Flame-retardant resin composition

A resin composition and flame retardant technology, applied in the field of flame retardant resin compositions, can solve problems such as difficulty in enhancing the flame retardant effect of polyamide compositions, corrosion of forming machines and metal molds, environmental pollution by harmful substances, etc. Excellent water absorption, excellent flame retardancy, and the effect of small decrease in insulation

Inactive Publication Date: 2007-04-18

UBE IND LTD

View PDF6 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, for these compounds, difficulty in achieving a sufficient flame-retardant effect in a reinforced polyamide composition and a low decomposition temperature are mentioned as disadvantages (see Patent Document 1 for melamine cyanurate, and Patent Document 2 for melem).

[0005] There are problems with resin compositions mixed with halogen compounds: corrosive decomposition gas may be generated during molding processing, thereby corroding molding machines and metal molds, and harmful substances may be generated during incineration to pollute the environment

On the other hand, when a vinyl alloy is further mixed to improve the water absorption of the polyamide resin, there is a problem that the flame retardancy decreases.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0092] The material of Example 3 has a slower water absorption speed and a lower saturated water absorption than the material of Comparative Example 4, so the former is useful as a material for electrical components and the like.

[0093] Processing time (days)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

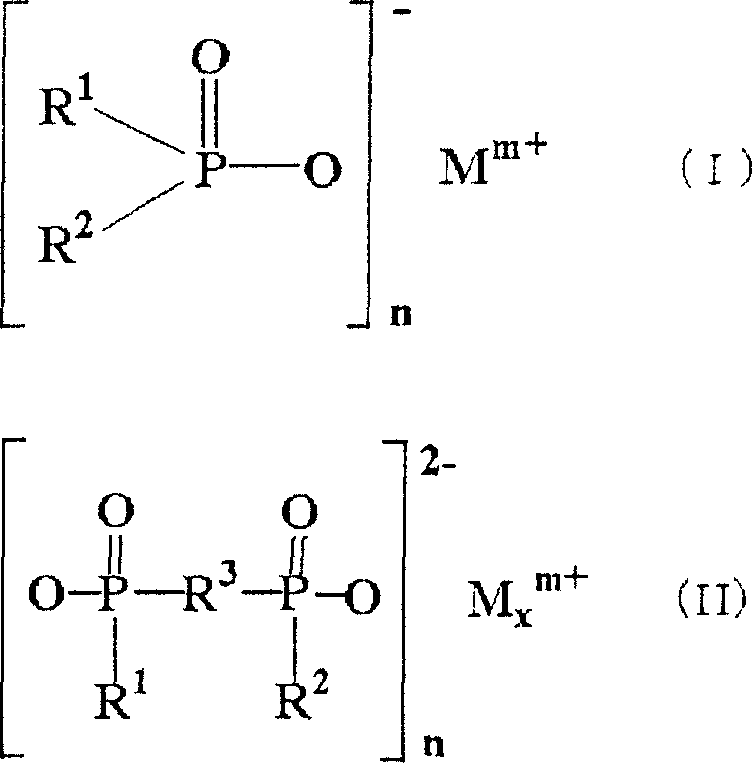

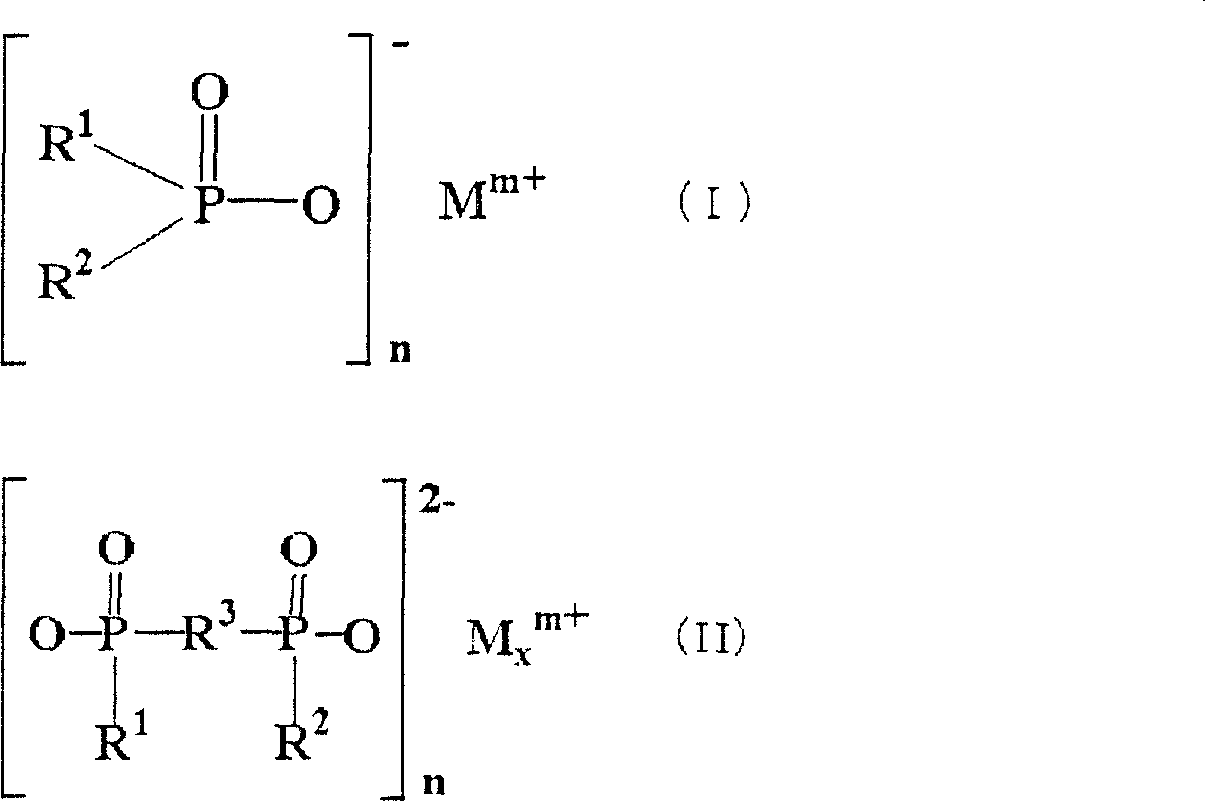

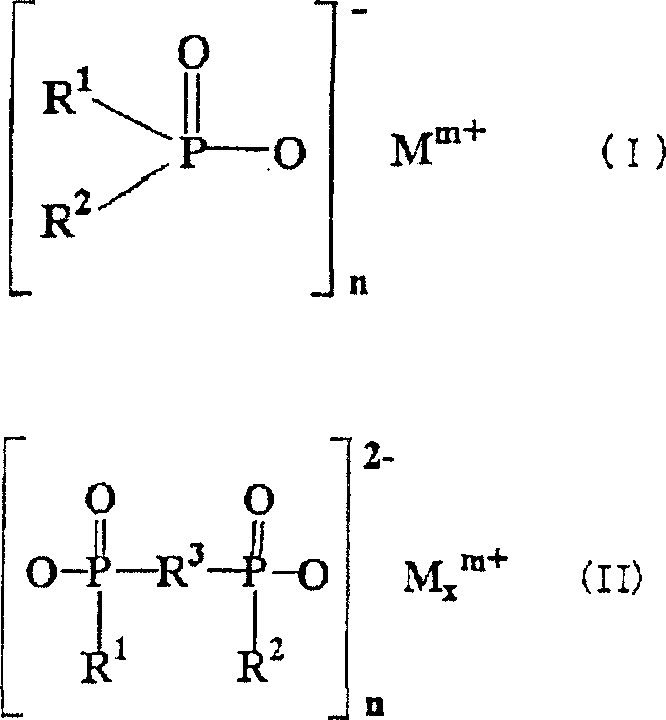

