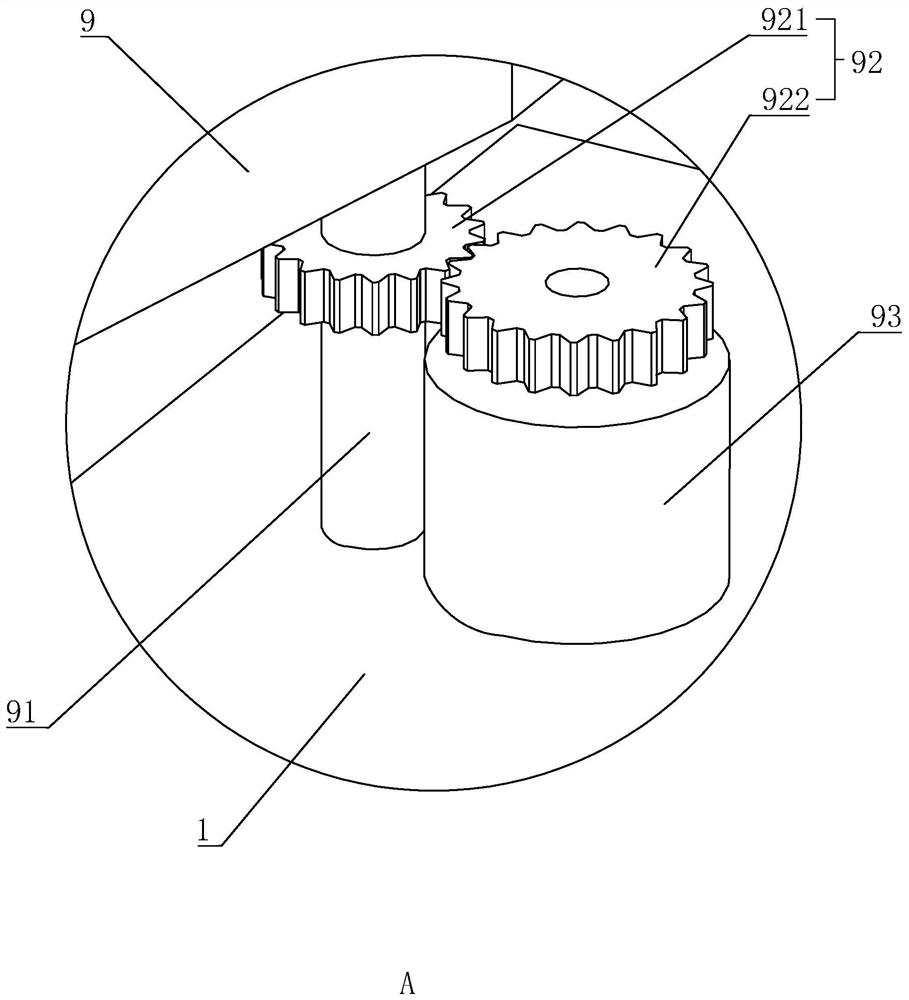

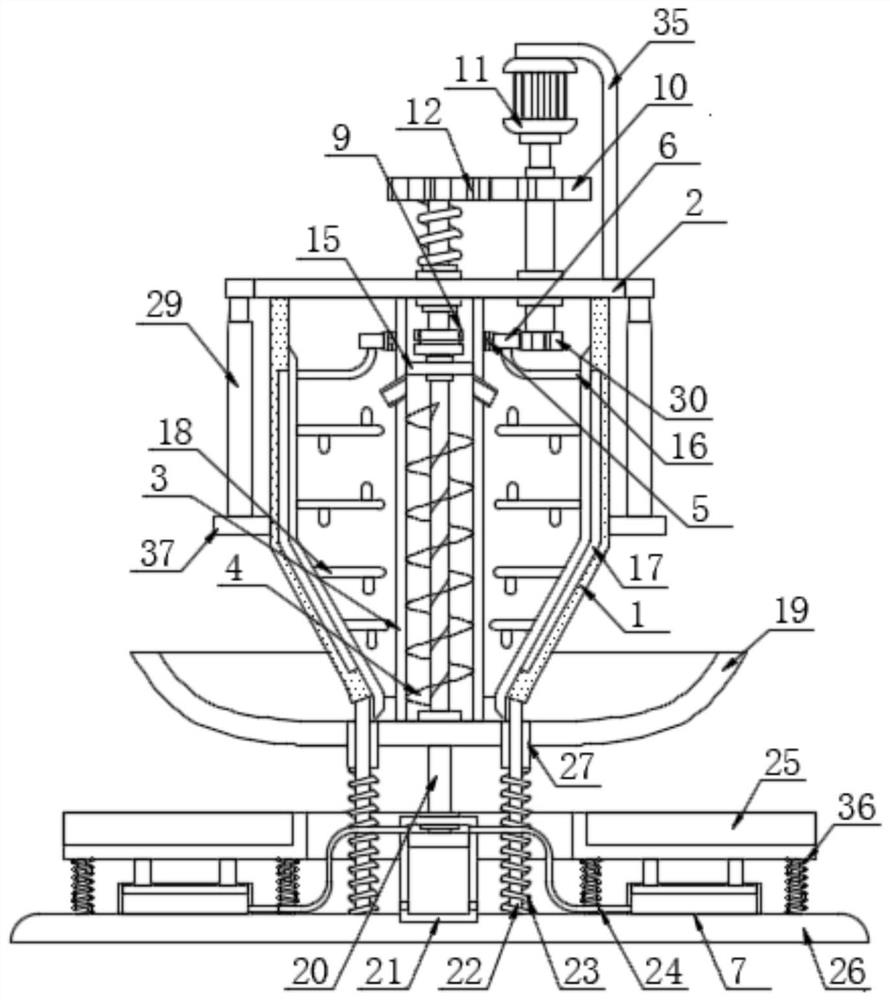

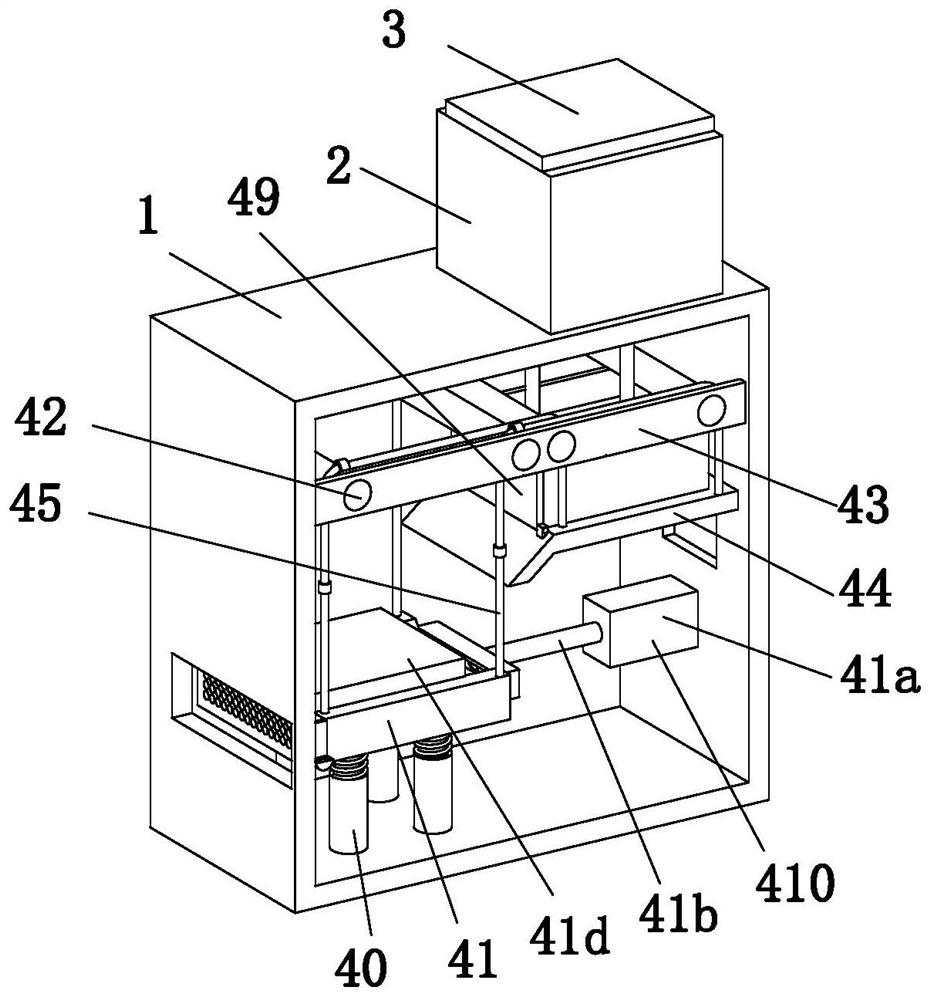

Lactating sow porridge feed machine capable of coping with feeding amount at each stage

