A feed mixing and crushing processing system

A mixing and crushing and processing system technology, which is applied in the direction of feed, mixer, mixer with rotating stirring device, etc., can solve the problems that the feed cannot be crushed repeatedly, the crushing effect is not complete, and the feed does not have the function of stirring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

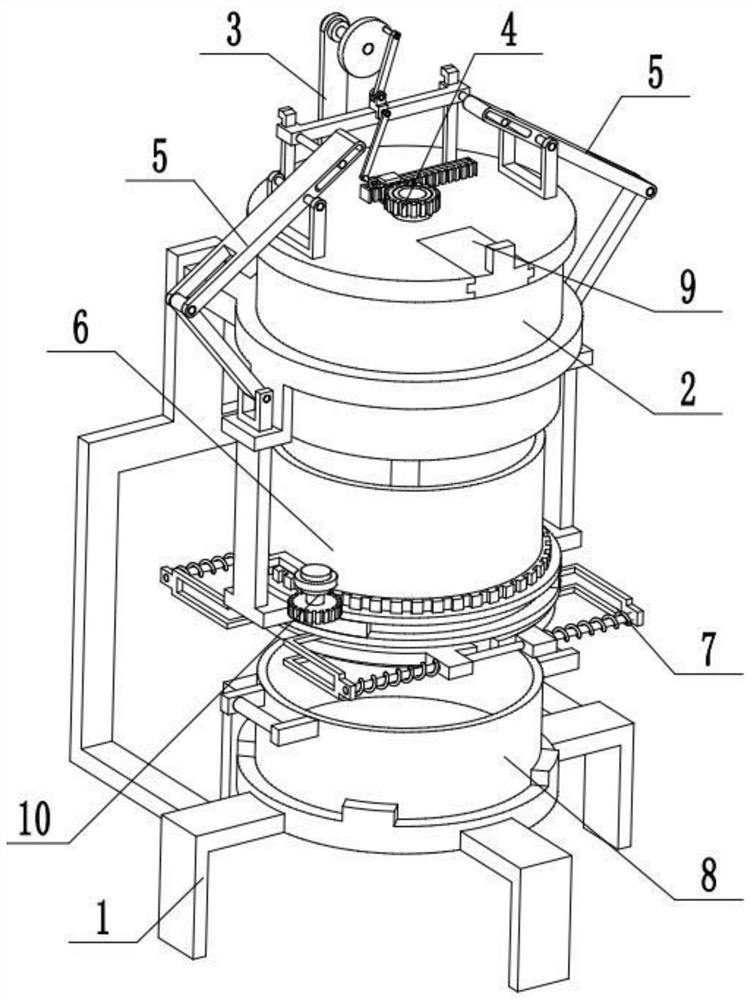

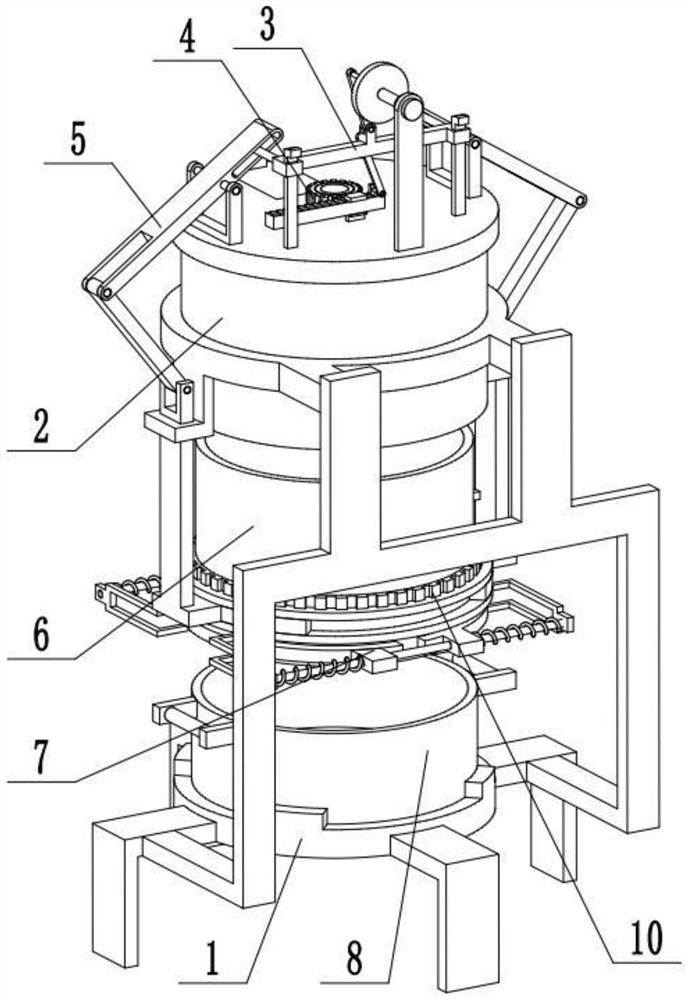

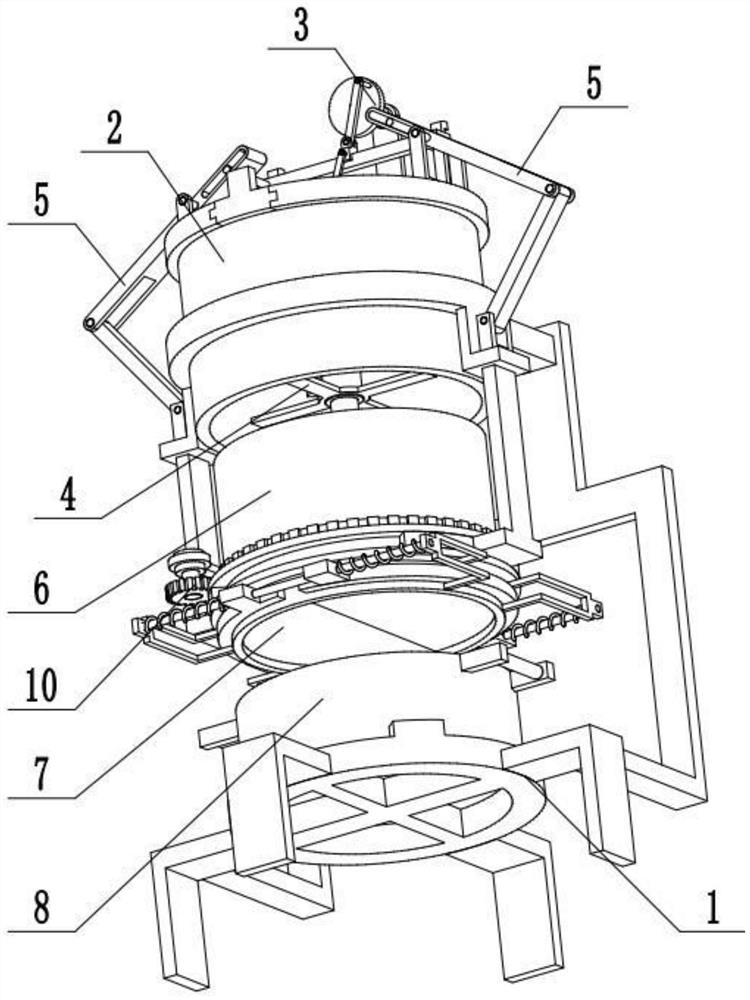

[0033] Combine below Figure 1-14 Describe this embodiment, a feed mixing and crushing processing system, including a support frame body 1, a grinder fixing seat 2, a power output device 3, a feed grinder 4, a reciprocating control member 5, a feed container 6, a bottom material plate 7, Feed basin 8, retaining cover 9 and rotating member 10, described pulverizer holder 2 is fixedly connected on the upper end of support frame body 1, power output device 3 is fixedly connected on pulverizer holder 2, and feed pulverizer 4 is arranged on On the pulverizer fixing seat 2, the feed pulverizer 4 is connected to the power output device 3 through transmission, and there are two reciprocating control parts 5, and the two reciprocating control parts 5 are symmetrically arranged on the left and right sides of the pulverizer fixing seat 2, and the two reciprocating control parts 5 are symmetrically arranged on the left and right sides of the pulverizer fixing seat 2, and the two reciprocatin...

specific Embodiment approach 2

