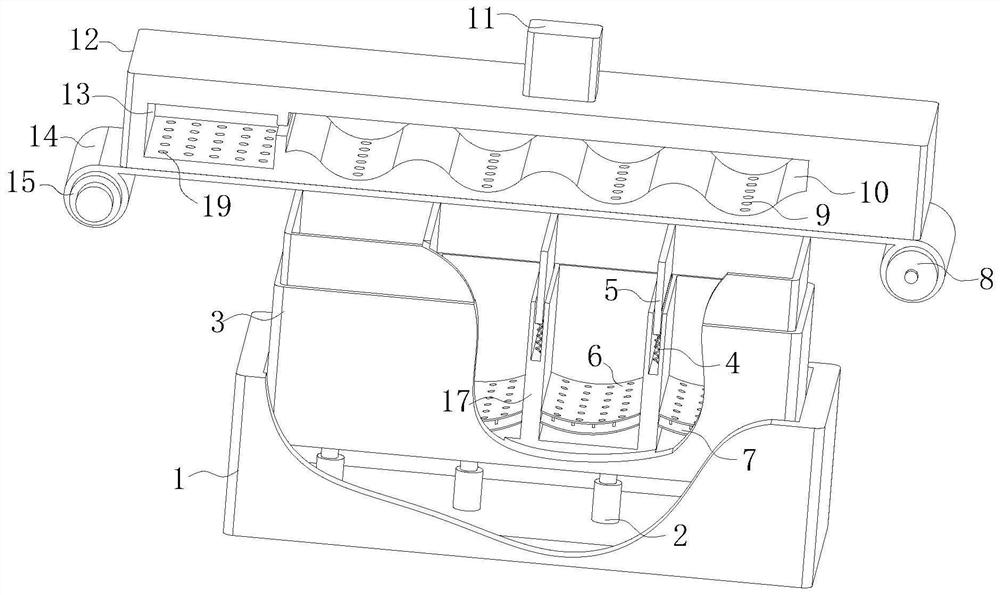

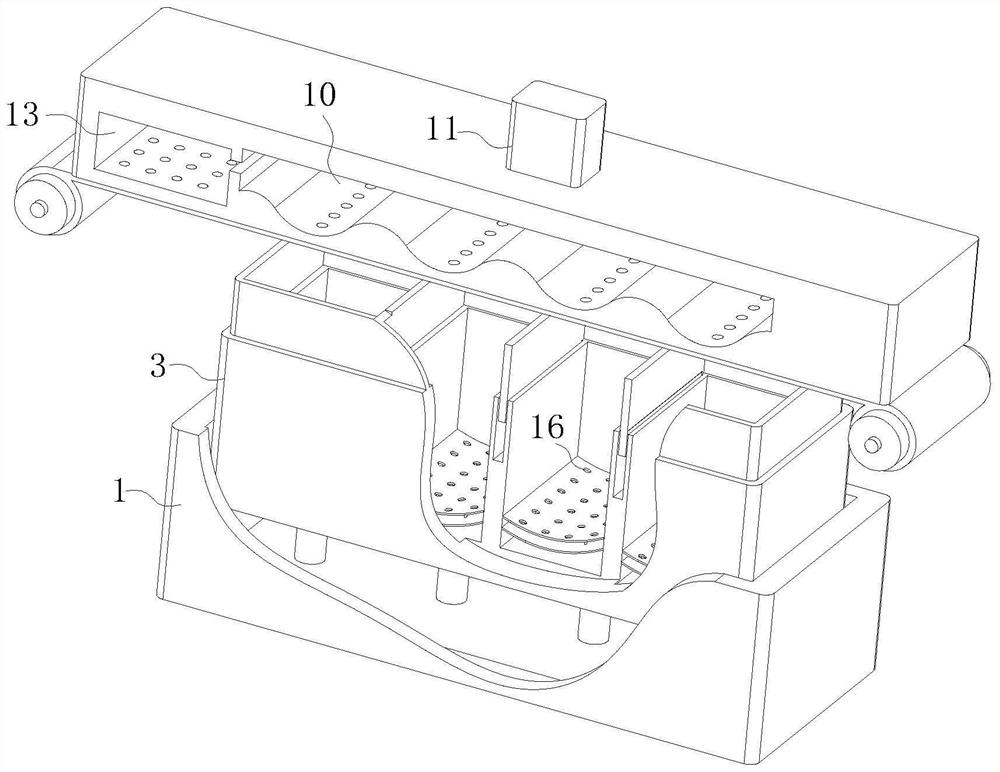

Textile fabric space dyeing machine

A technology for textile fabrics and dyeing machines, applied in the field of segment dyeing machines, can solve the problems of poor control of the amount of dyes, inability to collect and use dyes, and achieve the effect of saving dyes and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

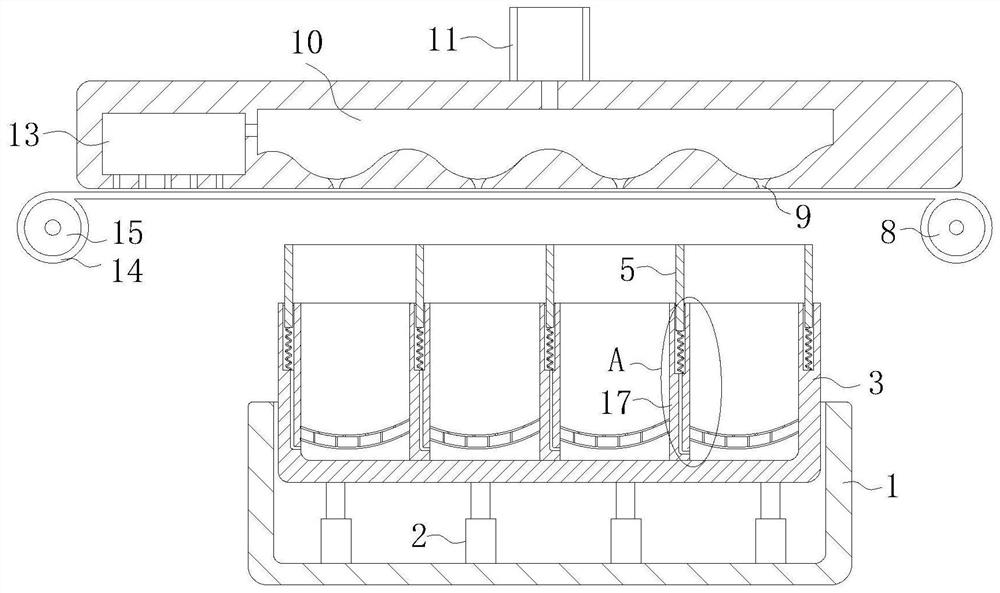

[0026] As an embodiment of the present invention, a drying chamber 13 is provided on the left side of the hot air chamber 10; the drying chamber 13 communicates with the hot air chamber 10; the bottom of the drying chamber 13 is uniformly arranged There is a third air outlet 19; during work, since the drying chamber 13 communicates with the hot air chamber 10, the air pumped into the hot air chamber 10 from the hot air pump 11 will flow into the drying chamber 13, and then from The third air outlet 19 at the bottom of the drying chamber 13 sprays out, which can be used for drying of the textile fabric body 14 after the space dyeing.

[0027] As an embodiment of the present invention, the first air outlet 9 is a funnel-shaped structure, and the diameter of the upper port of the first air outlet 9 is greater than the diameter of the lower port of the first air outlet 9; during work, due to the first air outlet 9 is a funnel-shaped structure design, which can prevent the dye from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com