Clothes washing machine

A technology for washing machines and driving motors, which is applied in the field of washing machines and can solve problems such as the failure of normal operation of washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

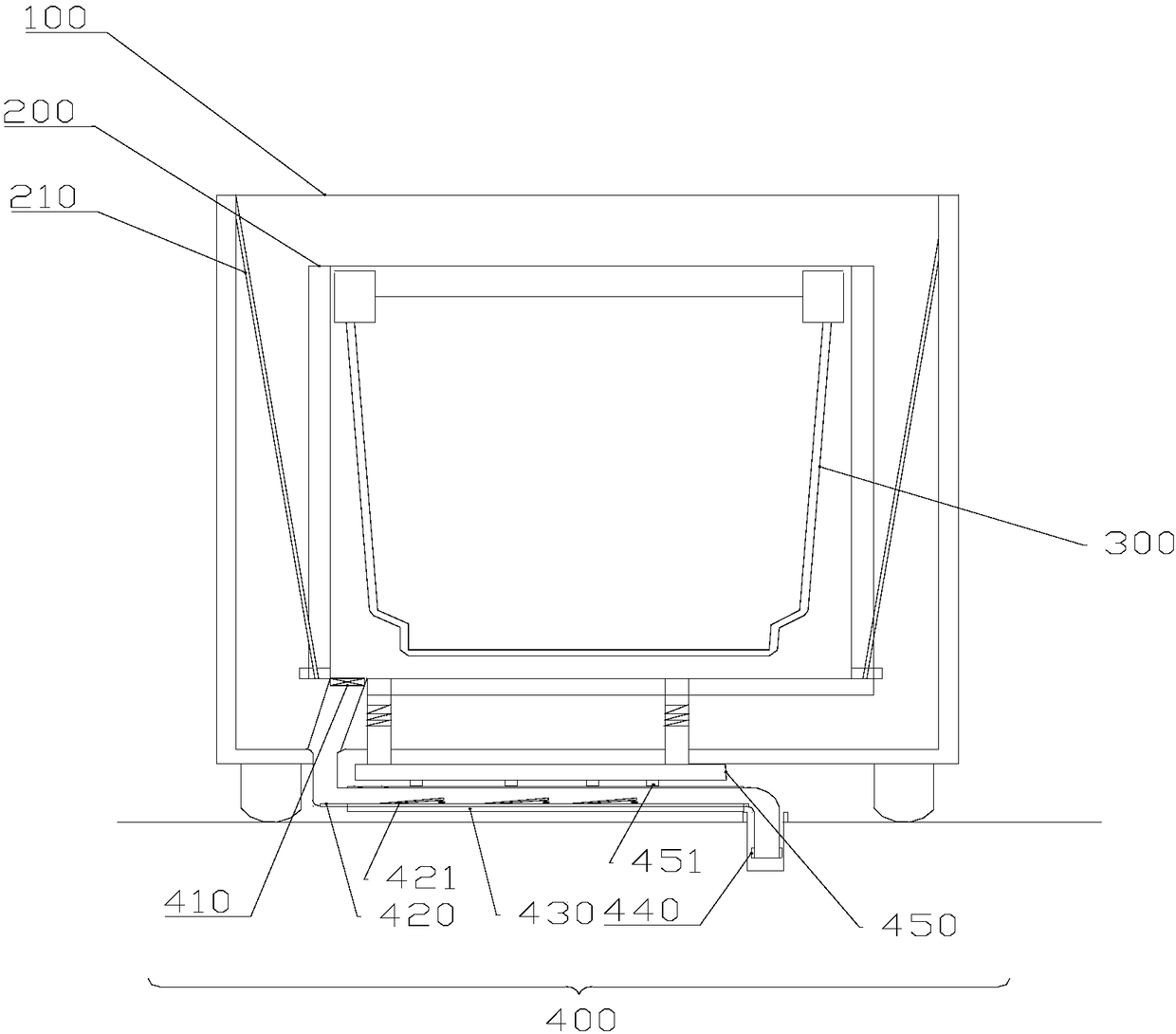

[0020] Embodiment 1 is basically as attached figure 1 Shown: a washing machine, including a housing 100, and a water storage outer tub 200 arranged in the housing 100. The water storage outer tub 200 is fixed on the inner wall of the housing 100 through four elastic suspenders 210, and is arranged outside the water storage. The laundry inner tub 300 in the tub 200 is made of stainless steel and provided with protrusions and water-permeable through holes. It is fixed to the base at the bottom of the housing 100 by bolts. The base is located below the water storage outer tub 200. The drive motor installed on the base And the deceleration part connected with the driving motor, the output shaft of the deceleration part is connected with the impeller, and the impeller is located at the bottom of the laundry inner tub 300 .

