Methods for extracting high-quality shrimp oil from Antarctic krill and for preparing defatted krill protein powder

An Antarctic krill and extraction method technology, applied in the directions of edible oil/fat, tallow oil/fat production, tallow oil/fat refining, etc. Improve efficiency, reduce moisture and save consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

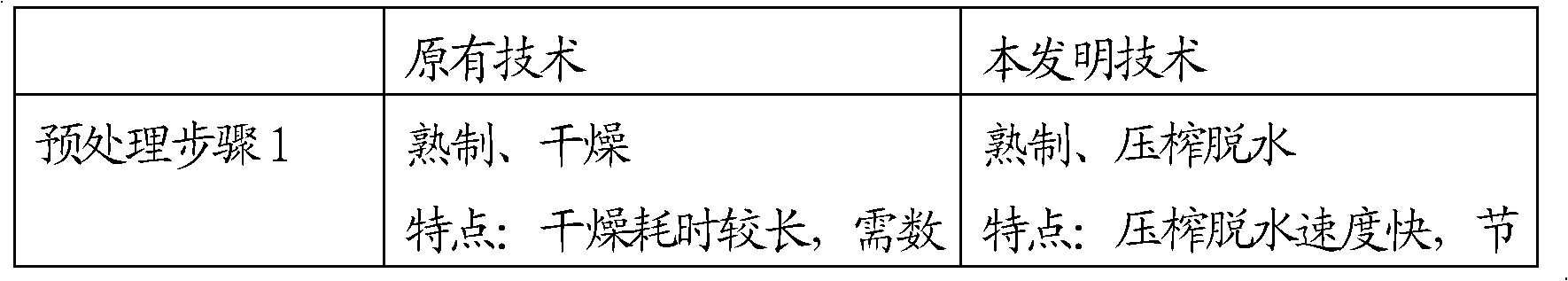

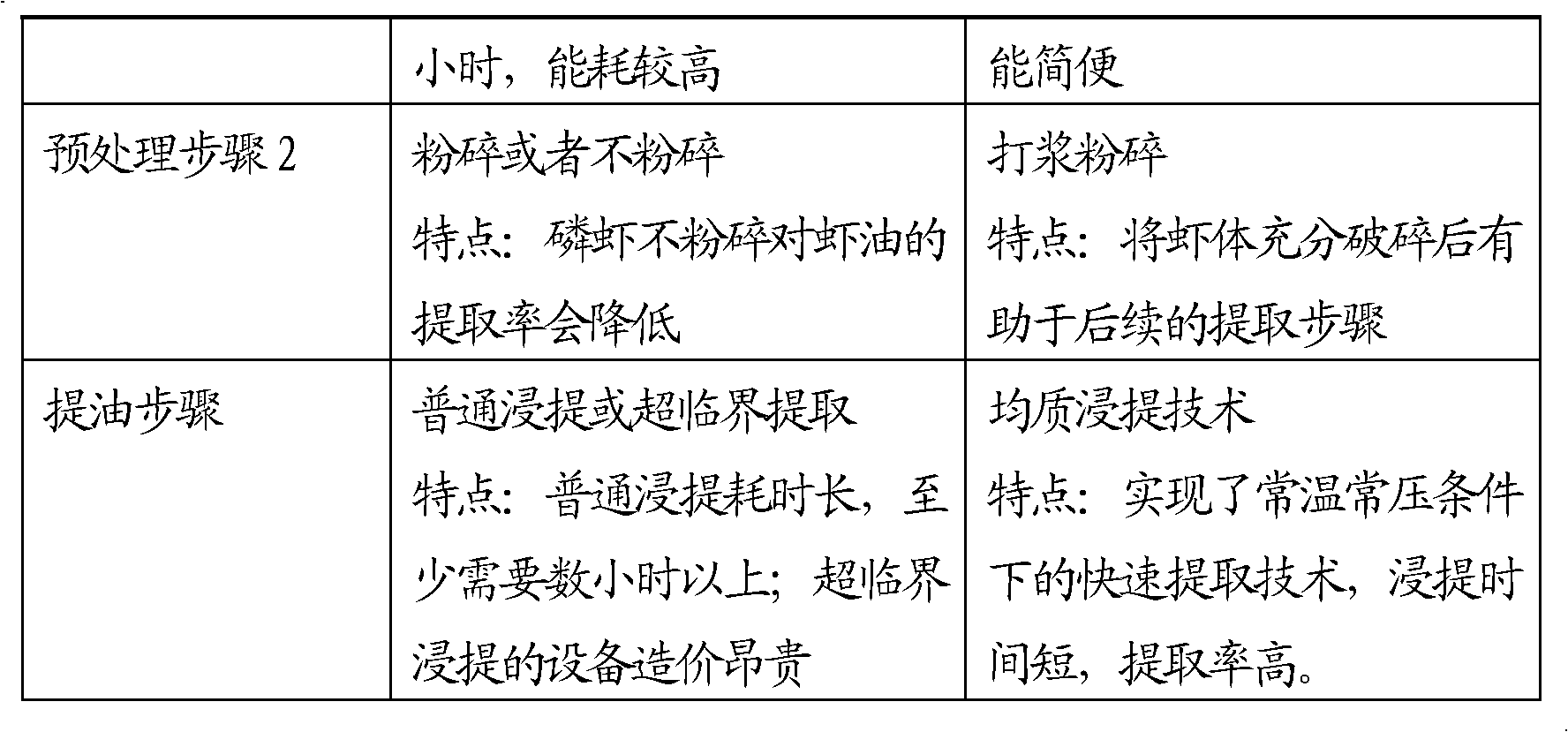

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Extraction method of high-quality shrimp oil from Antarctic krill:

[0030] 1. Pretreatment of raw materials of Antarctic krill: Take 660g of frozen Antarctic krill, put it in a room temperature environment of 22°C, and let it thaw naturally;

[0031] 2. Cooking the pretreated raw materials in step (1): after draining excess water, 590 g of thawed krill were obtained, which were put into a cooking pot, and heated and cooked for 5 minutes to obtain 590 g of cooked krill;

[0032] 3. Squeeze and dehydrate the cooked raw materials in step (2): put 590 g of cooked krill into a cloth bag, seal the mouth of the bag, place it in a pressing device for pressing and dehydrating, take it out after the pressing is completed, and obtain shrimp Cake 180g, shrimp cake contains 36% water, and krill squeezed liquid 410g is obtained;

[0033] 4. Crush and beat the dehydrated raw materials in step (3) to obtain a paste: put 180g of shrimp cakes into the stirring and crushing equipment...

Embodiment 2

[0043] 1. Extraction method of high-quality shrimp oil from Antarctic krill:

[0044] 1. Pretreatment of Antarctic krill raw materials: Take 1.8kg of frozen krill and place it in a room temperature environment of 20°C to allow it to thaw naturally;

