Production technology of polyester staple fibers

A polyester staple fiber and production process technology, which is applied in the field of fiber production, can solve the problems of difficult removal of metal impurities and complex fiber production process, and achieve the effects of saving manpower, improving cleanliness, and accelerating shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

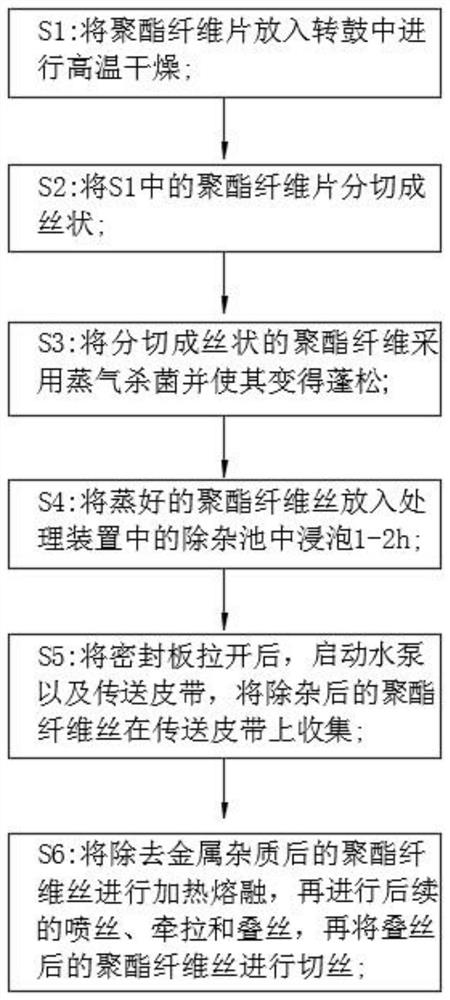

Method used

Image

Examples

Embodiment approach

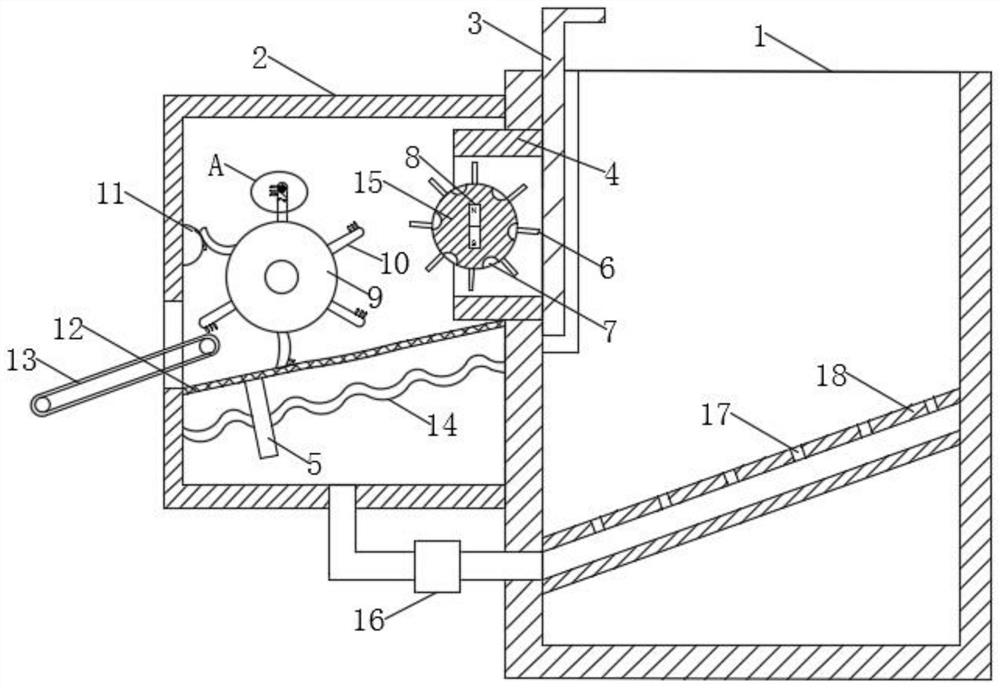

[0041] As an embodiment of the present invention, the inside of the impurity removal tank 1 is located below the short water inlet pipe 4 and is fixed with an inclined liquid separator 18; the cavity inside the liquid separator 18 is connected to one end of the pipe fitting Connected; the liquid separator 18 is uniformly provided with water outlet holes 17; the water outlet 17 is inclined towards the short water inlet pipe 4; during work, the water flowing out from the fiber filament sorting pool 2 enters the liquid separator 18 through the connecting pipe fittings In the inner cavity, and spray out from the water outlet hole 17 on the liquid separator 18, the sprayed water can stir the polyester fiber filaments located on the liquid surface of the impurity removal tank 1, and accelerate the polyester fiber filaments. The shedding of metal impurities on the surface can improve the removal efficiency while improving the quality of the removal of impurities; and because the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com