Filtering device for paper pulp

A filter device and pulp technology, which is applied in textiles and papermaking, fiber raw material processing, etc., can solve the problems of safety accidents, block the sight of workers, and it is difficult for workers to observe the working conditions of the filter device, and achieve the effect of small impact force.

Active Publication Date: 2018-06-19

重庆云新包装有限公司

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, during the filtration process, when the pulp flows down from the top and hits the filter net, the pulp is easy to splash upwards, and the pulp that has just been cooked has a high temperature, and it is easy to burn the workers after splashing, causing safety accidents

Secondly, during the pulp filtration process, the water in the pulp with a higher temperature will form water vapor, which will block the workers' sight, making it difficult for workers to observe the specific working conditions of the filter device, and unable to deal with possible emergencies in time

In addition, a large amount of chemical reagents are added to the pulp during the cooking process. When the water evaporates to form water vapor, the chemical reagents are easily dissolved into the water vapor, and the inhalation of chemical reagents is harmful to the health of workers.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

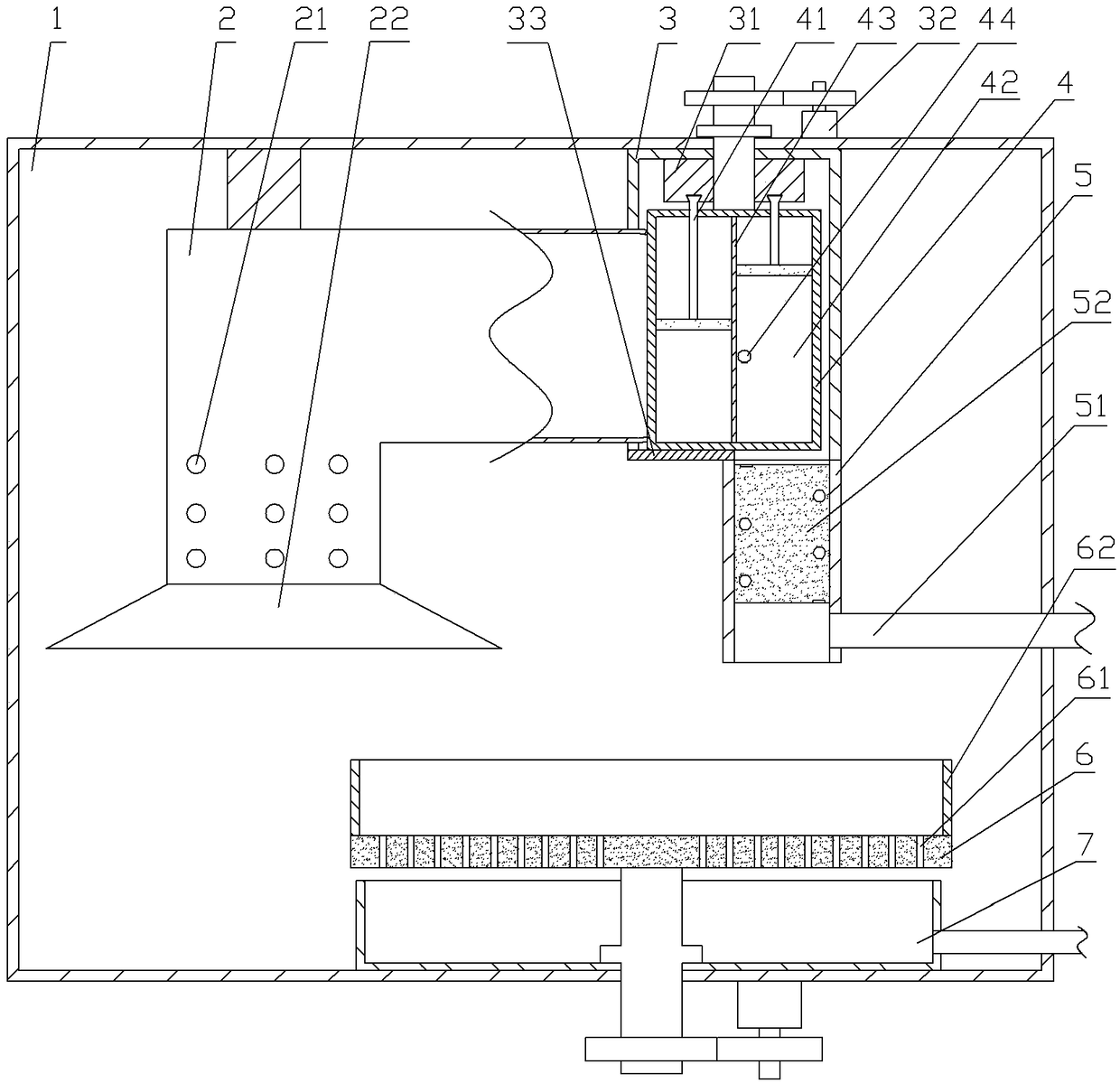

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of paperboard production, and particularly discloses a filtering device for paper pulp. The filtering device comprises a seal cover, a pulp entering mechanism, a filtering disc and a collecting groove, filtering holes are formed in the filtering disc, a rotary shaft is fixed to the axis of the filtering disc, a rotating motor is fixed to the exterior of the sealcover, and a discharging pipe is communicated with the collecting groove; the pulp entering mechanism comprises an air-blowing pipe, a guiding pillar, a rotary barrel, a fixing barrel, an air-collecting pipe and a pulp entering motor; a seal plate is fixed to the opening of the fixing barrel; a plunger piston is fixed inside the fixing pipe, a spiral channel is formed inside the plunger piston, and the pulp entering pipe is communicated with the air-blowing pipe; the lower end of the guiding pillar is an inclined face, a clamping groove is formed in the lower end of the guiding pillar, the rotary shaft is fixed to the rotary barrel, and the pulp entering motor drives the rotary shaft; a partitioning plate is fixed inside the rotary barrel and divides the rotary barrel into a first cavity and a second cavity, and air inlets and air outlets are formed in the side wall of the rotary barrel; a first piston and a second piston are arranged in the first cavity and the second cavity, and a first piston rod and a second piston rod are fixed to the first piston and the second piston. In the scheme, workers are prevented from being scalded by the paper pulp.

Description

technical field [0001] The invention relates to the field of paperboard production, in particular to the field of pulp filtration. Background technique [0002] In today's society, in order to meet the needs of the market, it is necessary to transport goods from the place of origin to the place of consumption. During the transportation process, the goods need to be packaged in transport boxes to prevent the goods from being damaged. In order to save costs, goods are generally packaged in cartons at present. The raw materials of cartons are various plant fibers. During the production process, the fiber raw materials are mechanically ground to form pulp, and then the pulp is cooked. During the cooking process, some different chemical reagents are added to improve the final production. The folding resistance and tear strength of the cardboard are improved, and finally the service life of the carton made of this cardboard is improved. [0003] There are still large fibers rema...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21D5/00

CPCD21D5/005

Inventor 刘露

Owner 重庆云新包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com