Technology of preparing aluminium oxide based continuous fibers by sol-gel process

A technology of sol-gel method and continuous fiber, which is applied in the technical field of preparing alumina-based continuous fiber by sol-gel method, can solve the problems of high cost of aluminum alkoxide and achieve good toughness, stable physical and chemical properties, and dense fiber cross-section Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific examples.

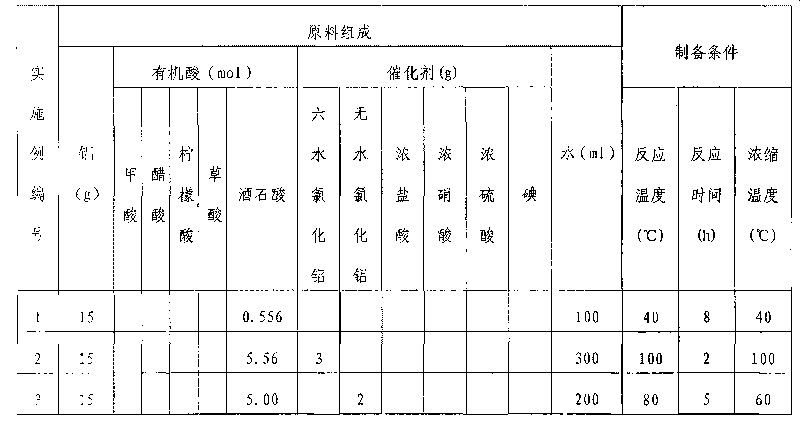

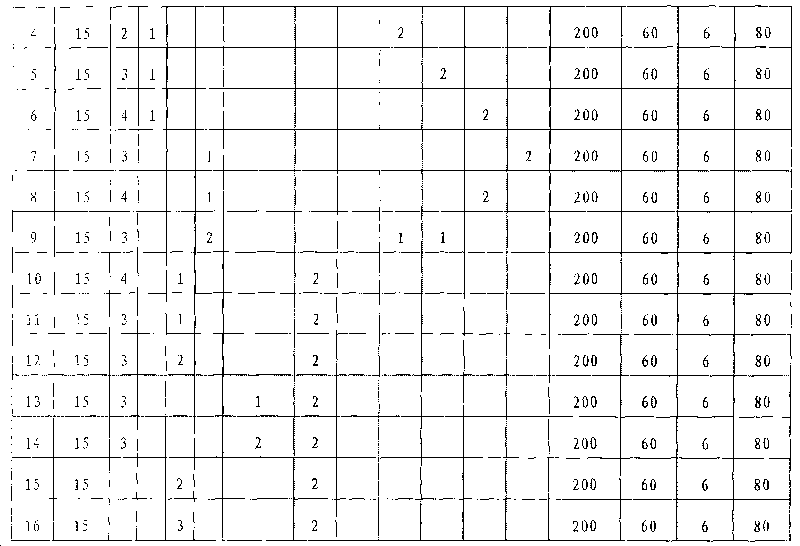

[0022] Table 1 has listed 16 embodiment step process conditions that are numbered 1-16: determine the kind and the addition of aluminum powder, water, organic acid and catalyst according to the different embodiments of table 1, and determine the preparation of aluminum sol condition, the aluminum carboxylate sol was prepared.

[0023] Table 1. Preparation of aluminum carboxylate sol

[0024]

[0025]

[0026] Note: the concentration of concentrated nitric acid in Table 1 is 60% (mass percentage), the concentration of concentrated hydrochloric acid is 36% (mass percentage), and the concentration of concentrated sulfuric acid is 98% (mass percentage).

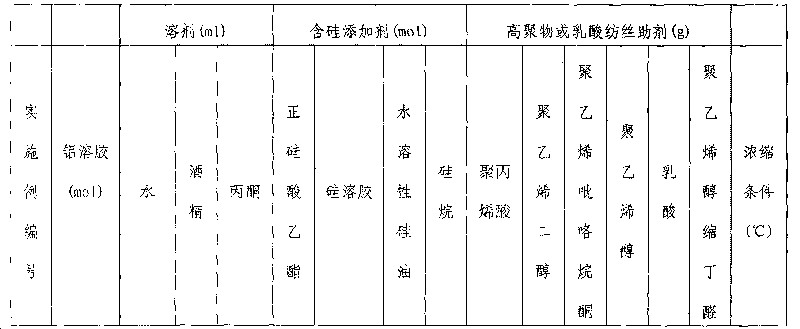

[0027] Table 2 has listed the second and third step process conditions of the embodiment of table 1: add solvent, silicon-containing additive, high polymer spinning aid or lactic acid in aluminum carboxylate sol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com