The invention discloses a lactating sow porridge feed machine capable of coping with the feeding amount at each stage, and particularly relates to the technical field of livestock breeding. Hydraulic drive operation can be achieved through control of a control panel, then descending of a hopper can be controlled, and feed can be smoothly discharged for feeding work; and meanwhile, different descending positions of the hopper can be controlled through the body weight of sows, then the purpose of controlling the feed discharging amount can be achieved, the machine is suitable for feeding the sow in different stages, when the hopper elastically resets, it can be ensured that a fourth gear is meshed with a third gear, then a spiral shaft is driven to convey redundant feed in the hopper, feed remaining can be avoided, and the constant-temperature environment of the feed can be kept. According to the machine, the feeding amount can be adjusted according to the weight of the sows, redundant feed can be conveyed back, the quality of the feed is improved, the appetite of the sow for eating again is guaranteed, and therefore better application prospects can be brought.

Owner:武汉中畜智联科技有限公司

Auxiliary tool for adding toner to printer

InactiveCN106773574ASolve the above-mentioned difficult problems that are eager to be solvedSolve the blockageElectrographic process apparatusEngineeringBottle

The invention relates to an auxiliary tool for adding toner to a printer. The auxiliary tool comprises a working part inserted in a toner bottle and a holding part located at the outside of the toner bottle, wherein the working part is strip-shaped, and the length of the working part is matched with the height of the toner bottle. As the auxiliary tool is inserted in the toner bottle, when the toner bottle is inverted to add the toner, the auxiliary tool is stirred, pulled out and inserted in so as to avoid the toner from blocking a toner adding head, realize reliable addition of the toner and avoid leakage pollution of the toner.

Owner:安徽智汇和科技服务有限公司

Microbial culture device for medical examination

PendingCN114350497AFully contactedPromote growthBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention relates to a microbial culture device, in particular to a microbial culture device for medical examination. The invention aims to provide the medical examination microorganism culture device capable of enabling microorganisms to be in full contact with air. The medical examination microorganism culture device comprises a frame, door plates, a sliding frame and the like, the front portions of the left side and the right side of the frame are rotationally provided with the door plates used for dust prevention, and the lower portion of the inner side of the frame is slidably provided with the sliding frame used for storing culture bottles. According to the device, an air pump is used as a driving force, a nozzle can spray sterile air into a sliding frame, a first driving motor is used as a driving force, a missing gear can be driven to rotate, so that a fluted disc can be driven to reciprocate back and forth, a culture bottle can be driven to shake back and forth back and forth, and microorganisms can be in full contact with the air; therefore, the growth is better.

