Heat resistant polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of heat-resistant polylactic acid composite material and its preparation, can solve the problems of inability to meet high usage requirements, low efficiency, slow molding cycle, etc., and achieve rapid and continuous injection molding process and improved production efficiency. , the effect of fast crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

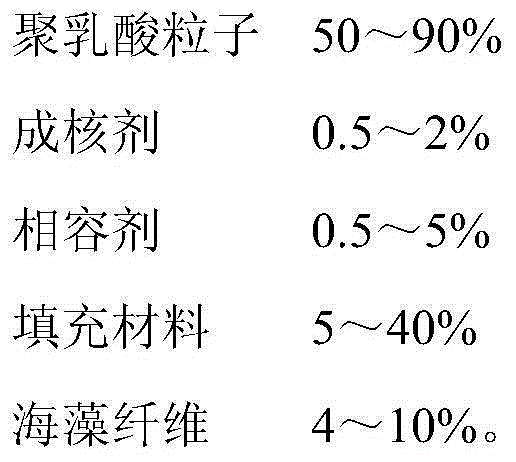

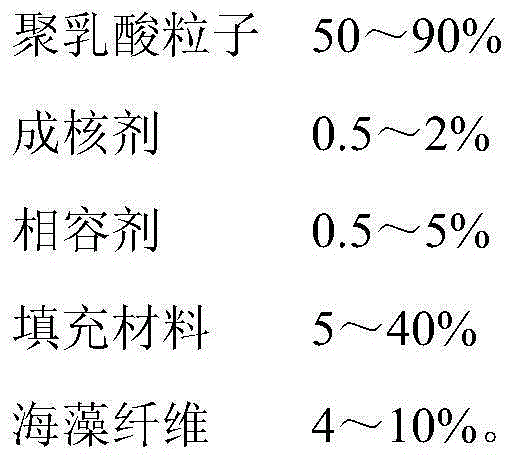

[0029] Preparation of heat-resistant polylactic acid composites:

[0030] The polylactic acid particles are commercially available Natureworks products, the brand is 3001D, and the dew point is used to dry to a moisture content below 50ppm before use. 0.5%, the talcum powder adopts commercially available Guangxi Huamei superfine 5000 mesh talcum powder, and the addition amount is 40%, and the compatibilizer adopts commercially available EX-501 (ethylene-vinyl acetate copolymer, EVA), and the addition amount is 5% , using commercially available seaweed fiber, the addition amount is 4%. The pellets were melted and extruded in a twin-screw extruder. The temperature of each section of the extruder was shown in Table 1. The screw speed was 200 rpm, and the pellets were suspended and air-cooled. Therefore, they were packaged in aluminum foil bags and ready for use without additional drying.

[0031] Table 1 Temperature distribution of each section of the extruder

[0032] ...

Embodiment 2

[0041] Preparation of heat-resistant polylactic acid composites:

[0042] The polylactic acid particles are commercially available Natureworks products, the brand is 3001D, and the dew point is used to dry to a moisture content below 50ppm before use. Guangxi Huamei superfine 5000-mesh talc powder is sold, and the addition amount is 20%. The compatibilizer adopts commercially available EX-501 (ethylene-vinyl acetate copolymer, EVA), and the addition amount is 2%. The amount is 7%. Melt extrusion and granulation in a twin-screw extruder. The temperature of each section of the extruder is shown in Table 1, and the screw speed is 200rpm. Suspended air-cooled granulation is used, so it can be used after being packaged in an aluminum foil bag without additional drying.

[0043] The shrinkage rate of the mold is 0.3%. The above-mentioned particles are injected into disposable cutlery knives through the injection molding machine. The injection temperature is 170°C, and the injection...

Embodiment 3

[0050] Preparation of heat-resistant polylactic acid composites:

[0051] The polylactic acid particles are commercially available Natureworks products, the brand is 3001D, and the dew point is used to dry the moisture content below 50ppm before use. The nucleating agent is commercially available polylactic acid nucleating agent TMP-3000, and the addition amount is 2%. Guangxi Huamei superfine 5000-mesh talcum powder is sold, and the addition amount is 5%. The compatibilizer adopts commercially available EX-501 (ethylene-vinyl acetate copolymer, EVA), and the addition amount is 0.5%. The amount is 10%. Melt extrusion and granulation in a twin-screw extruder. The temperature of each section of the extruder is shown in Table 1, and the screw speed is 200rpm. Suspended air-cooled granulation is used, so it can be used after being packaged in an aluminum foil bag without additional drying.

[0052] The shrinkage rate of the mold was 0.3%, and the above-mentioned particles were in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com