Sintered zirconia, and sintering composition and calcined object therefor

A zirconia and sintered body technology, applied in zirconia and other directions, can solve the problems of crystal structure damage, inability to ensure strength, and unresolved long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

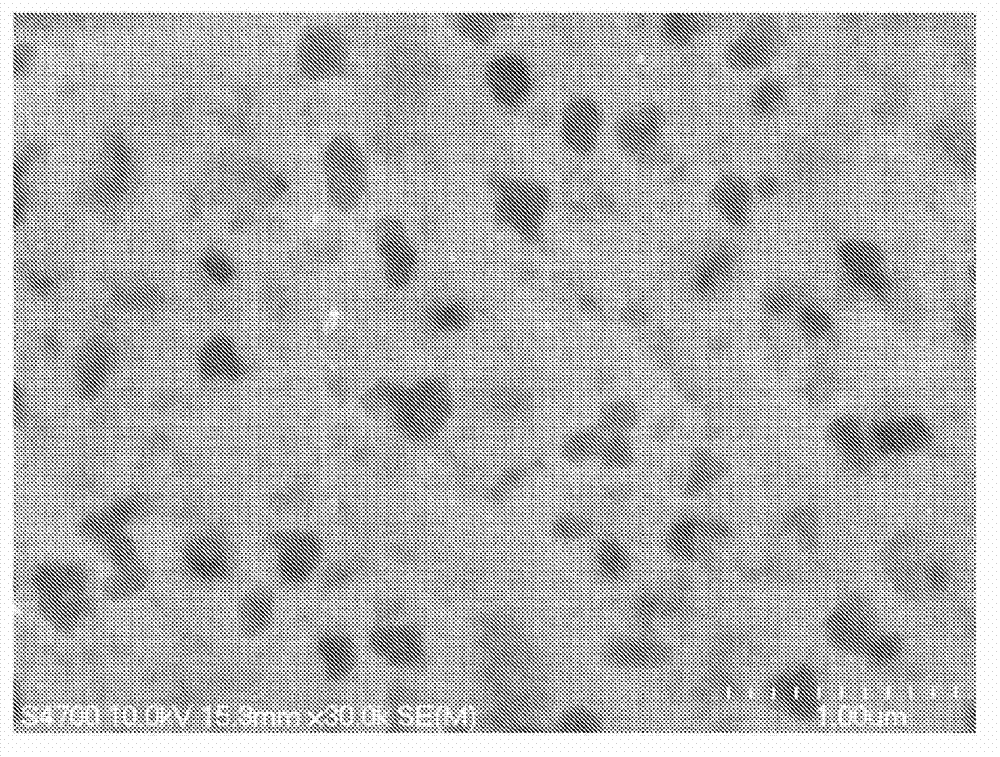

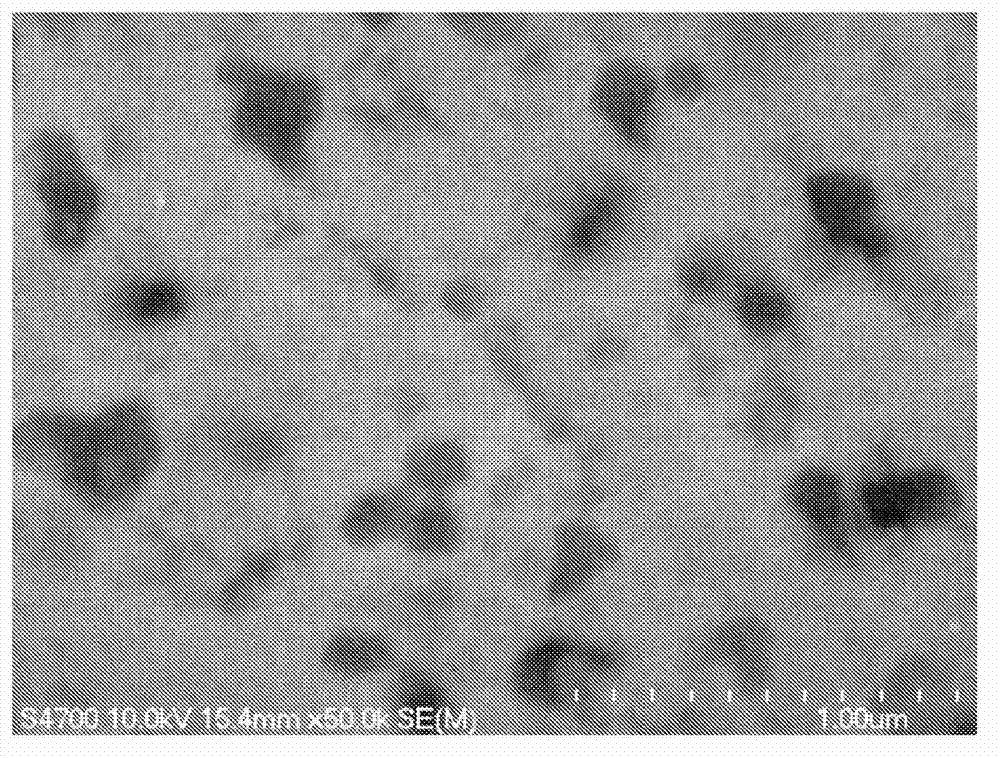

Image

Examples

Embodiment 1~24

[0202]Zirconia sintered bodies with different contents of each element and sintering temperature were produced, and hydrothermal treatment was performed as an accelerated test of low-temperature deterioration for each zirconia sintered body, and the degree of monoclinic crystal in the hydrothermally treated zirconia sintered body was confirmed. peak ratio. In addition, flexural strength and fracture toughness values were also measured for each zirconia sintered body.

[0203] In this example, yttria was used as a stabilizer. Phosphoric acid was used as the phosphorus-containing compound for adding phosphorus. As the boron-containing compound for adding boron, boron oxide or boric acid is used. In Examples 1 to 24, instead of using several types of partially stabilized zirconia crystal powders having different stabilizer content rates, one type of partially stabilized zirconia crystal powders having a stabilizer content rate was used. In Examples 1 to 22, partially stabili...

Embodiment 25~32

[0254] In order to confirm the effect of adding boron, for the zirconia sintered body containing a certain amount of phosphorus and silica, only the addition rate of boron oxide was changed, and the monoclinic crystal after hydrothermal treatment was confirmed in the same manner as in Examples 1 to 24. peak