Production process of energy-saving and environmentally-friendly direct-spinning FDY fine-denier cationic polyester filament

A cationic polyester and production process technology, applied in the field of polyester yarn production, can solve the problems of uneven dyeing of cationic polyester, easy occurrence of filaments and broken ends, poor antistatic performance, etc., to shorten the conveying distance, improve the specificity, The effect of improving antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with regard to specific embodiment:

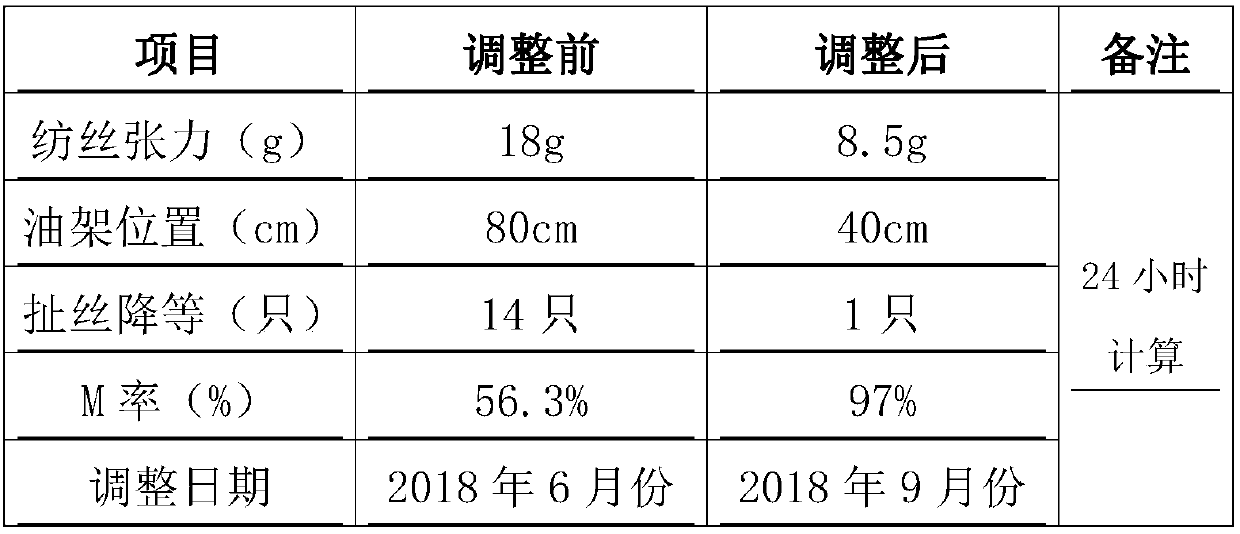

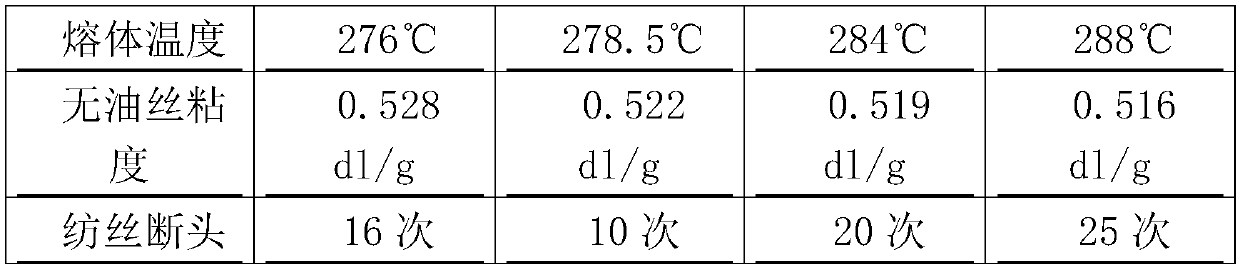

[0016] An energy-saving and environment-friendly direct-spun FDY fine denier cationic polyester filament production process, the process flow is as follows, three-pot polymerization process→melt distributor→booster pump→melt delivery→cooler→static mixer→melt Distributing valve→spinning box→melt extrusion of metering pump→spinning assembly→ring blower→cooling forming→magnetic ring→oiling nozzle→spinning tunnel→filament guide→GR0→first heat roller→second Heat roller → third heat roller → fourth heat roller → fifth heat roller → GR1 → GR2 → main network → GR3 → wire guide → broken wire detector → winding machine → automatic doffing machine → overhead rail transportation → Dyeing and determination → quality inspection and packaging → automatic storage in three-dimensional warehouse, wherein the viscosity of polyester melt is 0.522-0.525dl / g, and the windless area of the fan box is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com