Blended yarn and preparation method and application thereof

A technology of blended yarn and siro spinning, which is applied in the field of blended yarn and its preparation, can solve the problems of easy yarn breakage of single yarn, lower production efficiency, and poor yarn quality, so as to improve spinning efficiency, Reduced production cost and good hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

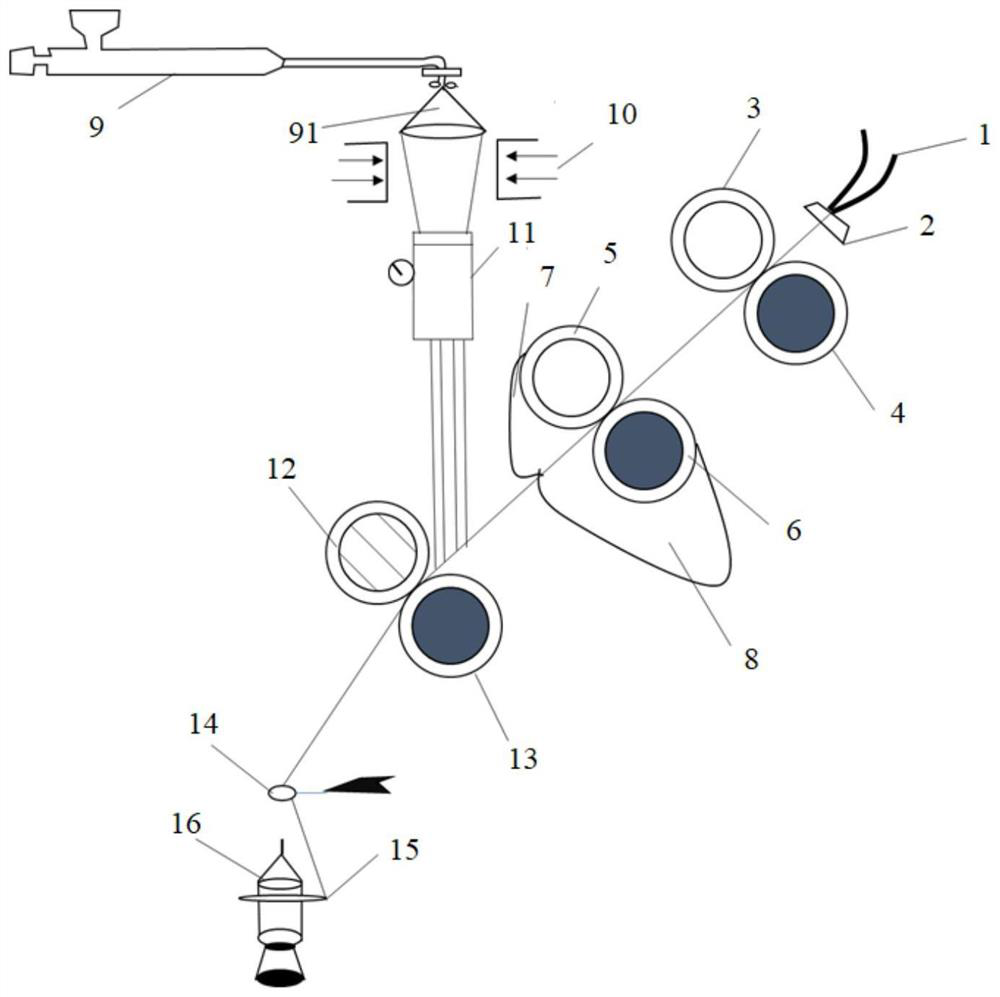

Method used

Image

Examples

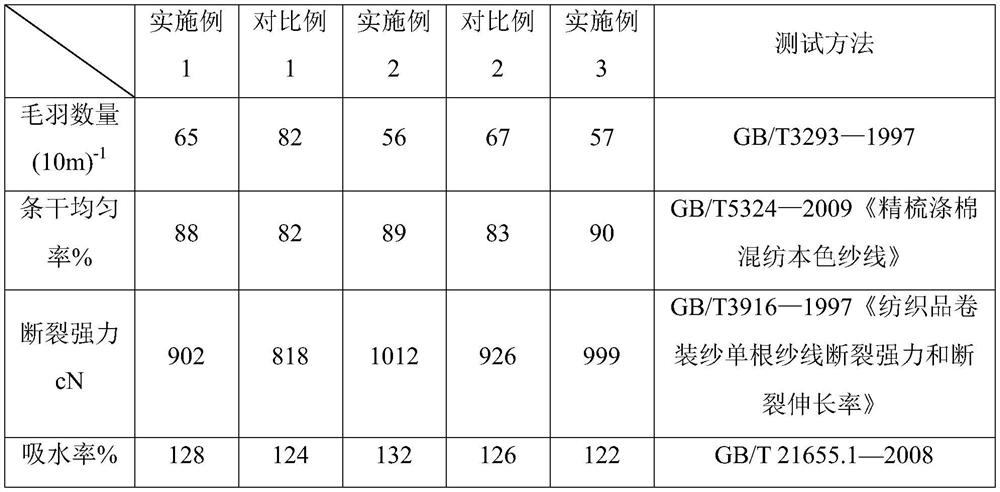

Embodiment 1

[0038]This example provides a blended yarn and a preparation method thereof. The preparation method of the blended yarn includes: in the process of siro spinning, using the siro spinning method to carry out several times of siro spinning, drafting and twisting on a plurality of roving sliver to obtain the siro spinning primary yarn, and then making The siro-spun virgin yarn is plyed with the uncooled fiber bundle spun by melt spinning, and then simultaneously subjected to at least one siro-spinning drafting and twisting to obtain a blended yarn; wherein, the incompletely cooled fiber bundle is In the process of plying, the fiber bundles that are not completely cooled are bonded to the siro-spinning primary yarn, and the drafting and twisting of siro-spinning is carried out by the rubber roller and the roller for drafting and twisting. operate.

[0039] Specifically, the preparation method of the blended yarn of this example combines the siro spinning method and the melt spinn...

Embodiment 2

[0053] Basically the same as Example 1, the difference is only:

[0054] (1) Melt spinning method adopts polyamide as raw material, specifically adopts polyamide fiber chip (purchased from Belden Nylon, trade mark BTD12DW) with a melting temperature of 130 ° C as raw material, and simultaneously controls the blending ratio to be 7%;

[0055] Melt spinning process parameters: the temperature of the first zone of the screw is 160℃, the temperature of the second zone of the screw is 180℃, and the temperature of the third zone of the screw is 176℃;

[0056] (2) The pressure of the front rubber roller is 140N, the pressure of the middle rubber roller is 121N, and the pressure of the rear rubber roller is 125N.

Embodiment 3

[0058] Basically the same as Example 1, the only difference is that the blending ratio is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com