a biomass burner

A burner and biomass technology, which is applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve problems such as slag discharge trouble, leak hole blockage, oxygen can not be well contacted, etc., to increase the contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

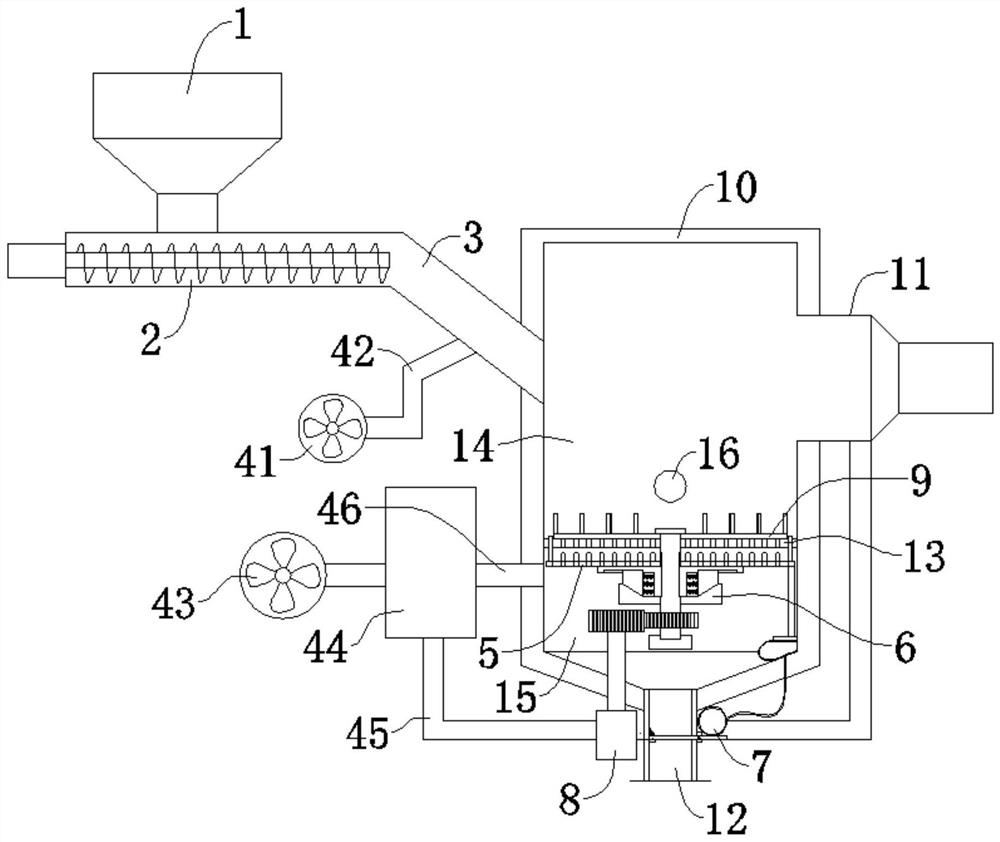

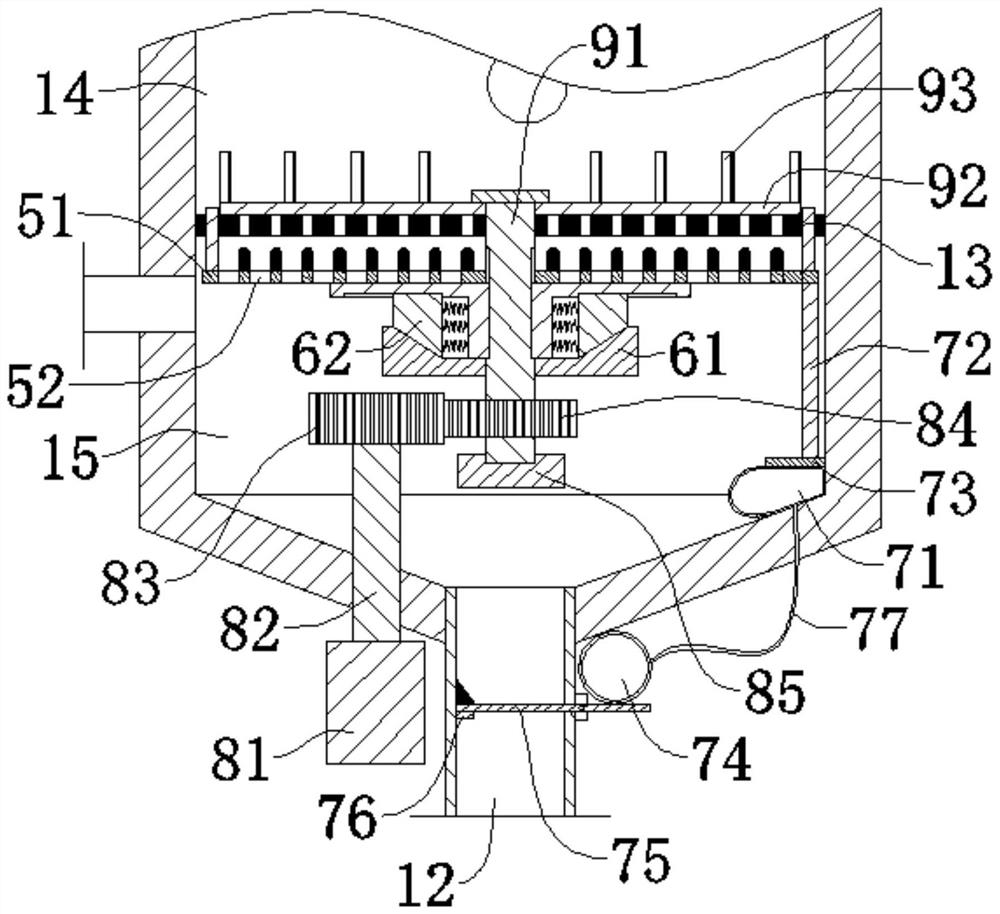

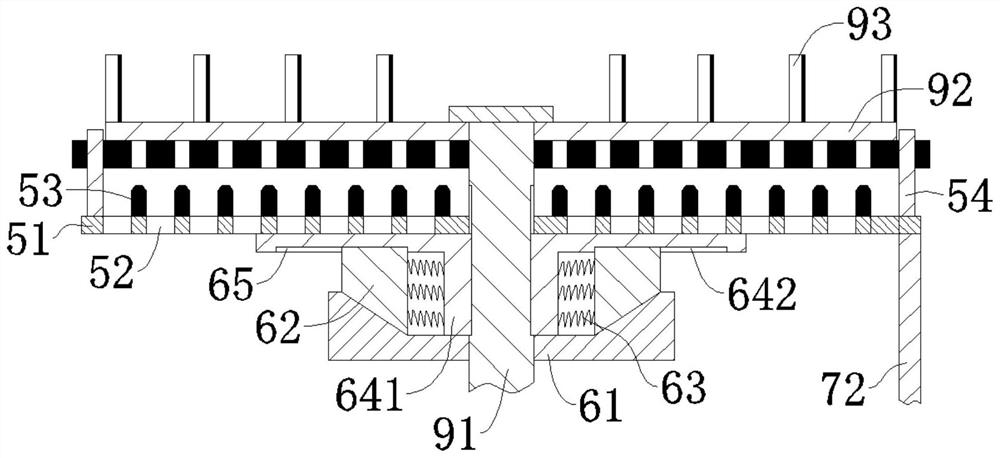

[0049] Embodiment: a kind of biomass burner, such as Figure 1-3 As shown, it includes a feed hopper 1, an auger 2, a feed channel 3, an air supply system and a combustion furnace 10. The feed hopper 1, the auger 2, the feed channel 3 and the combustion furnace 10 are sequentially connected, the feed hopper 1 is located on the upper part of the auger 2, the auger 2 is arranged horizontally and the outlet is connected to the feed channel 3. The feeding channel 3 is arranged obliquely, and the upper end is connected with the auger 2 , and the lower end is connected with the side of the combustion furnace 10 . The combustion furnace 10 includes a furnace 14 and a furnace bottom 15 . A fire outlet 11 and an ignition port 16 are provided on the side of the furnace 14 . The fire outlet 11 and the feed channel 3 are respectively located on opposite sides of the combustion furnace 10 . A carrier ring 13 is fixed in the combustion furnace 10, the upper part of the carrier ring 13 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com