Owner:CHANGCHUN UNIV OF CHINESE MEDICINE

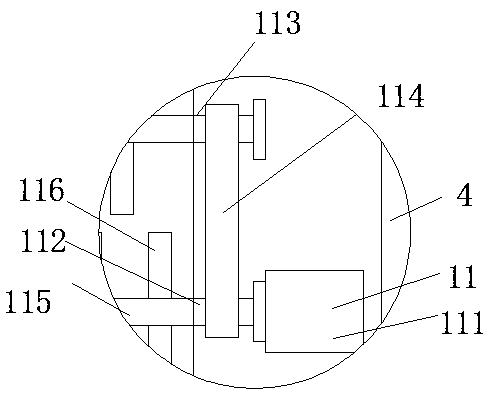

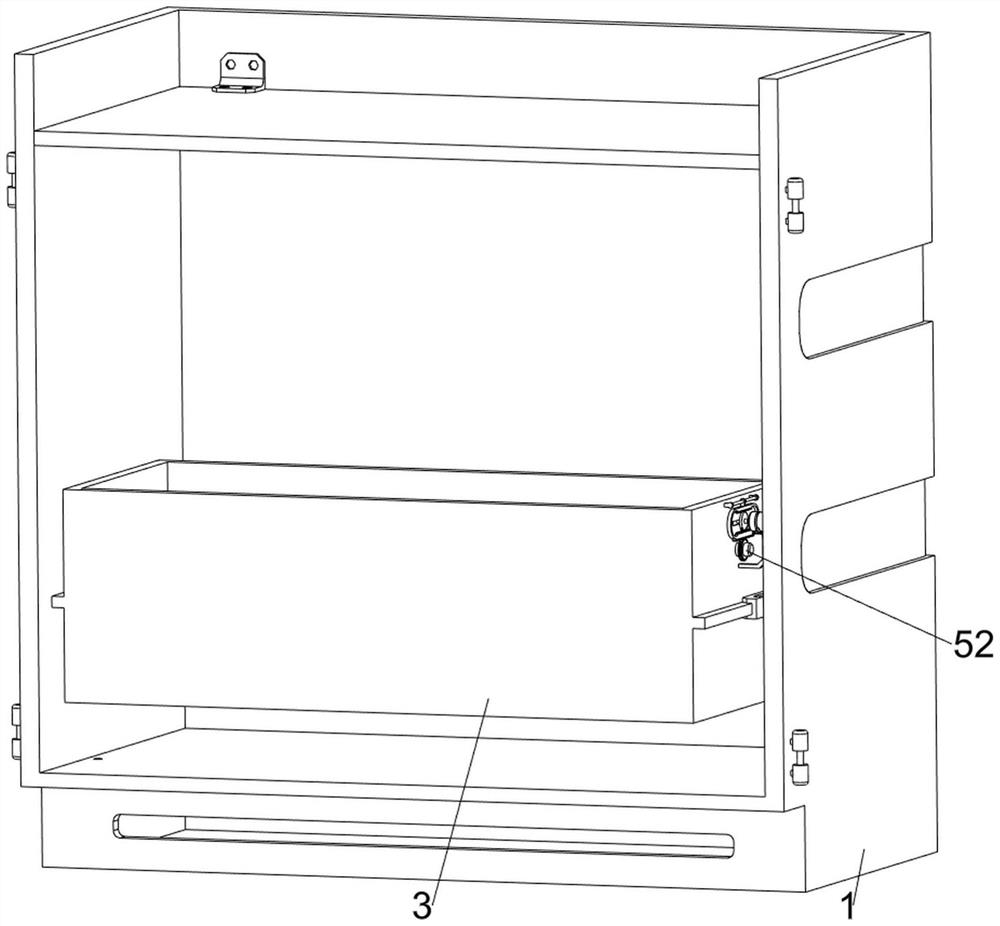

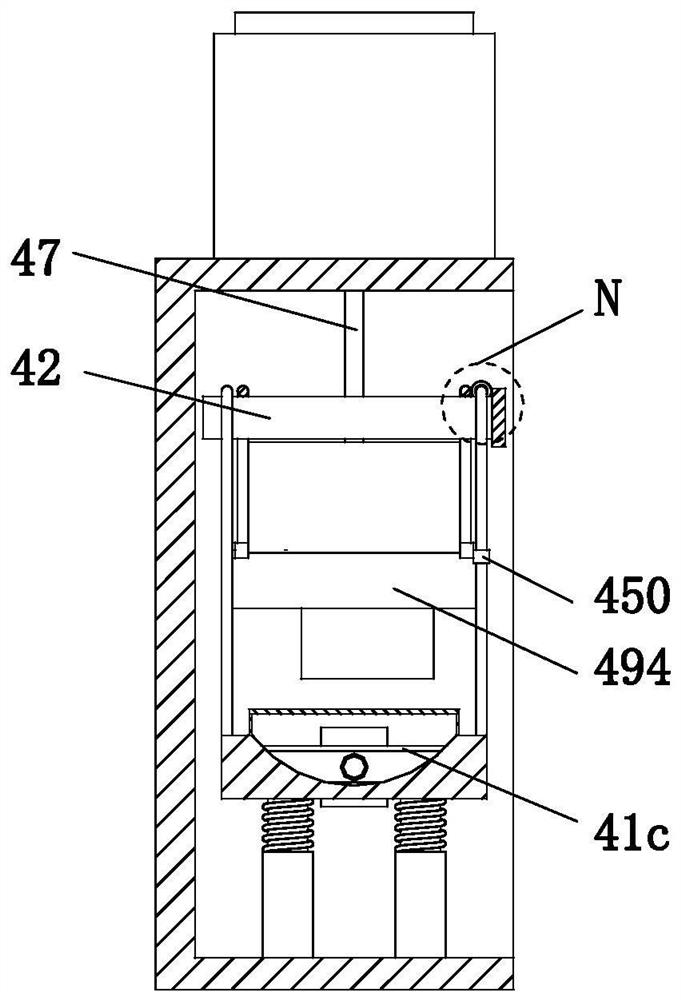

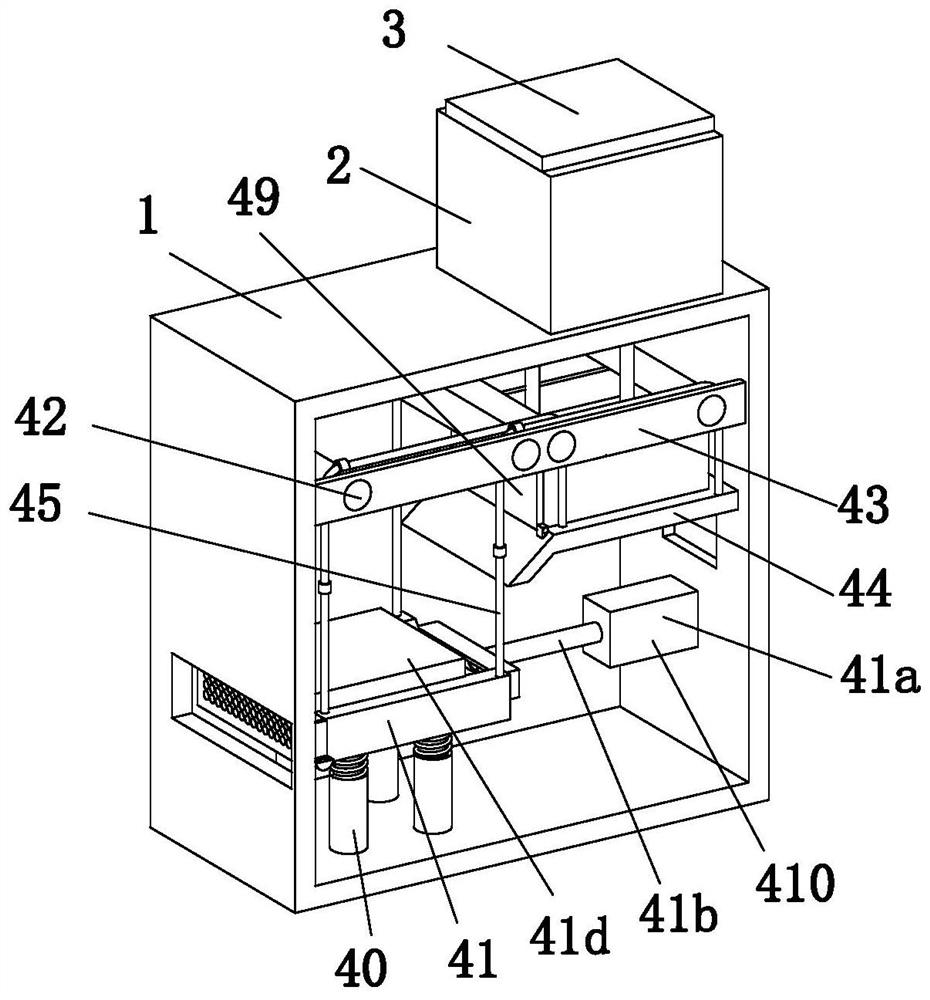

Automatic feeding, spraying and separating device for animal husbandry

ActiveCN112021191ARealize automatic replenishmentIncrease spread spreadGas current separationAnimal feeding devicesAnimal scienceCrop livestock

The invention relates to an automatic feeding, spraying and separating device for animal husbandry. The device comprises a cabinet body, a storage box, a sealing cover and a feeding mechanism, whereinthe storage box is installed at the right end of the upper end face of the cabinet body, the sealing cover is installed at the upper end of the storage box in a sliding fit mode, and the feeding mechanism is arranged inside the cabinet body. According to the automatic feeding, spraying and separating device for animal husbandry, livestock animals are fixed according to the design concept of combining multiple controllable clamping structures, automatic feed supply can be achieved through the arranged feeding mechanism, then the labor intensity of manual feeding can be reduced, meanwhile, thescattering distribution range of feed at feeding points can be widened, and therefore, the phenomenon of feeding dead angles caused by excessive accumulation of the feed is avoided.

