Water production system and operation method therefor

A method of operation and water generation technology, applied in chemical instruments and methods, water distribution pipes, seawater treatment, etc., can solve problems such as difficulty in ensuring sewage and wastewater, inability to fully adapt to large-scale systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Hereinafter, preferred embodiments of the present invention will be described using the drawings. However, the scope of the present invention is not limited to these embodiments.

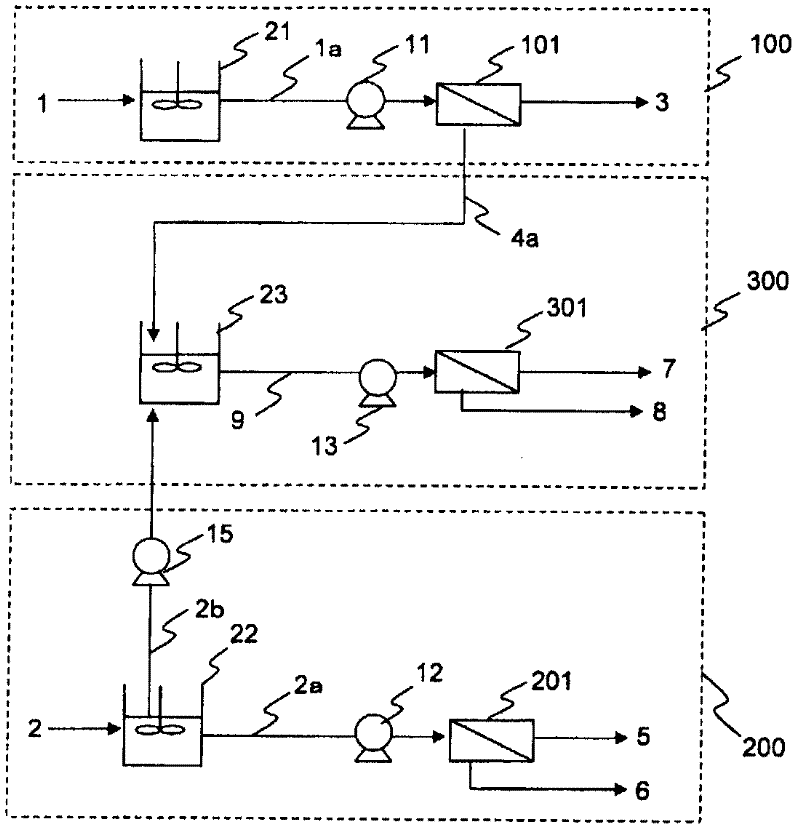

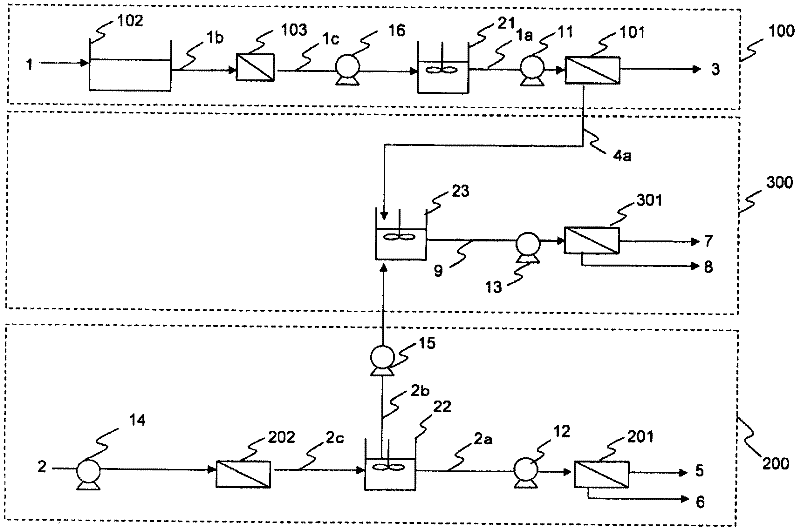

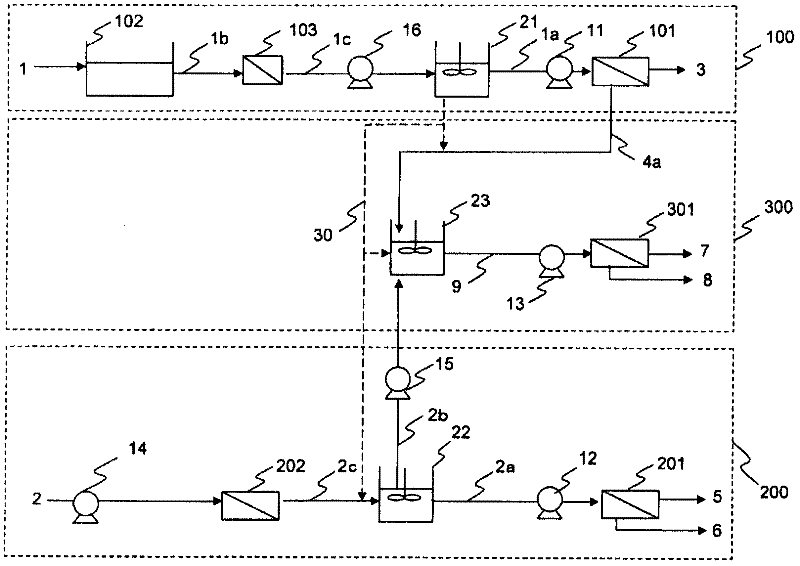

[0087] figure 1 It is a figure which shows the flow of one embodiment of the water generation system to which this invention is applied. The water generation system has a semi-permeable membrane treatment process A100 that uses a semi-permeable membrane treatment device A101 to treat the treated water A1 with a semi-permeable membrane, and a semi-permeable membrane that uses a semi-permeable membrane treatment device B201 to treat the treated water B2 with a semi-permeable membrane. Membrane treatment process B200, and semi-permeable membrane treatment process C300 for semi-permeable membrane treatment of mixed water with semi-permeable membrane treatment device C301.

[0088] In this semi-permeable membrane treatment process A100, it is equipped with: the treated water A tank 21, which con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com