Method for preparing glyceride rich in algal oil n-3 polyunsaturated fatty acid through enzyme process

An unsaturated fatty acid, algal oil-rich technology, applied in fermentation, chemical recovery, etc., can solve the problems of high reaction temperature, long reaction time, and low enrichment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

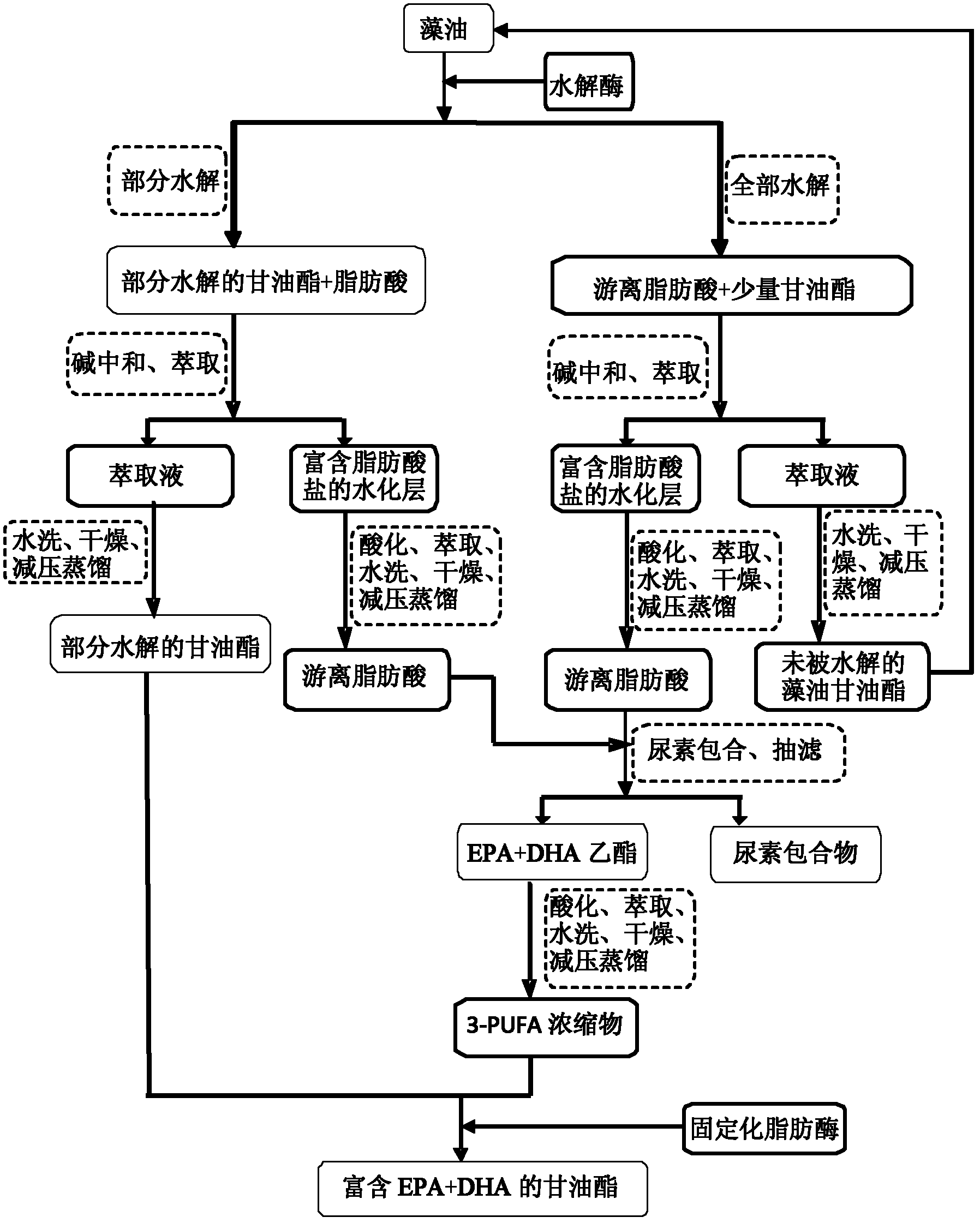

Method used

Image

Examples

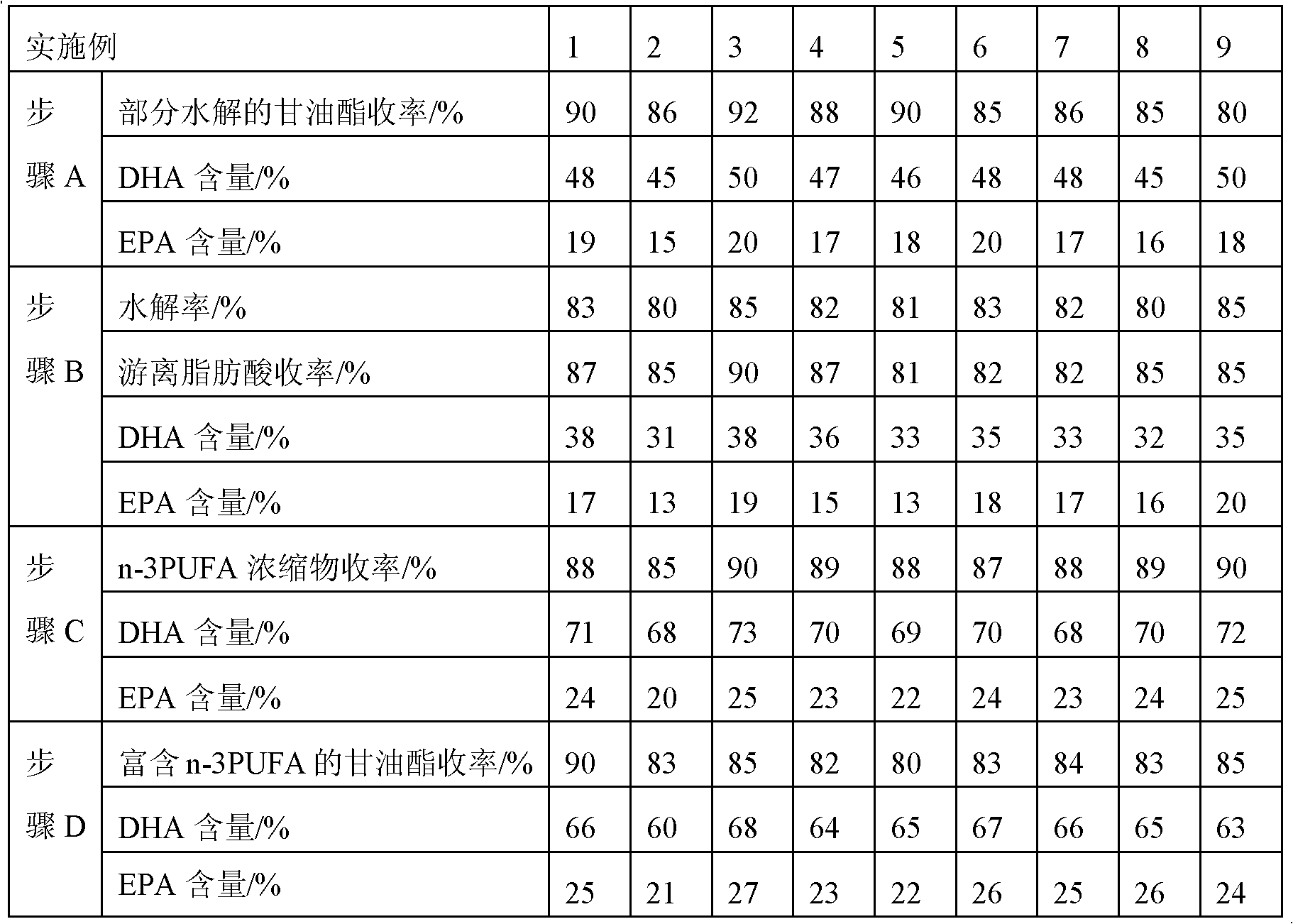

example 1

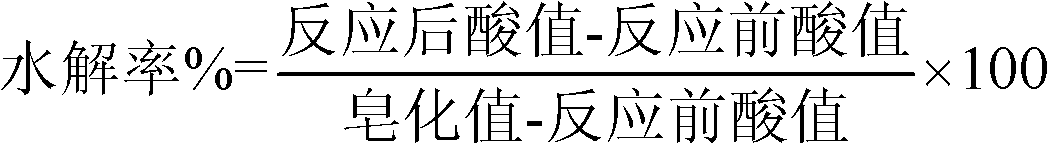

[0062] (1) Enzymatic partial hydrolysis of algae oil

[0063] Weigh 10 g of algae oil sample, add pH 8.0 phosphate buffer according to the mass ratio of algae oil to buffer of 1:0.6, add Candida sp.99-125 lipase enzyme according to the amount of 1500U / g algae oil powder, add cyclodextrin in an amount twice the mass of enzyme powder, fill nitrogen as an inert gas for sealing protection, hydrolyze at 50°C until the hydrolysis rate reaches 60%, stop the reaction, remove enzyme powder by suction filtration, and filtrate Neutralize with KOH, add n-hexane to extract partially hydrolyzed glycerides, and wash the extract with deionized water until neutral, and pass through