ratio. The method for producing the zirconia sintered body, the method for hydrothermal treatment, and the method for measuring X-ray diffraction lines are the same as in Examples 1 to 24. For the zirconia sintered body to which phosphorus was not added as Comparative Example 2, the peak ratio of the monoclinic crystal was similarly confirmed. In the zirconia sintered bodies of each Example and Comparative Example 2, the conditions other than the addition rate of phosphorus and the addition rate of boron oxide are: in the composition for sintering, the content of zirconia (yttria concentration: 3 mol%) in the base material The ratio is 92.6% by mass and the content of alum...

Embodiment 33~40

[0259] In order to confirm the effect of adding silica, for the zirconia sintered body containing a certain amount of phosphorus and boron, only the addition rate of silica was changed, and the monoclinic crystal after hydrothermal treatment was confirmed in the same manner as in Examples 1 to 24. peak ratio. The method for producing the zirconia sintered body, the method for hydrothermal treatment, and the method for measuring X-ray diffraction lines are the same as in Examples 1 to 24. In the zirconia sintered body of each example, the conditions other than the addition rate of phosphorus and the addition rate of boron oxide are: in the composition for sintering, the content rate of zirconia (yttria concentration: 3 mol%) in the base material is 92.6 mass % and the content of alumina was 7.4% by mass, the addition rate of the binder to the base material was 6%, and the sintering temperature was 1450°C. Table 14 shows the peak ratio measurement results of the monoclinic crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com