Double-phase high-entropy alloy and preparation method thereof

A technology of high-entropy alloy and alloy composition, which is applied in the direction of additive manufacturing and additive processing, can solve problems such as poor toughness, and achieve the effects of high forming precision, excellent comprehensive mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

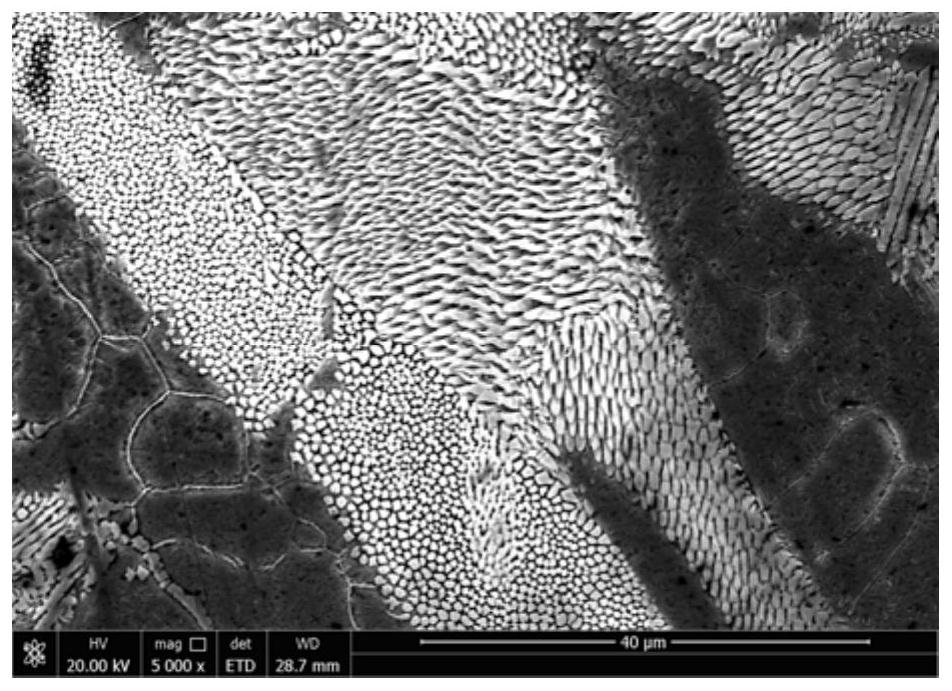

[0049]A double phase high entropy alloy comprising a first alloy component of an Fcc phase and a second alloy component of the BCC phase, the first alloy component is FECOCRNI, and the second alloy component is FECOCRNIAL.

[0050]In the first alloy component, the atomic molar ratio of Fe, CO, Cr, Ni is 1: 1: 1: 1; in the second alloy component, Fe, CO, Cr, Ni, Al, atomic molar ratio of 1: 1: 1: 1: 1.

[0051]The weight ratio of the first alloy component to the second alloy component is 1: 1.

[0052]Example 1 The double phase high entropy alloy provided was 826 MPa, the hardness of 400 HV, the toughness was 23%.

Embodiment 2

[0054]A double phase high entropy alloy comprising a first alloy component of an Fcc phase and a second alloy component of the BCC phase, the first alloy component is FECOCRNI, and the second alloy component is FECOCRNIAL.

[0055]In the first alloy component, the atomic molar ratio of Fe, CO, Cr, Ni is 1: 1: 1: 1; in the second alloy component, Fe, CO, Cr, Ni, Al, atomic molar ratio of 1: 1: 1: 1: 1.

[0056]The weight ratio of the first alloy component to the second alloy component is 1: 2.7.

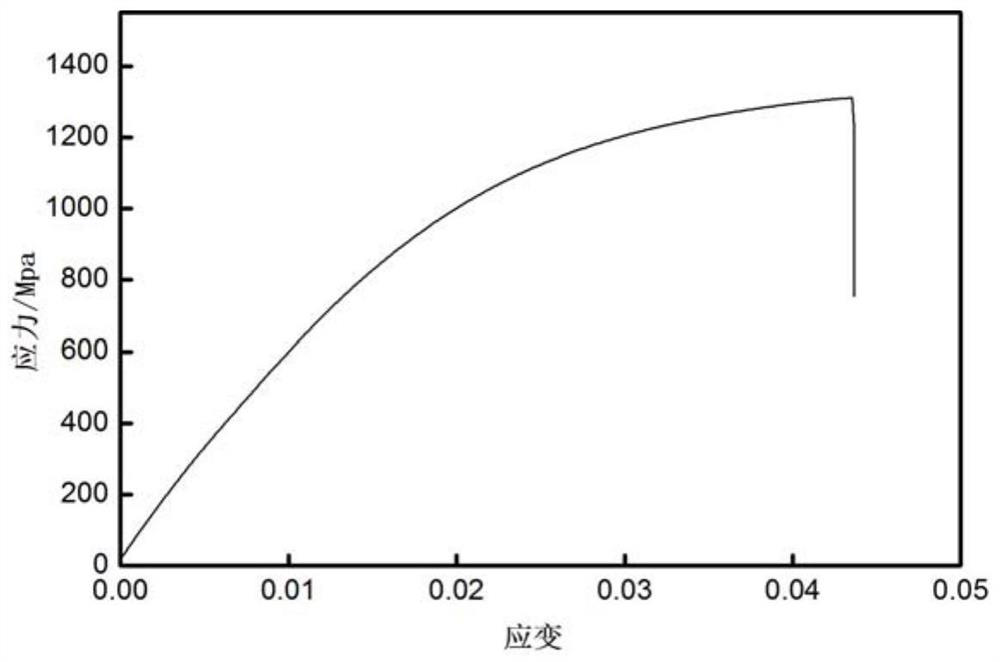

[0057]Example 2 Double-phase high entropy alloy has an intensity of 1510 MPa, a hardness of 863 HV, and a toughness of 2.1%.

Embodiment 3

[0059]A double phase high entropy alloy comprising a first alloy component of an Fcc phase and a second alloy component of the BCC phase, the first alloy component is FECOCRNI, and the second alloy component is FECOCRNIAL.

[0060]In the first alloy component, the atomic molar ratio of Fe, CO, Cr, Ni is 1: 1: 1: 1; in the second alloy component, Fe, CO, Cr, Ni, Al, atomic molar ratio of 1: 1: 1: 1: 1.

[0061]The weight ratio of the first alloy component to the second alloy component is 1: 1.85.

[0062]Example 3 The double phase high entropy alloy provided was 1416 MPa, a hardness of 712 HV, and the toughness was 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com