anhydrous Na 2 SO 4 Drying is carried out, and the solvent is distilled off under reduced pressure to obtain partially hydrolyzed glycerides primarily enriched in n-3 polyunsaturated fatty acids as the main product. The hydration layer was acidified with 2mol / L HCl, and then the free fatty acids were extracted wit...

Embodiment 2

[0071] Embodiment 2 is different from embodiment 1 in that:

[0072] In step (1), the mass ratio of algae oil to buffer is 1:1, lipase enzyme powder is added according to the amount of 600U / g algae oil, and cyclodextrin is added according to the amount of 0.5 times the mass of enzyme powder; Under hydrolysis, after the hydrolysis rate reaches 40%, stop the reaction.

[0073] In step (2), according to the mass ratio of algae oil and buffer solution, add the amount containing 5mMCaCl 2 phosphate buffer solution, add lipase enzyme powder according to the amount of 600U / g algae oil, add cyclodextrin according to the amount of 0.5 times the mass of enzyme powder; carry out hydrolysis reaction at 35 ° C, after the hydrolysis rate reaches 20%, according to The amount of 0.5wt% algae oil is supplemented with Ca(OH) 2 , The total hydrolysis time is 48h.

[0074] In step (3), the ratio of fatty acid: urea: ethanol is 1:2:5 (w / w / v), blending at 60°C for 60 minutes, and inclusion at 4°...

Embodiment 3

[0078] Embodiment 3 is different from embodiment 1 in that:

[0079] In step (1), the mass ratio of algae oil to buffer is 1:0.8, lipase enzyme powder is added according to the amount of 1200U / g algae oil, and cyclodextrin is added according to an amount 1.5 times the mass of the enzyme powder; Under hydrolysis, after the hydrolysis rate reaches 59%, stop the reaction.

[0080] In step (2), according to the mass ratio of algae oil and buffer solution, add the amount containing 8mMCaCl 2 Phosphate buffer solution, add lipase enzyme powder according to the amount of 1200U / g algae oil, add cyclodextrin according to the amount of 1.5 times the mass of enzyme powder; carry out hydrolysis reaction under the condition of 40 ℃.

[0081] In step (3), the ratio of fatty acid: urea: ethanol is 1: 3.5: 9 (w / w / v), and they are blended at 70°C.

[0082] In step (4), the molar ratio of partially hydrolyzed glyceride to n-3 polyunsaturated fatty acid concentrate is 1:8, and immobilized lipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com