[0045] 2. Cooking the pretreated raw materials in step (1): after draining excess water, 1.6 kg of thawed krill was obtained, which was put into a cooking pot, heated and cooked for 28 minutes, and 1.6 kg of cooked krill was obtained;

[0046] 3. Squeeze and dehydrate the cooked raw materials in step (2): put 1.6kg of cooked krill into a cloth bag, seal the mouth of the bag, and put it in a pressing device for pressing and dehydrating. The pressing time is 25 minutes, and the pressing is completed Finally, it was taken out to obtain 480g of shrimp cakes, the water content of shrimp cakes was 34%, and 1.1kg of krill squeezed liquid was obtained;

[0047] 4. Crush and beat the dehydrated raw materials in step (3) to obtain a paste:...

Embodiment 3

[0054] 1. Extraction method of high-quality shrimp oil from Antarctic krill:

[0055] 1. Pretreatment of Antarctic krill raw materials: Take 10.7kg of frozen krill and place it in a room temperature environment of 21°C to allow it to thaw naturally;

[0056] 2. Cooking the pretreated raw materials in step (1): after draining excess water, 9.6 kg of thawed krill were obtained, which were put into a cooking pot, heated and cooked for 55 minutes, and 9.6 kg of cooked krill were obtained;

[0057] 3. Press and dehydrate the cooked raw materials in step (2): put 9.6 kg of cooked krill into a cloth bag, seal the mouth of the bag, put it in a pressing device for pressing and dehydrating, take it out after the pressing is completed, and obtain Shrimp cake 2.9kg, shrimp cake water content 37%, obtain krill squeeze liquid 6.7kg;

[0058] 4. Crush and beat the dehydrated raw materials in step (3) to obtain a paste: put 2.9kg of shrimp cakes into the mixing and crushing equipment, start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com