[0035] Combine below Figure 1-14 To illustrate this embodiment, the support frame body 1 includes a feed pot placement seat 1-1, a support foot 1-2, a connecting frame 1-3 and a stopper 1-4; the feed pot placement seat 1-1 is evenly arranged around Four supporting feet 1-2, the connecting frame 1-3 are fixedly connected on the left and right supporting feet 1-2, the feed basin is placed on the seat 1-1 and surrounded by four stoppers 1-4, and the feed basin 8 is placed on The feed basin is placed on the seat 1-1, and the feed basin 8 is positioned between four blocks 1-4. Four stoppers 1-4 limit the feed basin 8 to move on the feed basin placement seat 1-1, and the feed basin 8 can be taken out after upwardly lifting the feed basin 8 and breaking away from the four stoppers 1-4.

specific Embodiment approach 3

[0037] Combine below Figure 1-14 To illustrate this embodiment, the pulverizer holder 2 includes a cylinder 2-1, a cylinder holder 2-2, a fixed sliding sleeve 2-3, a top cover 2-4 and a cover chute 2-5; the cylinder 2-1 is fixedly connected to the tube fixing seat 2-2, the tube fixing seat 2-2 is fixedly connected to the connecting frame 1-3, and the two ends of the tube fixing seat 2-2 are respectively fixedly connected to a fixed sliding sleeve 2-3, The upper end of the cylinder 2-1 is fixedly connected to the top cover 2-4, and the front end of the top cover 2-4 is provided with a cover chute 2-5, and the cover chute 2-5 communicates with the inside of the cylinder 2-1, and the cover chute 9 interference fits are connected in the blocking cover chute 2-5. After pulling away from the retaining cover 9, feed is put into the cylinder 2-1, and the feed falls into the retaining cover 9, and the retaining cover 9 is reset and closed after throwing in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com