There is provided a flame-retardant resin composition which is excellent in flame retardancy and excellent in low water-absorbing property and exhibits a small dimensional change and a small decrease in insulating properties. A flame-retardant resin composition containing: (A) an aliphatic polyamide resin; (B) an aromatic polyamide resin; (C) a flame retardant containing (c1) a phosphinic acid salt represented by the following formula (I) and / or (c2) a diphosphinic acid salt represented by the following formula (II) and / or a polymer containing at least one of these (c1) and (c2) as a component C1 and containing (c3) a melamine condensation product and / or (c4) a reaction product of melamine with phosphoric acid and / or (c5) a reaction product of a melamine condensation product with phosphoric acid and / or a mixture containing at least two of these (c3) to (c5) as a component C2; and (D) an inorganic filler.

Description

technical field [0001] The present invention relates to a flame retardant resin composition which is excellent in flame retardancy and is excellent in low water absorption, small dimensional change, and small drop in insulating properties. Background technique [0002] Reinforced flame-retardant polyamide resins in which inorganic fillers are added to flame-retardant polyamide resins are widely used as electrical parts such as power circuit breakers, electromagnetic switches, wiring connectors, and electric tools because of their excellent mechanical properties. [0003] As the flame-retardant polyamide resin, those in which a triazine compound, a halogen compound, magnesium hydroxide, or red phosphorus is mixed as a flame retardant are used, but each has a problem. [0004] A resin composition containing a triazine compound such as melamine cyanurate cannot suppress the generation of ammonia gas, amine gas, cyano gas, etc. during processing or fire. In addition, these comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L77/00C08K3/00C08K5/3492C08K5/5313C08K5/52C08L77/02C08L77/06C08L77/10

CPCC08L77/10C08K5/5313C08L77/02C08K5/34928C08L77/06C08L77/00C08K5/5205C08L2666/20

Inventor 浦田嘉浩安井哲也

Owner UBE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com