Owner:张新厂

An automatic feeding and spraying separation device for livestock

ActiveCN112021191BRealize automatic replenishmentIncrease spread spreadGas current separationAnimal feeding devicesAnimal scienceAgricultural science

The invention relates to an automatic feeding and spraying separation device for livestock, comprising a cabinet body, a material storage box, a cover and a feeding mechanism. A cover is installed in a matching manner, and a feeding mechanism is arranged inside the cabinet. The present invention adopts the design concept of combining multiple controllable clamping structures to fix livestock animals, and the provided feeding mechanism can realize automatic feed supply, thereby reducing the The labor intensity of artificial feeding can also increase the distribution range of feed at the feeding point, thereby avoiding the phenomenon of feeding dead ends due to excessive accumulation of feed.

Owner:张新厂

Carbon powder adding set

InactiveCN106842856ASolve the above-mentioned difficult problems that are eager to be solvedSolve the blockageElectrographic process apparatusToilet paperCarbon dust

The invention relates to a toner filling set, which includes a toner bottle and auxiliary equipment. The toner bottle includes a powder filling head and a bottle body. The holding part outside the powder bottle and the working part inserted into the toner bottle, the working part includes a material guide section and a connecting section, the connecting section is located between the material guiding section and the holding part, and the material guiding section rotates around the core line of the bottle The projection of the formed rotator on surface A is projection A, and the projection of the rotator formed by the connecting section rotating around the centerline of the bottle body on surface A is projection B, and surface B is a plane perpendicular to the centerline of the bottle body , the size of projection A is larger than the size of projection B. The above scheme can effectively solve the problem of toner blockage at the toner filling head, and realize the reliable addition of toner in the toner bottle to the toner tank. After adding toner, it is only necessary to pull out the strip and use toilet paper Wipe it clean, so that you can avoid the problem of pollution and waste caused by the easy spillage of toner powder in the traditional solution.

Owner:安徽智汇和科技服务有限公司

Device for feeding improved nanocrystallized sterilant

The invention discloses a device for feeding an improved nanocrystallized sterilant. The device comprises the following steps: dissolving alkannin with a purity of more than 99% and quinestrol with a purity of more than 99% in edible oil according to a mass ratio of 10: 1, and adding the same amount of distilled water; and carrying out nano-emulsification treatment on the prepared reagent by using an ultrasonic cell disruptor to prepare a sterilant emulsion. When the concentration of the sterilant emulsion is 30 mg / kg, the sterilant has no effect on non-target animals, so the problem that other species are accidentally injured is well solved, and the sterilant is extremely beneficial to maintaining the ecological balance of grassland; and compared with the prior art, the sterilant emulsion has the biggest characteristic that a dosage is greatly reduced, but pesticide effect is increased, so the above technical scheme provided by the invention can be really implemented, prevention and treatment cost is reduced, prevention and treatment effect is improved, and a technical support is provided for future drug delivery.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

A feed mixing and crushing processing system

ActiveCN110694755BCrushed fullyFully brokenFeeding-stuffRotary stirring mixersControl engineeringMachining system

The invention relates to a feed mixing and crushing processing system, which relates to the technical field of feed processing, and includes a support frame body, a grinder fixing seat, a power output device, a feed grinder, a reciprocating control part, a feed container, a bottom material plate, a feed basin, and a stopper. The beneficial technical effect of the cover and the rotating part is that the invention can repeatedly crush the feed, and at the same time, it can stir the feed, so that the feed is crushed more fully and the crushing effect is thorough; the phenomenon of feed blockage does not occur. The pulverizer fixing seat is fixedly connected to the upper end of the support frame body, the power output device is fixedly connected to the pulverizer fixing seat, the feed pulverizer is set on the pulverizer fixing seat, the feed pulverizer is connected to the power output device in transmission, and the reciprocating control part is set There are two, and two reciprocating control parts are symmetrically arranged on the left and right sides of the pulverizer fixing seat, and the two reciprocating control parts are all connected with the power output device, and the feed container is arranged on the two reciprocating control parts.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com