Multiunit coaxial injector component for test and manufacturing method

A multi-unit, injector technology, applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as complex design of injector components, long design of oxidizer nozzles, difficulty in ensuring coaxiality, etc., to achieve Low processing difficulty, low cost, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

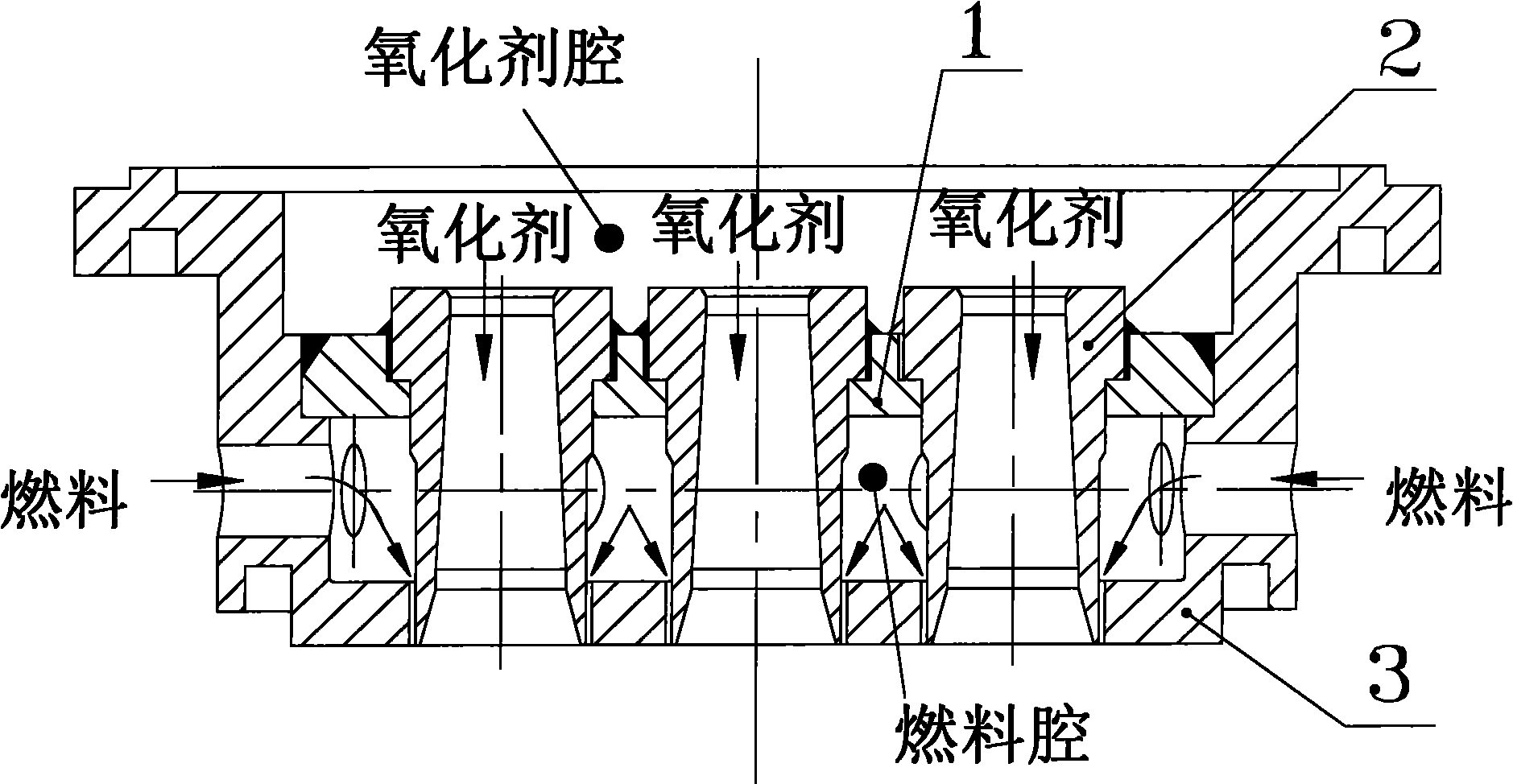

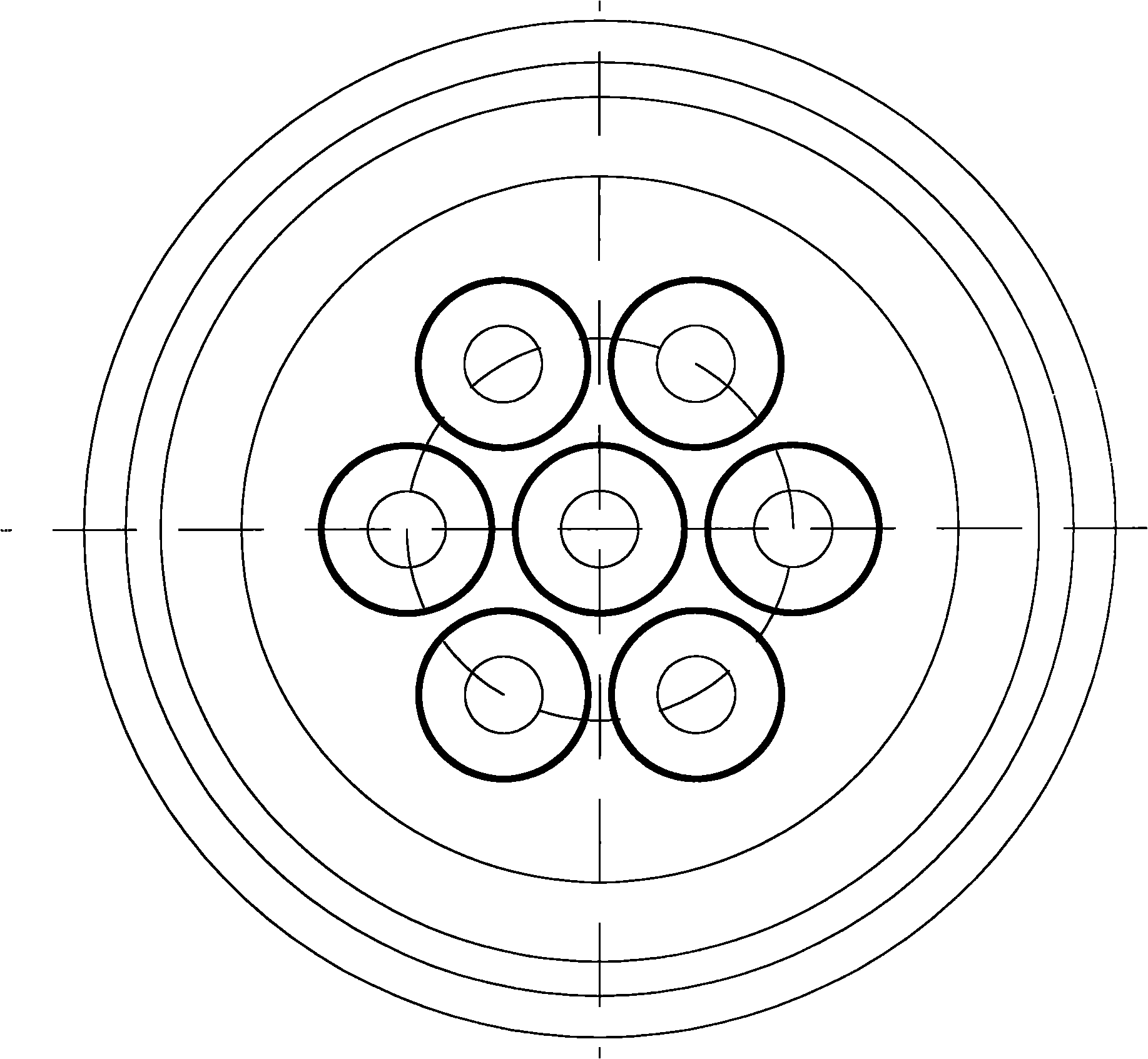

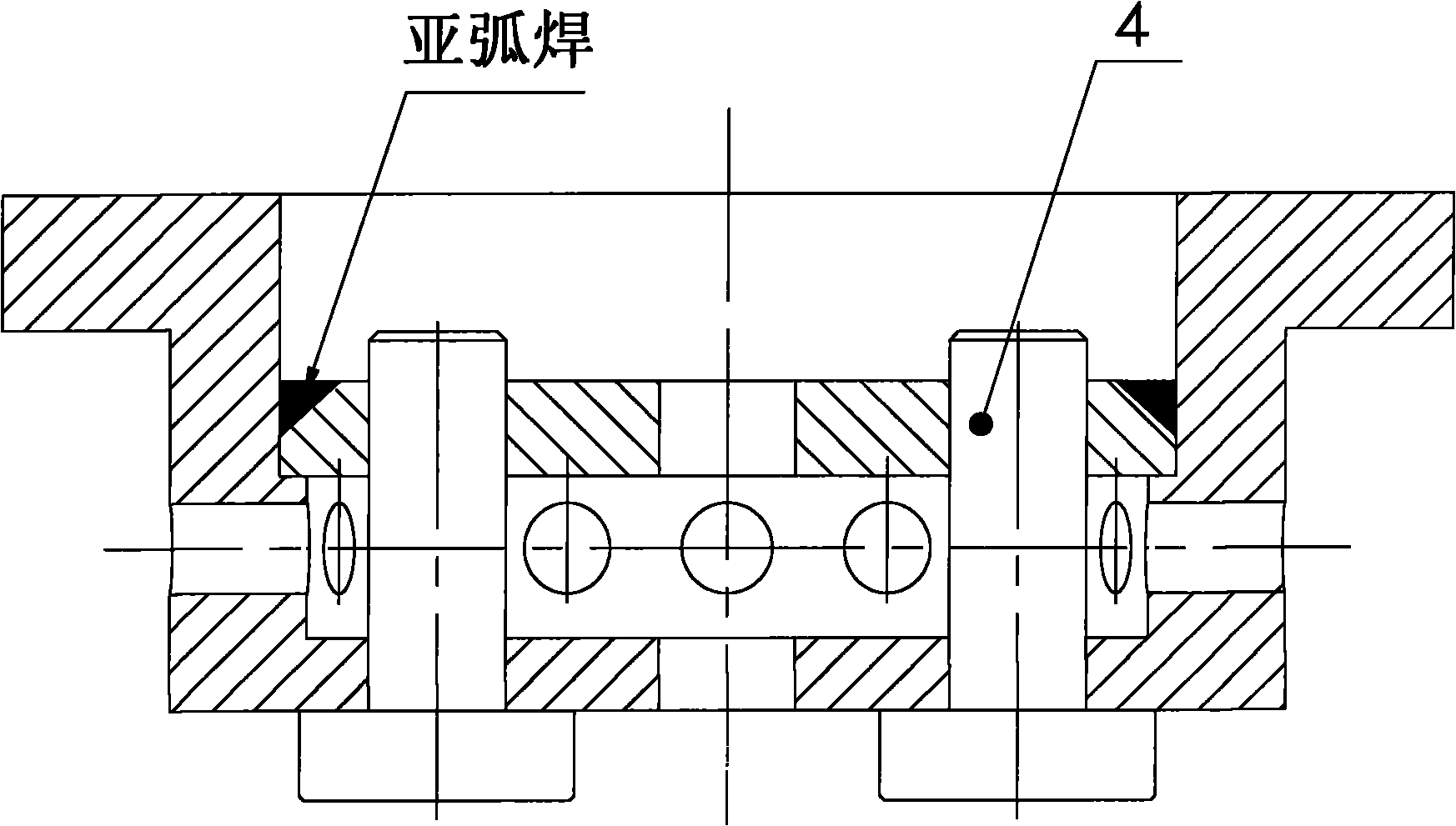

[0012] The present invention is further described below with embodiment in conjunction with accompanying drawing, and present embodiment is a liquid rocket motor multi-unit coaxial injector component for testing.

[0013] The injector component mainly includes: an upper plate 1, an oxidant nozzle 2, and an outer frame 3, and in the process of its manufacturing method, it also involves: injector hole tooling 4 and coaxiality guarantee tooling 5.

[0014] The present invention will be further described below with examples in conjunction with the accompanying drawings. The examples adopt a multi-nozzle thrust chamber structure for illustration, and the method is also suitable for single-nozzle combustion chamber working conditions.

[0015] Such as figure 1 It is an assembly diagram of the injector components, in which the upper plate 1 and the outer frame 3 are connected together by coaxial sub-arc welding, and the oxidant chamber and the fuel chamber are separated by the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com