Binary fluid matching and mixing device

A mixing device and binary fluid technology, applied in fluid mixers, gas and gas/vapor mixing, mixers, etc., can solve the problems of inability to perform temperature and pressure compensation, high cost, large volume, etc., and reduce the number of parts , compact structure, accurate control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

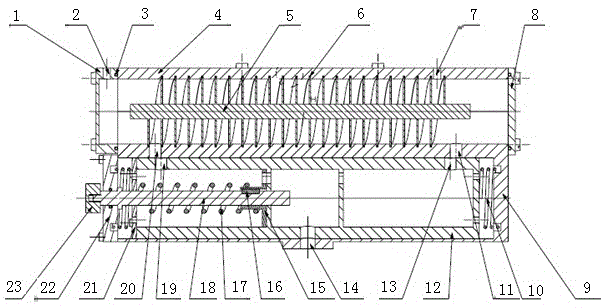

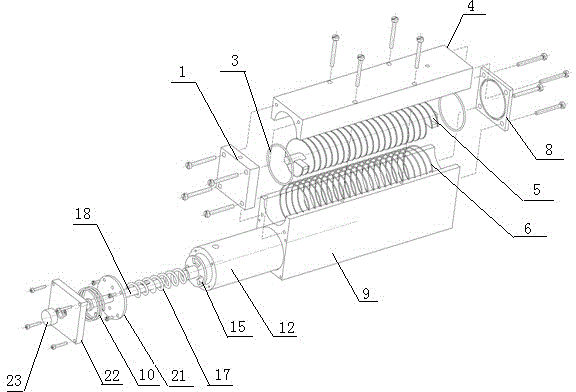

[0026] like figure 1 , figure 2 As shown, the binary fluid proportioning and mixing device of the present invention includes a valve body 9, a temperature regulating device, a mixing device, a pressure regulating device, and a flow regulating device. The valve body 9 is composed of an upper chamber and a lower chamber. The left end cover 1 and the right end cover 8 are respectively installed at the left and right ends of the upper cavity, and the left end cover 1 and the right end cover 8 are fixed on the upper cavity by screws, and a sealing ring is arranged between the left end cover 1, the right end cover 8 and the upper cavity 3. Prevent air leakage. The side wall of the left end cover 1 is provided with a main air intake hole 2, and the upper cover 4 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com