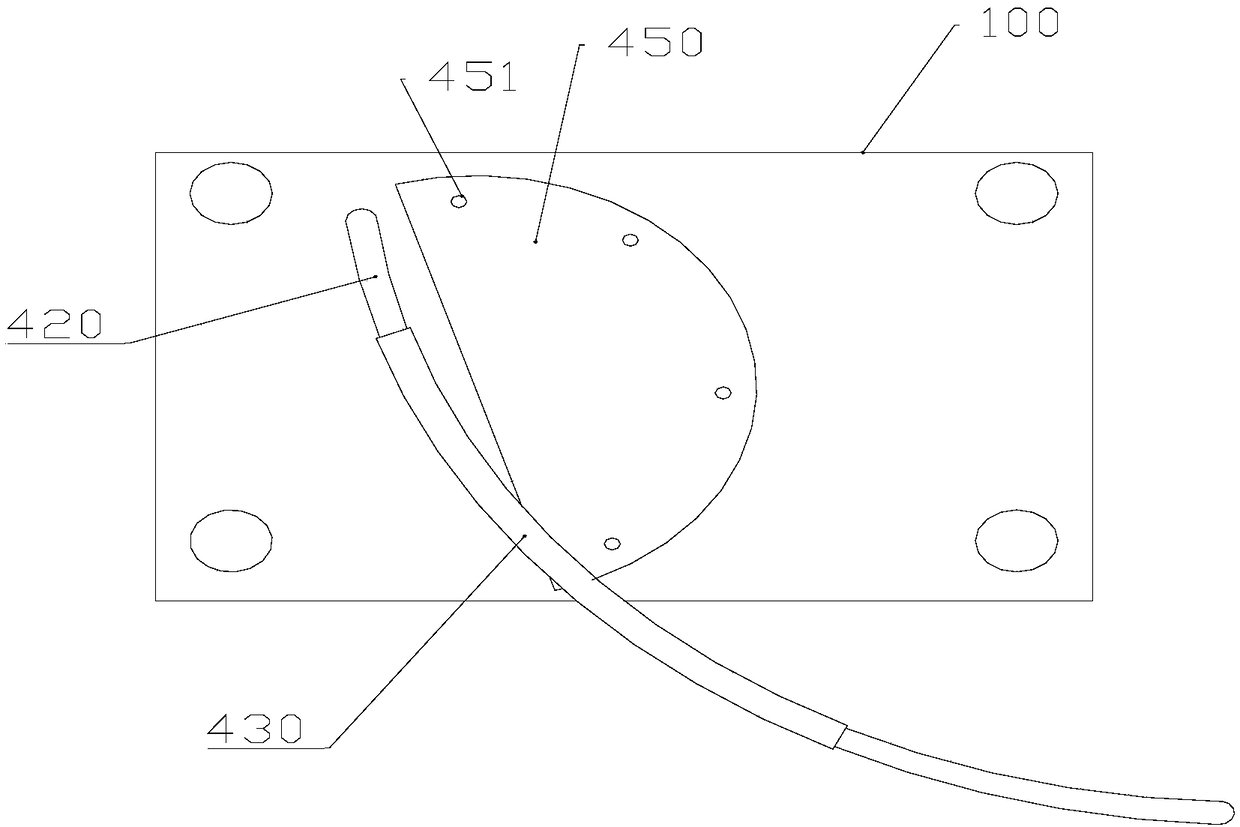

[0021] The bottom of the water storage outer barrel 200 is provided with a water outlet, and the water outlet is provided with a drain valve 410, and the drain...

Embodiment 2

[0024] Embodiment 2, the difference between embodiment 2 and embodiment 1 is that the elastic layer wraps a layer of helical elastic steel, and the inner surface of the elastic steel is bonded to the elastic layer. It is usually stretched when a large blockage is blocked. Pull out the water outlet from the drain pipe, compress the elastic steel, the inner diameter of the elastic steel is forced to become larger, and the inner diameter of the elastic layer becomes larger accordingly, and the large blockage in the drain pipe is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com