Building decorative coating stirring uniform mixing device

A technology of stirring and mixing and architectural decoration, which is applied to mixers with rotating stirring devices, mixers, transportation and packaging, etc. It can solve the problems of long mixing time, time-consuming and laborious, and increased hardness of coatings, etc., and reduce the dead angle of mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

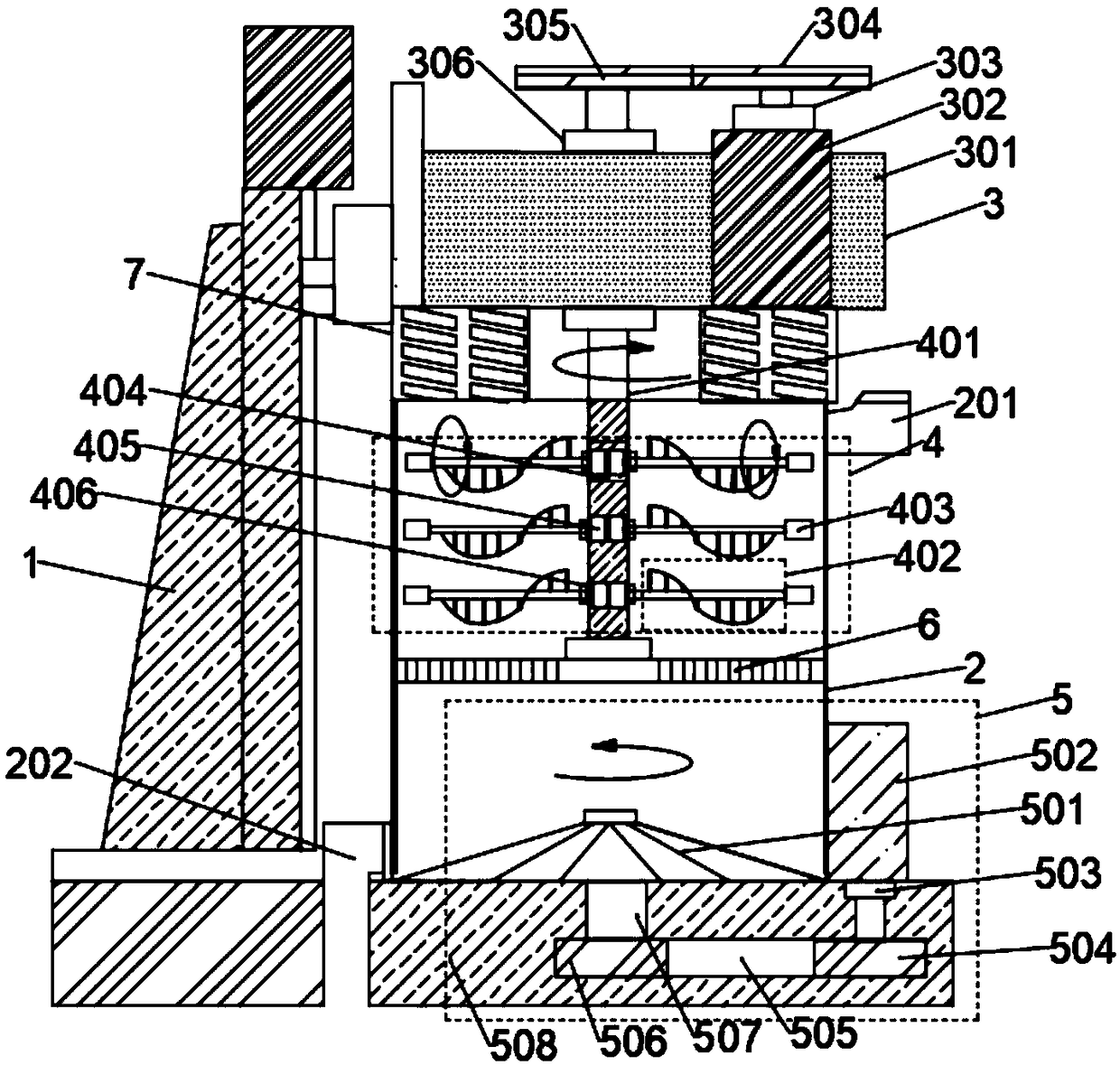

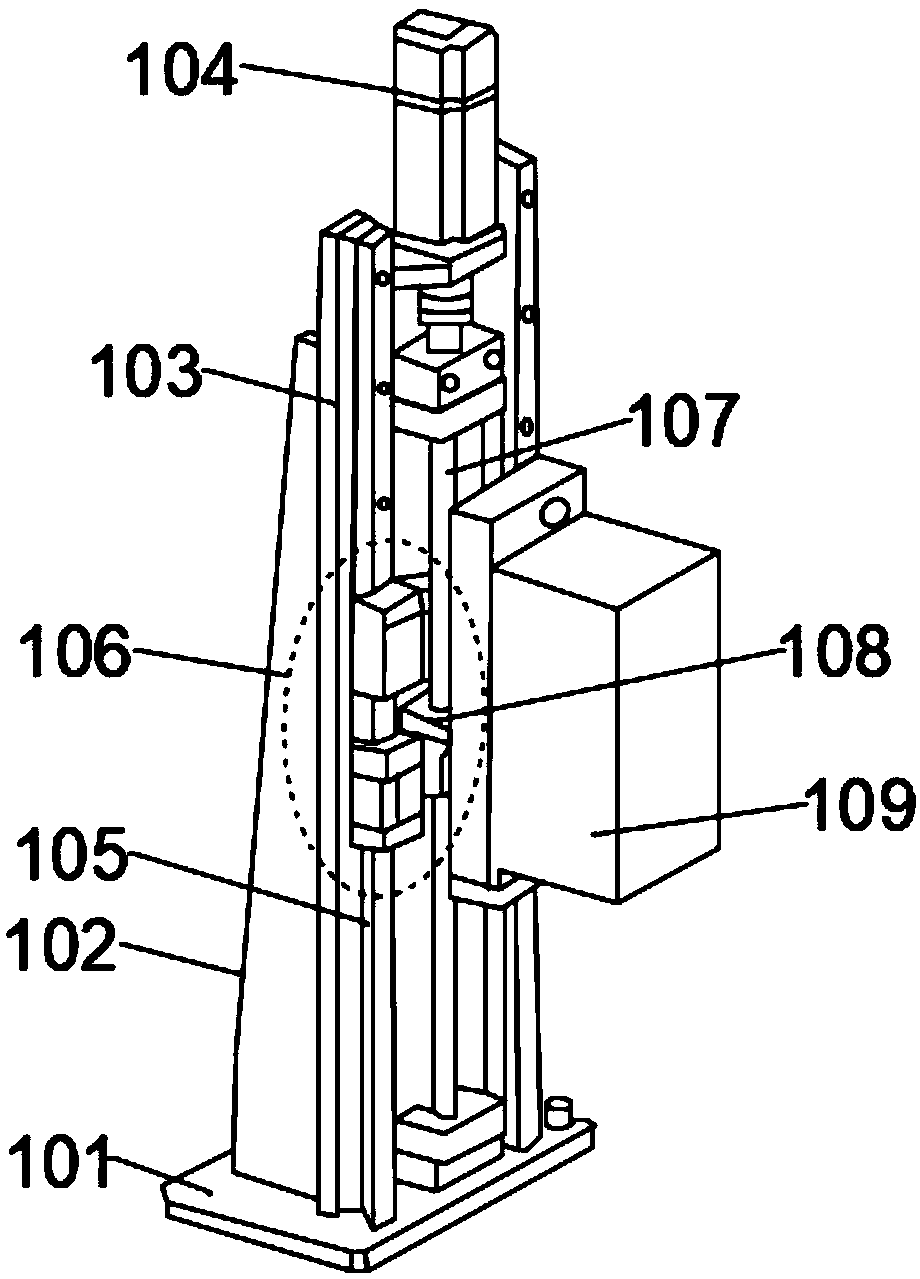

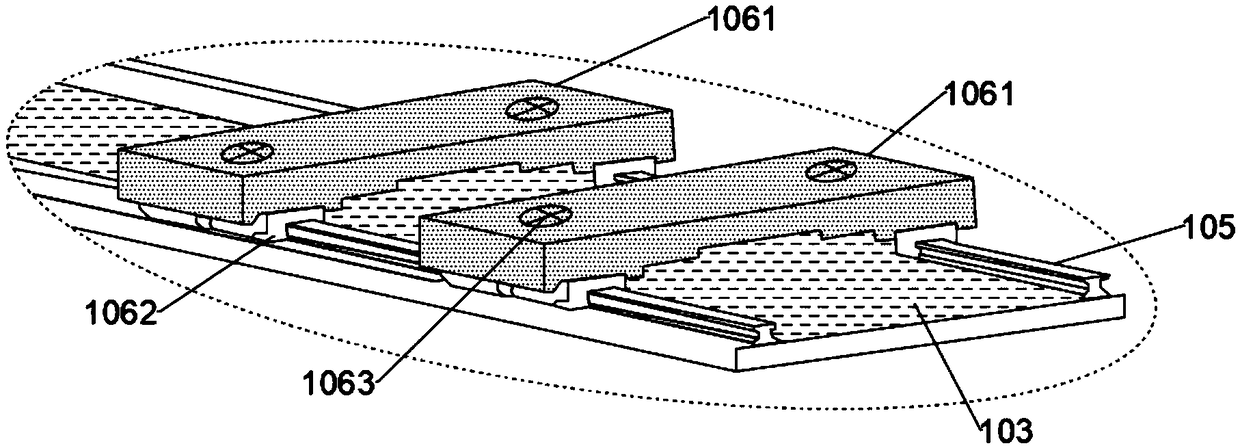

[0046] Such as figure 1As shown, the invention provides a kind of stirring and mixing device for architectural decoration coatings including a longitudinal adjustment device 1, the right side of the longitudinal adjustment device 1 is provided with a mixing drum 2, and the upper end of the mixing drum 2 is provided with a The stirring power assembly 3 connected to the adjustment device 1, the vertical omnidirectional stirring paddle 4 is arranged in the mixing drum 2, and the lower end of the vertical omnidirectional stirring paddle 4 is connected with a uniform sieve 6, and the front of the uniform sieve 6 is A paint raising device 5 is arranged below, and a shock-absorbing connector 7 is arranged at the connection between the stirring power assembly 3 and the mixing drum 2 .

[0047] The upper right end of the mixing drum 2 is provided with a paint inlet 201 , and the lower left end of the mixing drum 2 is provided with a mixing paint outlet 202 .

[0048] The specific impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com